Patents

Literature

218results about How to "Prevent stuck phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

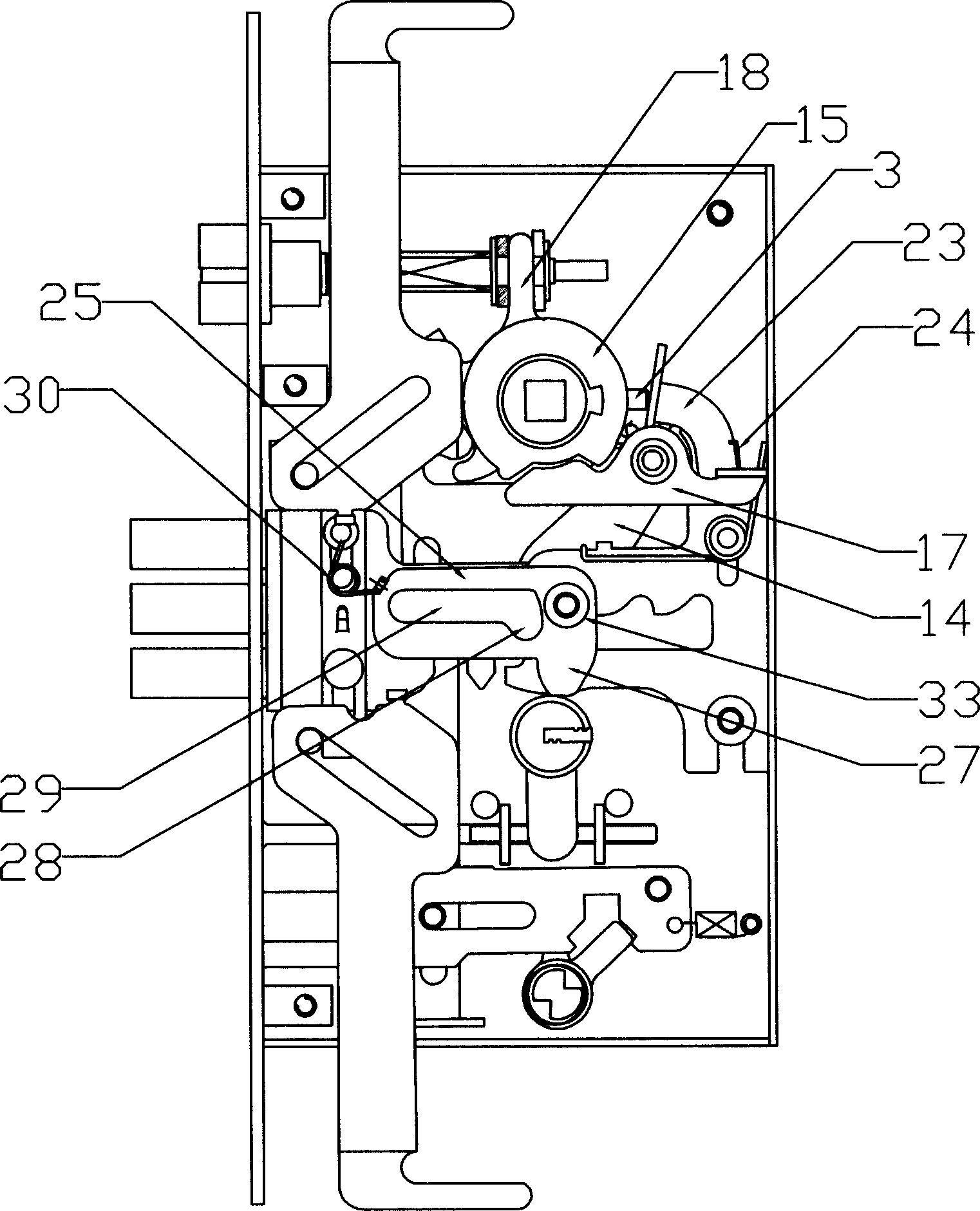

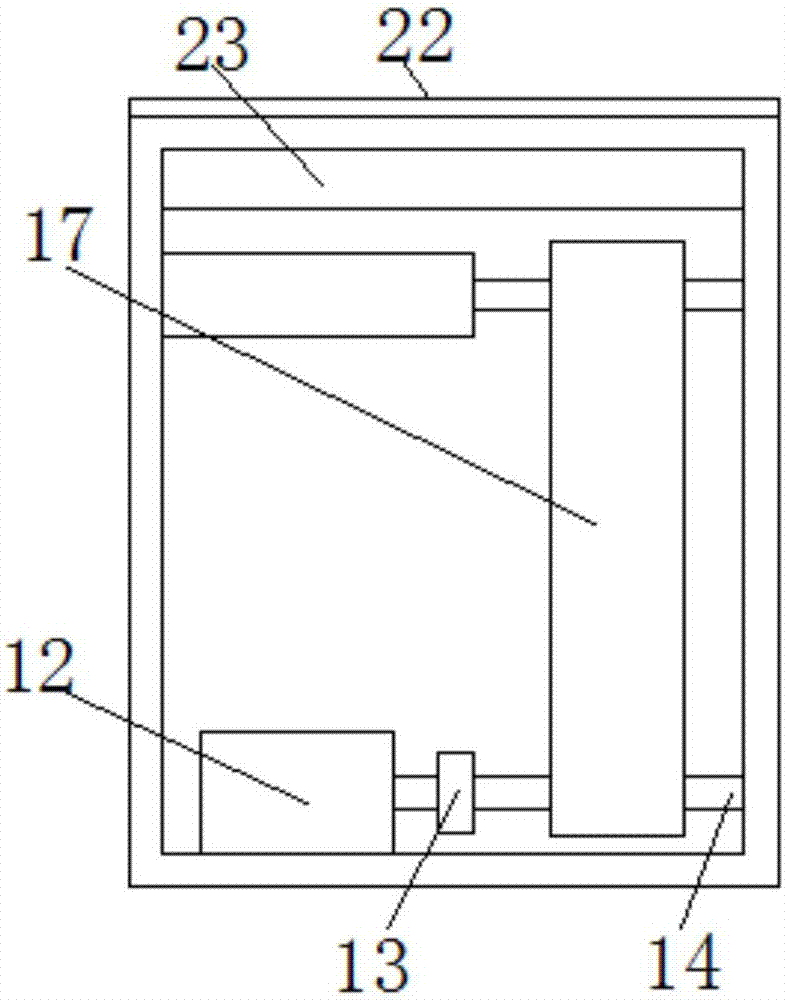

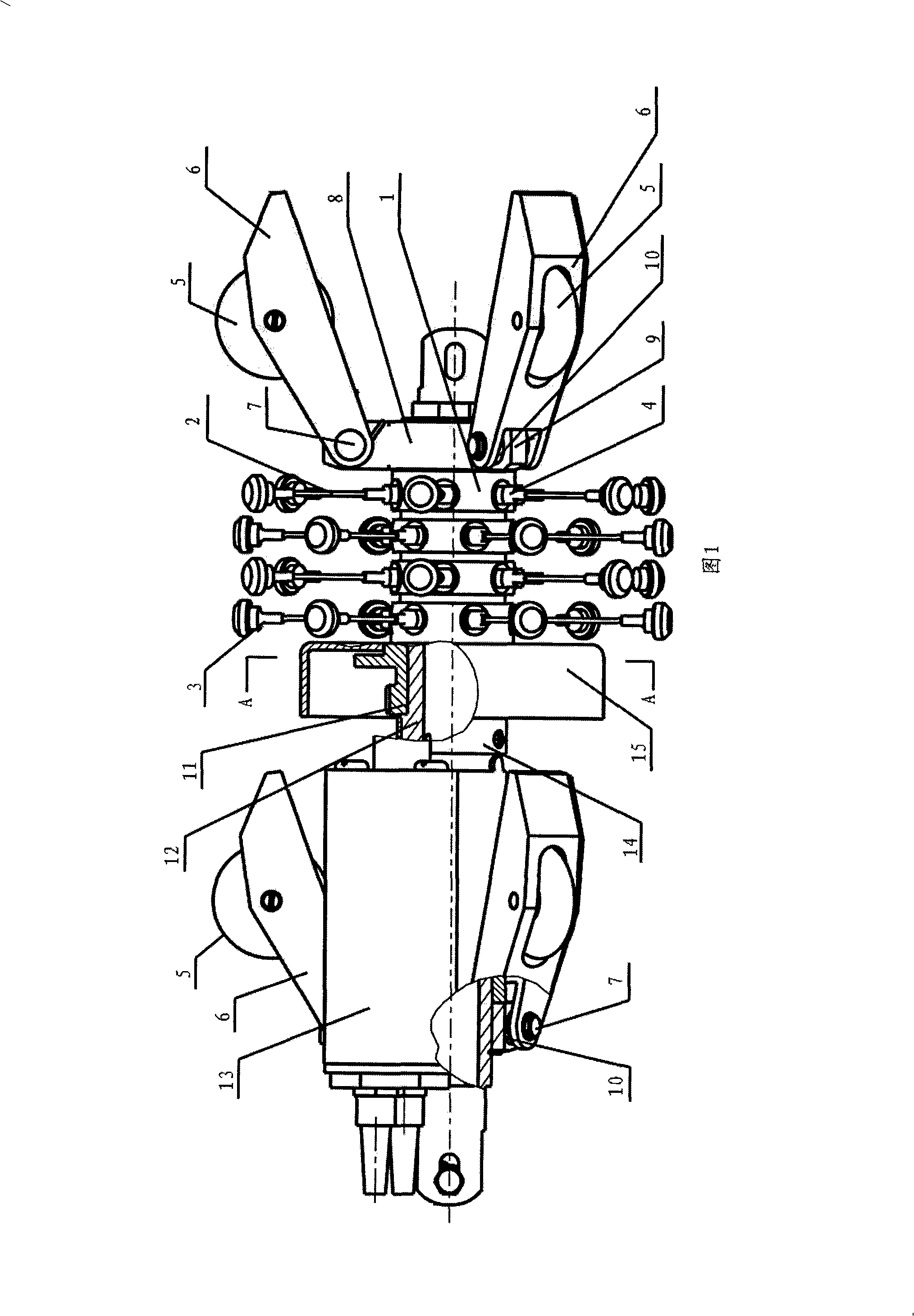

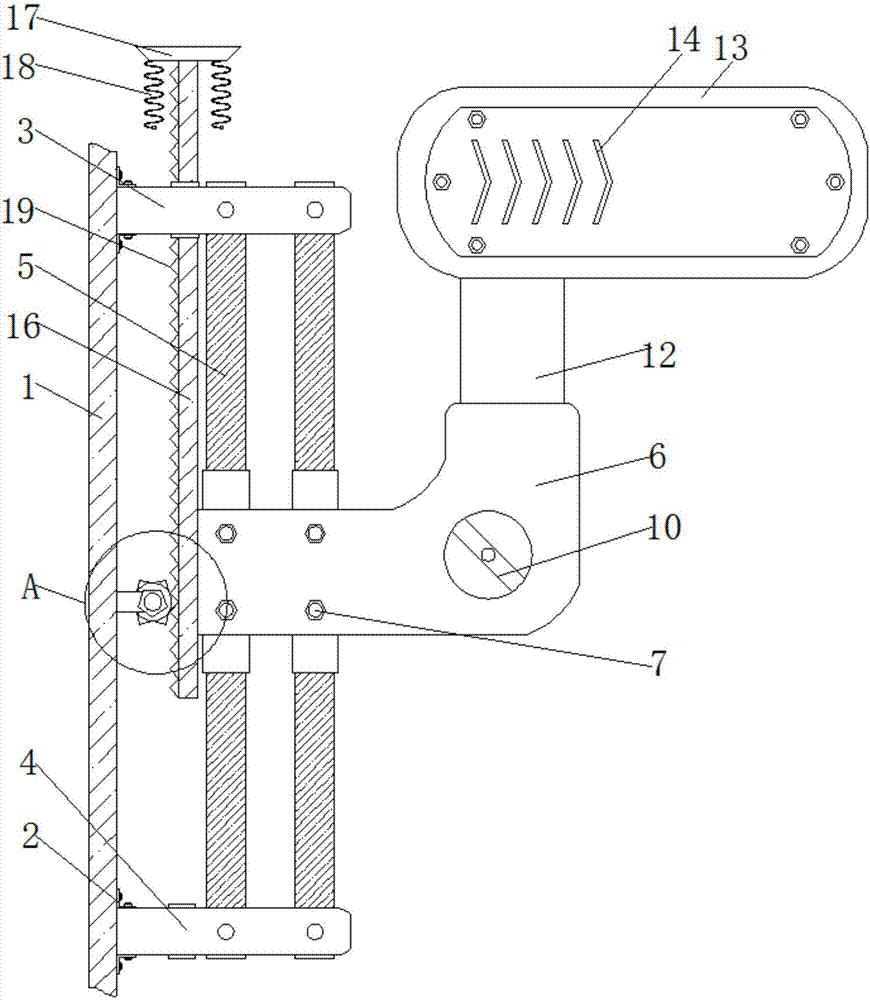

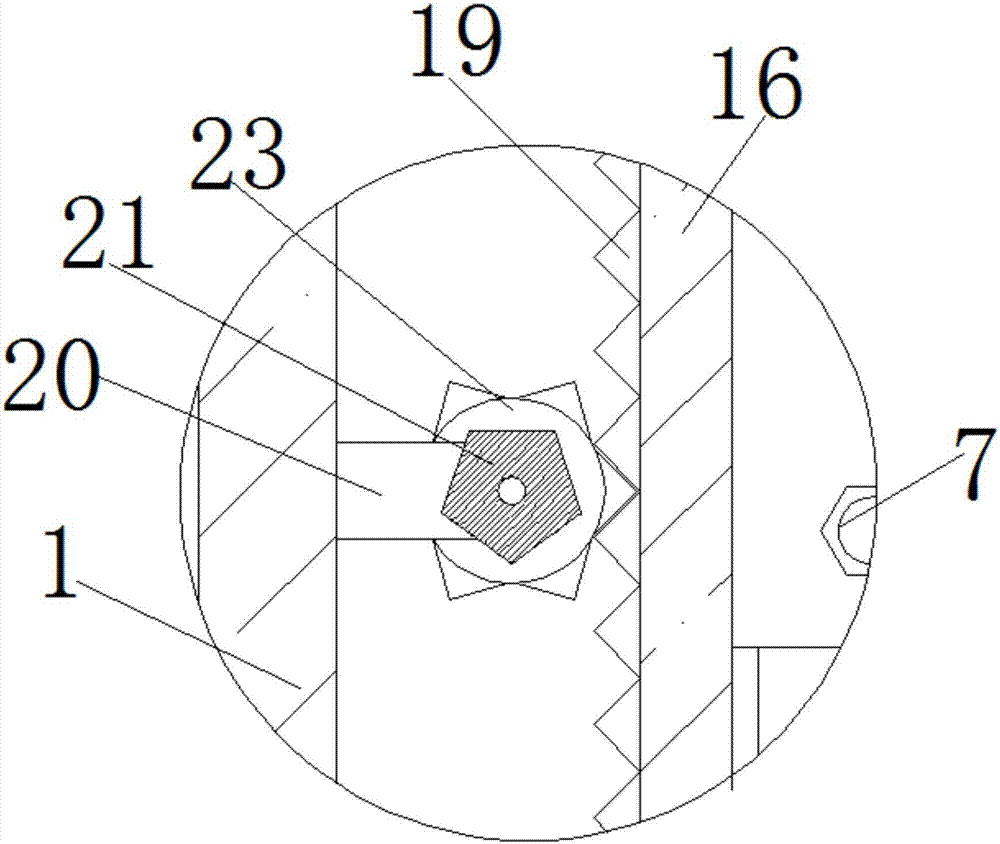

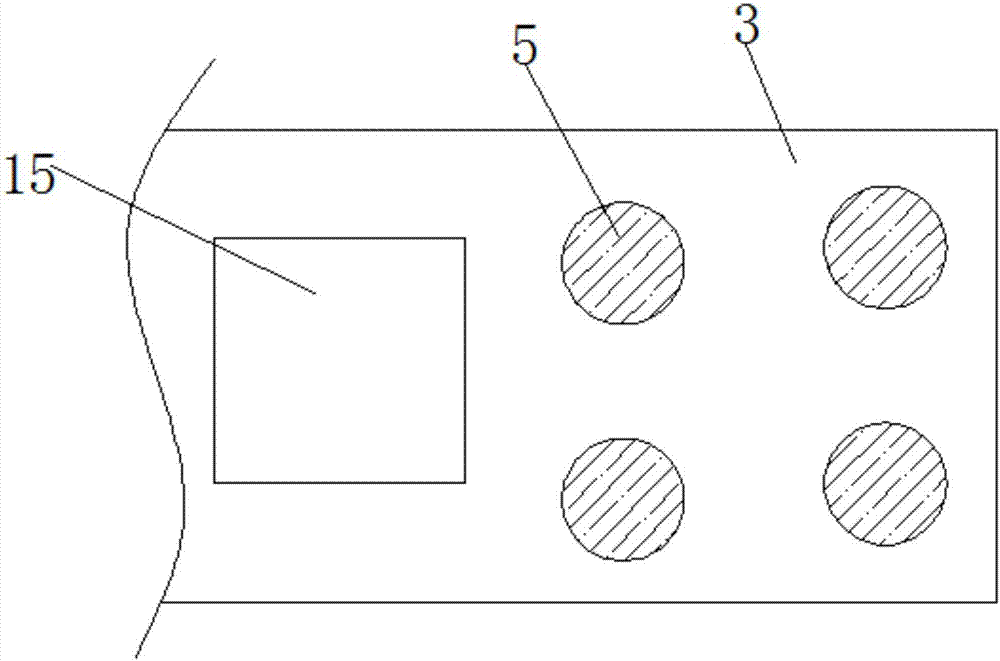

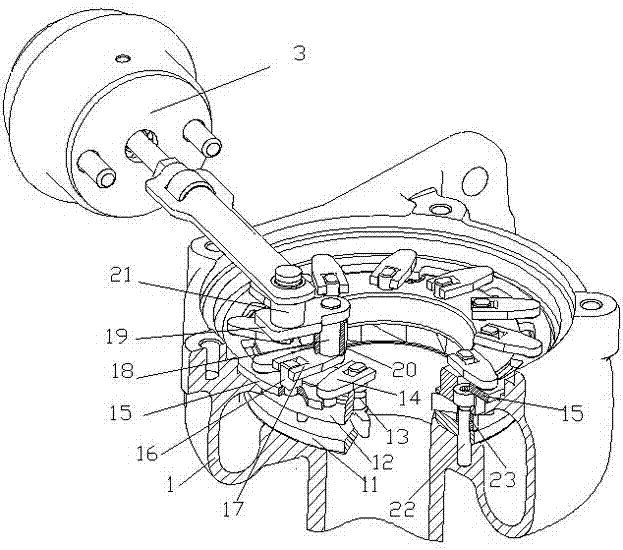

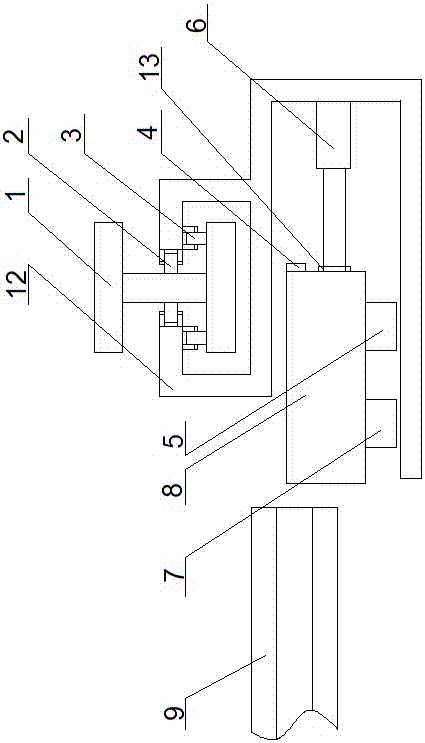

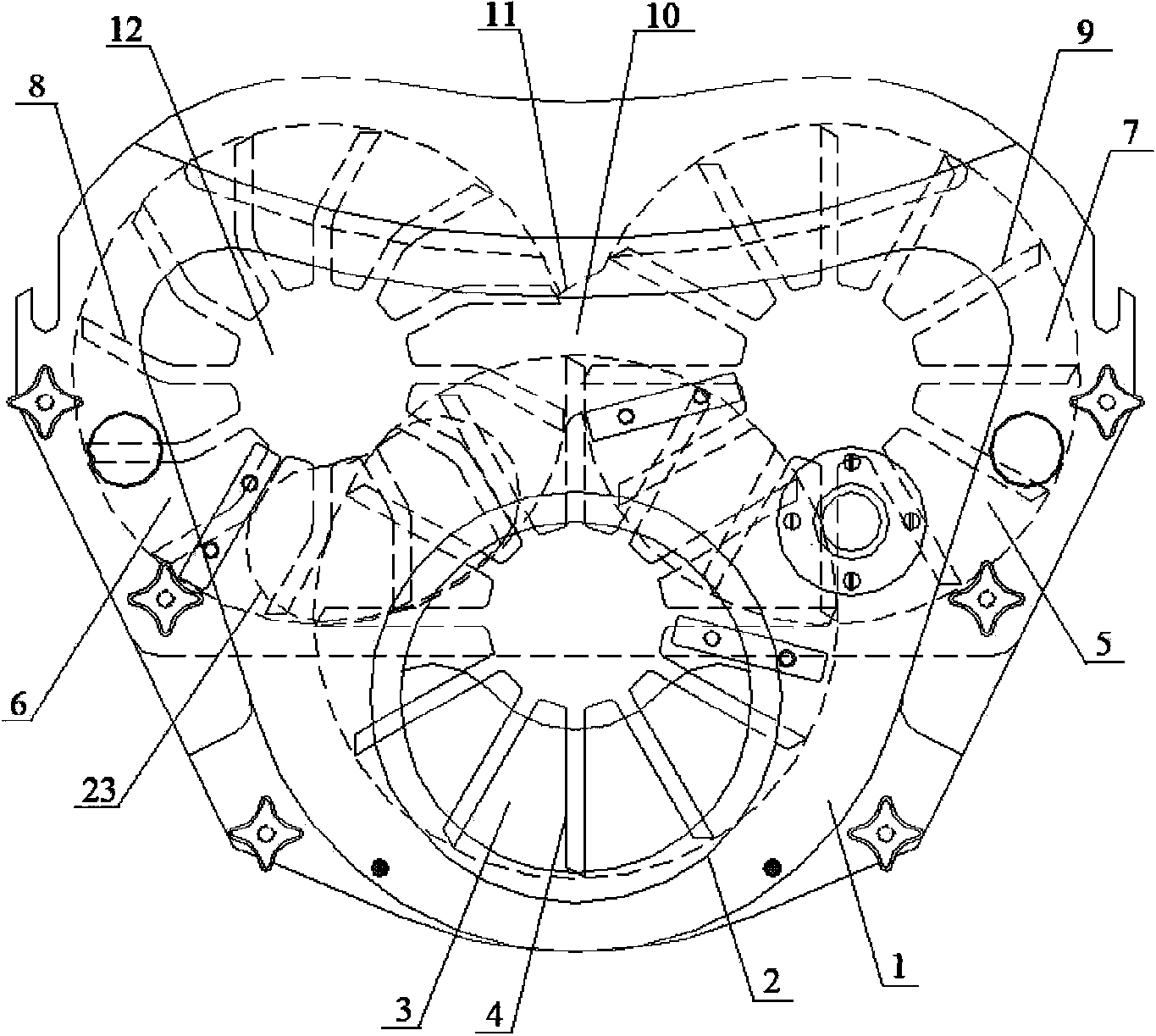

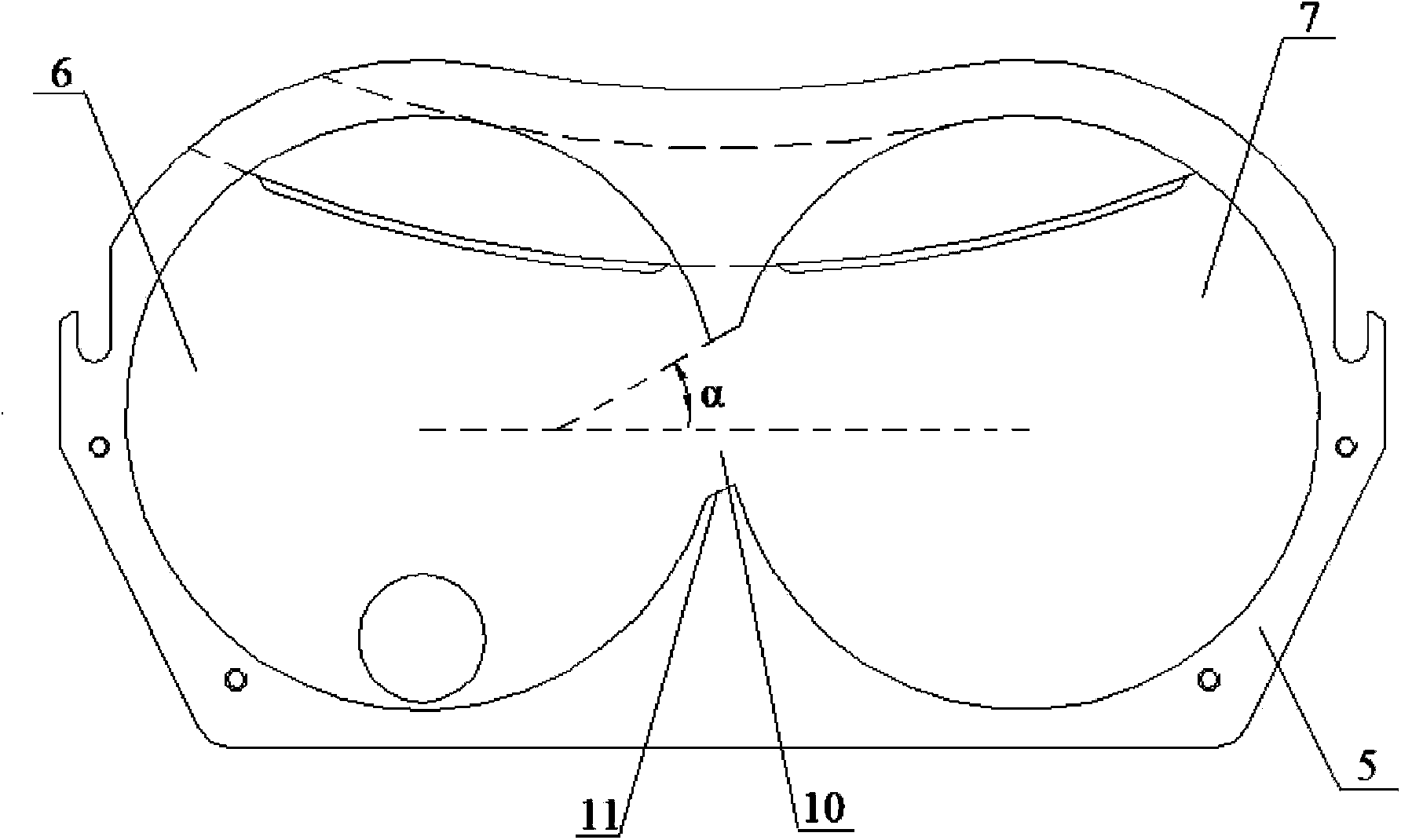

Three-way five-bolt anti-theft door lock

The present invention discloses a three-way five-bolt anti-theft door lock, which resolves the bug of open and close of existing three-way five-bolt anti-theft door lock. The technique is adding slant bolt shifting housing assembly, arranging slant bolt shifting piece, gear shifting piece and cultch piece on the periphery surface, thus fast open and lock can be achieved with inner hand; arranging sliding pin on the slant bolt shifting housing base, which can be clamped connection into a hole on the shifting housing core side wall, arranging sliding push piece on outer end of the sliding pin, thus fast open and lock can be achieved with outer hand, and the outer hand can not open the door after the main lock bolt is locked; arranging self locking piece on the connection plate of the main lock bolt, which has long hole and location pit, and arranging locking post corresponding to the long hole position on the side surface of the outer plate of the lock, thus the self locking operation can be achieved after the main lock bolt is locked, and inner hand can not open the door after the anti-theft door is locked, which increases safety factor of the anti-theft door lock. The three-way five-bolt anti-theft door lock of the invention can be widely applied for various anti-theft door.

