Sweeper for dredging underground pipeline

A technology for underground pipelines and cleaners, which is applied in the field of cleaners for dredging underground pipelines. It can solve problems such as difficulty in dredging pipelines, limitation of pipe length, and impact on cable laying quality, and achieves the effect of overcoming resistance and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

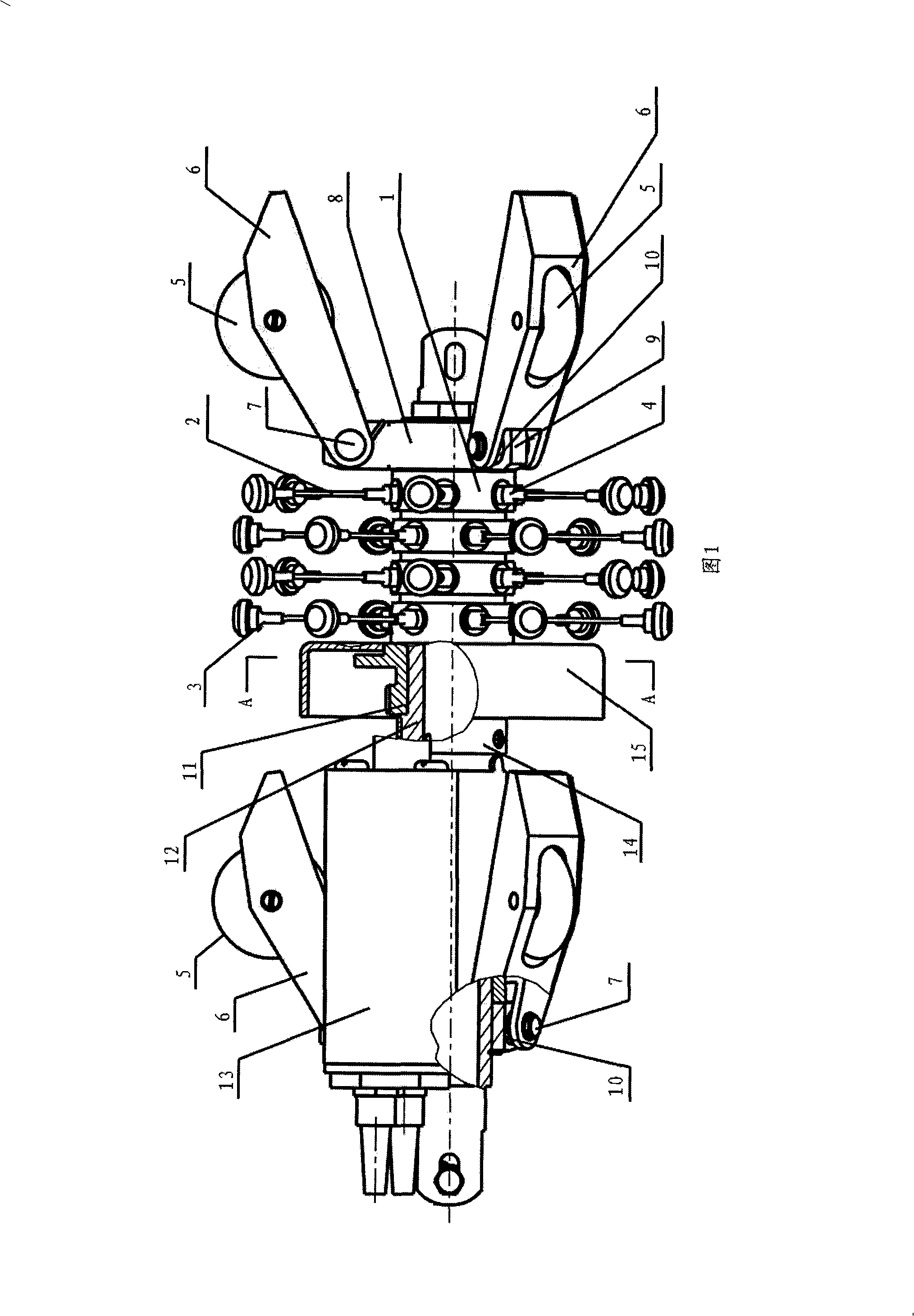

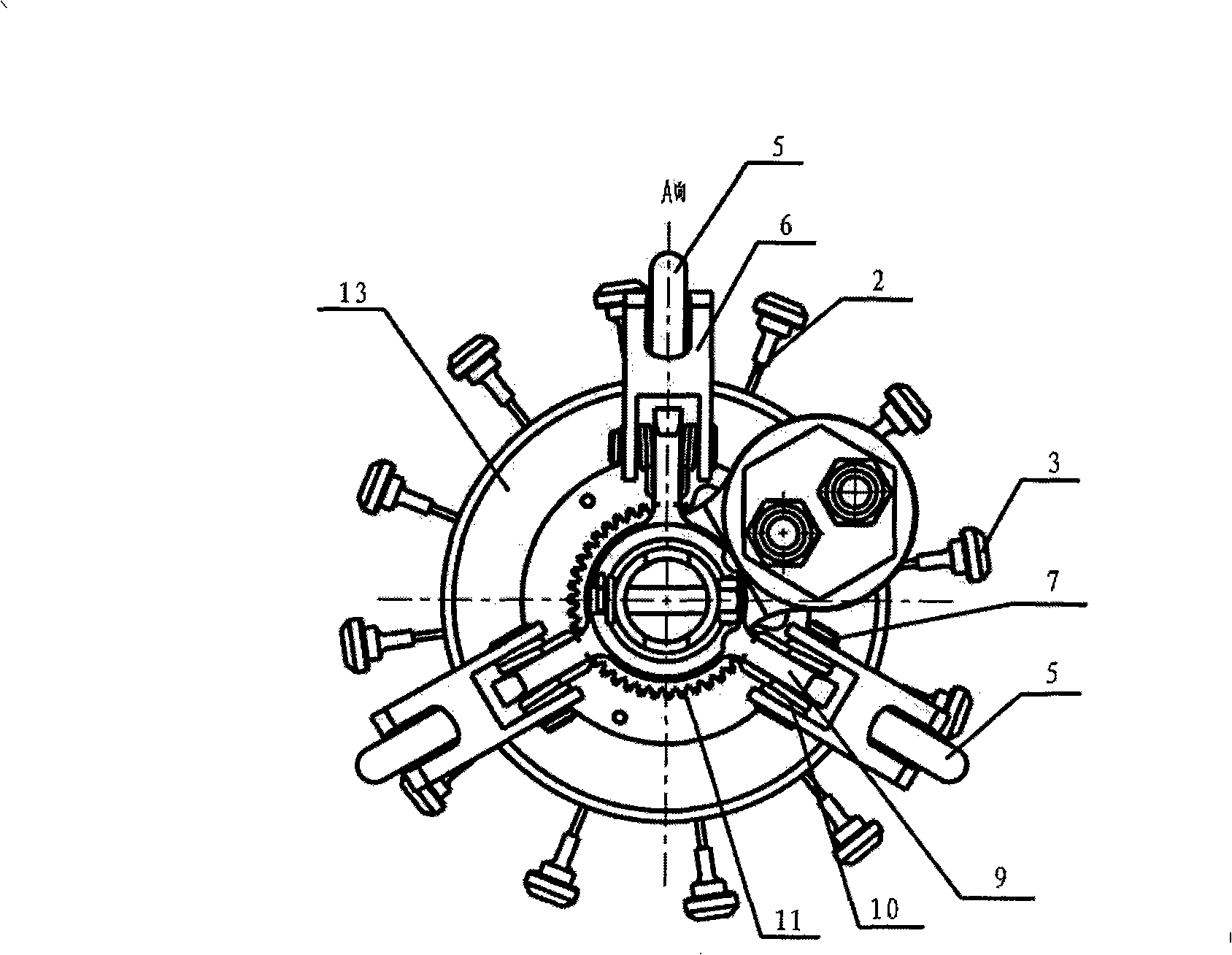

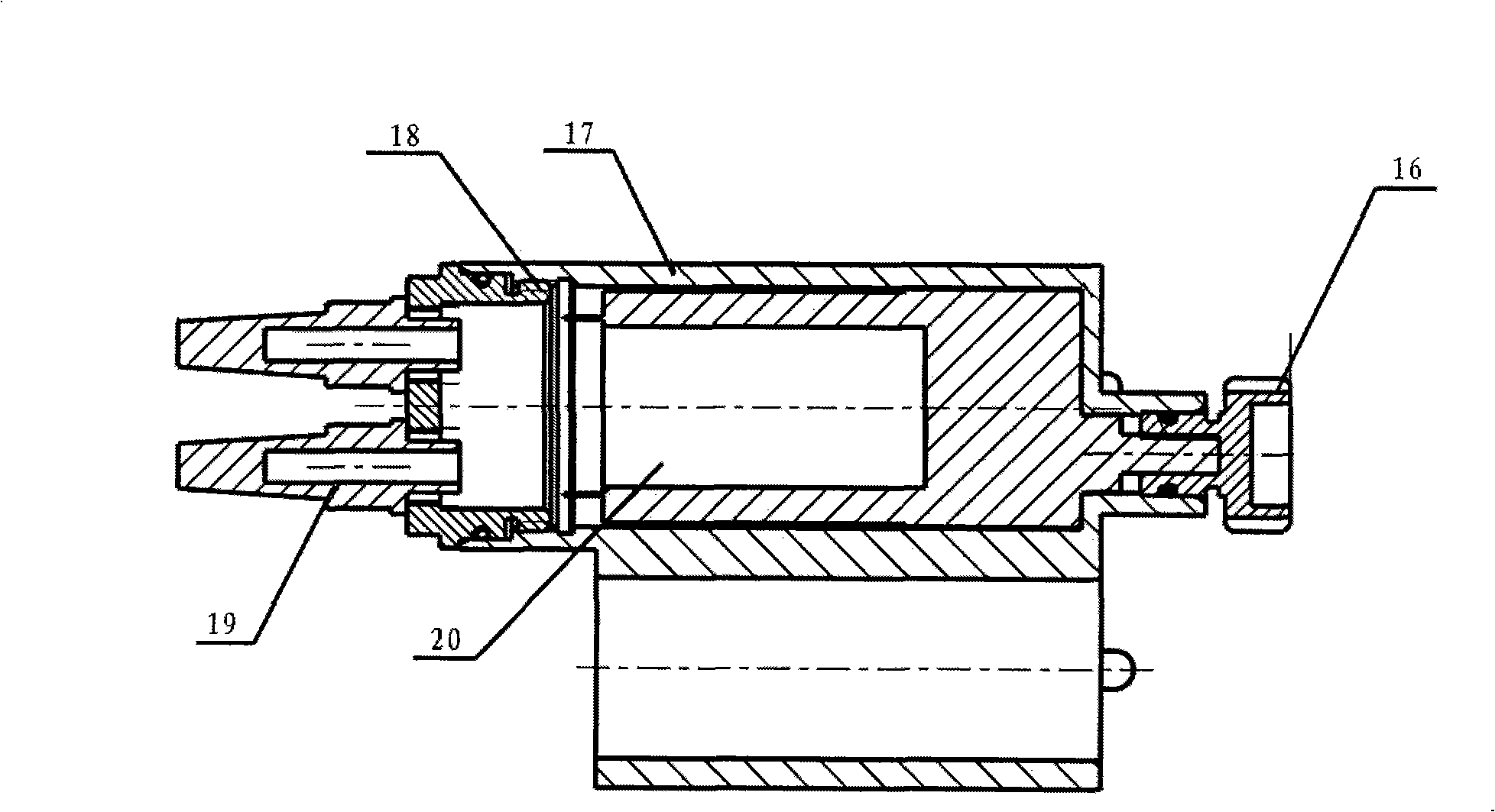

[0017] As shown in the figure: the sweeper includes a centerer, a sweeper and a drive mechanism 13 for driving the sweeper to rotate. In the sweeper mechanism, a number of flexible connecting arms 2 are arranged on the outer wall of the rotary body 1, and each The outer end of each connecting arm 2 is provided with a cleaning hammer 3, and the cleaning mechanism includes a rotary body 1, a connecting arm 2 and a cleaning hammer 3; Spring 10; the drive mechanism includes a motor and a transmission mechanism. When working, the motor 20 and the transmission mechanism make the flexible rotary hammer composed of the connecting arm 2 and the cleaning hammer 3 rotate. When the cleaning hammer 3 touches the concrete residue, the impact force generated by the stored kinetic energy of the flexible rotary hammer pushes the concrete residue from the inner wall of the pipeline. Peel and crush, while its flexible features keep the pipe cleaner from getting stuck in the pipe.

[0018] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com