Needle dial adjusting structure of double-faced knitting machine

A technology of adjusting structure and double-sided machine, applied in knitting, weft knitting, textile and papermaking, etc., can solve the problems of affecting the rigidity of the whole machine, unable to tighten the screws too tightly, reducing the assembly accuracy of the whole machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

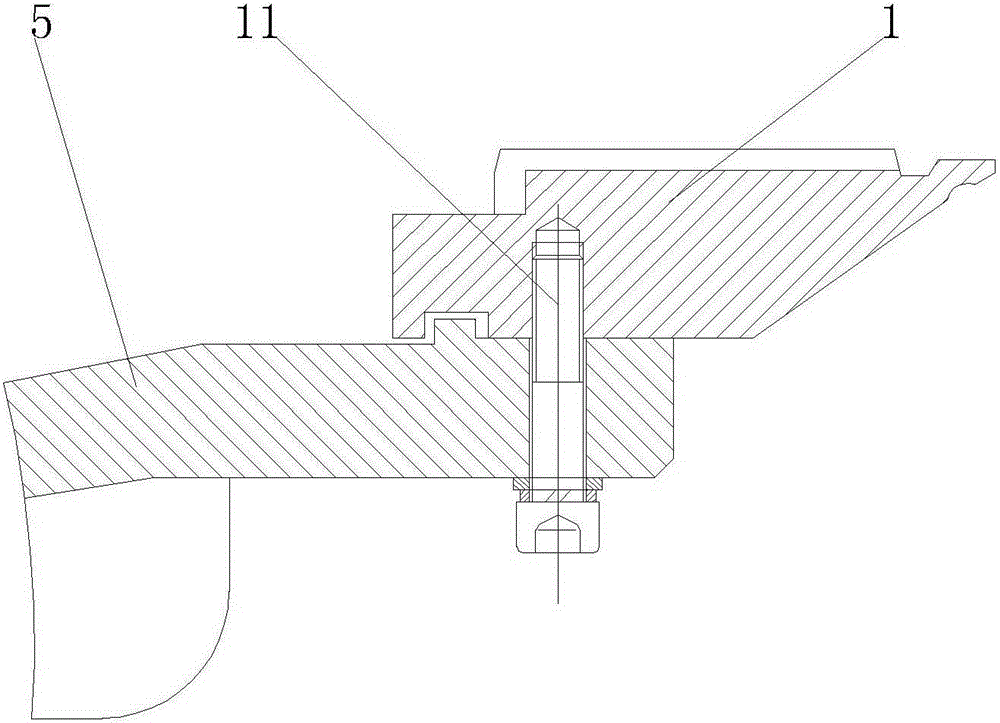

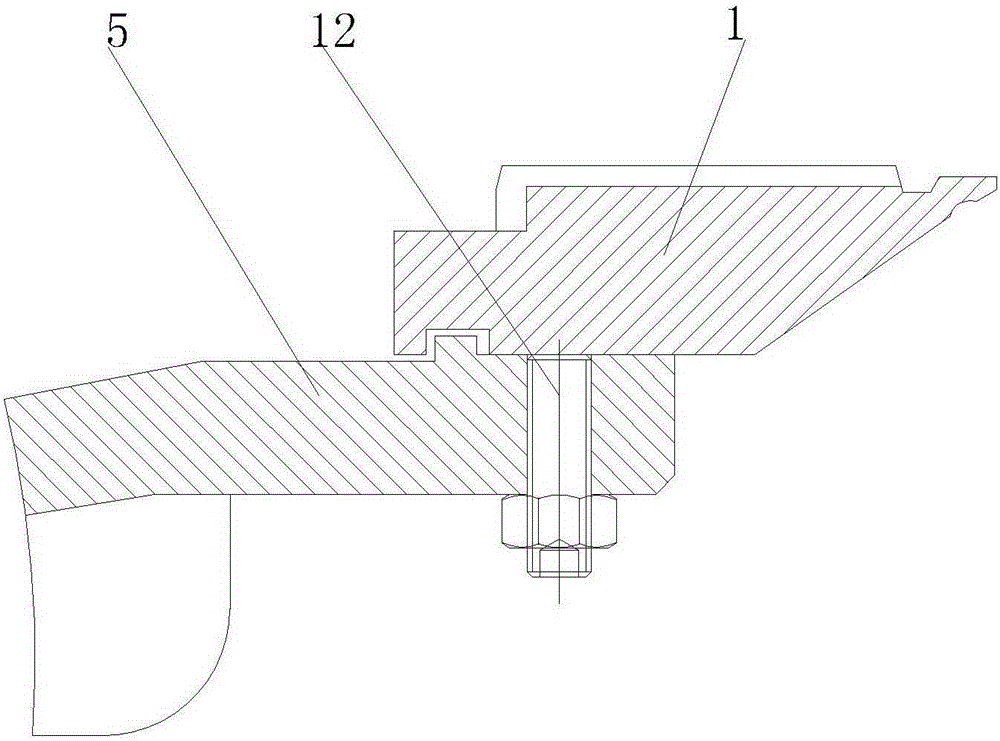

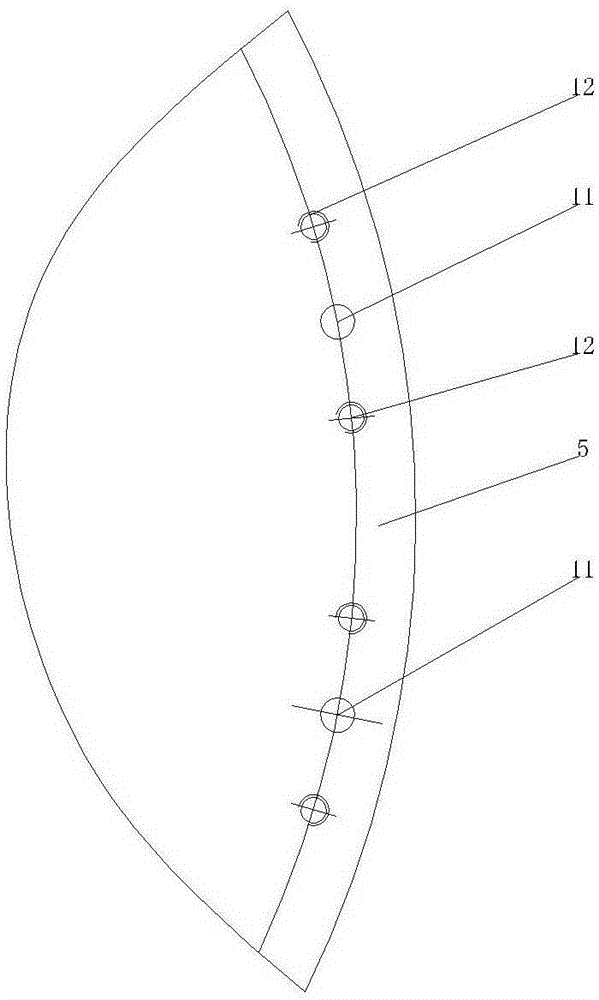

[0017] Such as Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the dial adjustment structure of double-sided machine includes locking screw 2, hollow screw cover 3 set on locking screw 2, locking block set under hollow screw cover 3 and set on locking screw 2 4. The locking screw 2 passes through the support plate 5 and is locked on the upper dial 1, the hollow screw cover 3 is set in the through hole 51 of the support plate 5, and the hollow screw cover 3 and the through hole of the support plate 5 Threaded connection, the bottom of the hollow screw jacket 3 is provided with a "ten"-shaped groove 31, and the upper end of the locking block 4 is provided with a "ten"-shaped convex key 41 to match the "ten"-shaped groove 31. The "ten" shaped protruding key 41 is inserted into the "ten" shaped groove 31 . The hollow screw jacket 3 is matched with the locking block 4 in the axial direction, the locking block 4 is an inverted T-shaped structure, and the lower part is pro...

Embodiment 2

[0019] Such as Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the patent of the present invention cancels all the stop screws 12 installed on both sides of the locking screw 2, and a hollow screw cover 3 is installed around each locking screw 2. The hollow screw jacket 3 is hollow, and a corresponding locking screw is installed, and the outside is connected with the threaded support disc at the bottom of the upper needle disc. At the bottom of the hollow screw jacket 3, a "ten" shaped concave keyway 31 is manufactured, and the "cross" shaped concave keyway 31 must be installed on the hexagonal locking block 4 below the screw jacket. The key 41 is matched, and in the axial direction, the installation position of the hollow screw sleeve 3 should be kept at the bottom and the hexagonal locking block equipped with the "ten"-shaped convex key to maintain a gap, and fully extend the support plate at the top of the upper plane. In this way, when all the hexagonal locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com