Owner:ASSA ABLOY BAODEAN SECURITY PROD

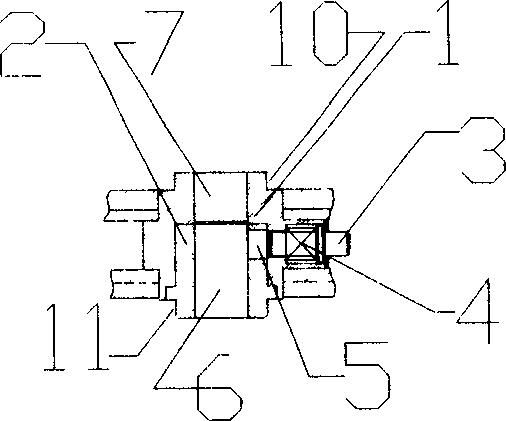

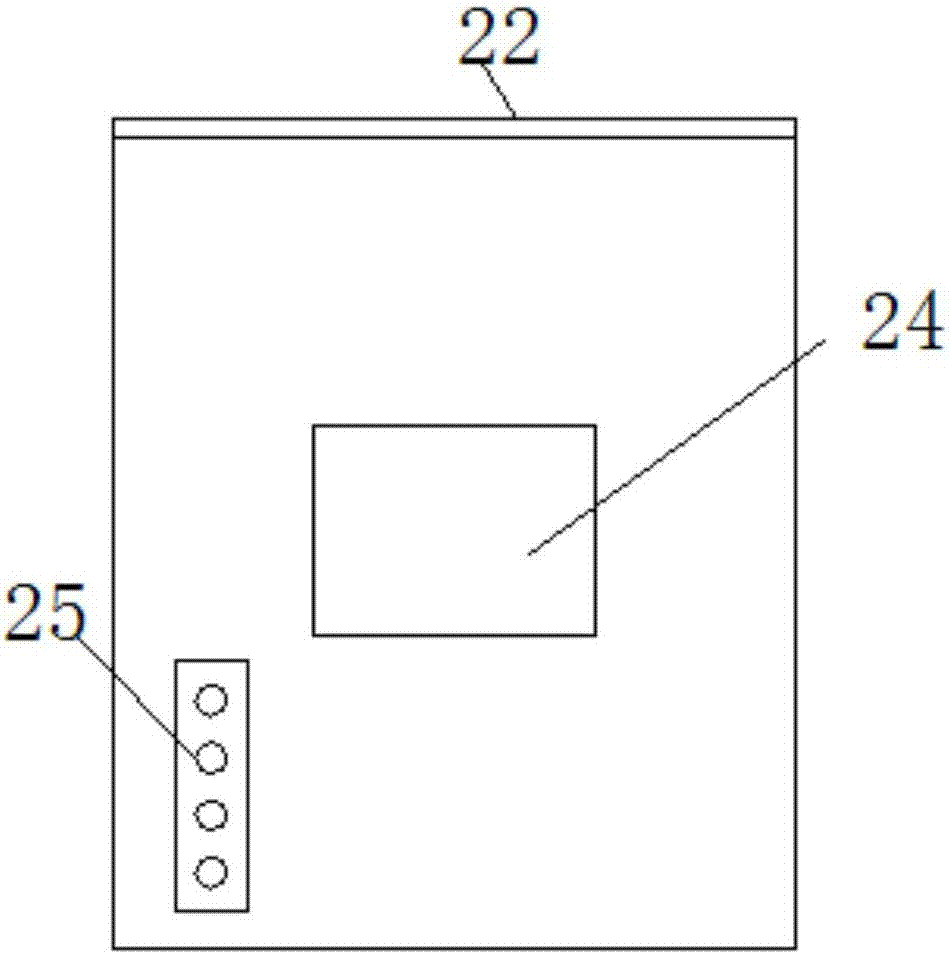

Movable adjustable method of intelligent monitoring device

ActiveCN107339576AAdjust the monitoring rangeAdjust the monitoring directionClosed circuit television systemsStands/trestlesDrive shaftElectrical and Electronics engineering

The invention discloses a movable adjustable method of an intelligent monitoring device. The intelligent monitoring device comprises a base. The two ends of the top surface on the inner side of the base are both fixedly connected with electric push rods. The tail ends of the two electric push rods are both fixedly connected to the middle portions of connecting plates. The middle portions of the bottom faces of the two connecting plates are fixedly connected with limiting telescopic rods. The ends, away from the connecting plates, of the two limiting telescopic rods are both fixedly connected with movable devices. The limiting telescopic rods are inserted into buffer springs. One ends of the two buffer springs are fixedly connected to the bottom faces of the connecting plates. The other ends of the two buffer springs are both fixedly connected to the top faces of the movable devices. A driving shaft is fixedly connected between the two movable devices. According to the movable adjustable method of the intelligent monitoring device provided by the invention, a rotation motor and an adjusting motor are matched with each other, the purpose of adjusting the monitoring device is achieved, the method has the advantage that the monitoring device can be moved and adjusted, and the problem that the monitoring range of an existing movable intelligent monitoring device cannot be adjusted is solved.

Owner:金税信息技术服务股份有限公司

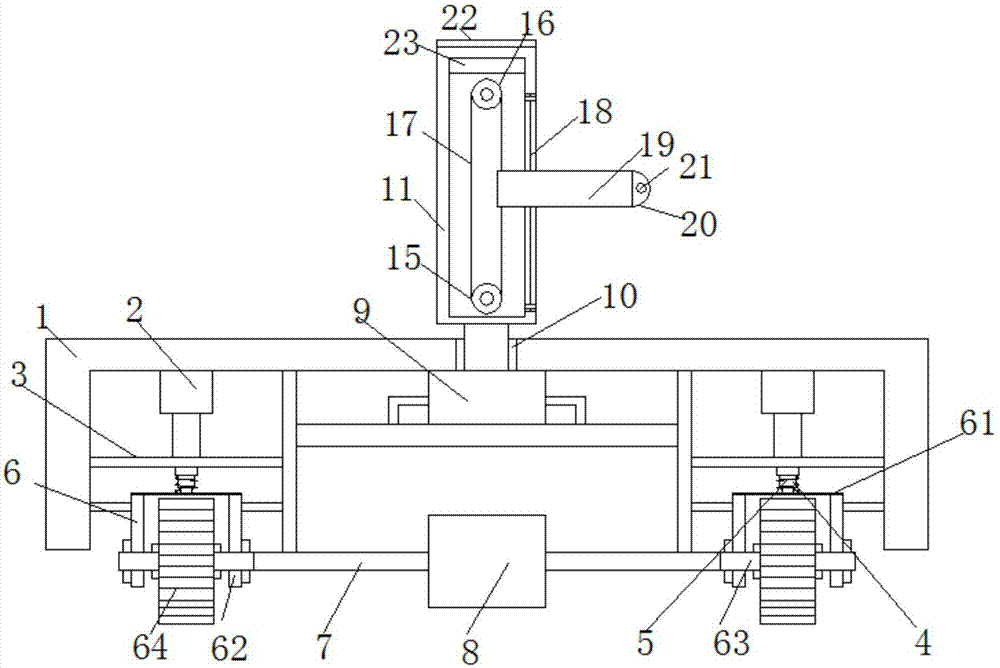

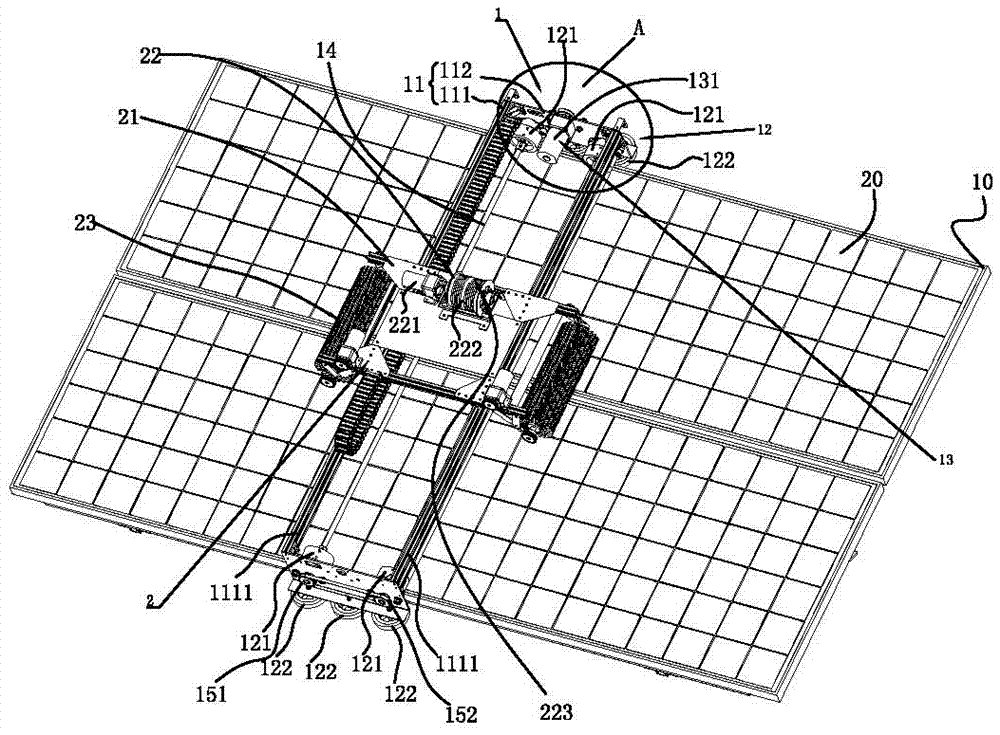

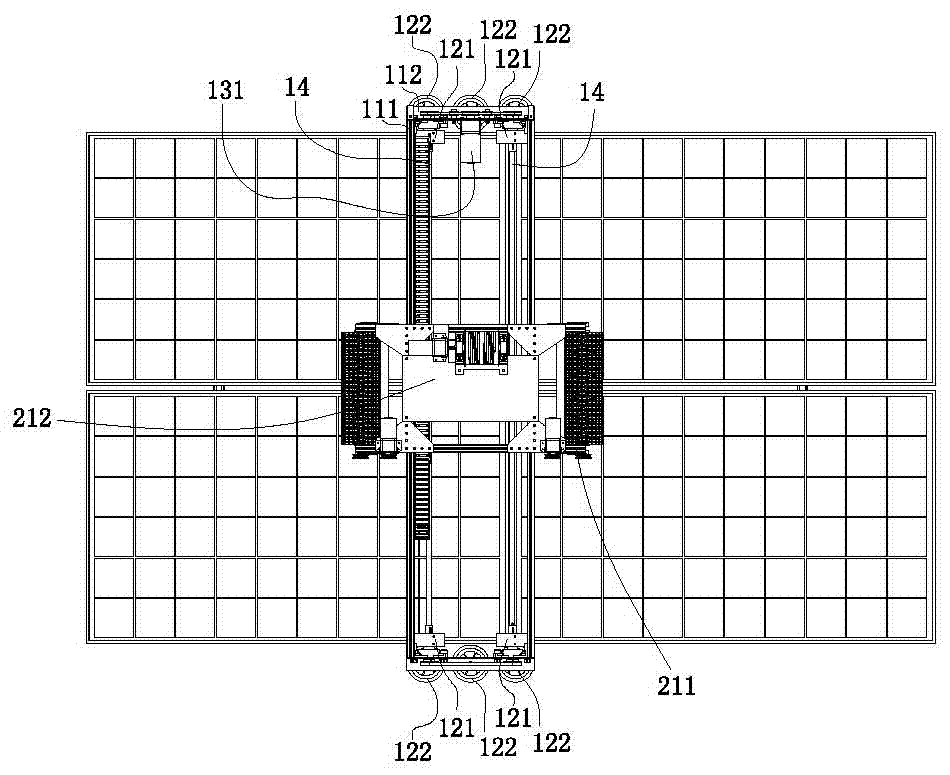

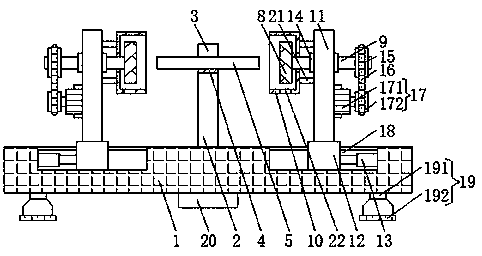

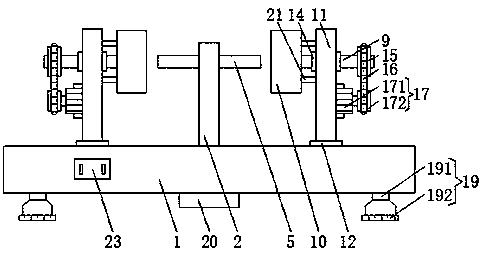

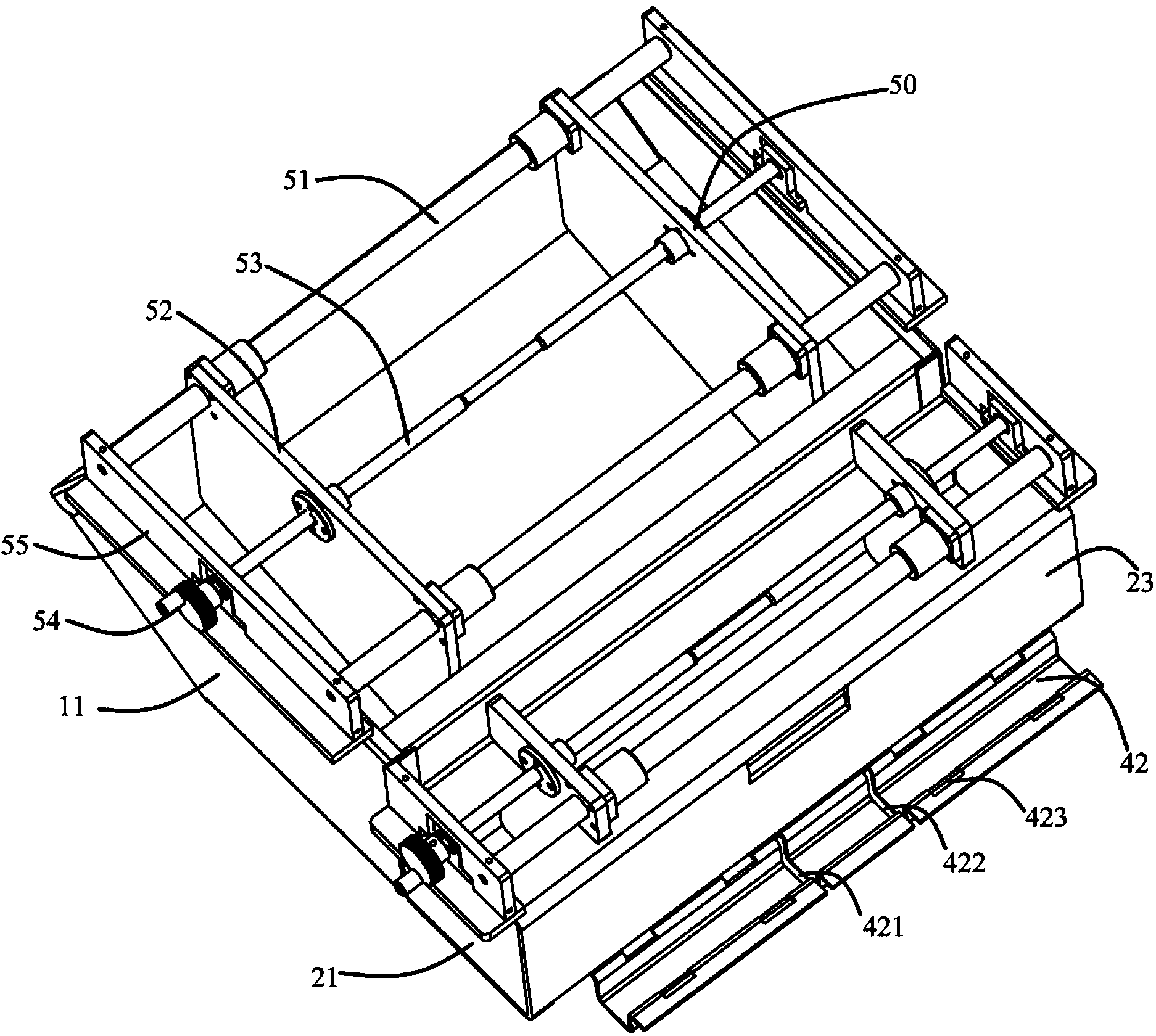

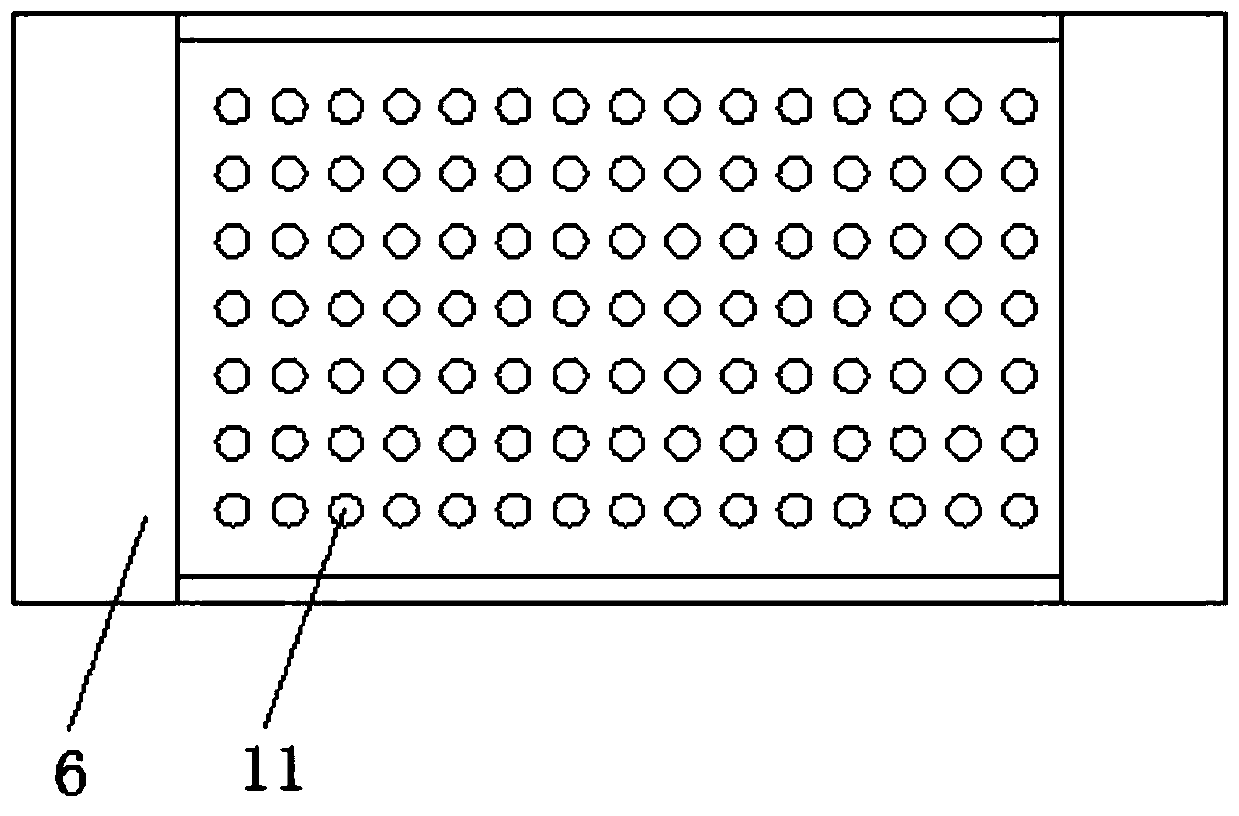

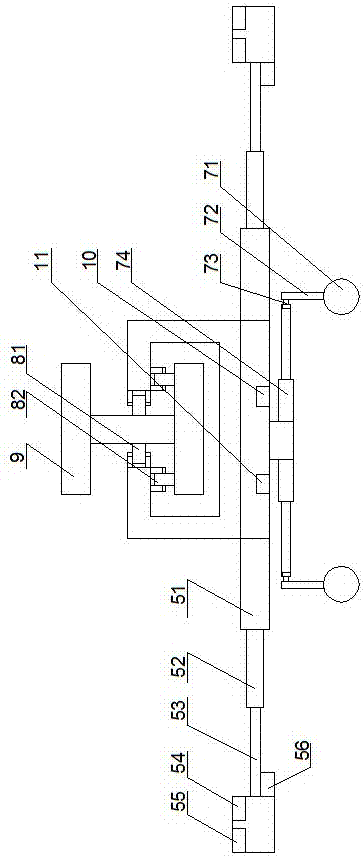

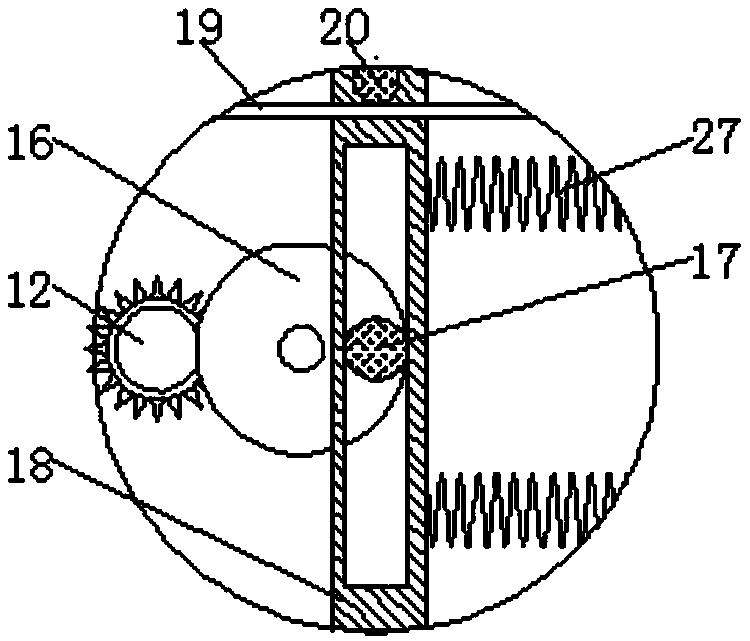

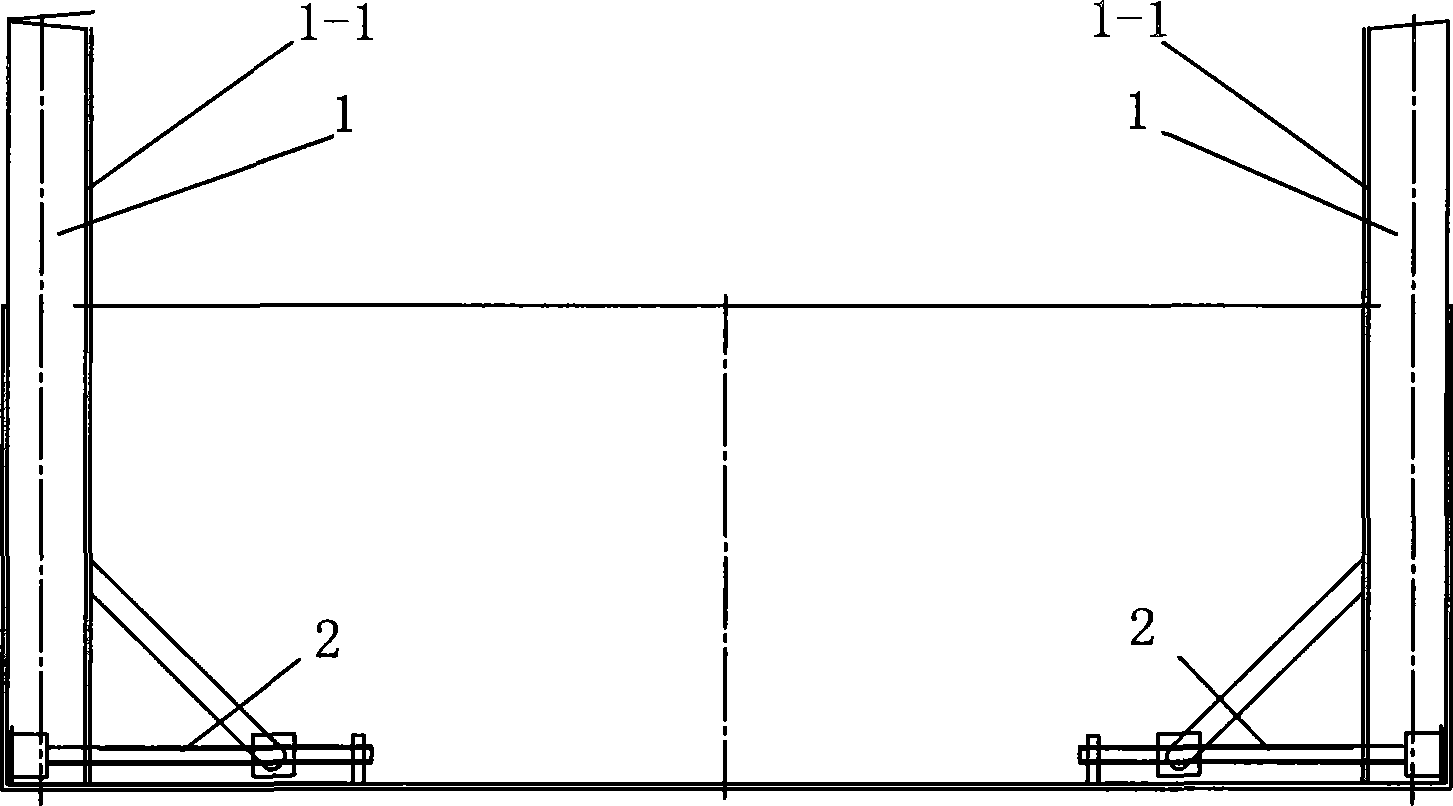

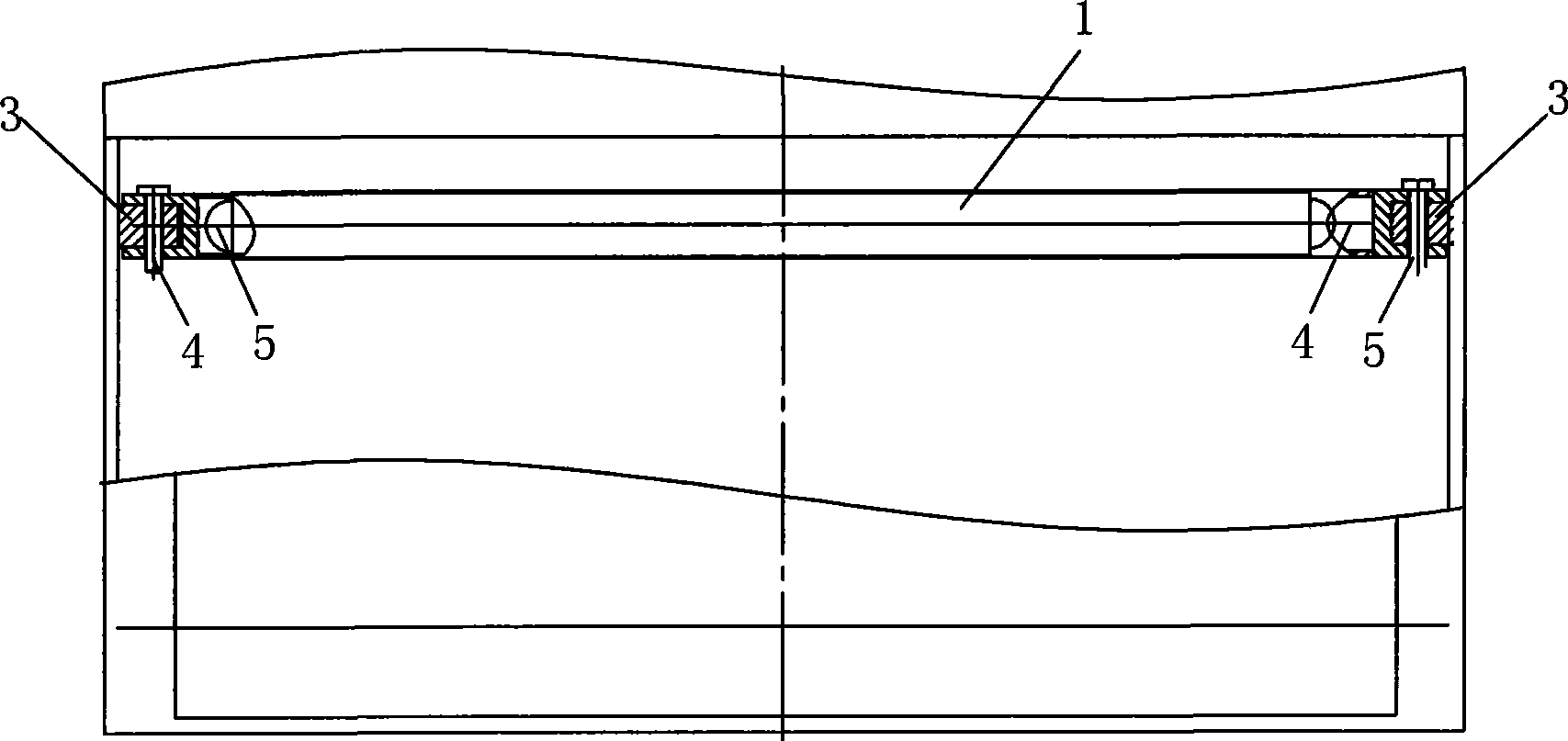

Solar panel washing equipment and washing method

PendingCN107159608AEven by forceAvoid resistancePhotovoltaicsCleaning using toolsEngineeringMechanical engineering

The invention discloses solar panel washing equipment and a washing method. The washing equipment comprises a washing tackle and a washing trolley; the washing tackle comprises a large frame, guide sliding devices are installed at the two ends of the large frame, and a first driving mechanism is installed on the large frame; the large frame is provided with a longitudinal sliding rail; the washing trolley comprises a small frame, a second driving mechanism and a washing device, the small frame is arranged on the longitudinal sliding rail in a sliding manner, and the second driving mechanism is arranged between the small frame and the large frame; and the washing device comprises a washing brush, an adjusting mechanism connected between the small frame and the washing brush and a third driving mechanism for driving the washing brush. According to the washing method, Z-shaped motion of the washing brush is achieved through the first driving mechanism, the second driving mechanism and the third driving mechanism. The equipment and method can be suitable for washing solar panels in different sizes; and in addition, the acting force of the washing brush on the solar panels is adjustable, the solar panels can be better washed, and the solar panels cannot be damaged.

