Ripper die scrap material ejecting and sliding mechanism

A lifting mechanism and sliding material technology, applied in the field of stamping die parts, can solve the problems of unsmooth discharge of waste, sliding of waste into the die, collision between cutting edges and cutting edges, etc., to achieve the effect of stable route and smooth discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

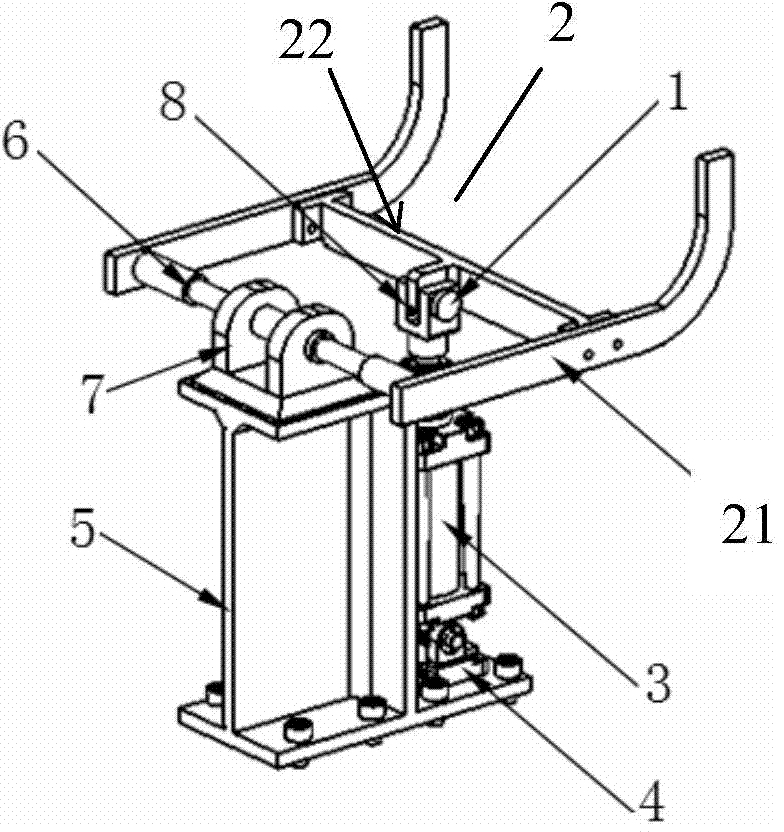

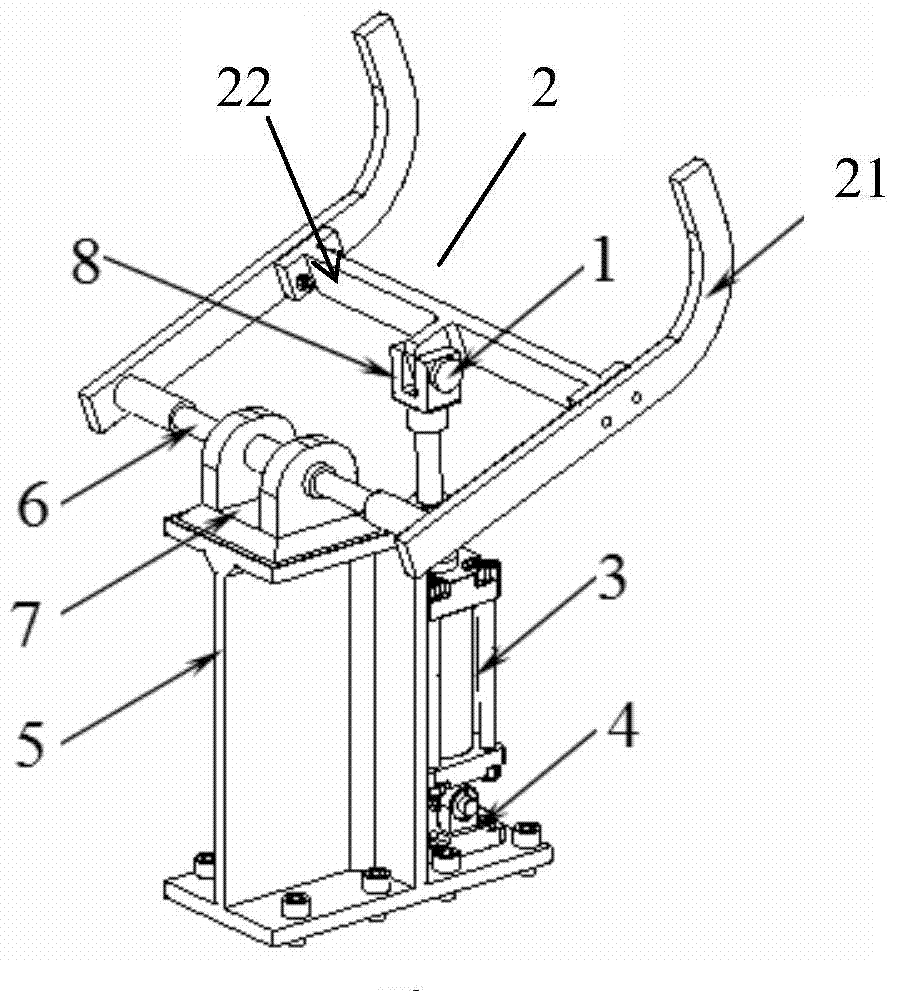

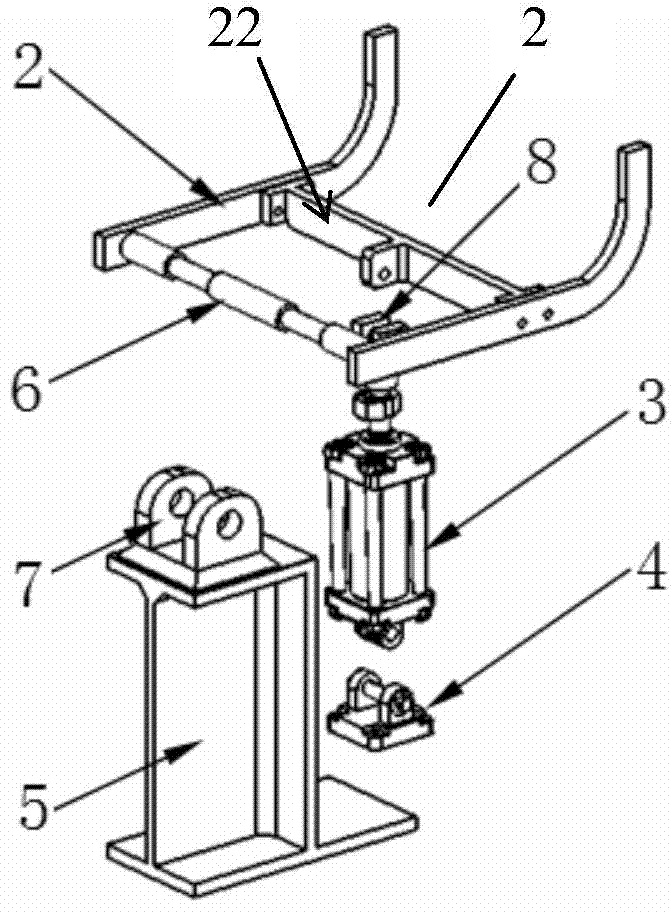

[0022] In order to solve the above technical problems, the present invention provides a scrap ejector sliding mechanism for punching dies, which includes a fixed frame 5, a ejector slider frame 2 and a jacking mechanism.

[0023] The jacking slide frame 2 is installed on the top of the fixed frame 5 in a pivoted manner, and the jacking mechanism is arranged on one side of the fixed frame 5, and the jacking mechanism can jack up and drop the top material slide frame 2 so that the top material slide frame 2 Pivot at the top of the fixed frame 5. It can realize the automatic discharge of waste materials, and the waste materials will not be jammed and discharged smoothly, and the route is stable.

[0024] The specific structure is as Figure 1 to Figure 3 As shown, the jacking mechanism is the driving cylinder 3, which is easy to purchase, low in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com