Locking structure for round plastic container

A plastic container and locking mechanism technology, applied in clamping devices, closures, packaging, etc., can solve problems such as high production cost, employee injury, and metal hoops that cannot be recycled, and achieve good sealing and fixing effects, simplifying The effect of working procedures, saving production and raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

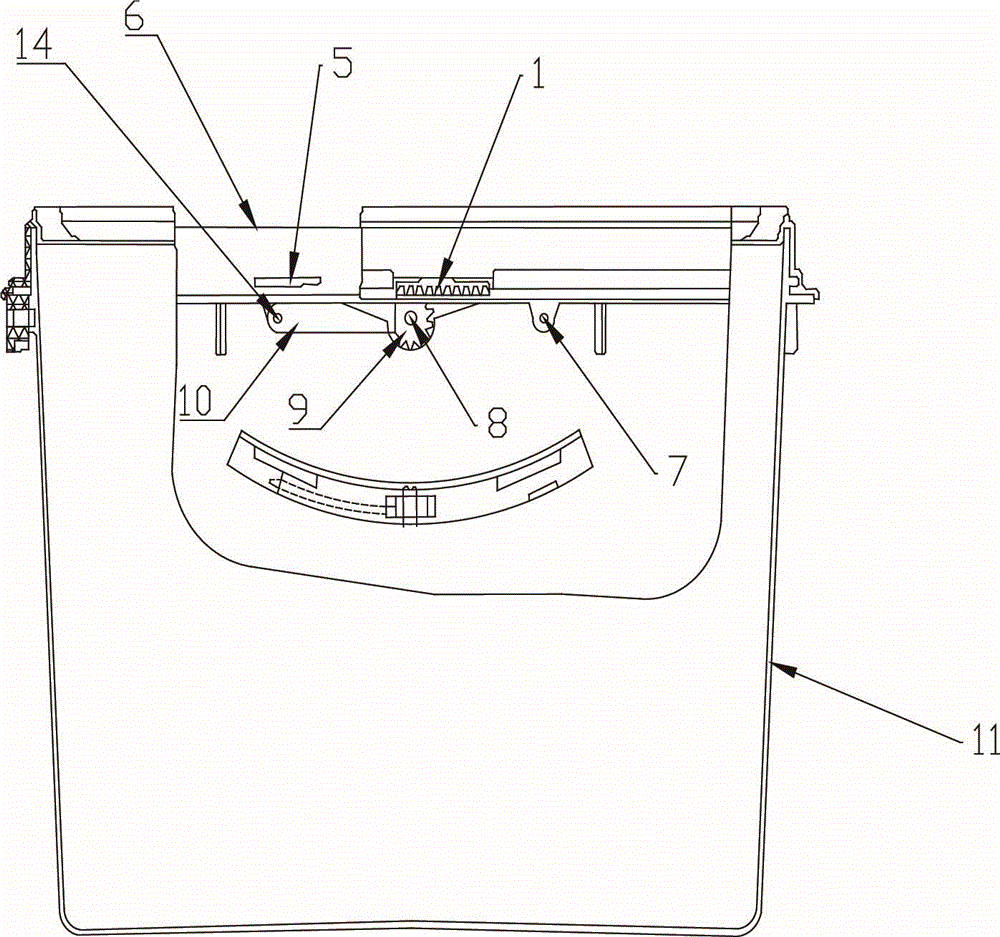

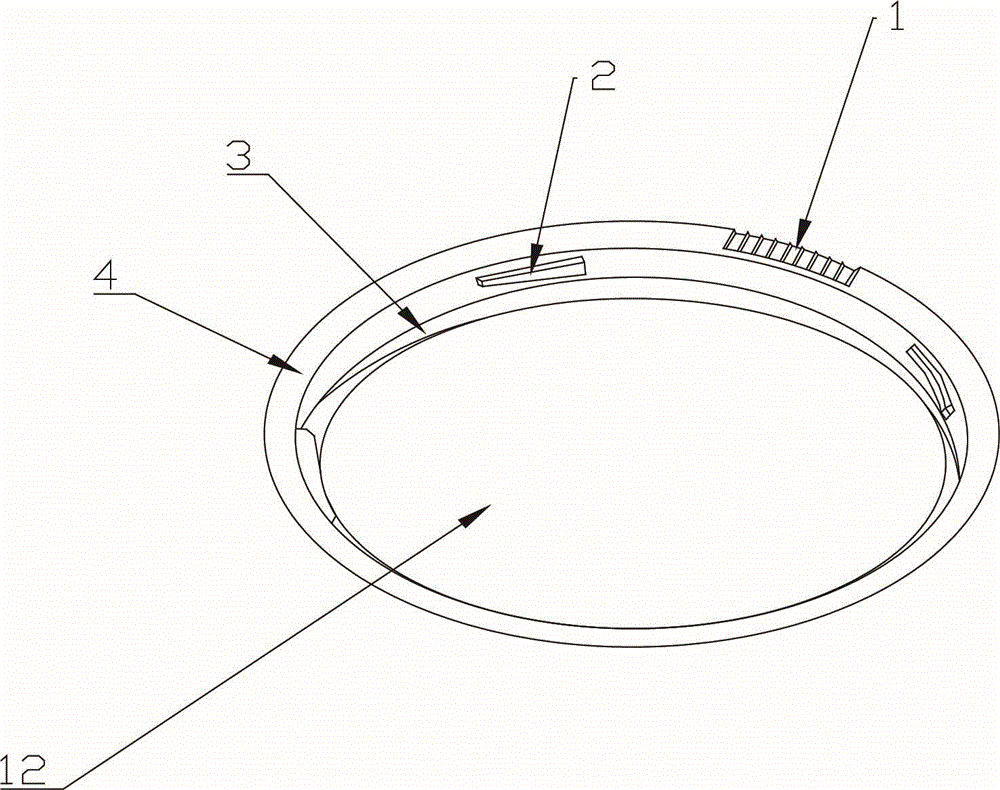

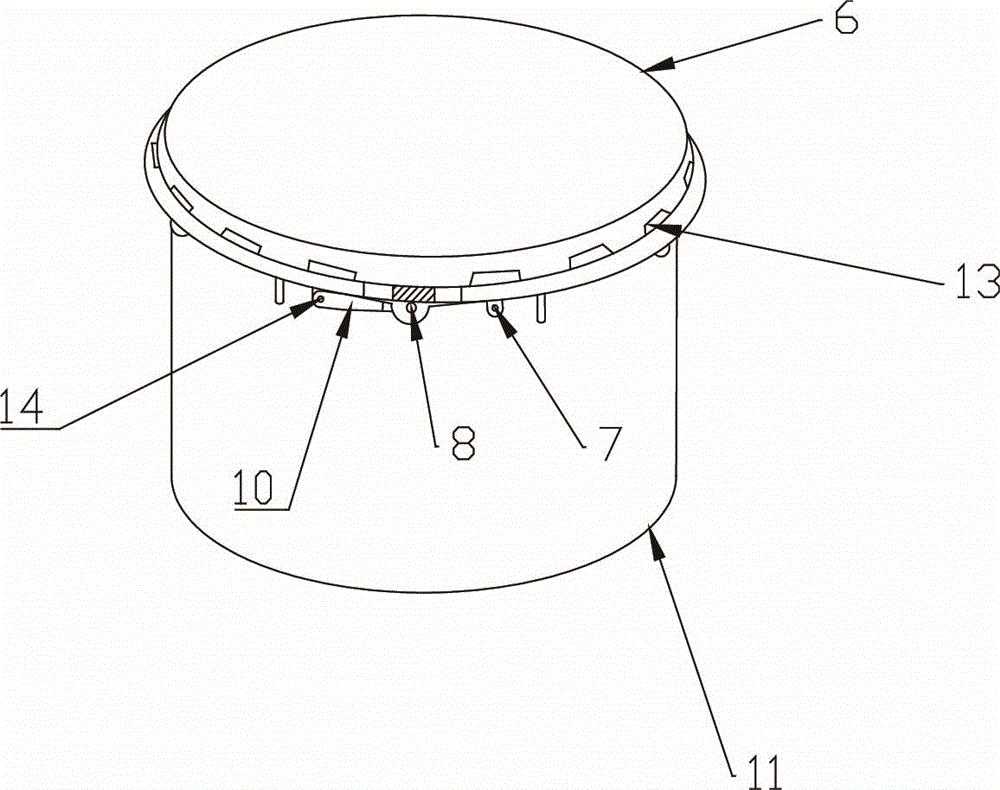

[0015] See Figure 1 to Figure 3 , a locking mechanism for a circular plastic container, comprising a barrel body 11 and a barrel cover 12, the inner side of the barrel cover 12 is provided with several raised barrel cover thread strips 2, and the barrel cover 12 is connected with the barrel body 11 The connected side is provided with a rack 1, the rack 1 is about 40 mm long, about 10 mm wide, and the tooth depth is ≥ 1 mm. A set of teeth 9 is arranged on the upper edge of the barrel body 11. The outer diameter of the gear 9 is ф 20-50 mm, tooth height ≥ 1 mm, tooth depth ≥ 1 mm, several raised barrel thread strips 13 are provided on the outer periphery of the mouth of the barrel body 11, the barrel cover thread strip 2 and the barrel The threaded strip 13 of the body coincides with each other, and a group of gears 9 are arranged along the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com