Owner:广州市威控机器人有限公司

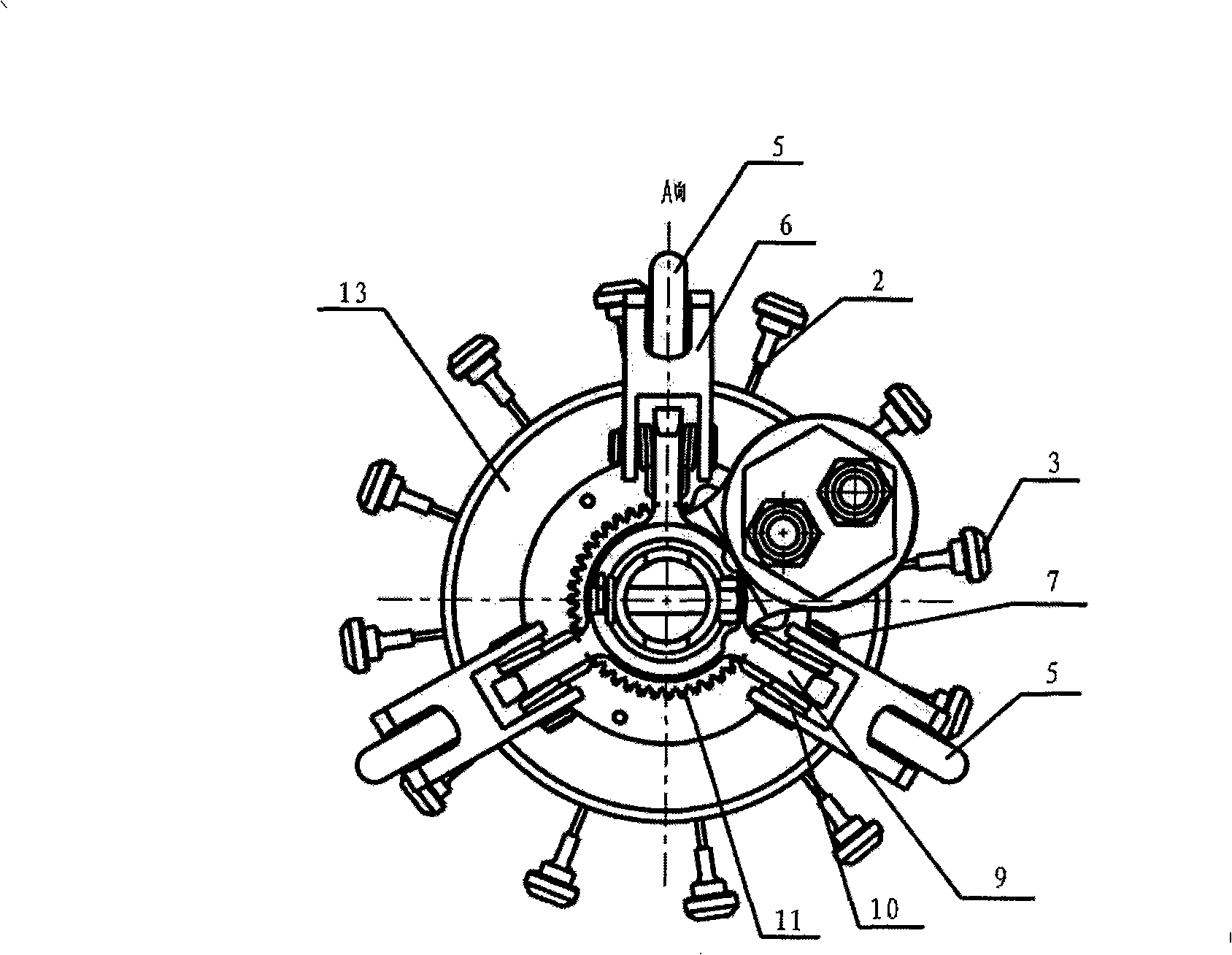

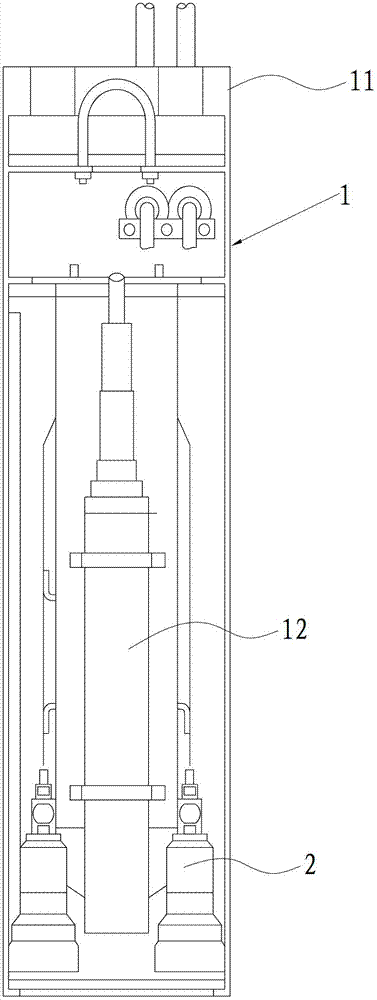

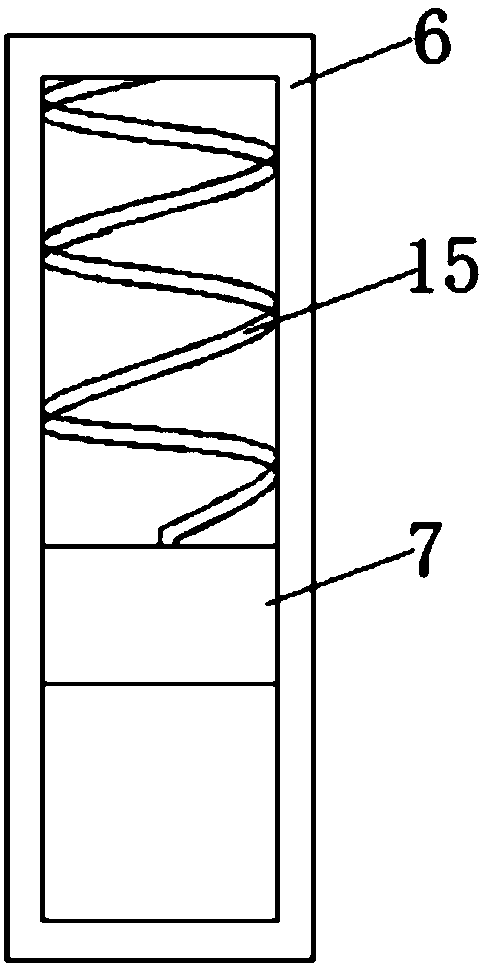

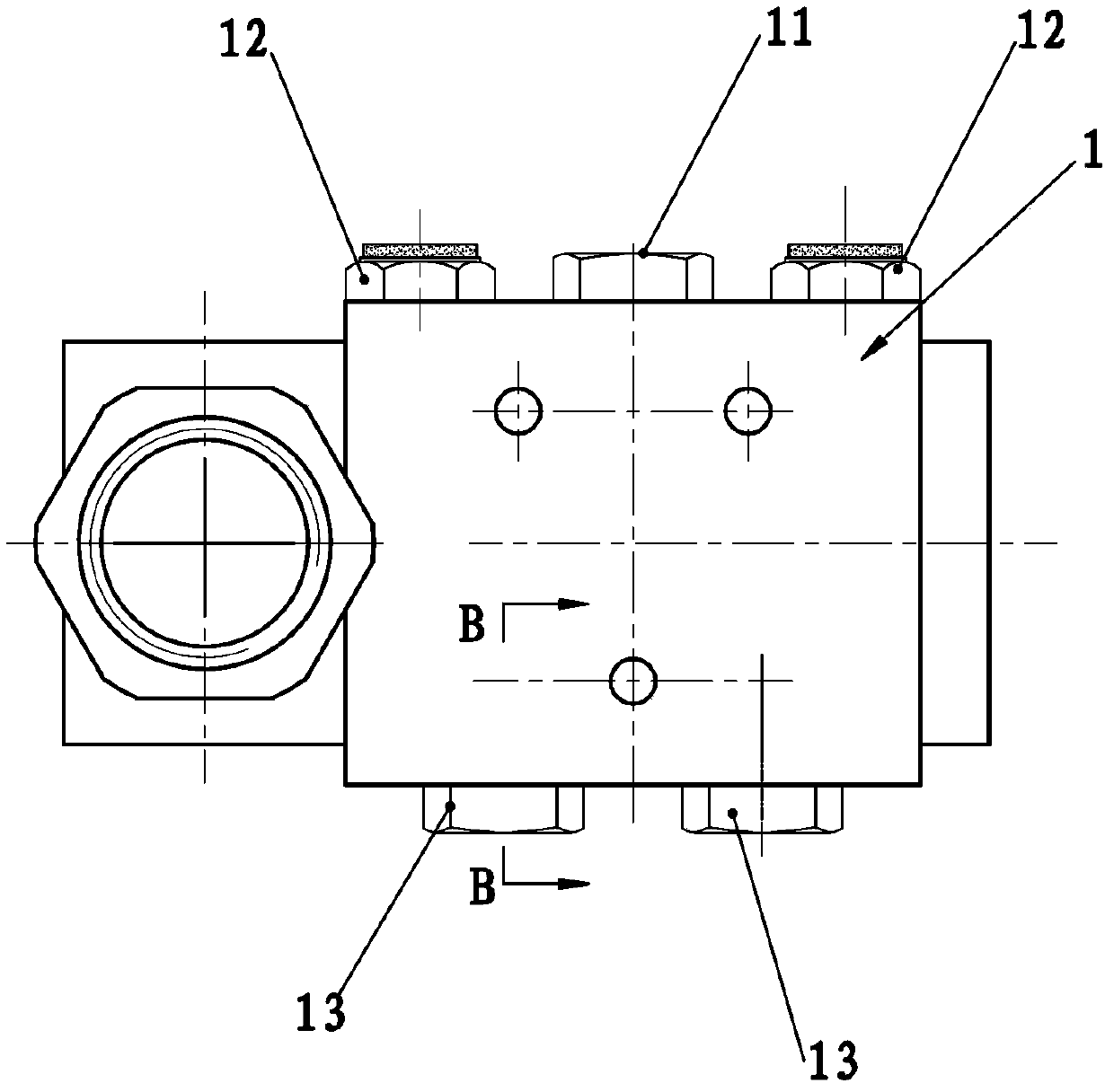

Sweeper for dredging underground pipeline

ActiveCN101308998AOvercome obstaclesPrevent stuck phenomenonHollow article cleaningApparatus for laying cablesPower cableEngineering

The invention belongs to a power cable laying device, in particular to a clearing device for dredging the underground pipeline. According to the technique proposal provide by the invention, the clearing device for dredging the underground pipeline includes a center positioned device, a clearing device, and a driving mechanism that drives the clearing device to rotate. The invention is characterized in that a plurality of flexible connecting arms are arranged at the outer wall of a rotator in the clearing mechanism; a clearing hammer is arranged at the outer end of each connecting arm. The clearing hammer includes a tube part which is used to be connected with the tube shape connecting arm, and a head part with the function of collision. The head part is bigger than the tube part. The tube part is provided with a tube space for the connecting arm to insert in; and the outer end of the connecting arm is inserted in the tube space. The power cable laying device of the invention can expediently clear the inner wall of a pipeline, thus avoids the damage to the power cable by the thorn on the inner wall of the pipeline.

Owner:WUXI POWER SUPPLY JIANGSU PROVINCE ELECTRIC POWER +1

Intelligent camera with adjusting function

Owner:鲲鹏数字技术有限公司

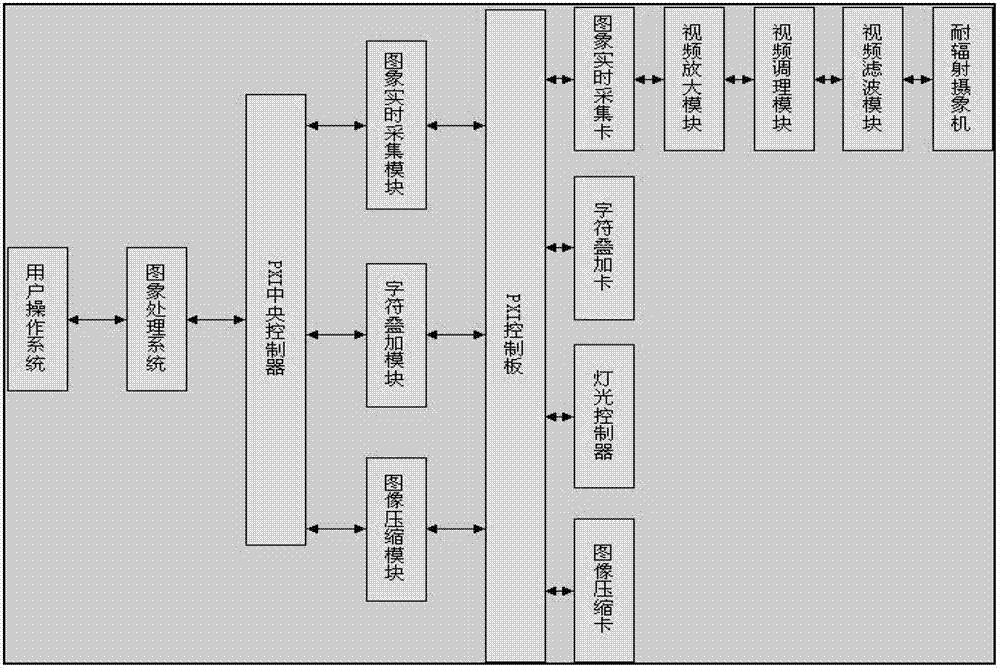

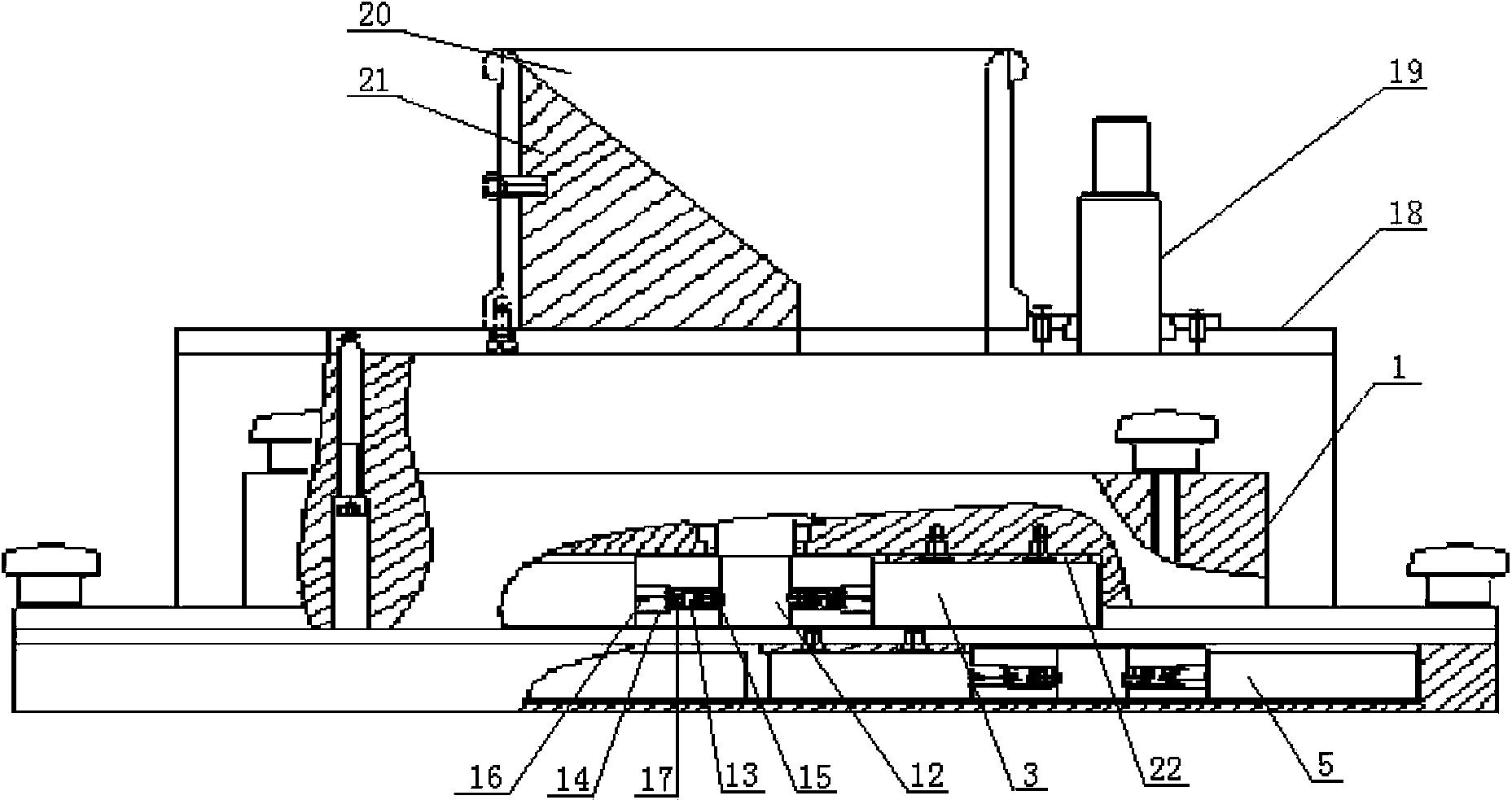

Measuring method and system for actual-position deviation of fuel assembly of nuclear power station reactor core

ActiveCN103594132AAvoid large position deviationImprove safety and reliabilityNuclear energy generationNuclear monitoringNuclear powerNuclear engineering

The invention is suitable for the field of reactor core safety system of a nuclear power station, and discloses a measuring method and a system for actual-position deviation of a fuel assembly of a nuclear power station reactor core. The method comprises following steps of: moving an image acquisition device to a position above a target fuel assembly; acquiring the actual image position of the target fuel assembly by the image acquisition device; comparing the actual position of the target fuel assembly with a standard reference in an industrial machine; and calculating the difference between the actual coordinate and the standard reference by the industrial machine to obtain the deviation dimension. The system comprises the image acquisition device and the industrial machine. The measuring method and the system can measure the deviation between the actual position of a tube socket of the fuel assembly and a standard theoretical position accurately and efficiently, so as to discover abnormal situations and detect and examine timely during the abnormal situations, and therefore risks are effectively avoided and safety and reliability are high.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

Polishing device for aluminium alloy door and window support notch

InactiveCN108942461ALess hurtful thingsImprove work efficiencyEdge grinding machinesGrinding carriagesEngineeringAluminium alloy

The invention discloses a polishing device for an aluminium alloy door and window support notch, and relates to the technical field of aluminium profile machining. The polishing device comprises a working table, a clamping plate is fixedly connected to the middle portion of the upper surface of the working table, an object containing hole is formed in the top of the side face of the clamping plate, an elastic mat is fixedly connected to the lower surface of the inner wall of the object containing hole, and the upper surface of the elastic mat and the lower surface of an aluminium plate are inlap joint. According to the polishing device for the aluminium alloy door and window support notch, when polishing discs are in contact with the notch of the aluminium plate, polishing work can be done on the notch, a large quantity of flying chippings can be generated in the polishing process of the polishing discs, the flying chippings are limited into a protection cover under the effect of theprotection cover and then flows out through a drain outlet, the condition that the flying chippings hurt people can be effectively reduced, the two polishing discs can polish the two side faces of thealuminium plate at the same time, and therefore the working efficiency of a worker can be improved.

