A conveying device with a turnover function and its working method

A conveying device and functional technology, which is applied in the field of conveying devices with the function of turning board, can solve the problems of inconvenient speed adjustment, manual turning of PCB boards, etc., and achieve the effect of wasting manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

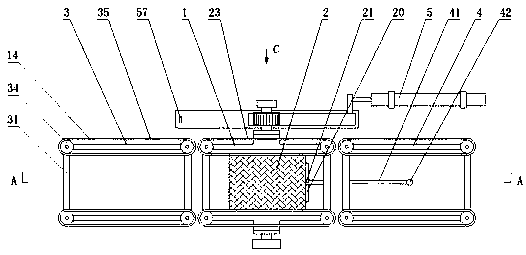

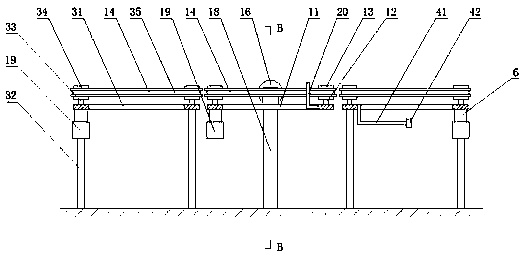

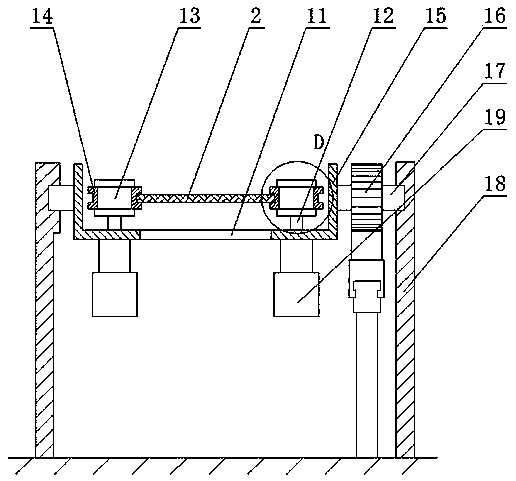

[0034] The embodiment of the present invention provides a conveying device with a turning plate function and its working method. By opening a groove 22 on the outer surface of the belt 14, the two sides of the PCB board can be placed in the groove 22 to follow the operation of the belt 14. And the transmission, so that the PCB board will not fall from the belt when it is turned over. By setting the panel turnover mechanism 1, automatic panel turnover can be realized, thereby solving the technical problems of wasting manpower and reducing efficiency caused by manual panel turnover. Through the following design of the turnover mechanism 1, the structure of the turnover machine can be simple and compact, and the turnover function can be effectively realized, reducing the cost of the turnover mechanism. By setting the transmission 6, it is convenient for the production line operators to adjust the speed of the conveying device, thereby solving the technical problem that the curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com