Automatic sorting device used for bolts

An automatic sorting and screw technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that affect the physical and mental health of employees in the working environment, difficulty in meeting production needs, and high vibration and noise, to achieve effective sorting and sorting, structure Simple, vibration- and noise-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

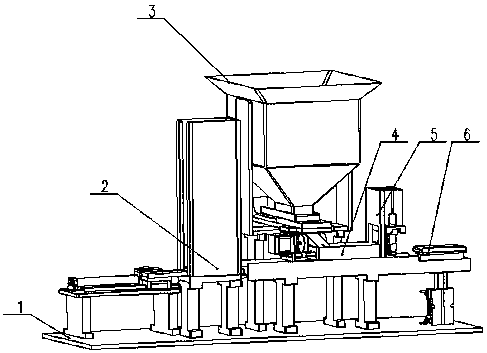

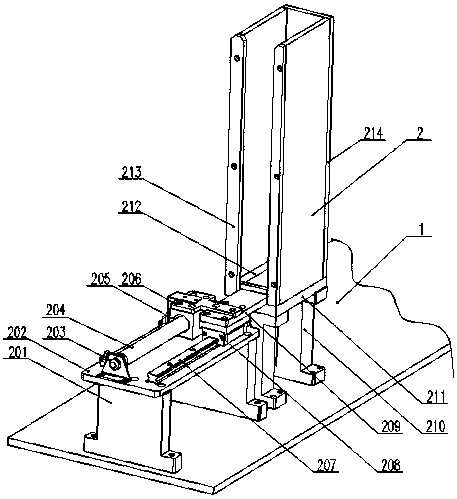

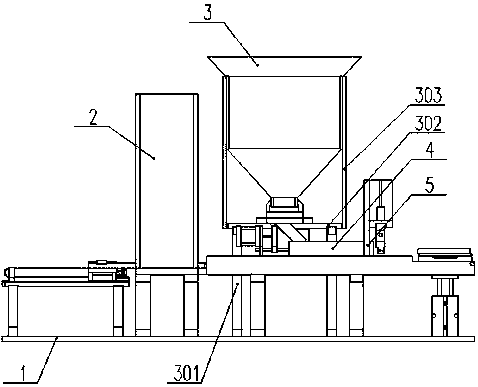

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 as well as Figure 18 As shown, an automatic sorting device for screws, including a bottom plate 1, a side plate 2, a first support block 201, a reinforcement plate 202, a cylinder bracket 203, a rodless cylinder 204, a cylinder slider 205, and a cylinder connecting plate 206 , the first guide rail 207, the first guide rail slider 208, the first push block 209, the second support block 210, the backing plate 211, the turnover box 212, the limit plate 213, the turnover box fixing plate 214, the screw bin 3, the third Support block 301, feeding bearing plate 302, loading fixing plate 303, guide rail backing plate 304, feeding liner 305, second feeding hole 306, third feeding hole 307, second push block 308, first feeding hole 309, mini cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com