Owner:黄山市强峰铝业有限公司

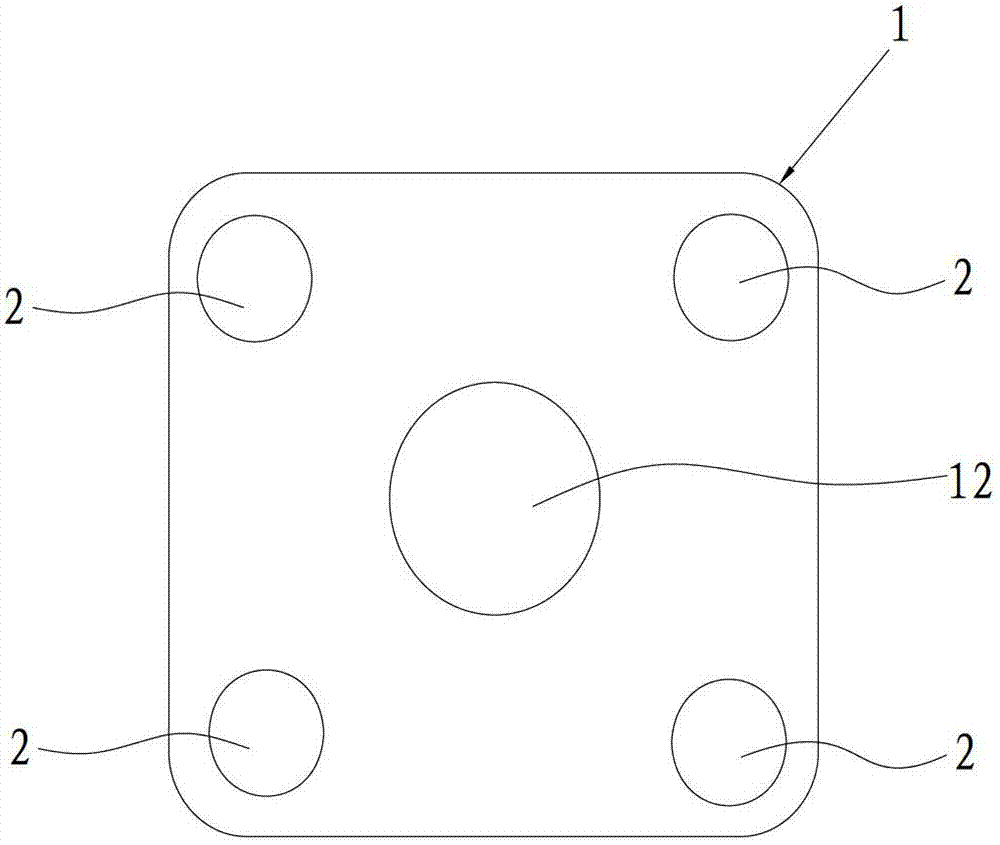

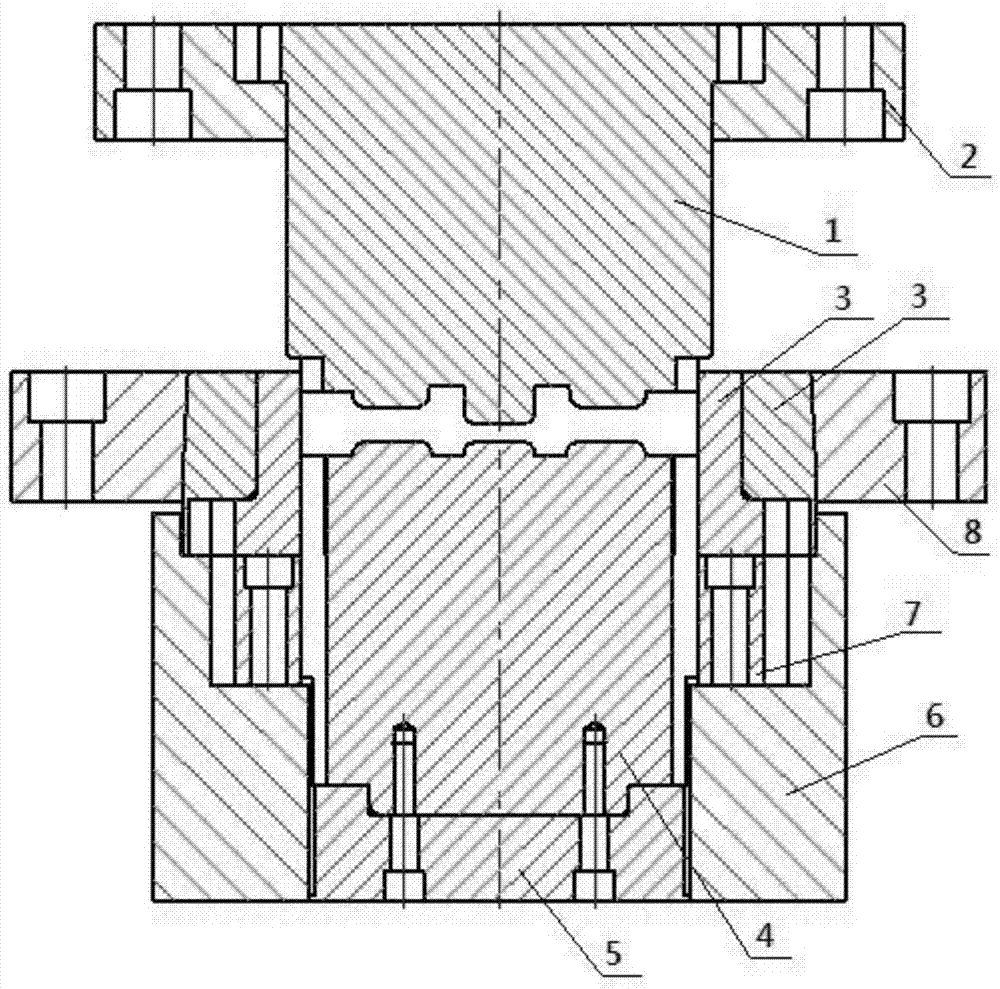

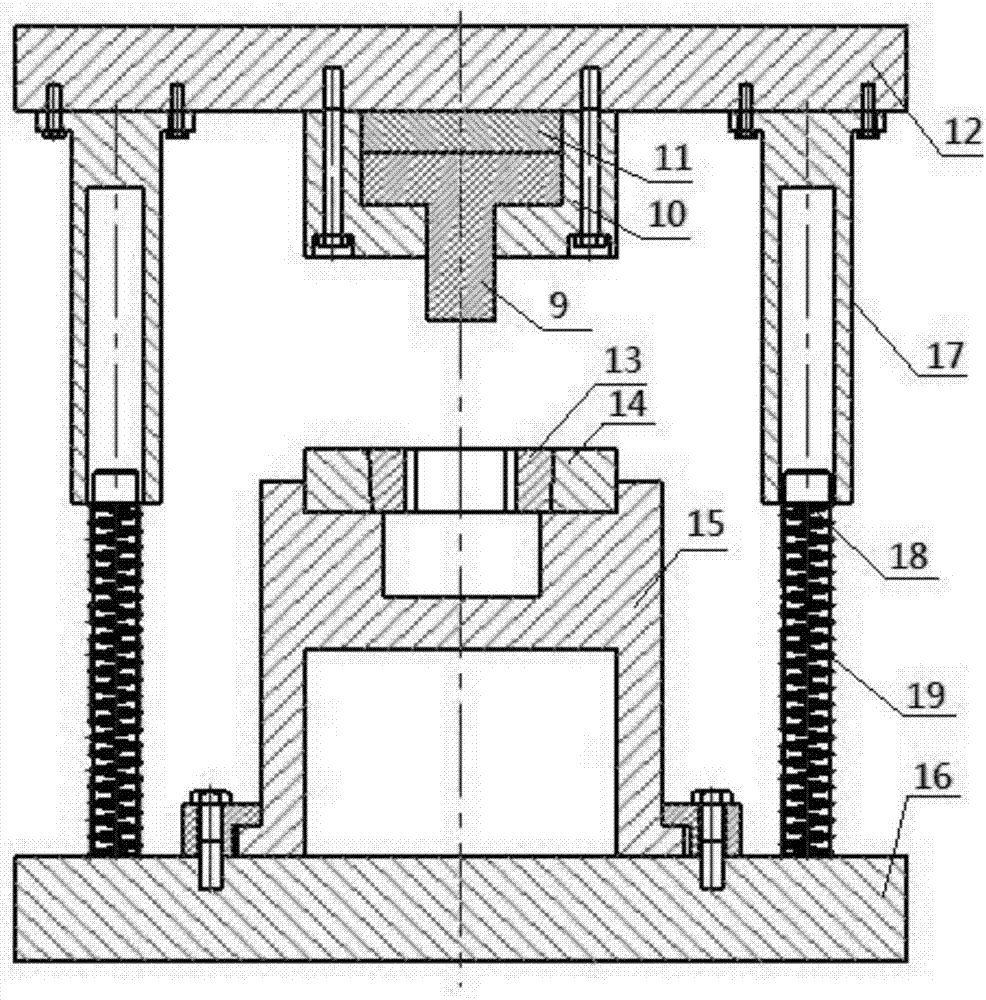

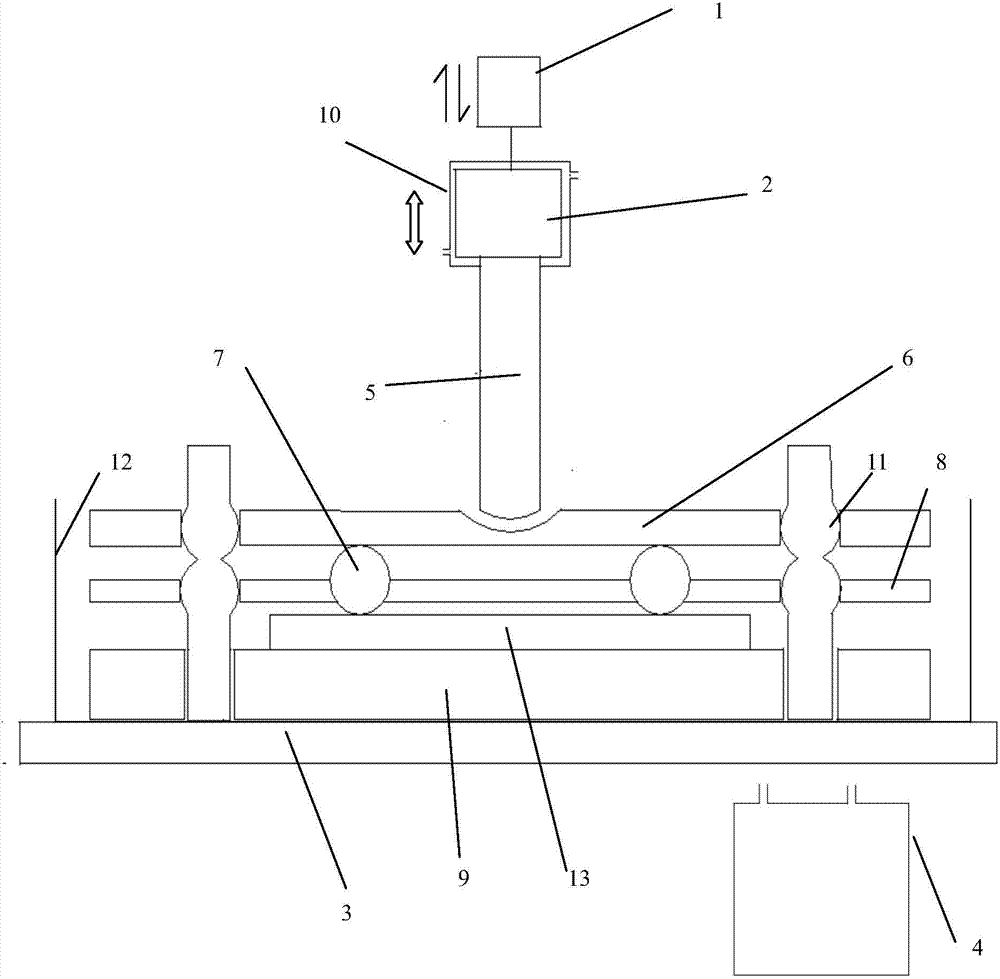

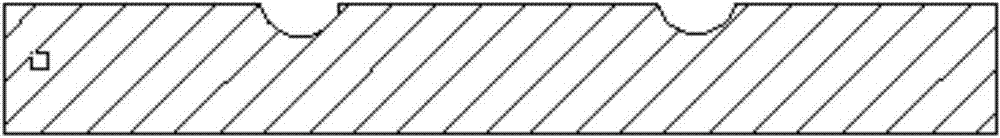

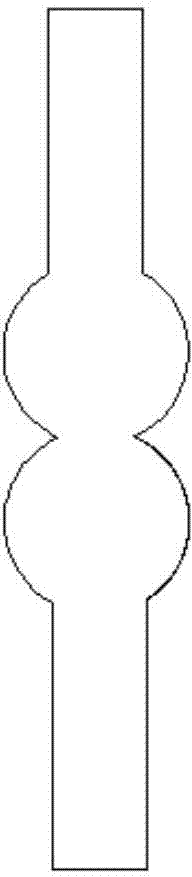

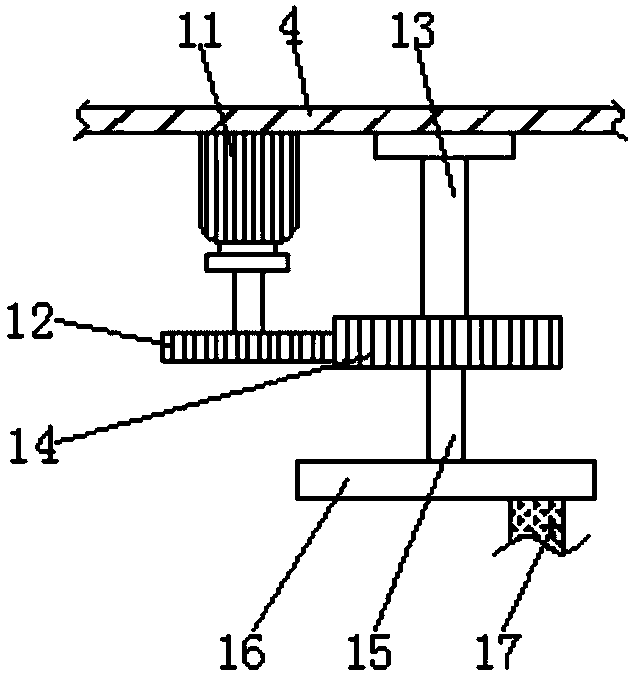

Idler machining method and combined mold for machining

PendingCN107470533AExtend your lifeAvoid chippingShaping toolsForging/hammering/pressing machinesPunchingCold sizing

The invention discloses an idler machining method and a combined mold for machining. The machining method includes accurate discharging, coating of an oxidizing preventing coating, non-oxidation induction heating, upsetting, forging forming, punching, spheroidizing annealing, shot blasting, cleaning, coating of a metal lubricant and cold sizing. The combined mold for machining comprises a hot fine forging forming mold; the hot fine forging forming mold comprises an upper mold part and a split type lower mold part; the upper mold part comprises a tooth-shaped upper mold and an upper pressing plate; the split type lower mold part comprises a lower mold body, a tooth-shaped lower mold and a lower ejecting rod; the lower ejecting rod is located below the tooth-shaped lower mold; a lower ejecting rod cushion plate is arranged below the lower ejecting rod; the lower mold body surrounds the lower ejecting rod and the lower ejecting rod cushion plate; a platform is arranged on the upper portion of the lower mold body along the periphery, and a lower cushion plate is arranged between the tooth-shaped lower mold and the platform; and an annular lower pressing plate is further included, and the tooth-shaped lower mold and the lower mold body are centered by the lower pressing plate. The near-net forming principle is adopted for the machining method, tooth profiles are forged at a time, and it is achieved that subsequent machining is little and even no subsequent machining exists.

Owner:山东大为齿轮传动有限公司

Easy-to-move intelligent camera device

ActiveCN107333039AEasy to moveEasy to adjustTelevision system detailsColor television detailsEngineering

Owner:肖慧

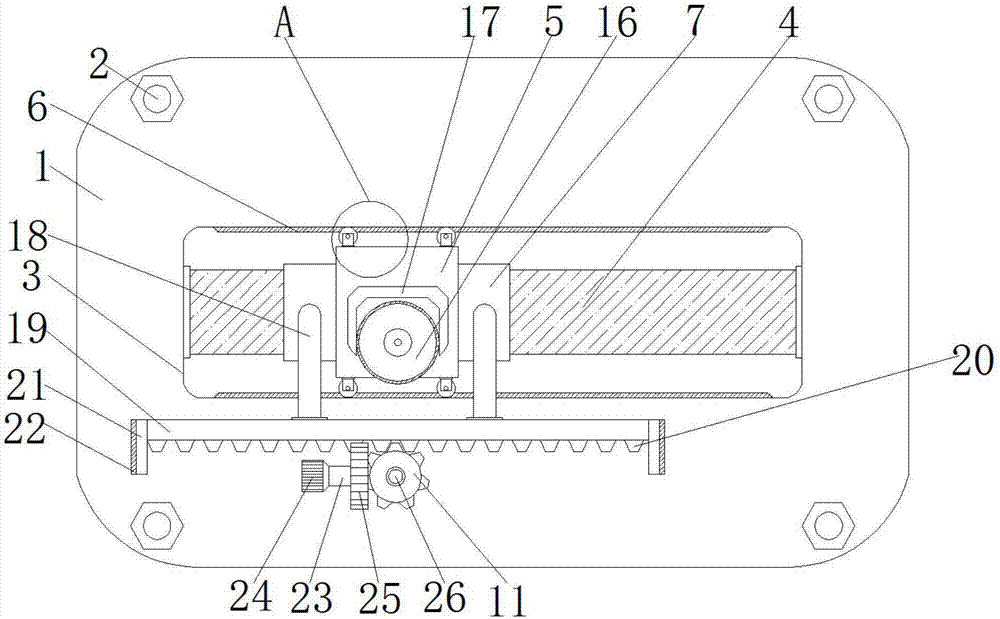

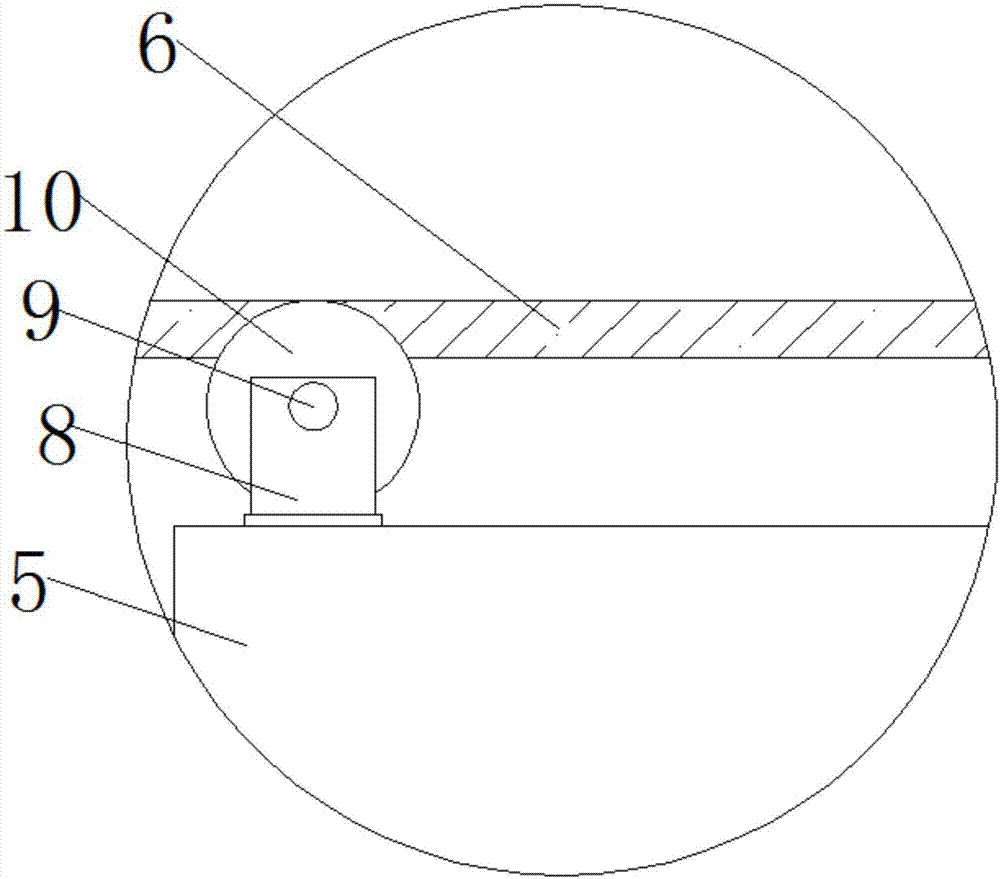

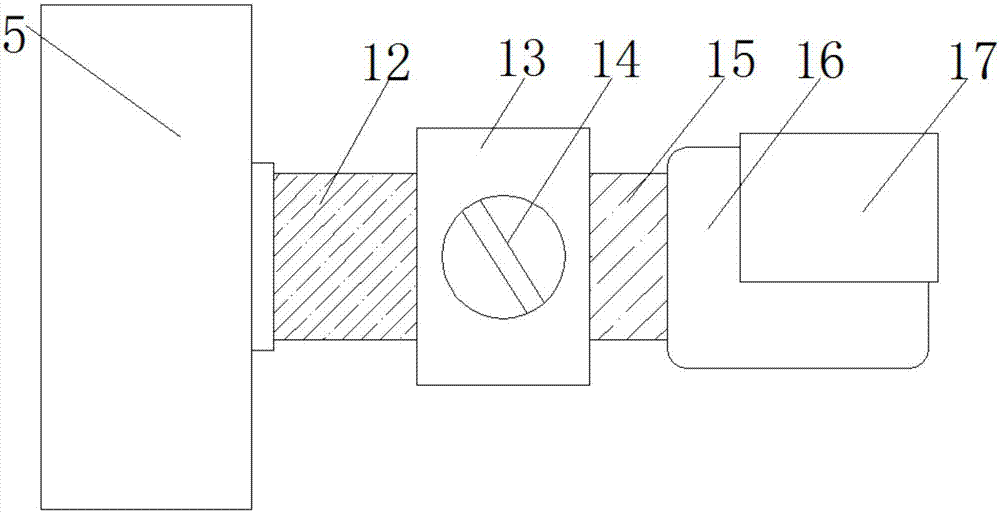

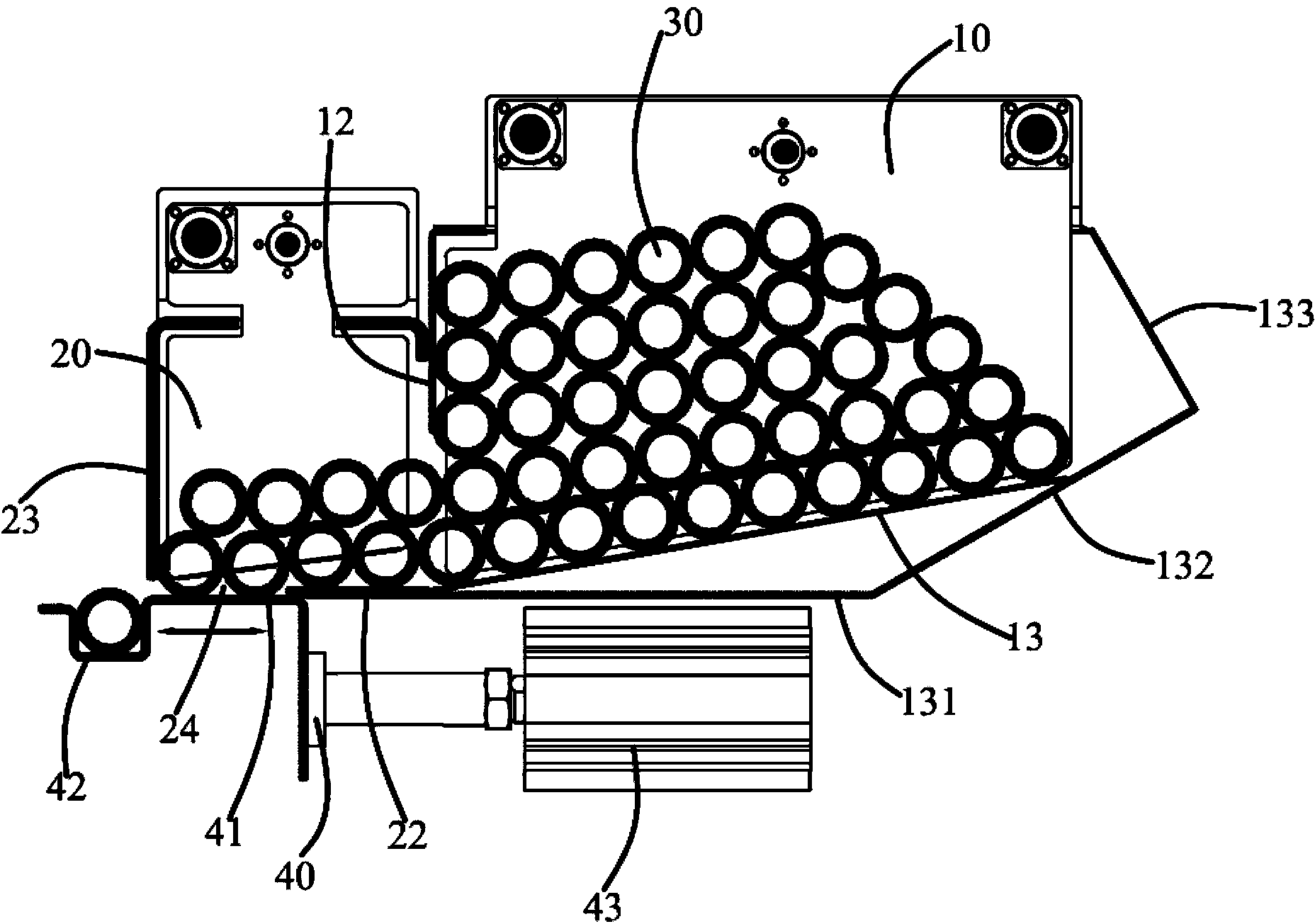

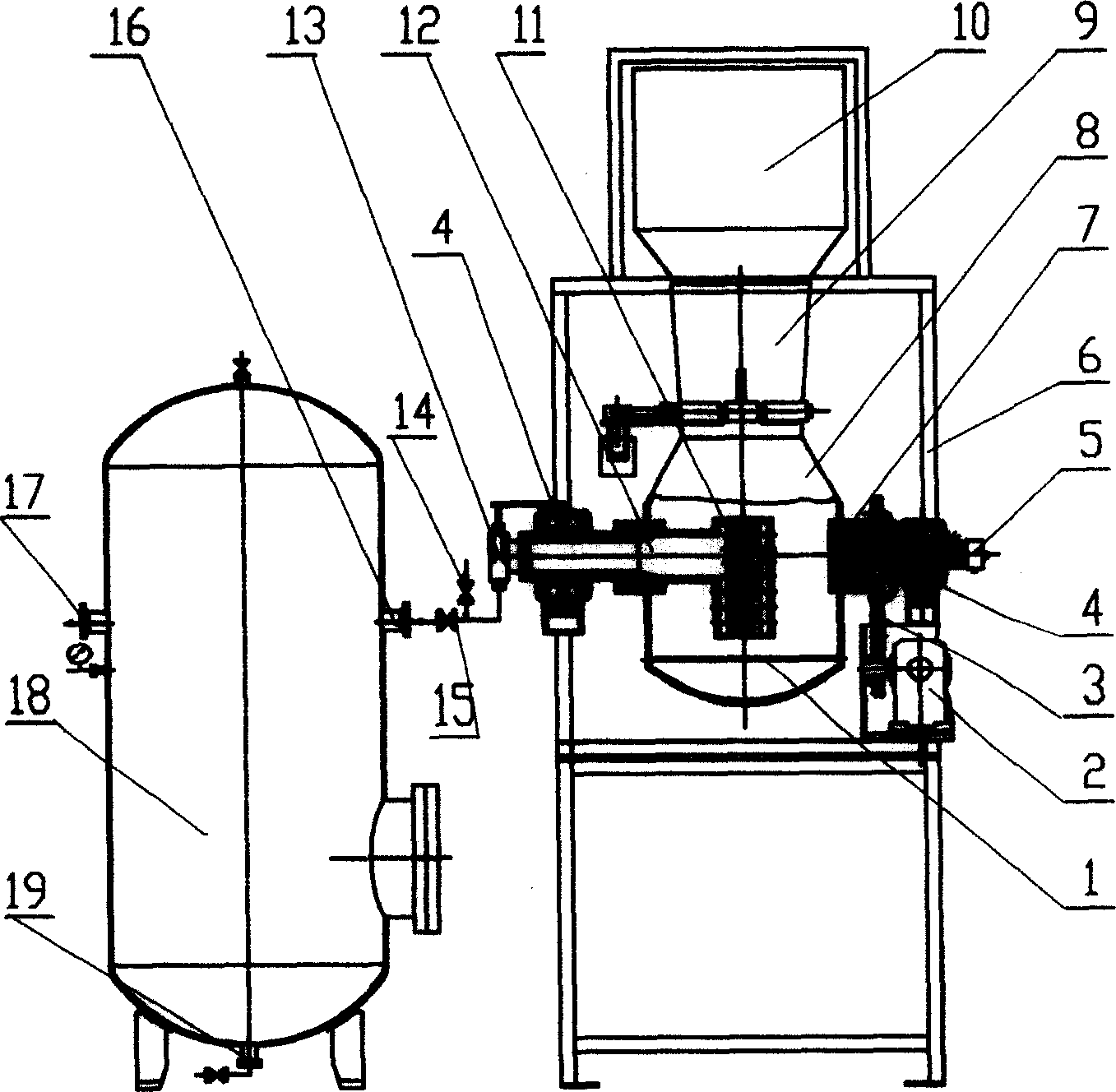

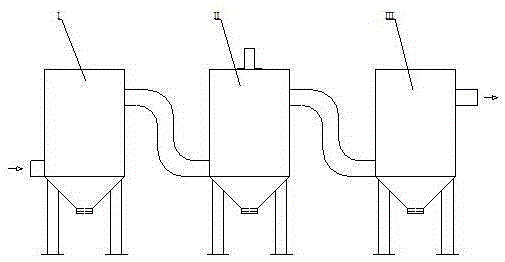

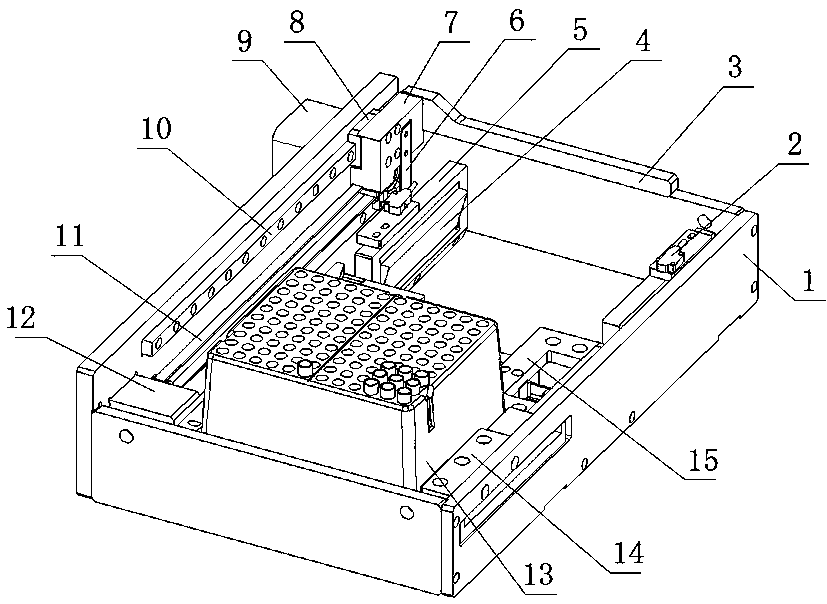

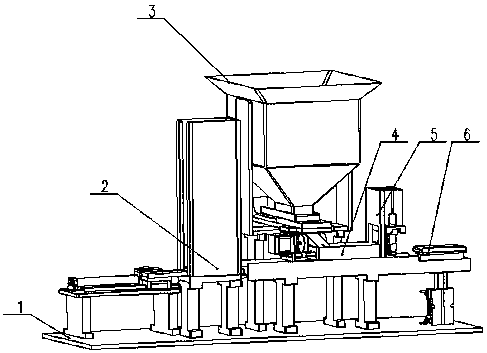

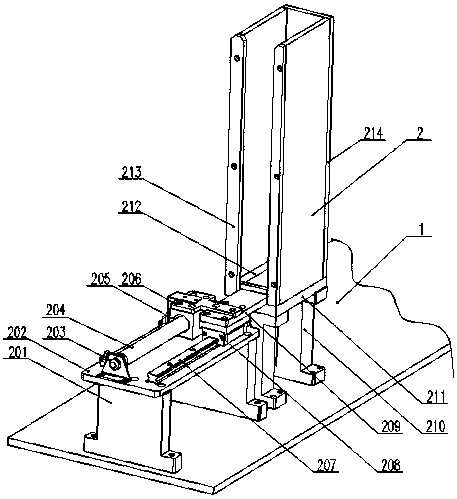

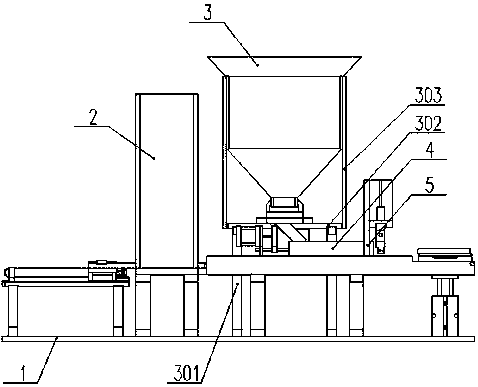

Automatic discharging system

InactiveCN103787089ARealize automatic dischargePrevent stuck phenomenonLoading/unloadingMechanical engineeringVertical distance

The invention discloses an automatic discharging system comprising a storing bin and a discharging bin which are used for placement of cylindrical workpieces and communicated with each other. Communication distance on vertical distance between the storing bin and the discharging bin is larger than diameter of a workpiece, a discharging port is arranged on the undersurface of the discharging bin, width of the discharging port is larger than the diameter of one workpiece, and a feeding device is arranged below the discharging port and comprises a retaining portion, a workpiece containing groove connected with the retaining portion and a driving device connected with the retaining portion and used for driving the feeding device to move back and forth. The automatic discharging system realizes full-automatic discharging of the cylindrical workpieces without robot participation.

