Water-based UV resin and preparation method thereof

A water-based, resin-based technology, applied in coatings, polyurea/polyurethane coatings, etc., to achieve excellent steel wool scratch resistance and overcome the incompatibility of high hardness and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Second aspect of the present invention provides the preparation method of waterborne UV resin as described above, comprises the steps:

[0041] (1) Add metered diisocyanate into the reactor, then drop polyol after dehydration, and react for 1 to 3 hours to obtain product A;

[0042] (2) In another reactor, under the protection of nitrogen, add the raw material ethanolamine, and then add the catalyst to raise the temperature of the system to 60-80°C; The mixture was reacted for 3 to 8 hours to obtain product B;

[0043] (3) Add the product B into the reactor under the protection of nitrogen, raise the temperature of the system to 60-80° C., then add the product A dropwise, react for 1-3 hours, and discharge to obtain the water-based UV resin.

[0044] When the water-based UV resin of the present invention is prepared, the polyol in step (1) needs to be dried and dehydrated before reacting with the diisocyanate, so as to avoid the reaction of moisture therein with the di...

Embodiment 1

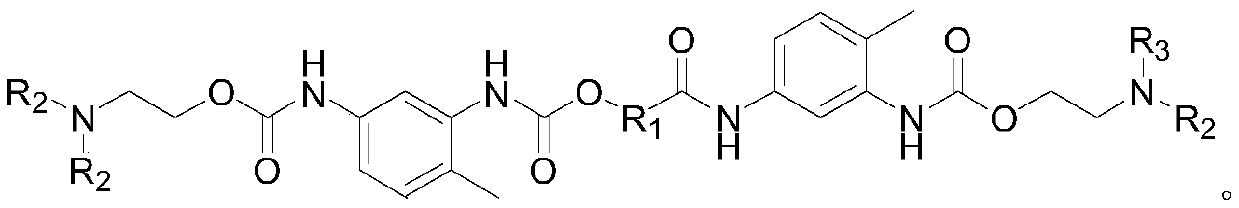

[0057] Example 1 Summary of the invention: a kind of water-based UV resin is provided, which has the following structural formula:

[0058]

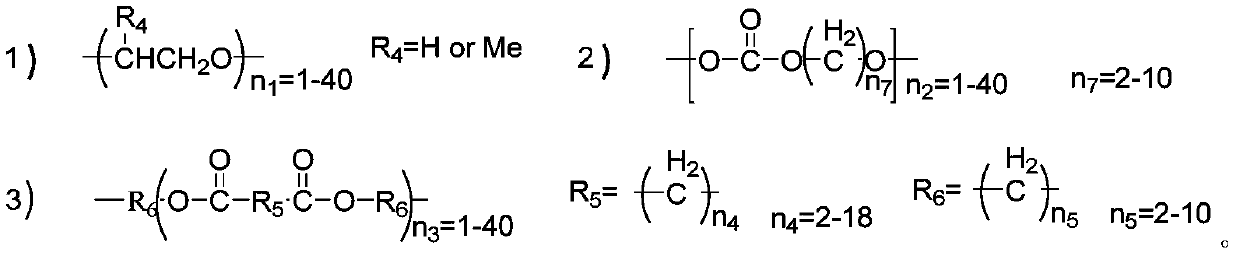

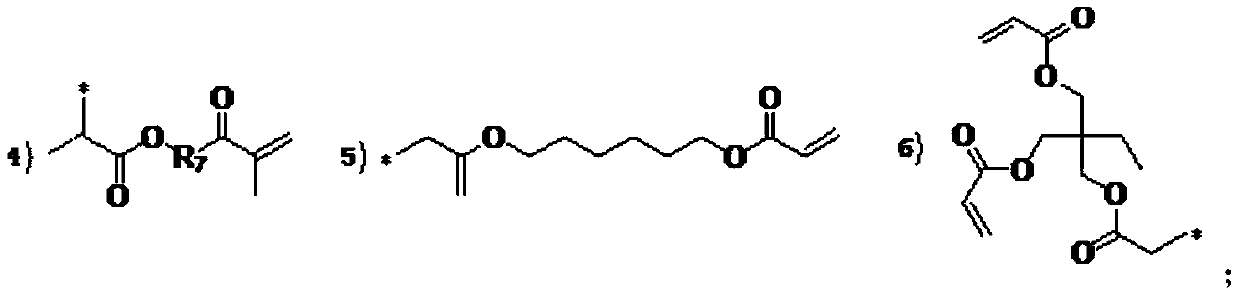

[0059] where R 1 Has the structure of formula 1, the degree of polymerization is 34; R 2 has the structure of formula 6; R 3 has the following structure: where the R 7 has the following structure: The degree of polymerization m=5.

[0060] The preparation method of above-mentioned waterborne UV resin comprises the steps:

[0061] (1) Toluene diisocyanate (34.8g) was added into the reaction flask, polypropylene glycol 2000 (400g) which had been dehydrated was added dropwise, and the product A was obtained by reacting for 2 hours.

[0062] (2) Add the raw material ethanolamine (12.2g) into the reaction flask, add sodium methoxide (0.6g) and hydroquinone (0.6g) in sequence, raise the temperature to 70°C, and slowly add methoxypolyethylene glycol acrylate dropwise (100g) and trimethylolpropane triacrylate (90g) mixed raw materia...

Embodiment 2

[0064] Example 2 Summary of the invention: a kind of water-based UV resin is provided, which has the following structural formula:

[0065]

[0066] where R 1 Be the polycarbonate (1.6 hexanediol) ester diol structure that number average molecular weight is 2000; R 2 has the structure of Formula 5; R 3 has the following structure: where the R 7 has the following structure: The degree of polymerization m=5.

[0067] The preparation method of above-mentioned waterborne UV resin comprises the steps:

[0068] (1) Toluene diisocyanate (53.5 g) was added in a reaction flask, and polycarbonate (1.6 hexanediol) diol 1000 (307.7 g) was added dropwise, and reacted for 2 hours to obtain product A.

[0069] (2) Add raw material ethanolamine (19g) into the reaction flask, add sodium methoxide (0.6g) and hydroquinone (0.6g) successively, raise the temperature to 70°C, slowly add dropwise methoxypolyethylene glycol acrylate ( 153.8g) and 1.6 hexanediol diacrylate (106g) mixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com