Automatic discharging system

A technology of automatic discharging and discharging bin, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high cost, workpiece stuck, complex shape, etc., to achieve low cost, prevent stuck, simple structure and control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

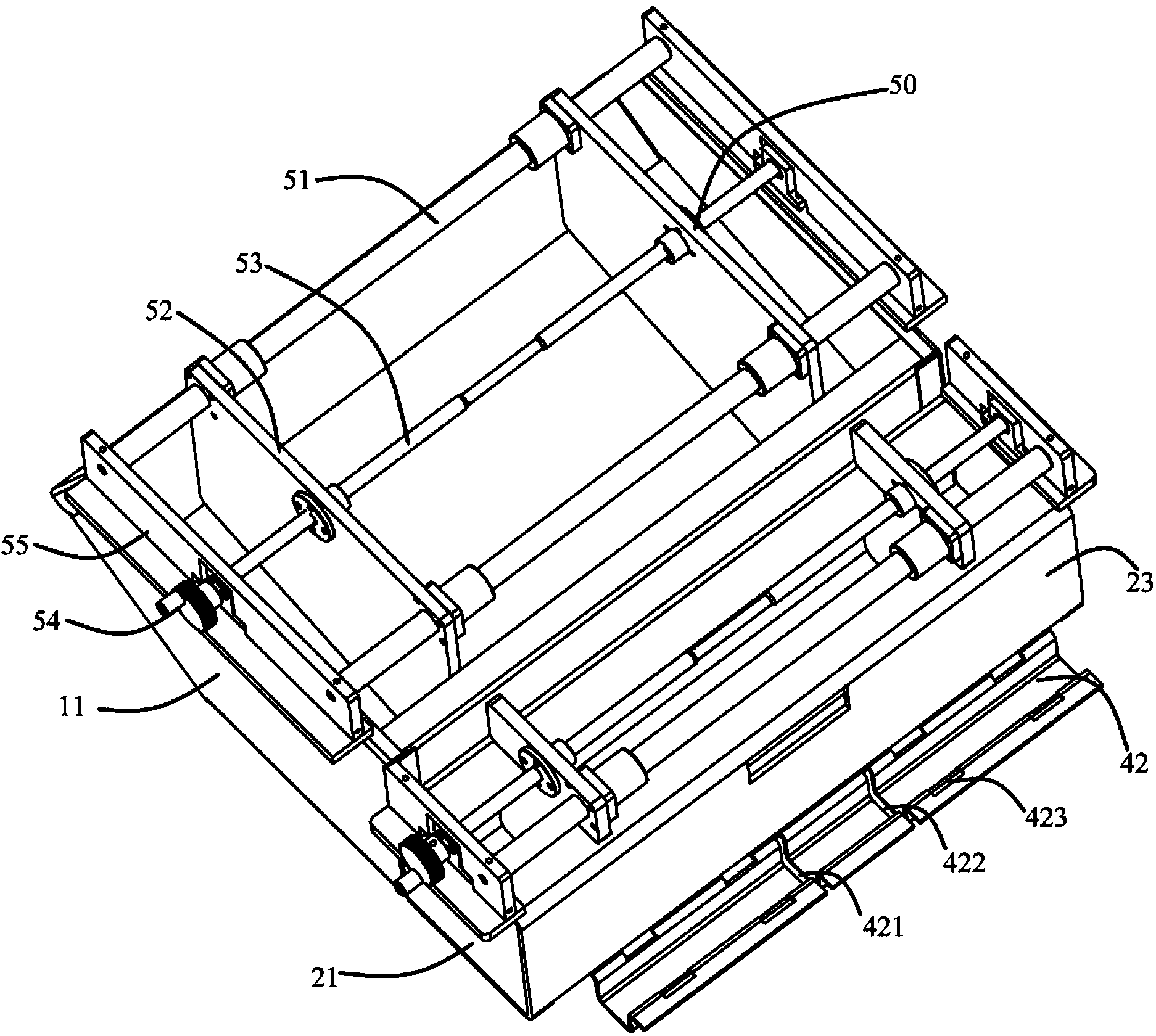

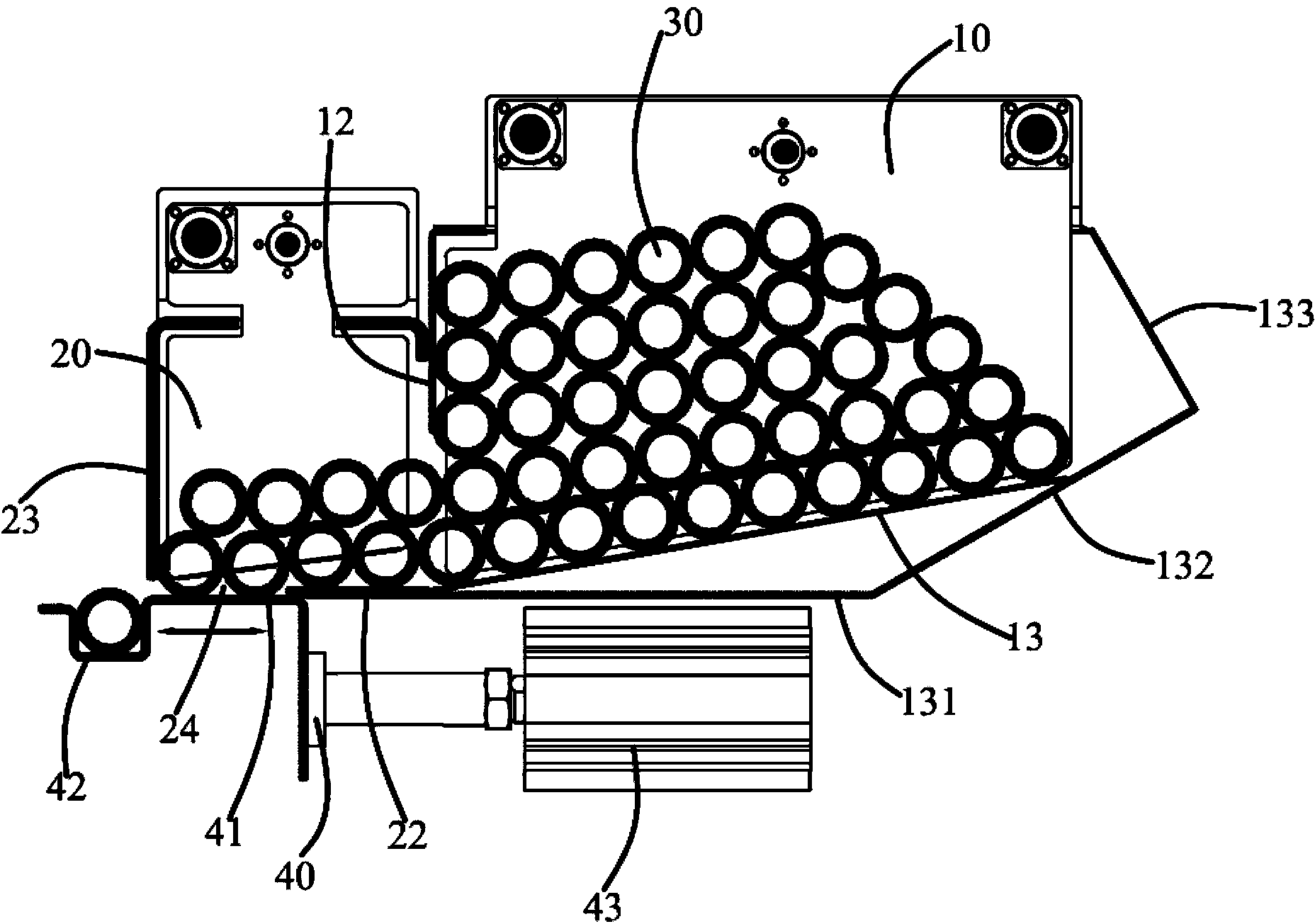

[0025] The invention discloses an automatic discharge system, which comprises a storage bin and a discharge bin which are used to place cylindrical workpieces and are connected to each other. The vertical distance between the storage bin and the discharge bin is greater than the diameter of a workpiece. The bottom surface of the storage bin is provided with a discharge port, the width of the discharge port is greater than the diameter of a workpiece, and a feeding device is provided below the discharge port, and the feeding device includes a stopper, a workpiece storage groove connected to the stopper, and a stopper connected to the stopper. The driving device connected to the stopper is used to drive the feeding device to move forward and backward.

[0026] The automatic discharge system set up above realizes the automatic discharge of cylindrical workpieces without the participation of robots.

[0027] In order to enable those skilled in the art to better understand the tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com