Owner:苏州久工自动化科技有限公司

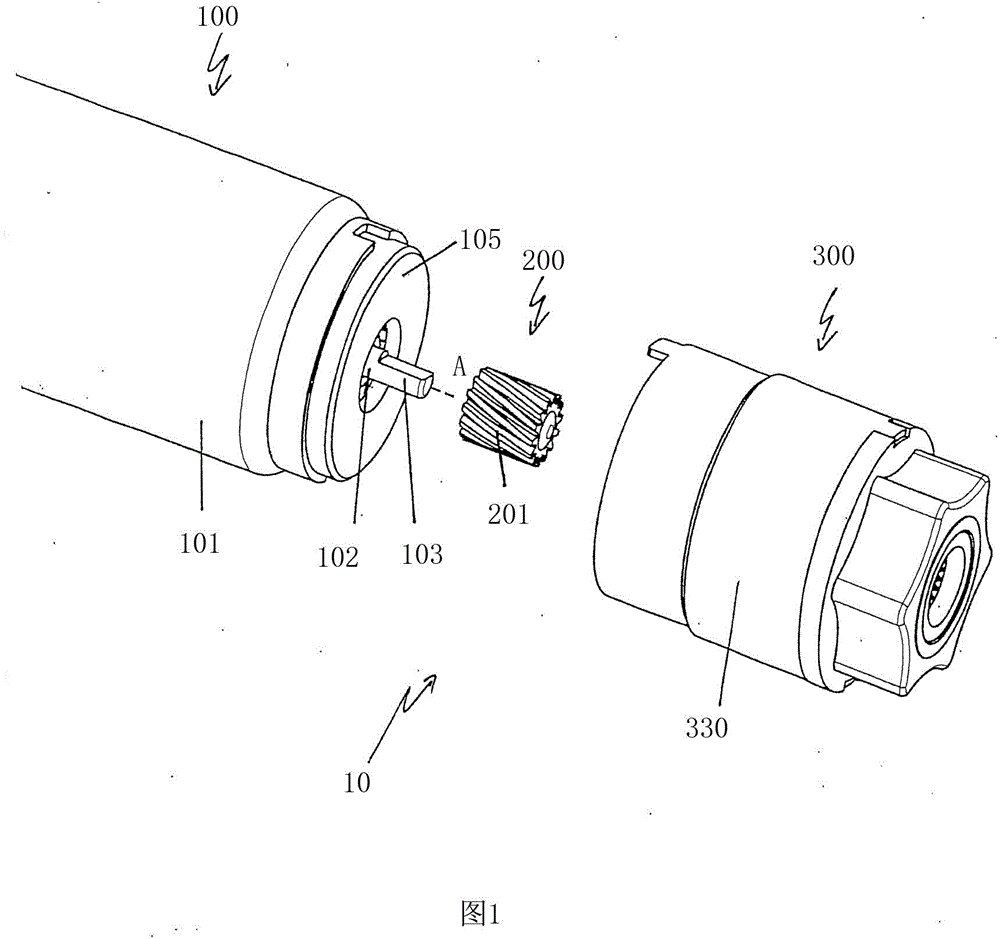

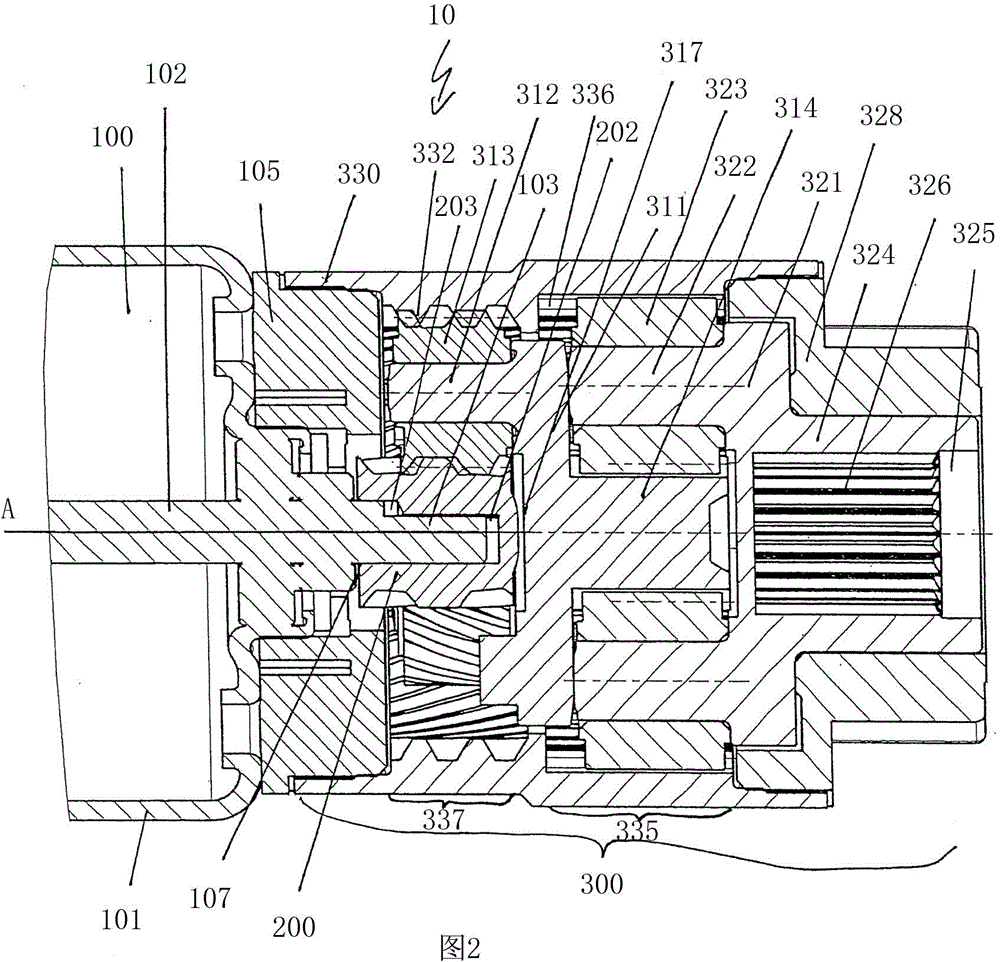

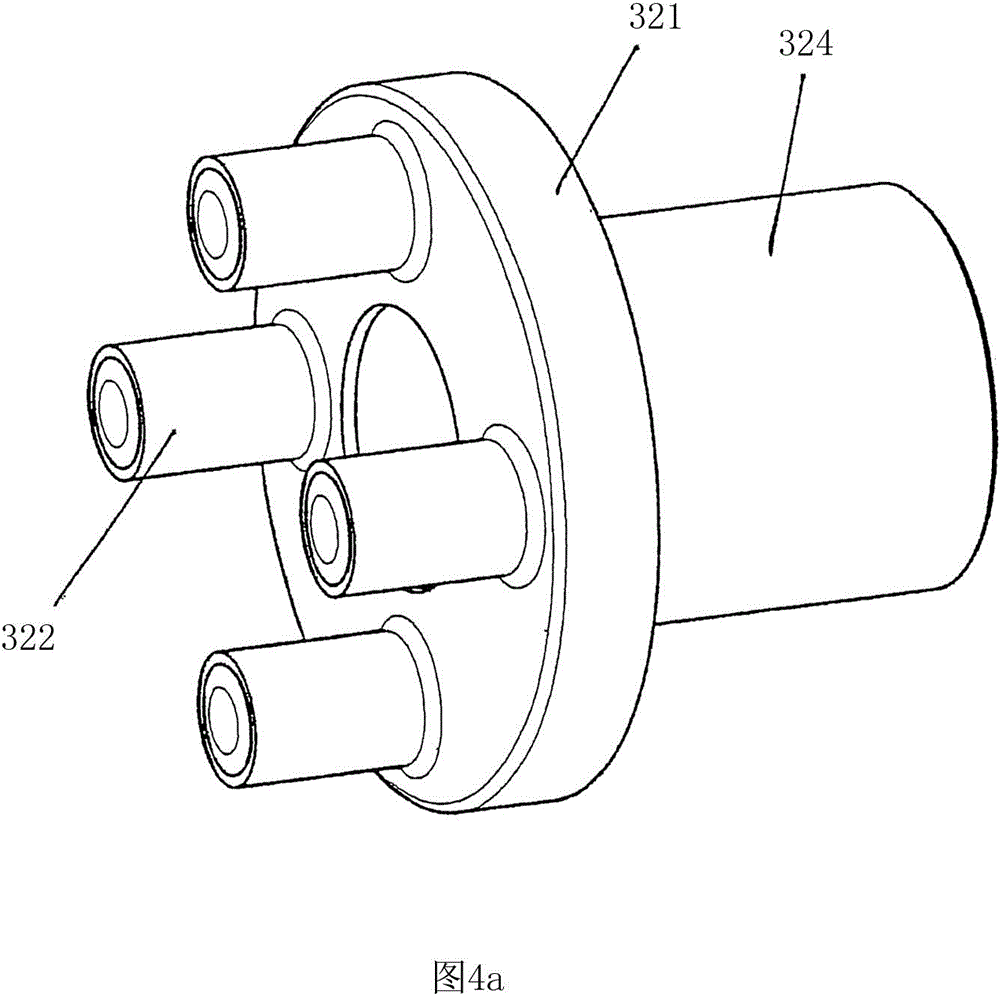

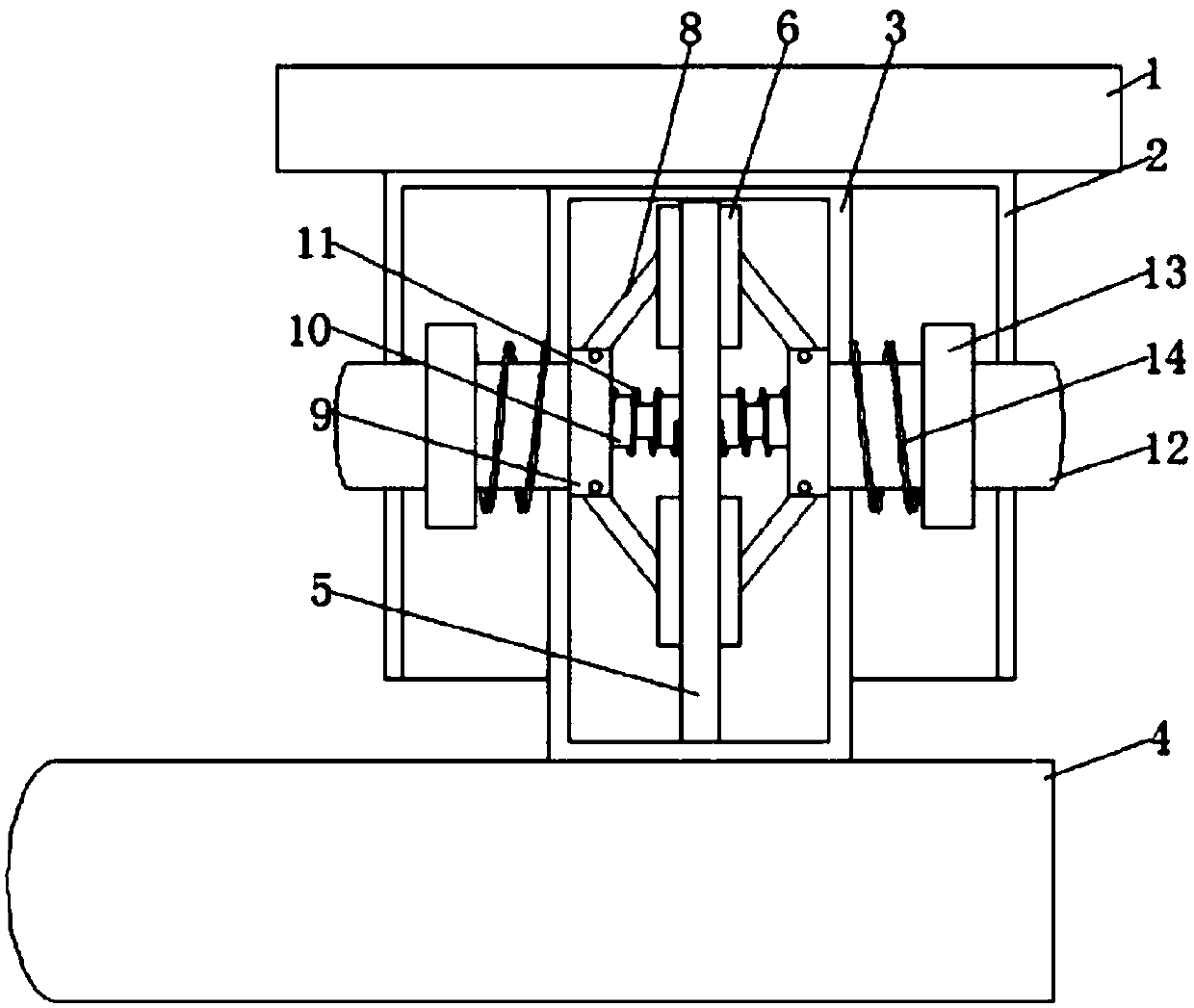

Driven hatch arrangement for a motor vehicle

InactiveCN104565330APrevent stuck phenomenonAffects operating characteristicsToothed gearingsPower-operated mechanismMobile vehicleDrive shaft

A driven hatch arrangement is provided, particularly a rear hatch arrangement, for a motor vehicle with a hatch and with a hatch drive for opening and / or closing the hatch, with the hatch drive comprising a motor with a motor shaft and a motor pinion and at least one planetary gear with a sun gear, planetary carriers with planetary rolling elements arranged on bearing pins, and an annulus, with the sun wheel of the planetary gear being formed by the motor pinion and a driven shaft being driven via the planetary gear, in which the bearing pins of the planetary gear projecting beyond the planetary rolling elements arranged on the bearing pins in the direction towards the motor.

