Driven hatch arrangement for a motor vehicle

A hatch and power technology, applied in the direction of power control mechanism, wing leaf control mechanism, transmission device, etc., can solve the problems of high transmission device, stuck, expensive, etc., to save production cost, avoid the change of installation position, The effect of mold cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

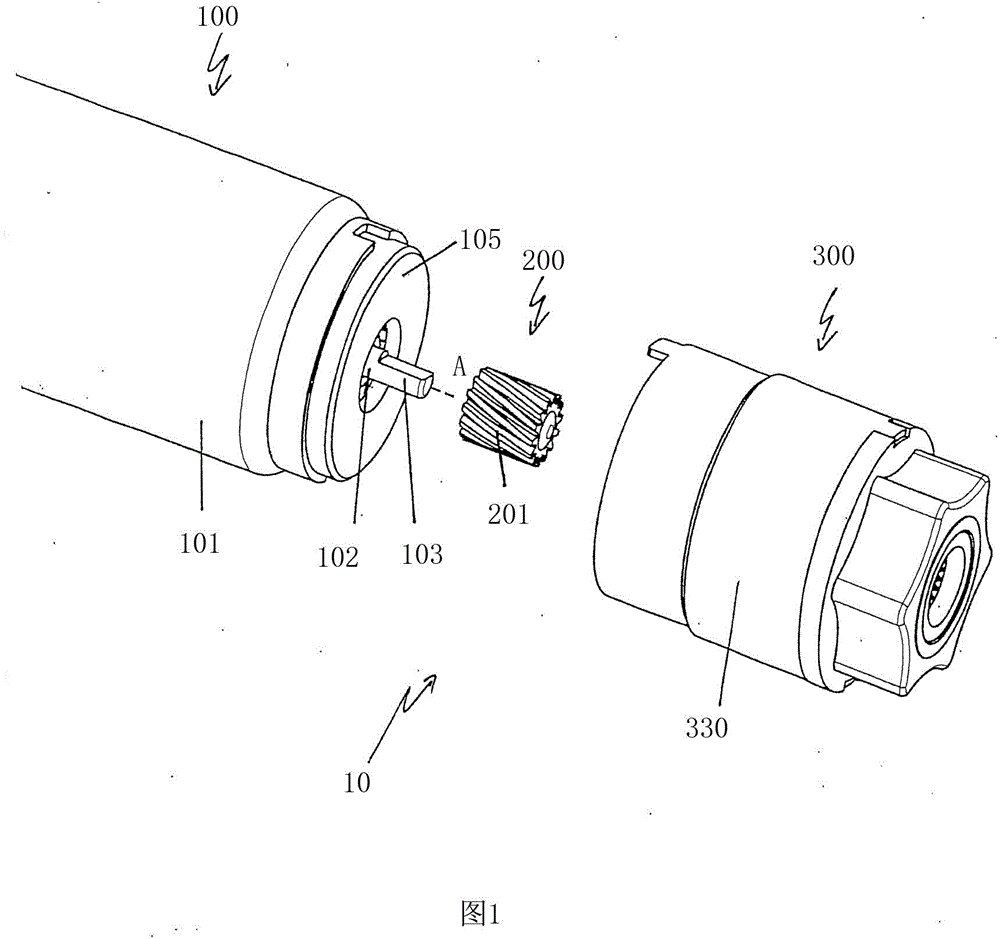

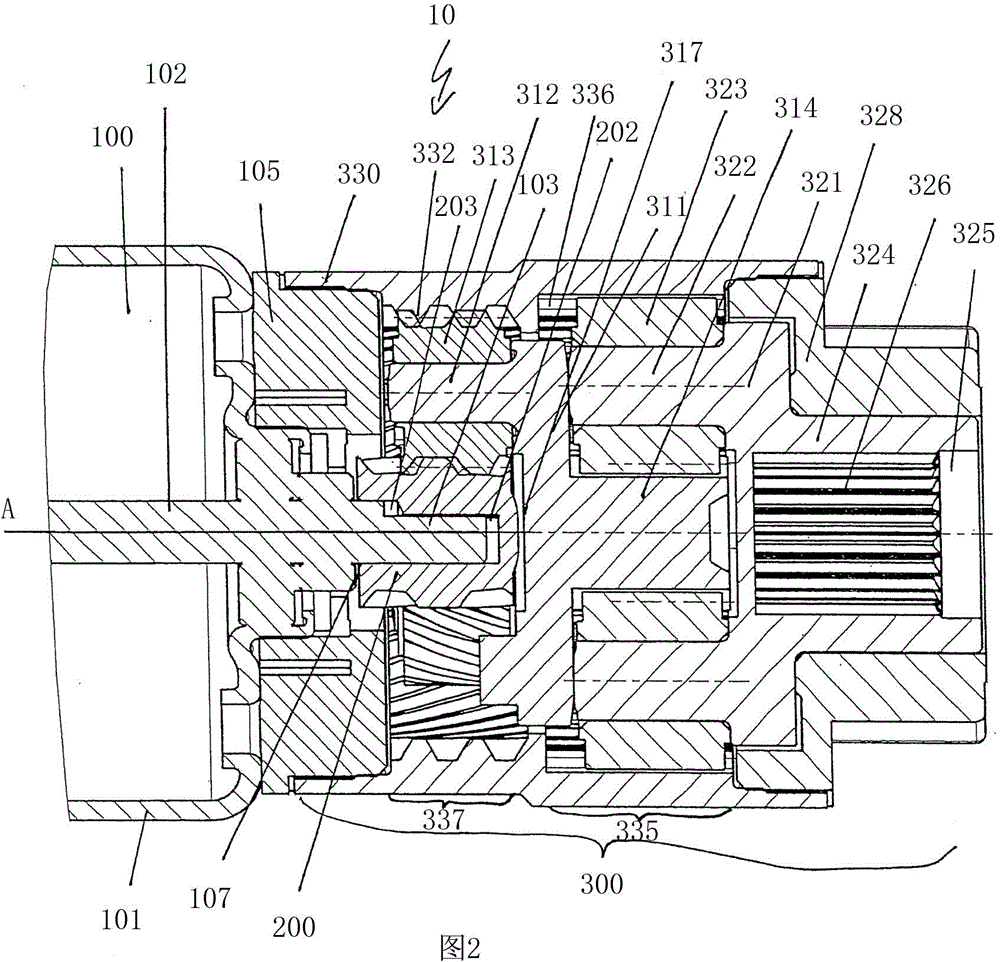

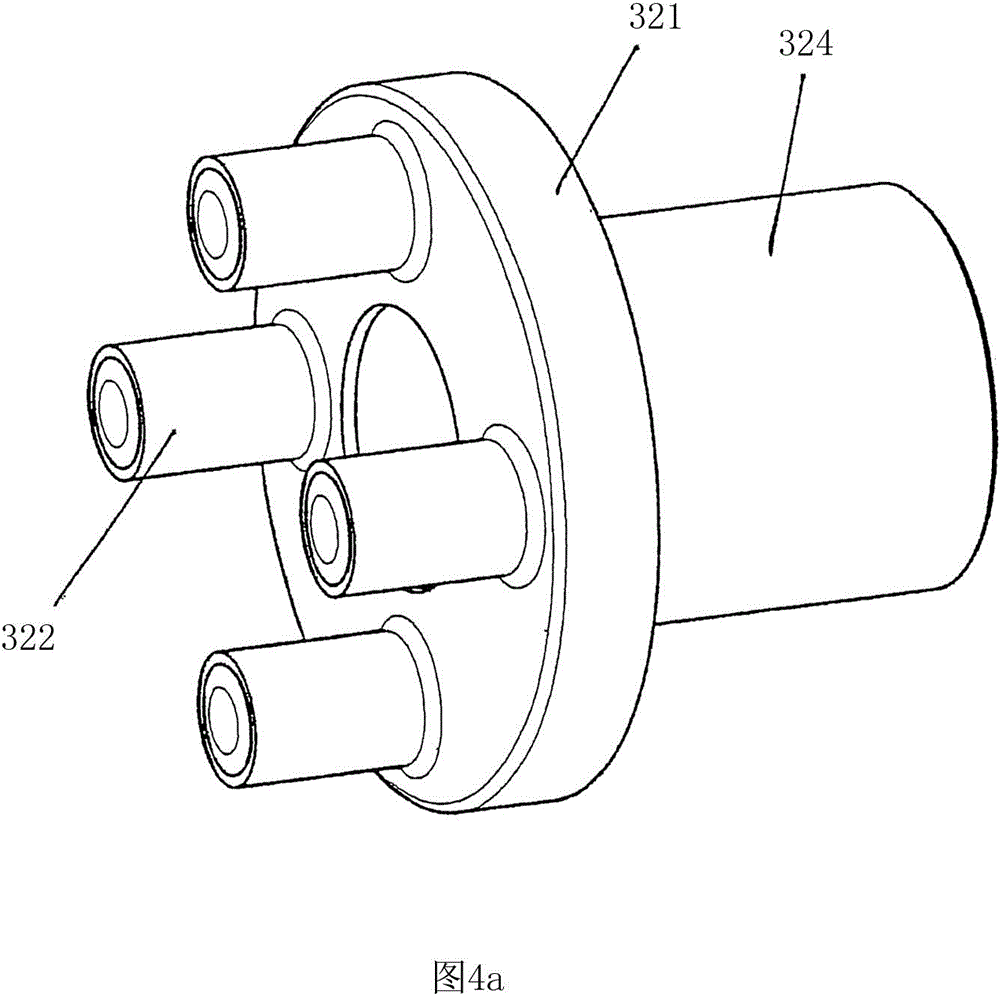

[0029] because figure 1 Different aspects of the same embodiment of the invention are shown through 4 and the same reference numerals will be used in these figures.

[0030] figure 1 The illustrated hatch drive device 10 includes the following components: a motor 100 having a motor housing 101, a motor housing cover 105 fixed on the motor housing 101, and a motor shaft 102 whose rotation axis is A. The drive device 10 is assembled to a motor pinion 200 with a helical gear 201 , and a transmission assembly 300 that is slipped onto the motor shaft 102 . The motor pinion 200 is preferably produced from plastic, but it is also possible to use, for example, metal pinions or ceramic pinions, which are mainly produced by MIM (Metal Injection Molding) or CIM (Ceramic Injection Molding) methods.

[0031] Also from figure 1 It can be seen that the motor shaft 102 has, on its side facing the transmission assembly 300, a section 103 having a D-shaped cross-section, which can be obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com