Environment-friendly water-based high-viscosity box pasting glue and preparation method thereof

A high-viscosity, box-pasting glue technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve problems such as insufficient adhesion, poor adhesion, high temperature aging resistance, etc. , to achieve the effects of increasing viscosity, strong viscosity, and improving aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

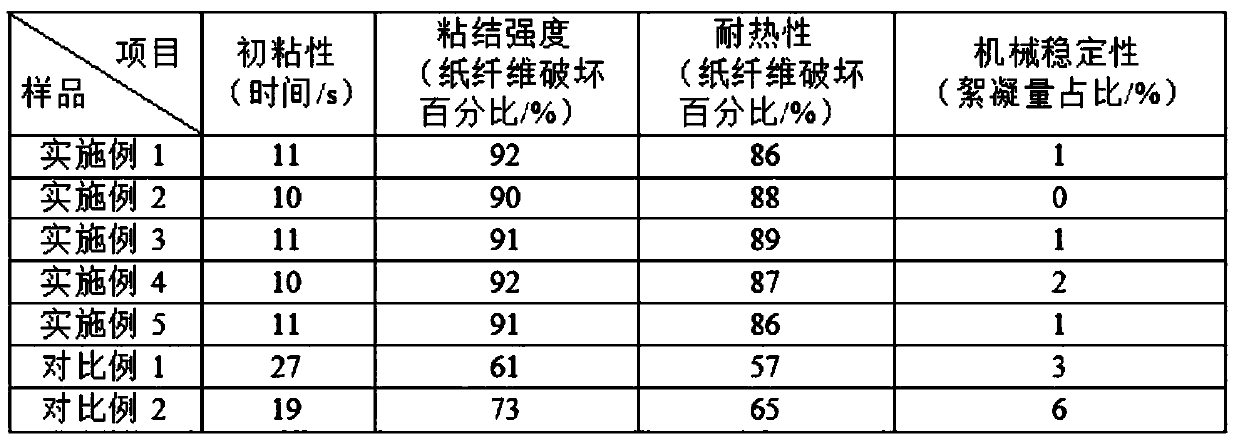

Examples

Embodiment 1

[0032] An environment-friendly water-based high-viscosity box gluer, which comprises the following components in parts by weight: 30 parts of ethylene-1-octene copolymer emulsion, 20 parts of water-based polyurethane-epoxy resin-acrylate composite resin 0.5 parts of hydroxypropyl methylcellulose, 5 parts of diphenylmethane diisocyanate, 10 parts of sodium antimonate, 0.1 part of emulsified silicone oil, 1 part of synthetic vegetable ester and 1 part of rosin polyol ester, ethylene-1-octyl The glass transition temperature of the ethylene copolymer emulsion is 20°C, the solid content is 20%, and the viscosity is 500mPa·s; the waterborne polyurethane-epoxy resin-acrylate composite resin is composed of polyether diol, toluene diisocyanate, trimethylolpropane , Dimethylol propionic acid, epoxy resin, triethylamine, methyl methacrylate, azobisisobutyronitrile and acetone.

[0033] A kind of environment-friendly water-based high-viscosity box glue is prepared by using the above-menti...

Embodiment 2

[0039] An environmentally friendly water-based high-viscosity box gluer, which comprises the following components in parts by weight: 35 parts of ethylene-1-octene copolymer emulsion, 25 parts of water-based polyurethane-epoxy resin-acrylate composite resin 1 part, 1 part of sodium carboxymethyl cellulose, 5 parts of toluene diisocyanate, 12 parts of calcium sulfate, 0.2 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 2 parts of tributyl citrate and 2 parts of hydrogenated rosin, ethylene-1- The glass transition temperature of the octene copolymer emulsion is 22°C, the solid content is 25%, and the viscosity is 800mPa·s; the waterborne polyurethane-epoxy resin-acrylate composite resin is composed of polyether diol, toluene diisocyanate, trimethylol Propane, dimethylolpropionic acid, epoxy resin, triethylamine, methyl methacrylate, azobisisobutyronitrile and acetone prepared.

[0040] A kind of environment-friendly water-based high-viscosity box glue is prepare...

Embodiment 3

[0046] An environmentally friendly water-based high-viscosity box gluer, which comprises the following components in parts by weight: 40 parts of ethylene-1-octene copolymer emulsion, 30 parts of water-based polyurethane-epoxy resin-acrylate composite resin 1.75 parts of polyacrylamide, 7.5 parts of hexamethylene diisocyanate, 15 parts of zinc borate, 0.55 parts of polyoxypropylene glyceryl ether, 3 parts of acetyl trioctyl citrate and 5.5 parts of petroleum hydrogenated resin, ethylene-1-octyl The glass transition temperature of ethylene copolymer emulsion is 27.5°C, the solid content is 30%, and the viscosity is 1250mPa·s; the waterborne polyurethane-epoxy resin-acrylate composite resin is composed of polyether diol, toluene diisocyanate, trimethylolpropane , Dimethylol propionic acid, epoxy resin, triethylamine, methyl methacrylate, azobisisobutyronitrile and acetone.

[0047] A kind of environment-friendly water-based high-viscosity box glue is prepared by using the above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com