Owner:IMS GEAR GMBH

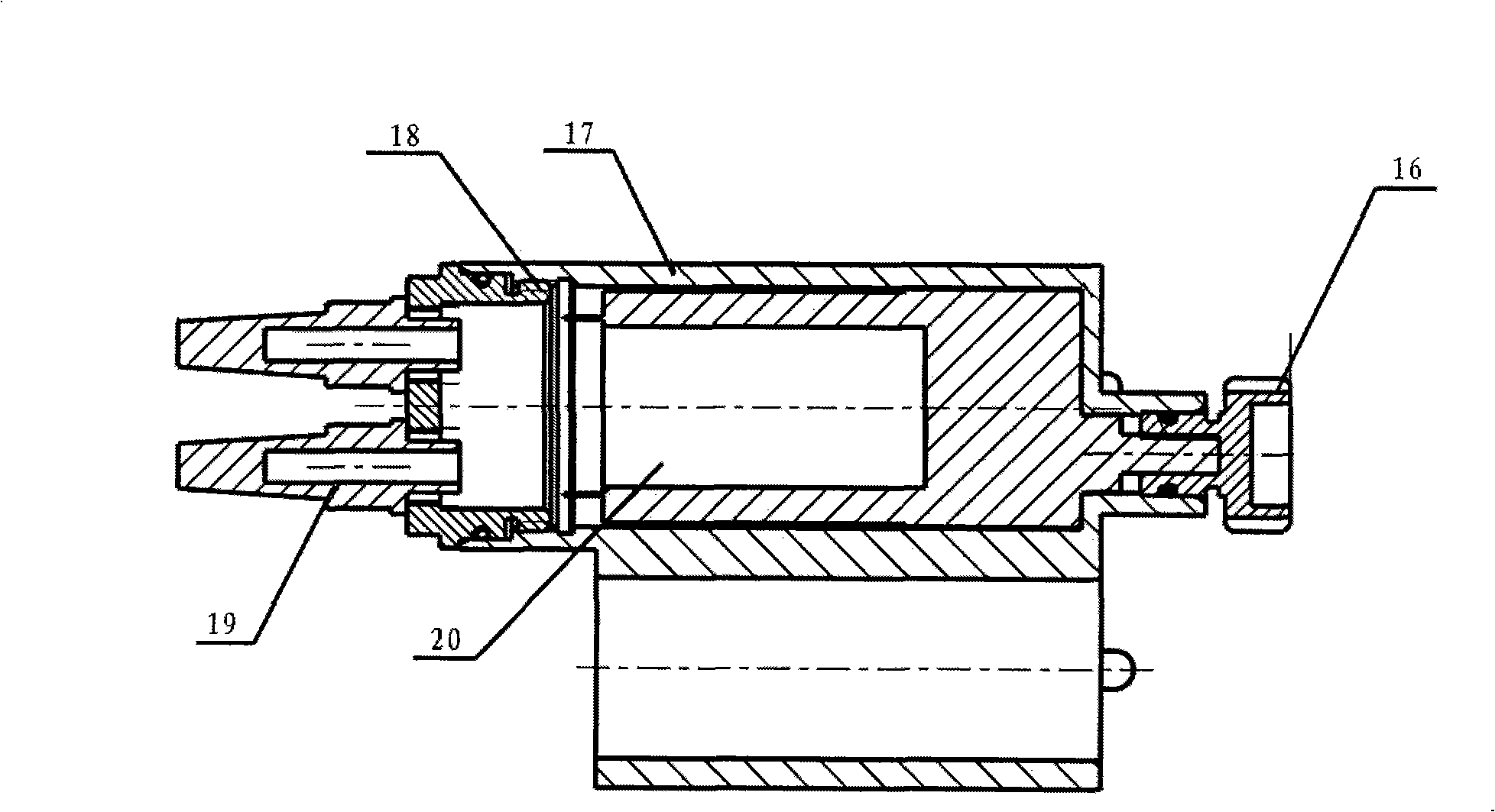

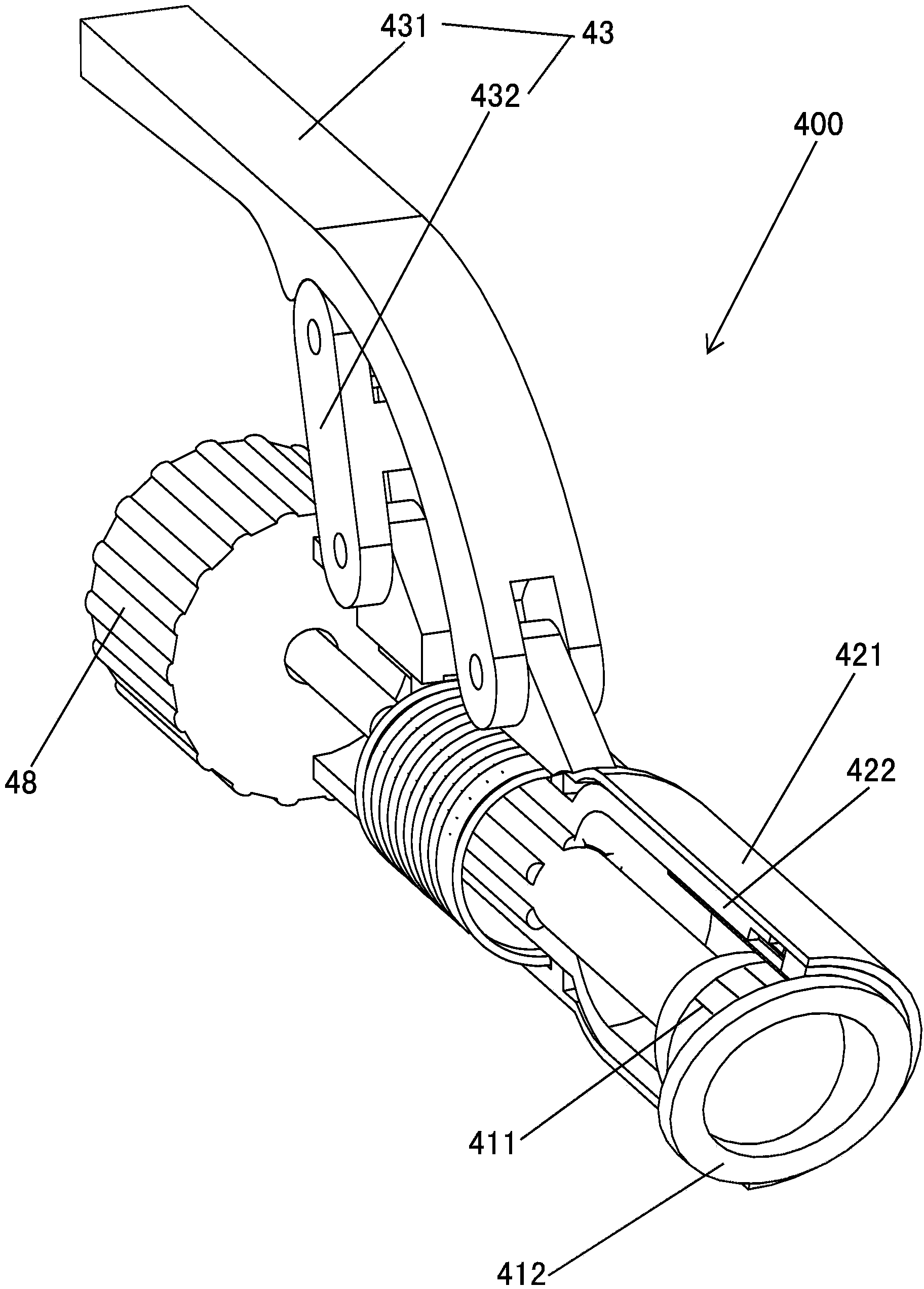

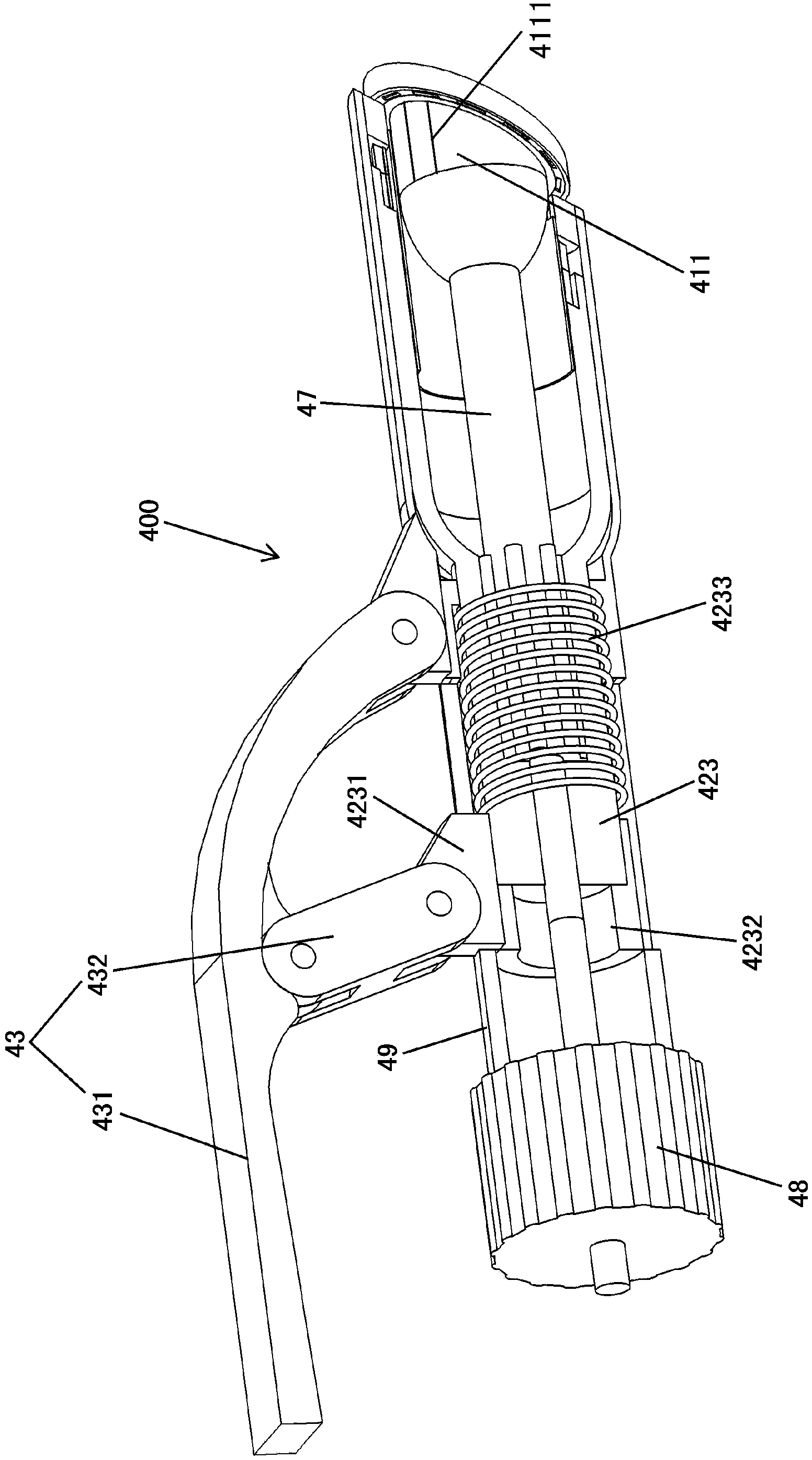

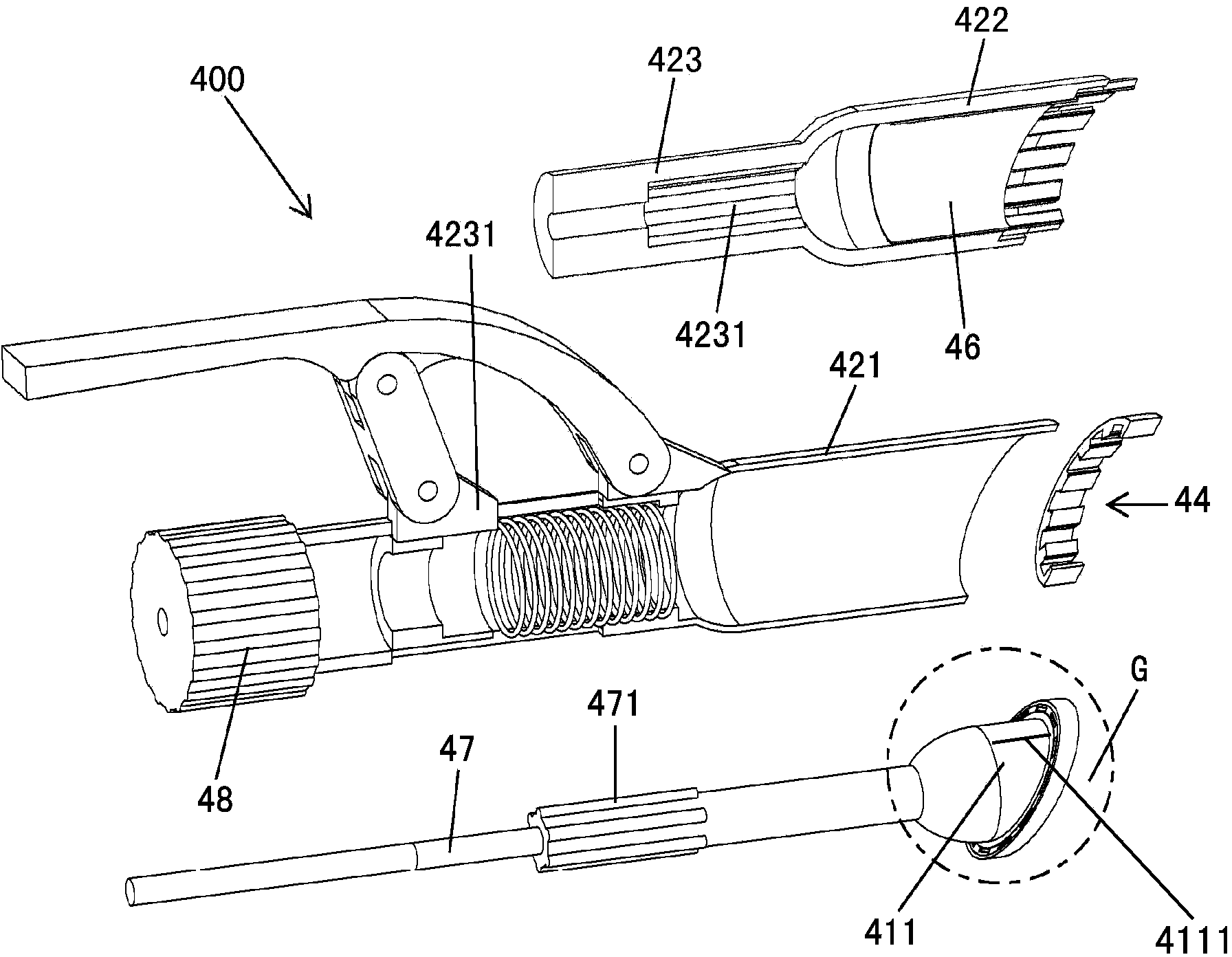

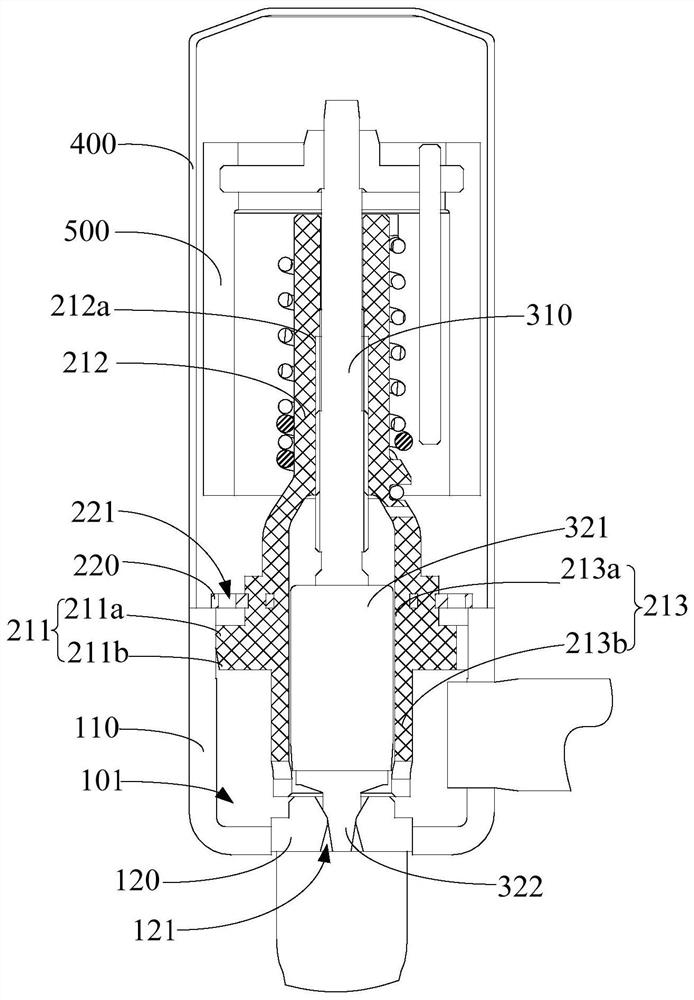

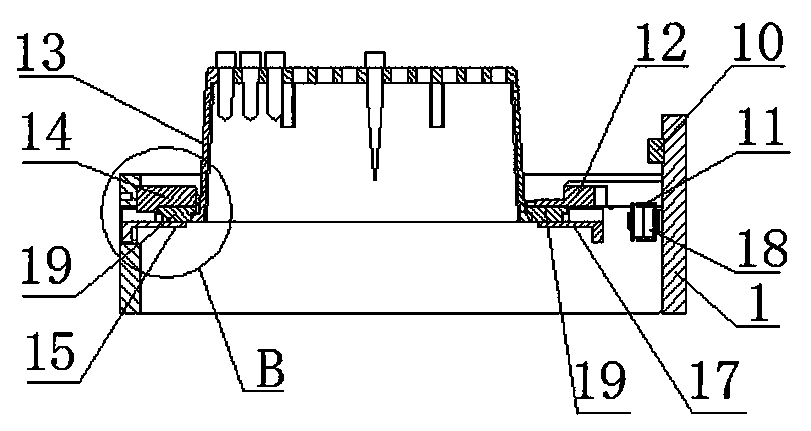

Positioning device and circumcision device

The invention discloses a positioning device and a circumcision device with the same. The positioning device comprises a positioning cylinder, a flange and a supporting surface. The balanus is partially inserted in the positioning cylinder which is provided with at least one air channel. The distal end of the positioning cylinder radially rises out to form the flange. The supporting surface is form on a side, facing the close end of the positioning cylinder, of the flange. The to-be-cut prepuce crosses the flange to be supported by the supporting surface. According to the arrangement, the blood vessels in the prepuce are ligated to stop bleeding, the overlong prepuce is cut, and an actuating device, ensuring the circumcision device, smoothly moves relative to the positioning device.

Owner:WUHU SNNDA MEDICAL TREATMENT APPLIANCE TECH

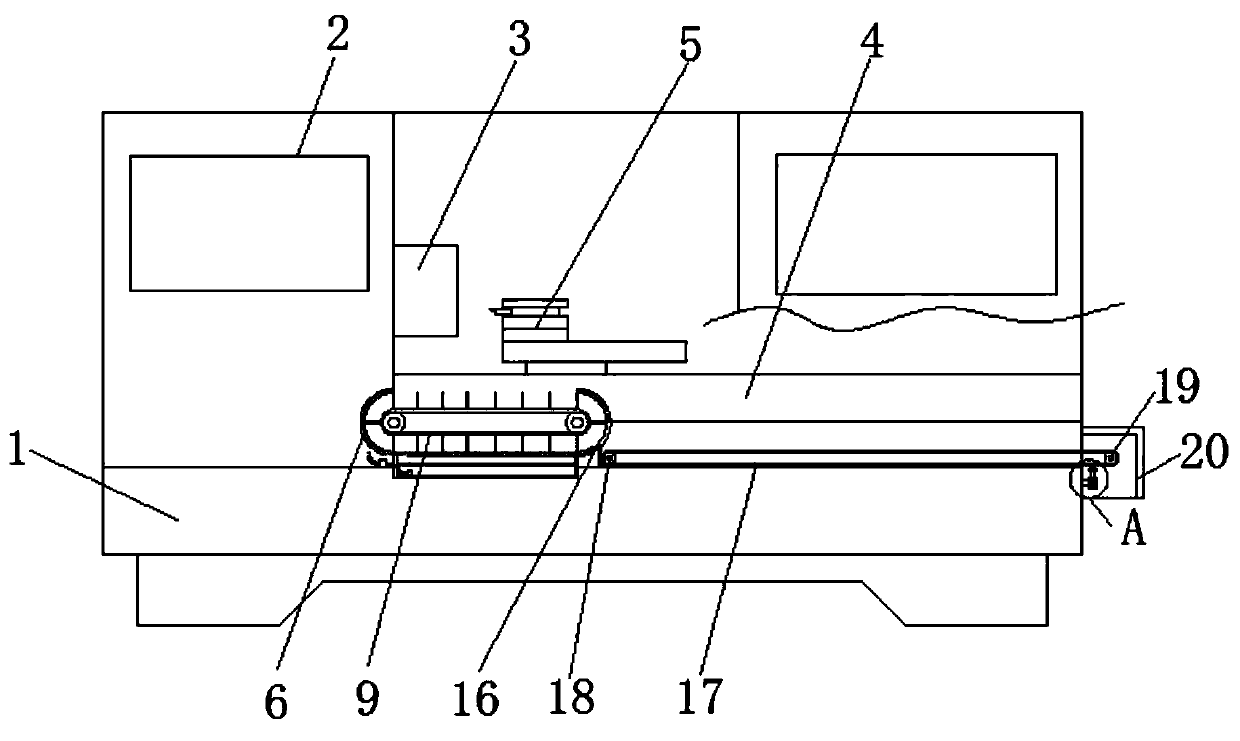

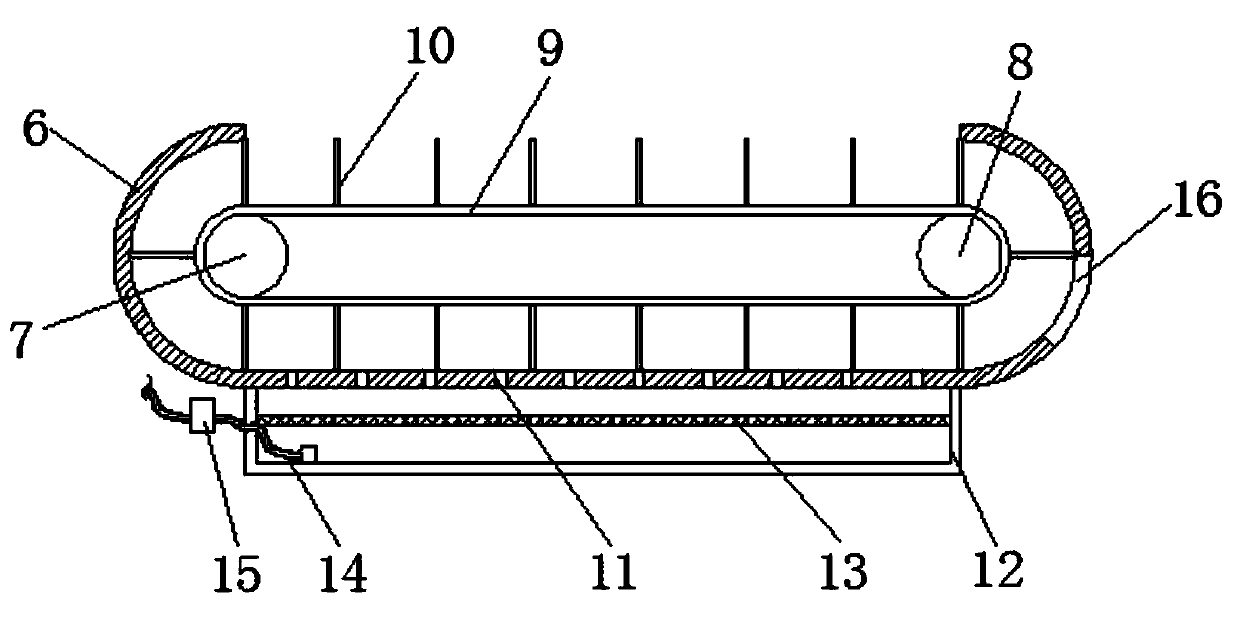

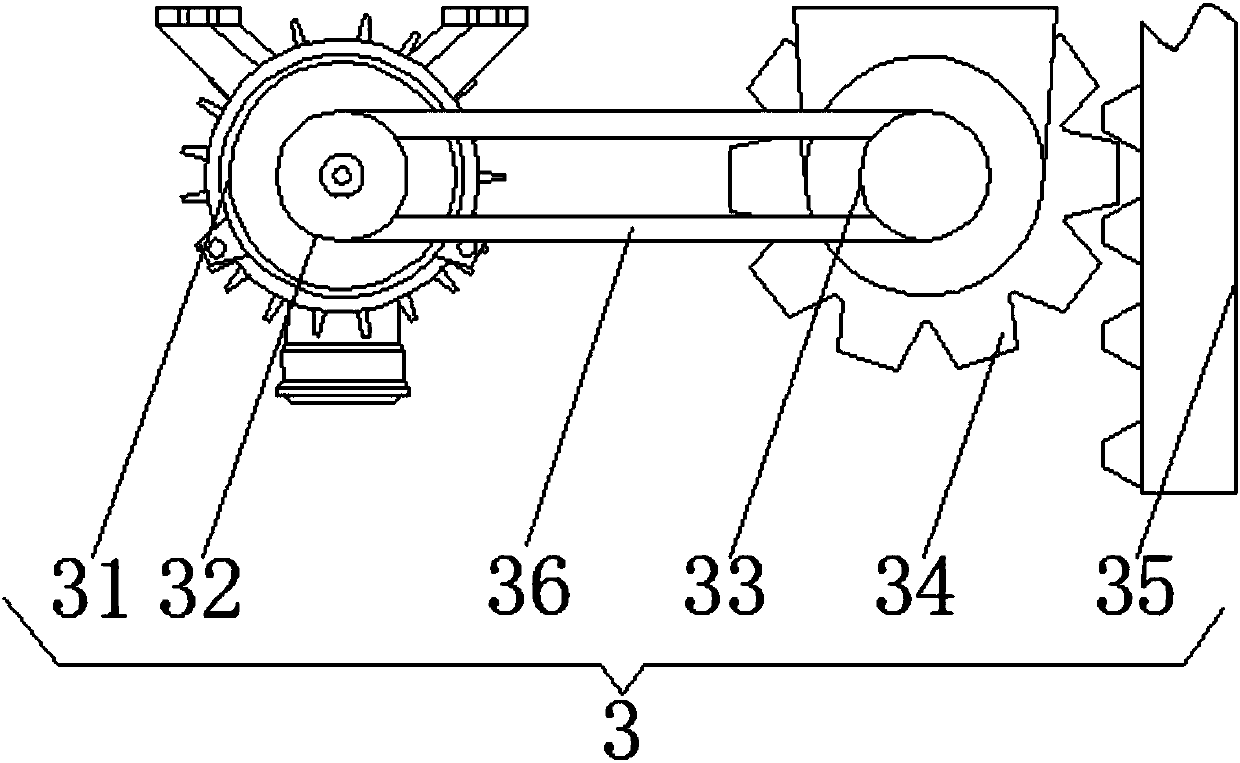

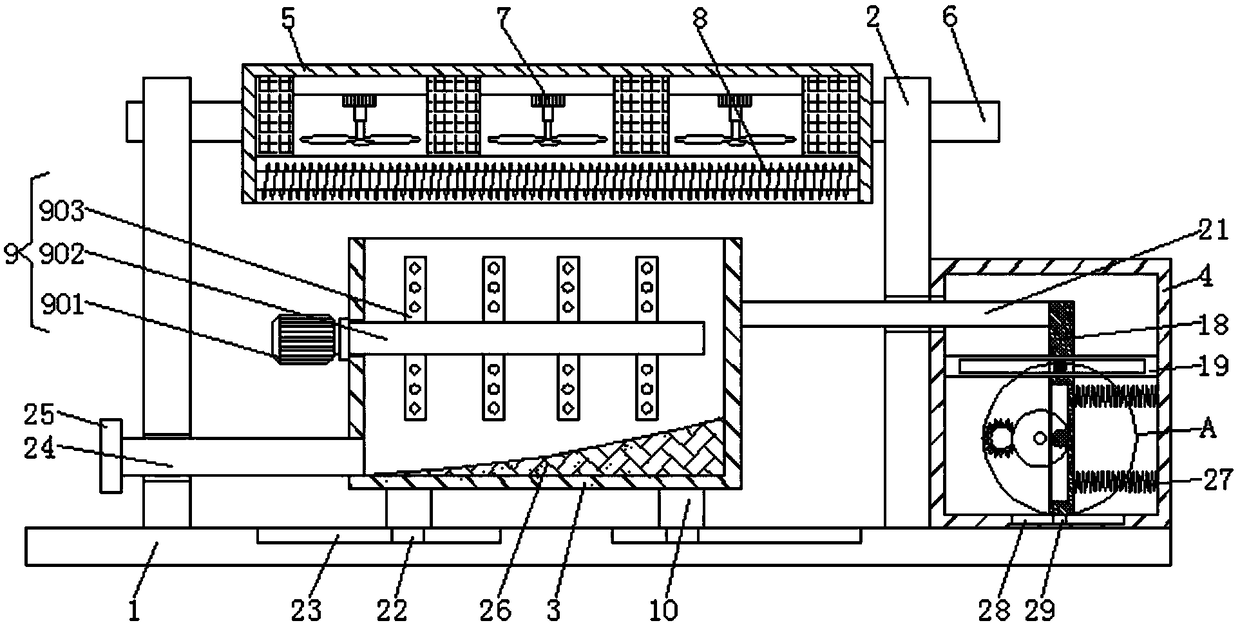

Conveyor belt principle-based scrap removal device for numerically controlled lathe

ActiveCN110977598AAvoid clutterAvoid pollutionMaintainance and safety accessoriesNumerical controlWorking environment

The invention belongs to the technical field of numerically-controlled machine tools and relates to a conveyor belt principle-based scrap removal device for a numerically controlled lathe. The conveyor belt principle-based scrap removal device for the numerically controlled lathe comprises a rack; the top of the rack is fixedly connected with a machining chamber; a clamp and movable guide rails are fixedly connected in the machining chamber; the tops of the movable guide rails are slidably connected with turning tool fixing seats; a waste scrap collecting box is fixedly connected between the movable guide rails; a first conveying wheel and a second conveying wheel are fixedly connected in the waste scrap collecting box; the exteriors of the first conveying wheel and the second conveying wheel are movably connected with a scrap removal belt; and the exterior of the scrap removal belt is fixedly connected with a scrapping plate. Through cooperative use of the waste scrap collecting box and a waste liquid collecting box, waste scraps and waste liquid can be collected; the waste scraps and the waste liquid are automatically separated, so that troubles in work are reduced; and the wastescrap collecting box collects the waste scraps, so that the scattered accumulation of the waste scraps is prevented, and therefore, the waste scraps are prevented from polluting the work environment,and the cleanliness of the work environment is guaranteed.

Owner:浙江欧鹰智能科技有限公司

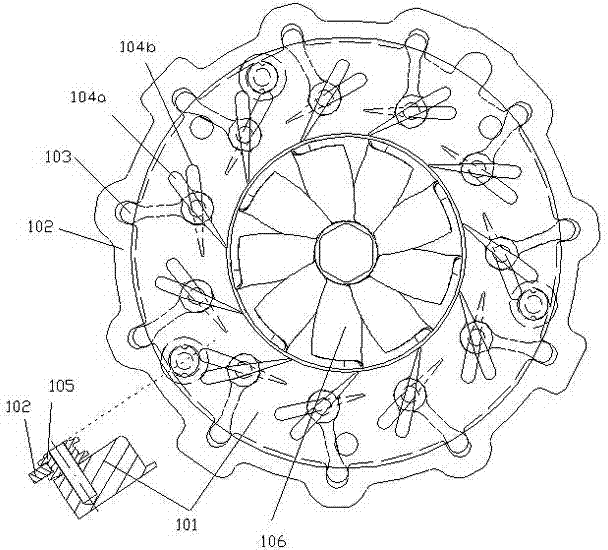

Sliding nozzle

InactiveCN103527264AAvoid precision lossHigh control precisionInternal combustion piston enginesStatorsThermal deformationEngineering

The invention discloses a sliding nozzle. A rotatable synchronous ring is arranged on an upper nozzle ring in a coaxial mode, and a synchronous ring inner circle connected with the upper nozzle ring in an assembling mode is of an interrupted structure in the radial direction. A first sliding block device comprises a flow guiding vane and an open shifting fork connected with the shaft end of the flow guiding vane. The shaft end of the flow guiding vane is provided with two parallel lateral planes. One end of the open shifting fork is connected with the two lateral planes in a matched mode. A second sliding block device comprises a main shifting fork assembly, one end of the main shifting fork assembly is connected with an actuator, and the other end of the main shifting fork assembly is connected with the synchronous ring through a synchronous pin. By means of the sliding nozzle, precision loss caused by fast abrasion of a line-plane friction pair in actual use is effectively avoided. Transmission precision and abrasion resistance are effectively improved. The inner circle is of an interrupted synchronous ring structure, matching area of the synchronous ring and the upper nozzle ring is reduced, and the phenomenon that the synchronous ring and the nozzle ring are clamped due to thermal deformation is effectively prevented.

Owner:汉美综合科技(常州)有限公司

Revolving steamy peeling machine

InactiveCN1759764ASmooth rotationPrevent "stuck" phenomenonVegetable peelingFood preparationPulp and paper industryCondensed water

A rotation-type steam peeling machine for potato, carrot, taro, etc is composed of machine frame, steaming cylinder with the hollow left axle and the right axle for supporting it on the machine frame, steam sprinkler at the internal end of hollow left axle, and condensed water separating plate in the steaming cylinder. Its advantages are high peeling productivity and no pollution.

Owner:何贤用

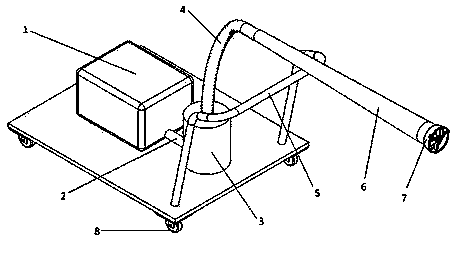

Air negative pressure differential tool bit leaf harvester

The invention discloses an air negative pressure differential tool bit leaf harvester. The harvester comprises a tubular nose, a collecting tank, a negative pressure machine, corrugated pipelines, a support pipe and a trolley. The leaf harvester adopts air negative pressure transmission driving and the differential rotation of multi-group cutting blades of the tubular nose is realized, thereby repeatedly cutting leaves to obtain small leaf fragments. The cut leaf fragments are collected and processed. The harvester can be used for harvesting leaves and tender branches and buds of broussonetia papyrifera in a large space range, also can be widely applied to pruning of jungles and shrubs in the field of landscaping, and integrates harvesting, pruning and collecting and processing, so that the labor intensity is greatly reduced, and the working efficiency is improved.

Owner:HUBEI UNIV OF TECH

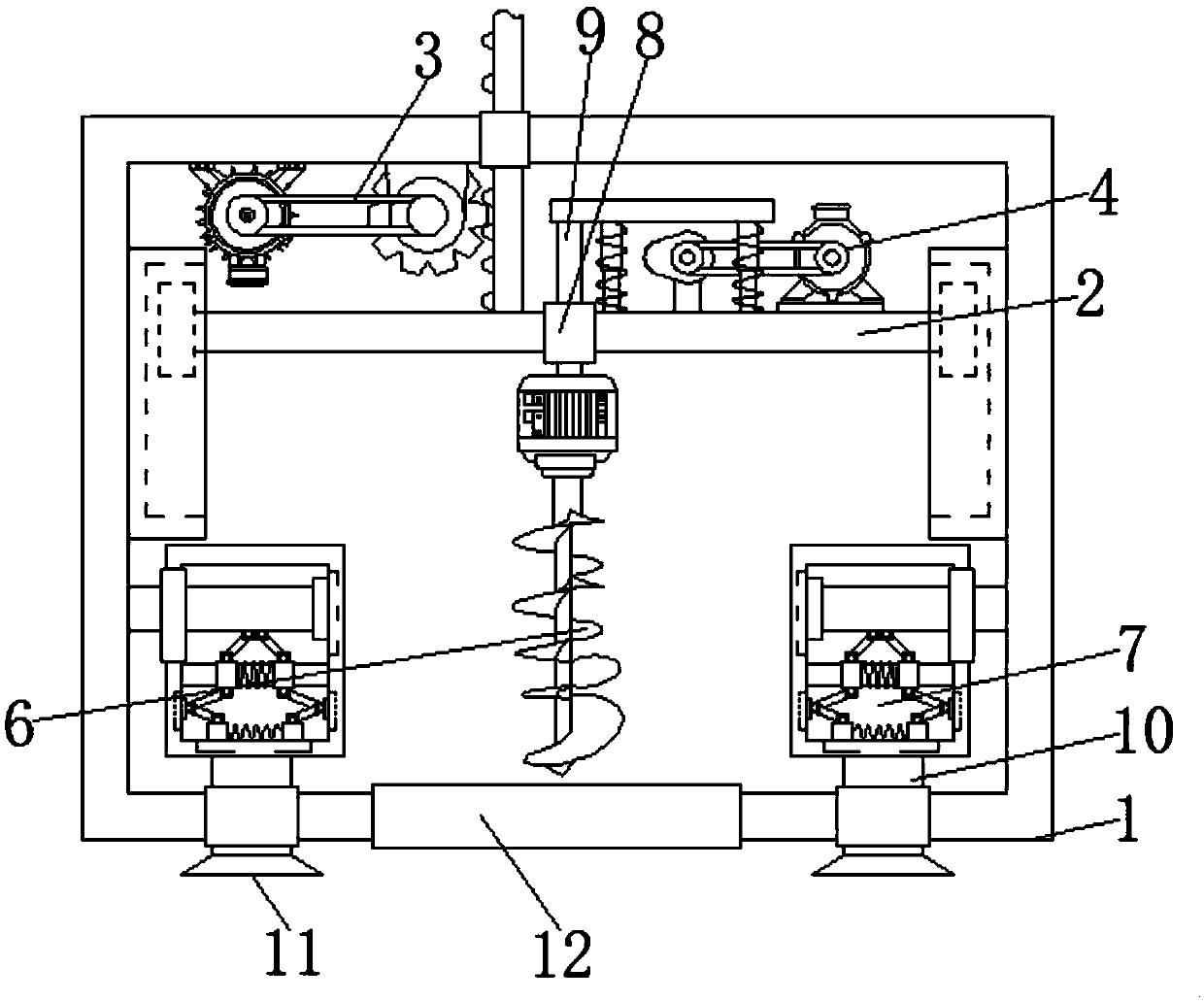

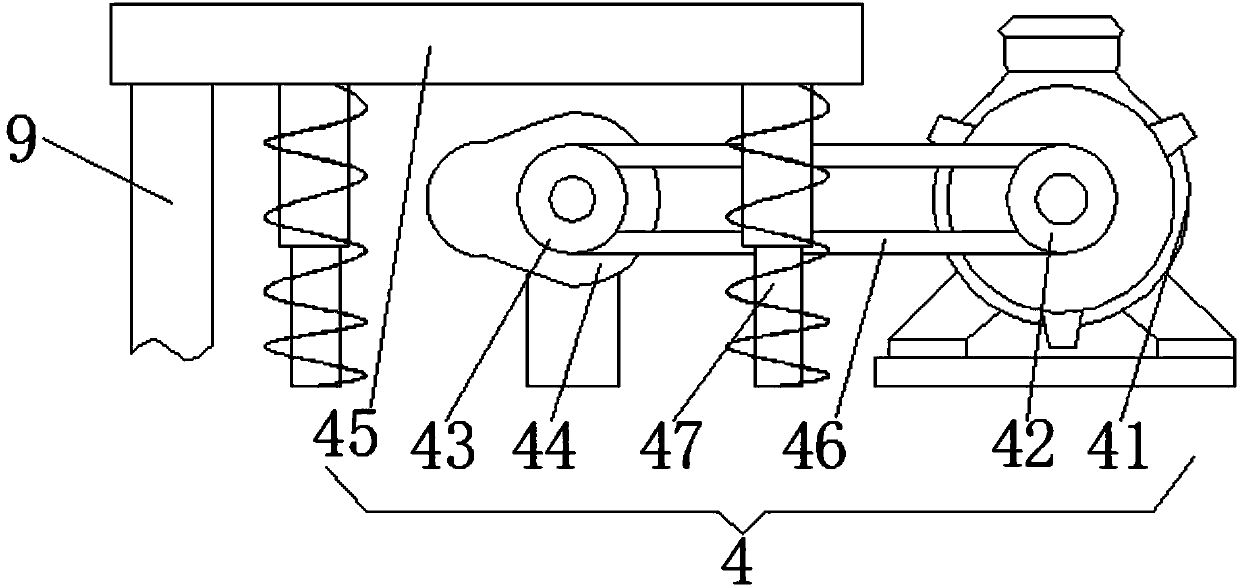

Building piling machine with damping function

InactiveCN107687319AWith shock absorption functionEasy to drillConstructionsDerricks/mastsShortest distanceDamping function

The invention discloses a construction piling machine with a shock absorbing function, which comprises a box body, a horizontal plate is slidingly connected between the two sides of the inner wall of the box, and a moving device is fixedly connected to the inner wall of the top of the box body on the left side above the horizontal plate. The right side of the top of the horizontal plate is fixedly connected with a moving device; both sides of the bottom of the inner wall of the box are fixedly connected with shock absorbing devices. The invention relates to the technical field of construction equipment. The moving device can drive the auger bit to move downward, which facilitates the auger bit to drill the ground; the moving device enables the auger bit to move up and down in a short distance without stopping, reducing the phenomenon of the machine being stuck; shock absorption The device prevents the device from shaking when it is moving and working, which improves the safety factor when the device is working and ensures the safety of workers.

Owner:GANZHOU YANSHUNFEI TECH CO LTD

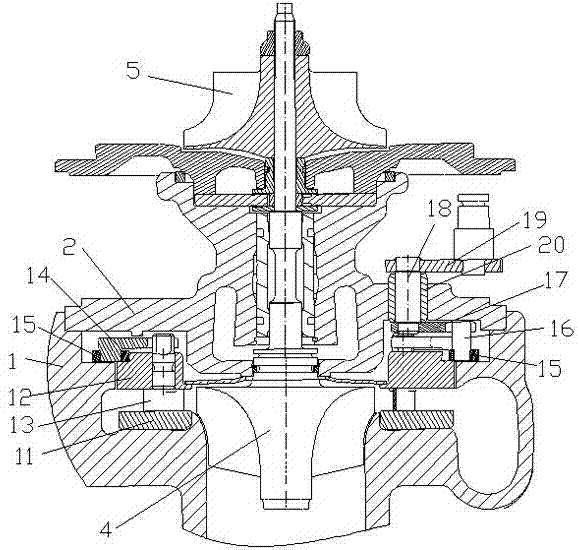

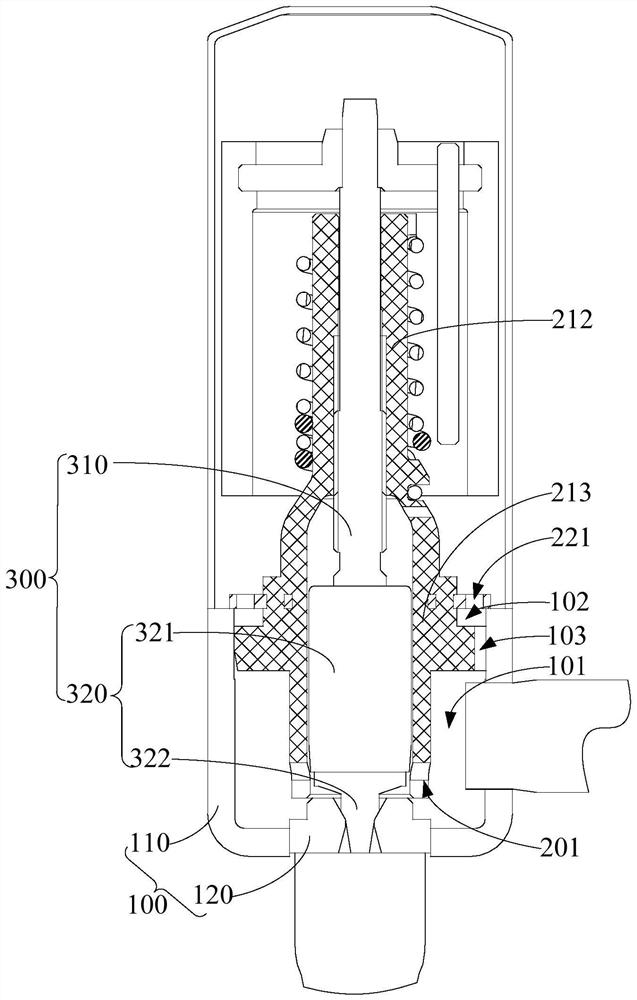

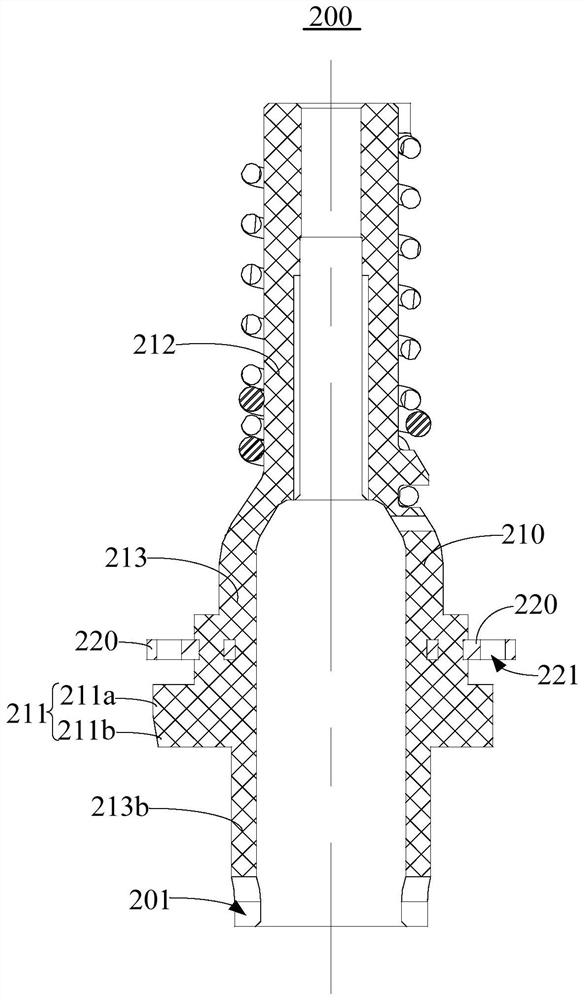

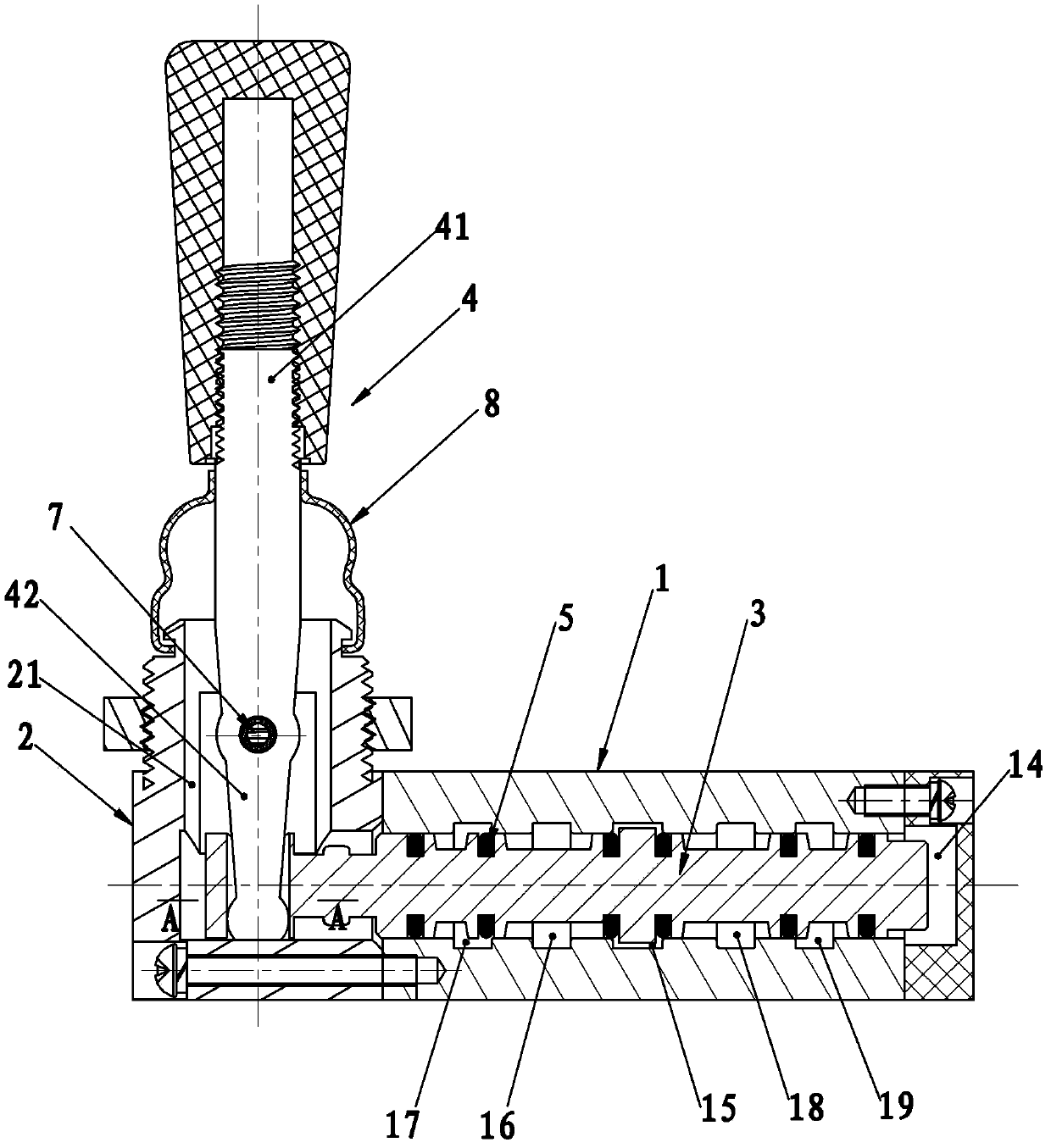

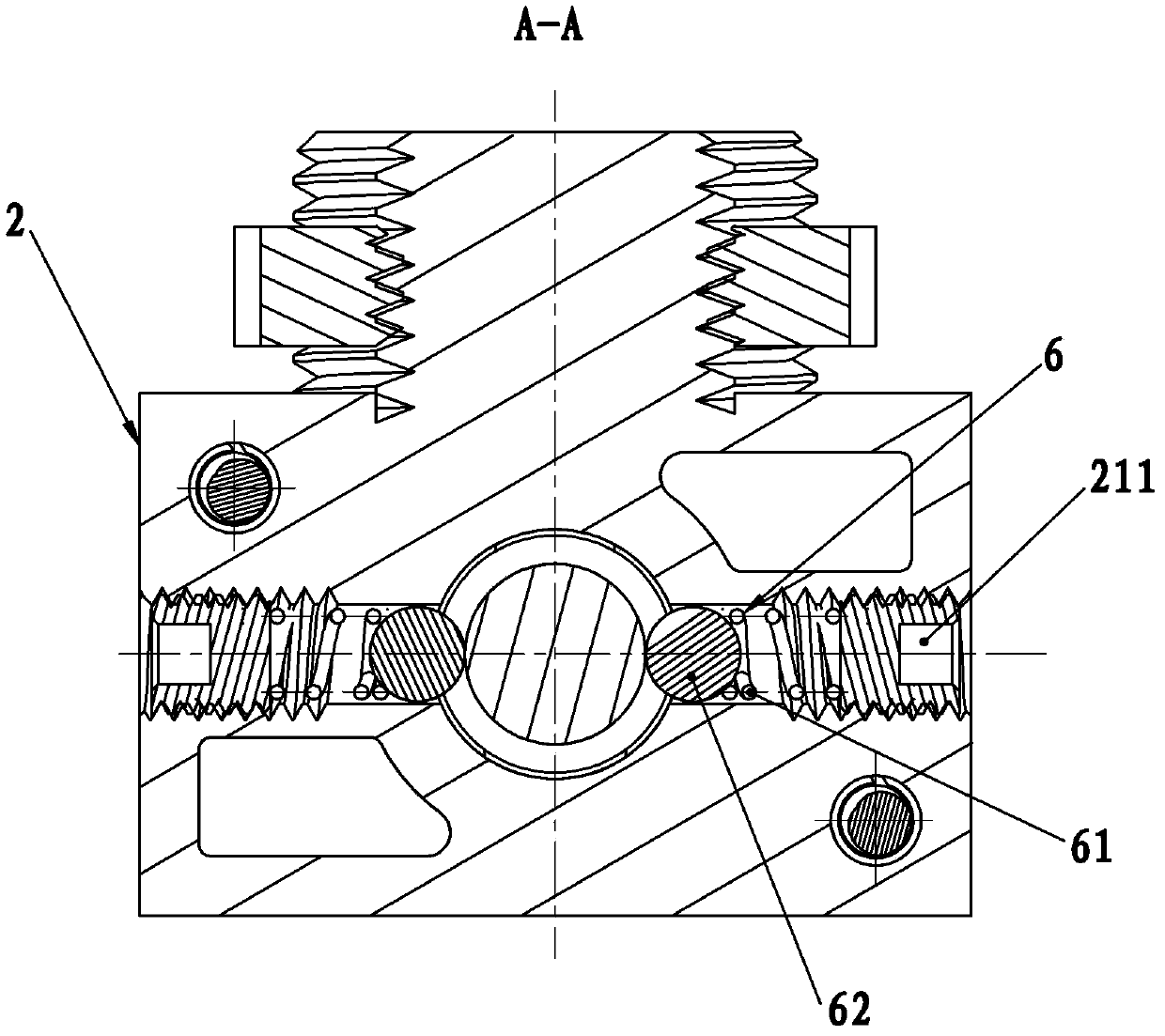

Electronic expansion valve and refrigeration equipment

PendingCN112524261APrevent stuck phenomenonImprove work performanceOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringElectronic expansion valve

The invention discloses an electronic expansion valve and refrigeration equipment. The electronic expansion valve comprises a valve seat, a nut and a connecting piece. The valve seat is provided witha valve cavity, one end of the nut is installed in the valve cavity, an annular positioning part is arranged on the outer wall of the nut in a protruding manner, and the positioning part is connectedwith the cavity wall of the valve seat in an abutting manner to achieve positioning. One end of the connecting piece is fixedly connected with the nut, and the other end of the connecting piece extends away from the nut and is fixedly connected with the axial end face of the valve seat. According to the technical scheme, the electronic expansion valve achieves the function of positioning the nut and the valve seat in the axial and radial directions, the coaxiality of the nut and the valve seat is guaranteed, then the coaxiality of the nut and the valve element seat is guaranteed, the phenomenon that the electronic expansion valve gets stuck is avoided, and the working performance of the electronic expansion valve is improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Real-time monitoring system for bottom surface of bridge

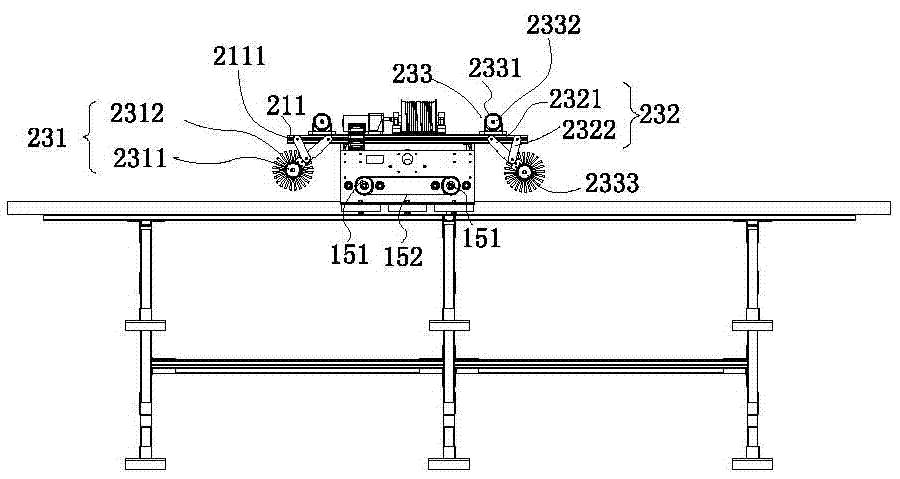

ActiveCN106906743AEnsure balanceAvoid leaningBridge structural detailsData informationMechanical engineering

The invention provides a real-time monitoring system for a bottom surface of a bridge. The real-time monitoring system comprises a rail mechanism which is arranged at the bottom surface of the bridge, and a detection mechanism which is arranged on the rail mechanism and is used for detecting the actual condition of the bottom surface of the bridge; a main rail is arranged on the bottom surface of the bridge and a secondary rail is arranged at the lower part of a bridge opening and the detection mechanism arranged on the main rail is used for bearing a secondary detection mechanism; the arranged main rail is higher than the vertical height of the secondary rail; the detection mechanism moves on the main rail and the secondary detection mechanism is laid on the secondary rail along the movement direction of the main rail, so that a monitoring test is carried out in all directions and a phenomenon that a detection period is long is avoided; and acquired data information is returned back to a central control room and is subjected to rapid comparison and analysis, so that the problems of the bottom of the bridge are rapidly compared.

Owner:CHANGAN UNIV

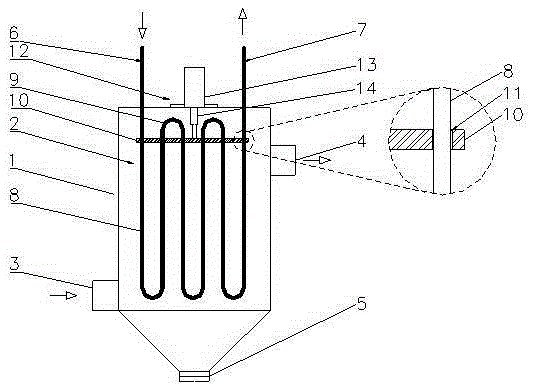

High-temperature flue gas dust removal and waste heat utilization system of metallurgical furnace

InactiveCN105318736ALower discharge temperatureHigh economic valueIncreasing energy efficiencyWaste heat treatmentHydraulic cylinderVertical tube

The invention relates to a high-temperature flue gas dust removal and waste heat utilization system of a metallurgical furnace. The system comprises a first-stage electric precipitator, a waste heat utilization device and a second-stage electric precipitator which are sequentially communicated, wherein the waste heat utilization device comprises a heat exchange tank and a heat exchange tube row; the heat exchange tube row is sleeved with a dedusting board; multiple through holes are formed in the dedusting board; vertical tubes of the heat exchange tube row penetrate through the through holes and are in sliding connection with the through holes of the dedusting board; a hydraulic cylinder is fixedly arranged on the top of the heat exchange tank; a cylinder barrel of the hydraulic cylinder is fixed to the top of the heat exchange tank; a piston rod of the hydraulic cylinder penetrates through the top of the heat exchange tank and is fixedly connected with the dedusting board inside the heat exchange tank. By means of the high-temperature flue gas dust removal and waste heat utilization system of the metallurgical furnace, the hydraulic cylinder drives the dedusting board to vertically move, smoke of the tube walls of the vertical tubes of the heat exchange tube tow is scraped, the higher heat exchange efficiency can be kept continuously, waste heat is sufficiently recycled, and the economic value of the waste heat system is improved.

Owner:马忠华

Automatic material box loading device

ActiveCN110155698AAutomate operationAchieve orderly operationConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to an automatic material box loading device and belongs to the technical field of material box transporting devices. The device comprises an enclosing plate formed by mounting four rectangular plates end to end. The internal area of the enclosing plate is partitioned into a feeding position, a guide position and a positioning position from right to left in sequence. The device further comprises a bottom plate mounted at the bottom of the enclosing plate, a check mechanism used for supporting a material box, a push rod mechanism used for pushing the material box from the feeding position to the positioning position, and a guide positioning mechanism used for guiding, positioning and discharging the material box. By arranging the push rod mechanism and the guide positioning mechanism, the material box is stably conveyed to the positioning position, meanwhile, the material box can be discharged after being positioned, the whole process of guiding, positioning and discharging can be completed through a power portion only, the requirement for the precision of the power portion is lower, the time for adjusting multiple power for mutual cooperation after mounting iscompleted is saved, power is simplified, and the equipment cost is lowered.

Owner:YANTAI ADEKANG BIOTECHNOLOGY CO LTD

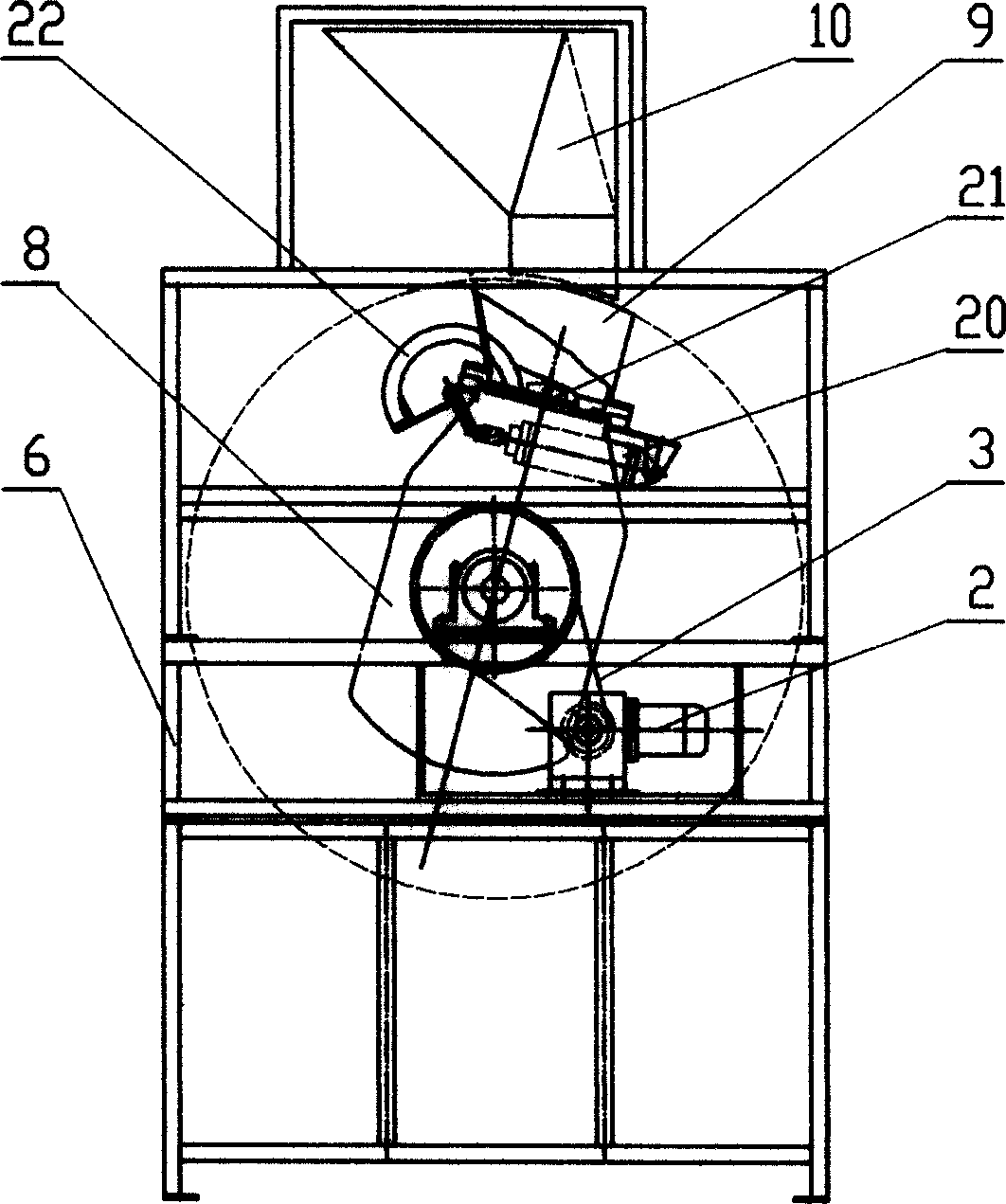

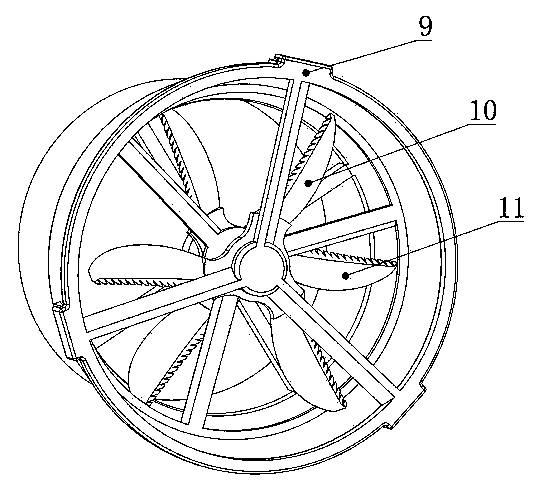

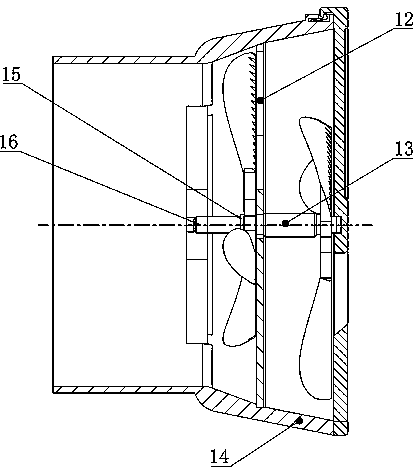

Forced feeding device

The invention discloses a forced feeding device. The forced feeding device comprises an impeller box, wherein an upper-layer impeller chamber, a lower-layer impeller chamber and a separation plate arranged between the upper-layer impeller chamber and the lower-layer impeller chamber are arranged in the impeller box; the upper-layer impeller chamber is internally provided with a material distribution impeller and the lower-layer impeller chamber comprises a feeding impeller chamber and a quantitative impeller chamber; a crossed part of the feeding impeller chamber and the quantitative impeller chamber is communicated; a feeding impeller is arranged in the feeding impeller chamber; a quantitative impeller is arranged in the quantitative impeller chamber; the rotating direction of the feeding impeller is opposite to the rotating direction of the material distribution impeller. According to the forced feeding device, the quantitative impeller chamber is arranged and surplus materials in the quantitative impeller chamber are added into the feeding impeller chamber again so that the materials flow smoothly in the forced feeding device; a material caking phenomenon is avoided so that the filling stability of the materials is ensured.

Owner:北京国药龙立科技有限公司

Automatic sorting device used for bolts

ActiveCN109353817ARealize automatic turnoverImprove work efficiencyConveyor partsEngineeringProcessing cost

The invention provides an automatic sorting device used for bolts. The automatic sorting device comprises a bottom plate, side plates, a first supporting block, a reinforcing plate, an air cylinder bracket, a rodless air cylinder, an air cylinder slide block, an air cylinder connecting plate, a first guide rail, a first guide rail slide block, a first pushing block, a second supporting block, a gasket, a transfer box, a limiting plate, a transfer box fixing plate, a bolt bin, a third supporting block, a feeding bearing plate, a bearing fixing plate, a guide rail gasket, a feeding lining, a second feeding hole, a third feeding hole, a second pushing block, a first feeding hole, a mini air cylinder fixing plate, a mini air cylinder, a second guide rail slide block, a second guide rail, a cover plate, a fourth supporting block, a baffle plate and the like, wherein the top end of the bottom plate is fixedly equipped with the first supporting block through the bolt. The device solves the problems of wasting time and labour, being low in efficiency, high in error rate, great in vibration noise and the like, also has an automatic sorting and feeding function, and has the characteristics of being simple in structure, convenient in use, free of vibrations during working, low in processing cost, and the like.

Owner:靖江市双鑫紧固件制造有限公司

Method for machining tiny grooves through ultrasonic grinding

ActiveCN104708502AImprove grinding efficiencyAvoid getting stuckGrinding work supportsGrinding/polishing safety devicesTransducerEngineering

The invention provides a method for machining tiny grooves through ultrasonic grinding. The method comprises the steps that firstly, grinding balls and a workpiece to be machined are all located in grinding fluid; secondly, after an ultrasonic generator emits out ultrasonic waves, a transducer converts the electric oscillation of the audio frequency of the input ultrasonic waves into mechanical vibration; thirdly, the ultrasonic vibration is transmitted to a vibrating bar to make the vibrating bar to vibrate up and down, vibration produced by the vibrating bar is transmitted to a vibrating plate, and the vibrating plate transmits vibration to the grinding balls on a locating plate so that vibration produced by the grinding balls can rapidly impact abrasive particles in the grinding fluid, and then the required grooves can be formed in the workpiece. By means of the method, the machining accuracy and the machining efficiency are both considered, the machining consistency is good, and the control mode of a machining device is simplified.

Owner:ZHEJIANG UNIV OF TECH

High-efficiency drying device for organic fertilizer production

InactiveCN109114919AEvenly heatedSolve the problem of incomplete dryingDrying gas arrangementsDrying machines with non-progressive movementsAgricultural engineeringOrganic fertilizer

The invention discloses a high-efficiency drying device for organic fertilizer production. The high-efficiency drying device for organic fertilizer production comprises a bottom plate, supporting columns are fixedly connected to the two sides of the top of the bottom plate, the top of the bottom plate is provided with a stirring box, the stirring box is positioned between the two supporting columns, and a transmission box is fixedly connected to the right side of the top of the bottom plate. According to the high-efficiency drying device for organic fertilizer production, the transmission box,a heater, a fan, a heating column, a first motor, a driving gear, a first transmission column, a driven gear, a second transmission column, a transmission disc, a first transmission pin, a first transmission frame, a second transmission frame, a second transmission pin and a third transmission column are used in a cooperated mode, and the drying effect is achieved through the fan and the heatingcolumn, the third transmission column is pushed to move left and right through the second transmission frame, so that the effect that the organic fertilizer is uniformly heated is achieved. Accordingto the high-efficiency drying device for organic fertilizer production, the problem that an existing drying device is not thorough in drying effect of the organic fertilizer is solved, the practicability of the drying device is enhanced, and the production efficiency of the organic fertilizer is improved.

Owner:湖州怡辉生态农业有限公司

Remotely-controlled controllable photographing collection device

InactiveCN107948469AImprove stabilityIncrease elasticityTelevision system detailsColor television detailsAcquisition apparatusStructural engineering

The invention relates to the technical field of electrics and electronics, particularly a remotely-controlled controllable photographing collection device. The remotely-controlled controllable photographing collection device comprises a mounting plate, wherein a mounting base is fixedly connected with the bottom of the mounting plate; a mounting rod is sleeved in the mounting base; the mounting rod is a hollow structure; a camera is fixedly connected with the bottom end of the mounting rod; a vertically-placed plate is fixedly connected with the bottom of the inner wall of the mounting rod; guide rails are fixedly connected with upper and lower ends of two sides of the vertically-placed plate; positioning blocks are in sliding connection in the guide rails; and one side of the positioningblocks is movably connected with the inner walls of the guide rails through return springs. According to the remotely-controlled controllable photographing collection device, through improvement of clamping rods, under the effect of the resilience force of the return springs and reset springs, one end of the clamping rods stretches out from the mounting base, so a camera can be mounted conveniently.

Owner:郑州庭淼软件科技有限公司

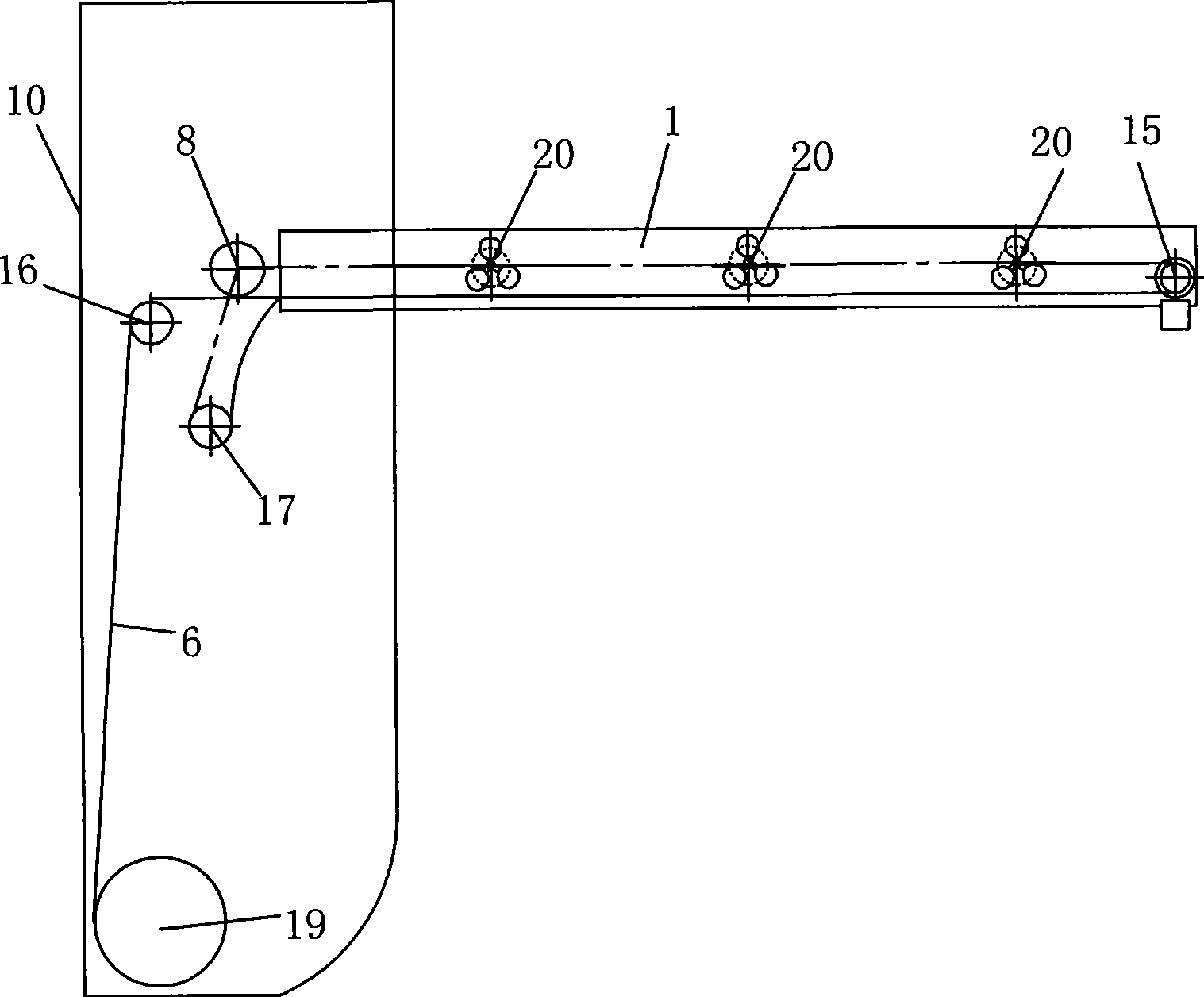

Automatic mosquito net

The invention relates to an automatic mosquito net, which comprises a pair of opposite telescopic arms, and the telescopic arms are arranged in a box body through a movable bracket. The front ends of the pair of the telescopic arms are provided with end head guide wheels, while the back ends of the telescopic arms are provided with feeding guide wheels driven by motors, wherein the lower side of the feeding guide wheel is provided with a return guide wheel and a mosquito net reeling drum; and the lower side of the return guide wheel is provided with a main motor which is connected with the mosquito net on the mosquito net reeling drum through a line through the return guide wheel, the end head guide wheel and the feeding guide wheel. When the automatic mosquito net is used, the telescopic arms unfold for 90 degrees towards both sides respectively through the movable bracket, and then spread forward so as to form a mosquito net bracket. After the main motor is started, the mosquito net on the mosquito net reeling drum is drawn out through the line through the return guide wheel, the end head guide wheel and the feeding guide wheel, and the drawing can be controlled through a limit switch. The automatic mosquito net has the advantages of convenient arrangement and use and is beautiful.

Owner:张奇

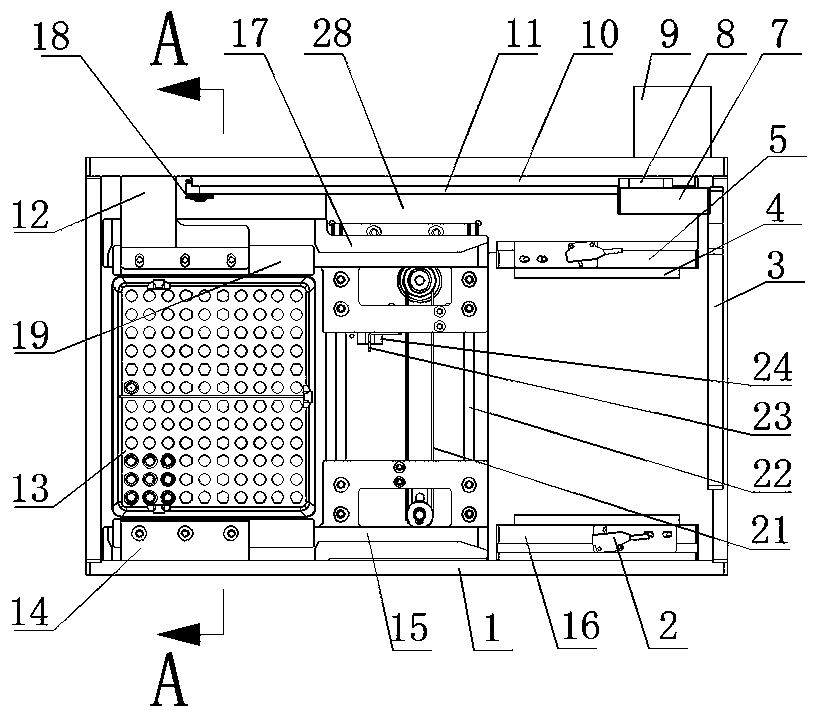

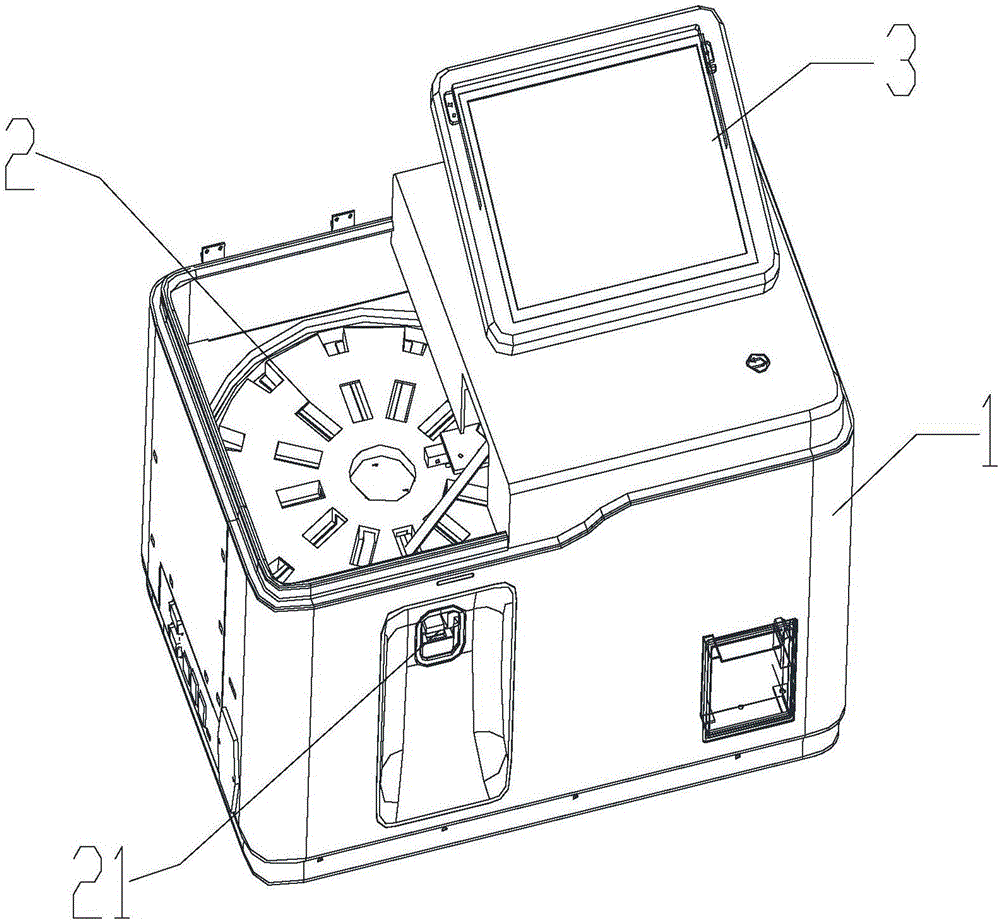

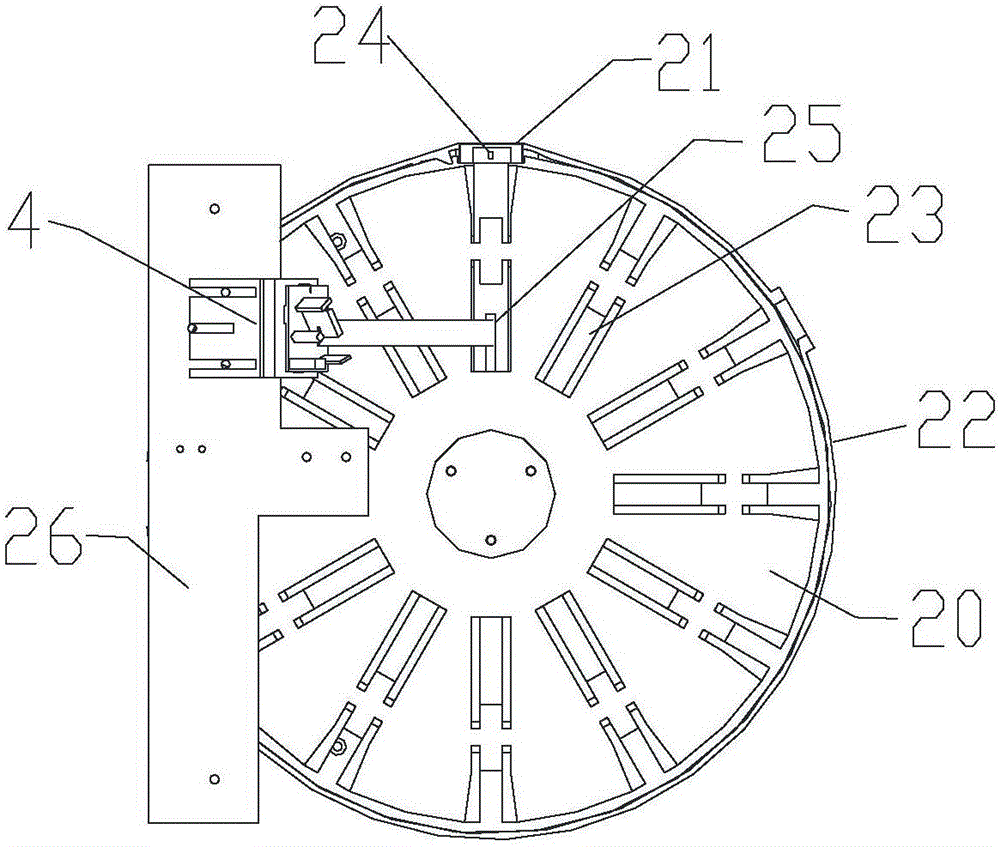

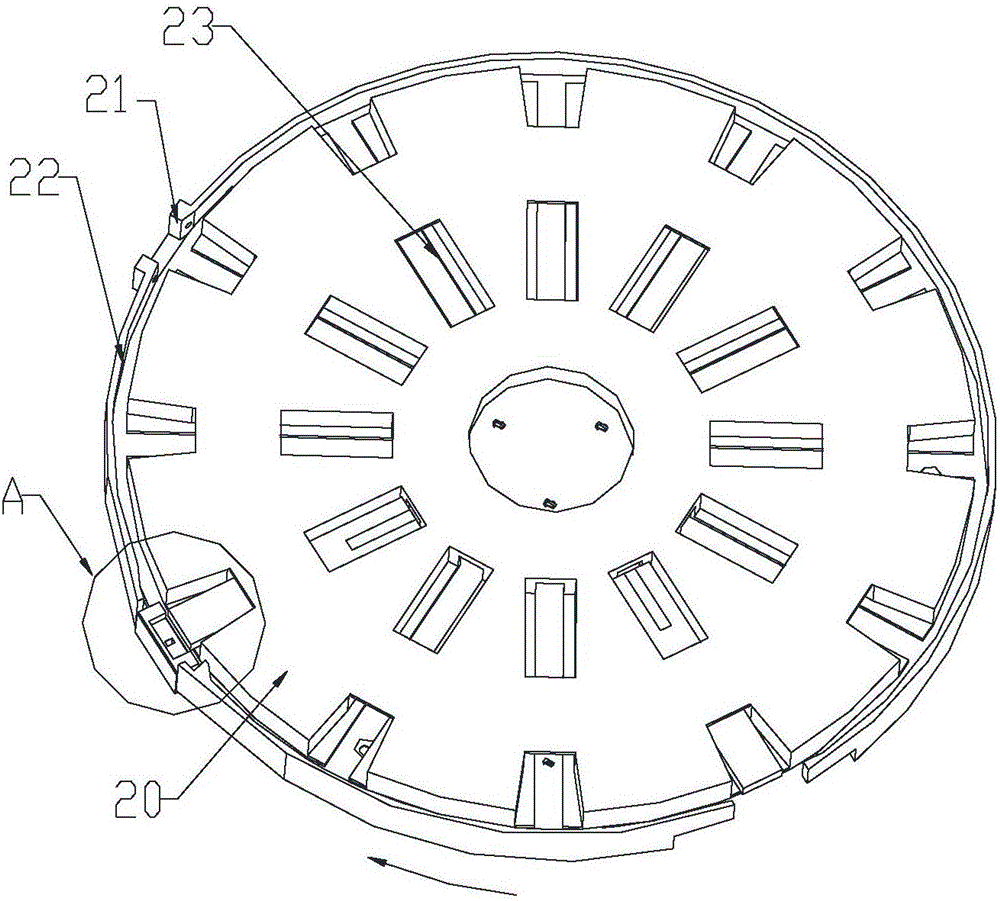

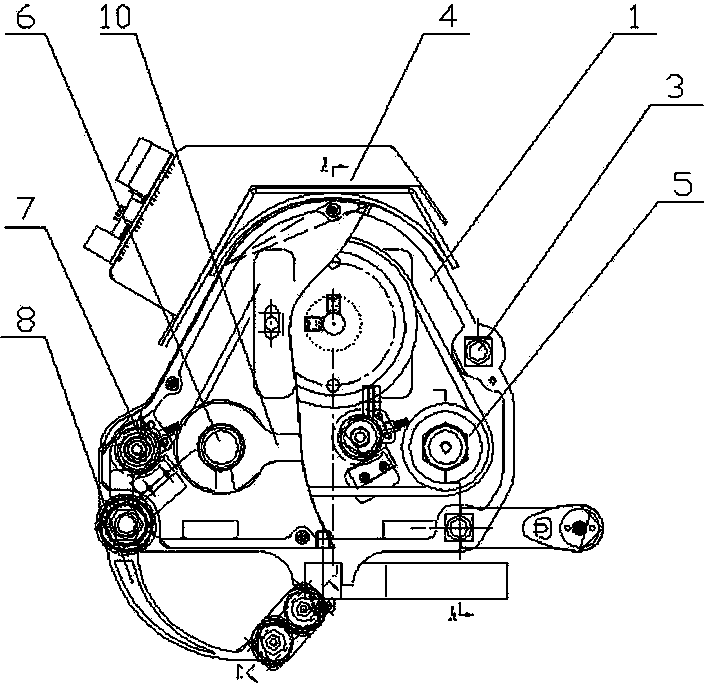

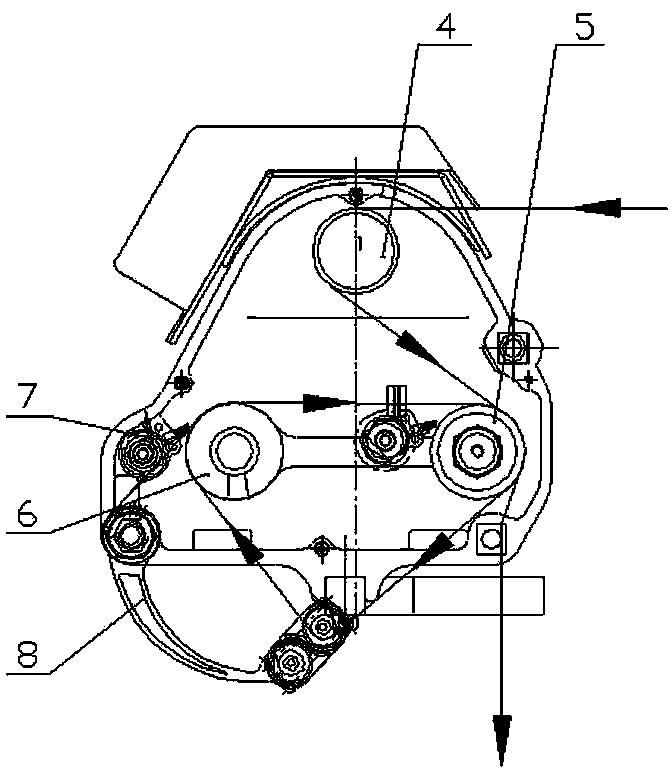

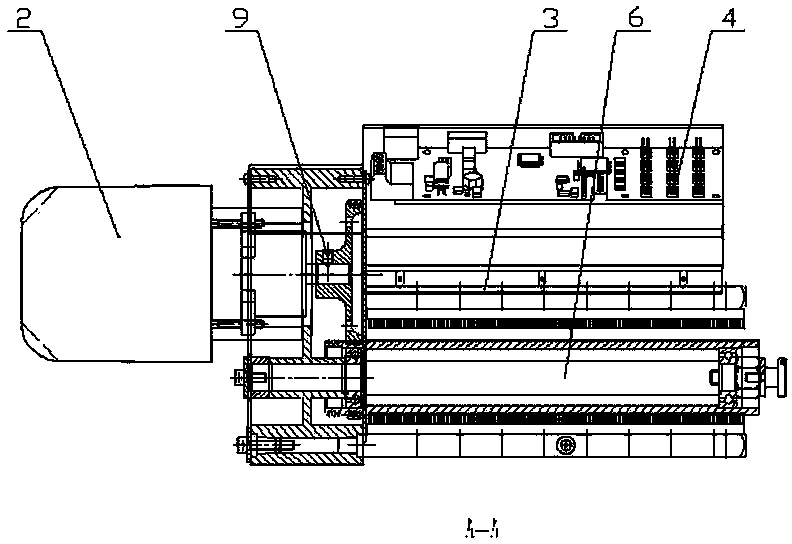

Semi-automatic dry type fluorescence immunoassay analyzer

ActiveCN106596914AGuaranteed successAvoid stuck phenomenonBiological testingSemi automaticFluorescence immunoassay analyzer

The invention discloses a semi-automatic dry type fluorescence immunoassay analyzer. The semi-automatic dry type fluorescence immunoassay analyzer comprises a card inlet mechanism, a card outlet mechanism, a system shell, code scanning devices, a measurement mechanism and a control board; the code scanning devices comprise the first code scanning device and the second code scanning device, and the card inlet mechanism, the card outlet mechanism and the measurement mechanism are installed on the system shell; the card inlet mechanism is provided with a first photoelectric sensor and a second photoelectric sensor; the card inlet mechanism is further provided with a card inlet and a card outlet, the first photoelectric sensor is arranged at the card inlet, and the second photoelectric sensor is arranged at the card outlet; the first code scanning device, the second code scanning device, the first photoelectric sensor, the second photoelectric sensor, the card outlet mechanism and the measurement mechanism are electrically connected with the control board. The semi-automatic dry type fluorescence immunoassay analyzer can solve the problems that reagent cards are blocked when entering and conveying are carried out and incompatible when read, and measurement is inaccurate and exceeds time.

Owner:GUANGZHOU KEFEN BIOTECH CO LTD

Computerized flat knitting machine yarn feeder and yarn detection control system thereof

The invention discloses a computerized flat knitting machine yarn feeder and a yarn detection control system of the computerized flat knitting machine yarn feeder. The computerized flat knitting machine yarn feeder comprises a box, a driving motor, a yarn guide rod, an encoder, a first yarn feeding roller, a second yarn feeding roller, paraffin removal devices and an adjusting device, wherein the driving motor is installed outside the box. The driving motor drives the first yarn feeding roller and the second yarn feeding roller to rotate through a yarn feeding belt wheel, the first yarn feeding roller and the second yarn feeding roller are connected in parallel through a connecting plate, the side face of the first yarn feeding roller and the side face of the second yarn feeding roller are provided with the paraffin removal devices respectively, the paraffin removal devices are composed of anti-caking rods and brushes, the brushes fixedly adhere to the corresponding anti-caking rods, and the adjusting device forms a swing arm type adjusting structure through a rotatable fixing supporting point, ceramic wheel carriers and two movable ceramic wheel sets installed on fixing blocks. The computerized flat knitting machine yarn feeder is provided with the encoder, the speed and the length of yarn can be measured, stitches can be adjusted, yarn feeding is uniform and stable, the paraffin removal devices and the adjusting device are arranged, paraffin on the surfaces of the yarn feeding rollers is removed in time, service life is prolonged, and knitting efficiency and knitting quality are effectively improved.

Owner:QUANZHOU JINGZHUN MACHINERY

Fast insertion type manual valve for vehicle

InactiveCN103470808AGuaranteed stabilityPrevent stuck phenomenonSpindle sealingsOperating means/releasing devices for valvesEngineeringPiston

The invention relates to a valve, in particular to a fast insertion type manual valve for a vehicle. The fast insertion type manual valve adopts the following technical scheme that the fast insertion type manual valve for the vehicle comprises a valve body, a valve cover, an air inlet, a silencer installing opening and a plurality of air outlets, wherein the air inlet is formed in the valve body, a valve cavity is arranged in the valve body, a manual pull rod capable of driving a valve core is arranged in the valve cavity, the inner wall of the valve cavity are arranged plurality of flow division cavities, the plurality of flow division cavities are respectively communicated with the air inlet and the silencer installing opening, the valve core is a piston, the piston is in coaxial arrangement with the valve cavity of the valve body, sealing bodies capable of sealing and plugging the air inlet, the silencer installing opening or the air outlets are arranged on the outer wall of the piston at intervals, the manual pulling rod is arranged vertically to the axis of the valve cavity, and extends into the valve cavity through the valve cover, in addition, one end, extending into the valve cavity, of the manual valve rod is hinged to the piston, and a balance regulating mechanism is arranged between the valve cover and the manual pulling rod. The technical scheme is adopted, and the invention provides the fast insertion type manual valve for the vehicle with the advantages that the structure is simple, the operation is convenient, and the size is small.

Owner:ANHUI ZHONGGONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com