Revolving steamy peeling machine

A peeling machine and rotary technology, which is used in the peeling of vegetables or fruits, food preparation, food science and other directions, can solve the problems of uneven cooking, broken materials, incomplete stirring and turning of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

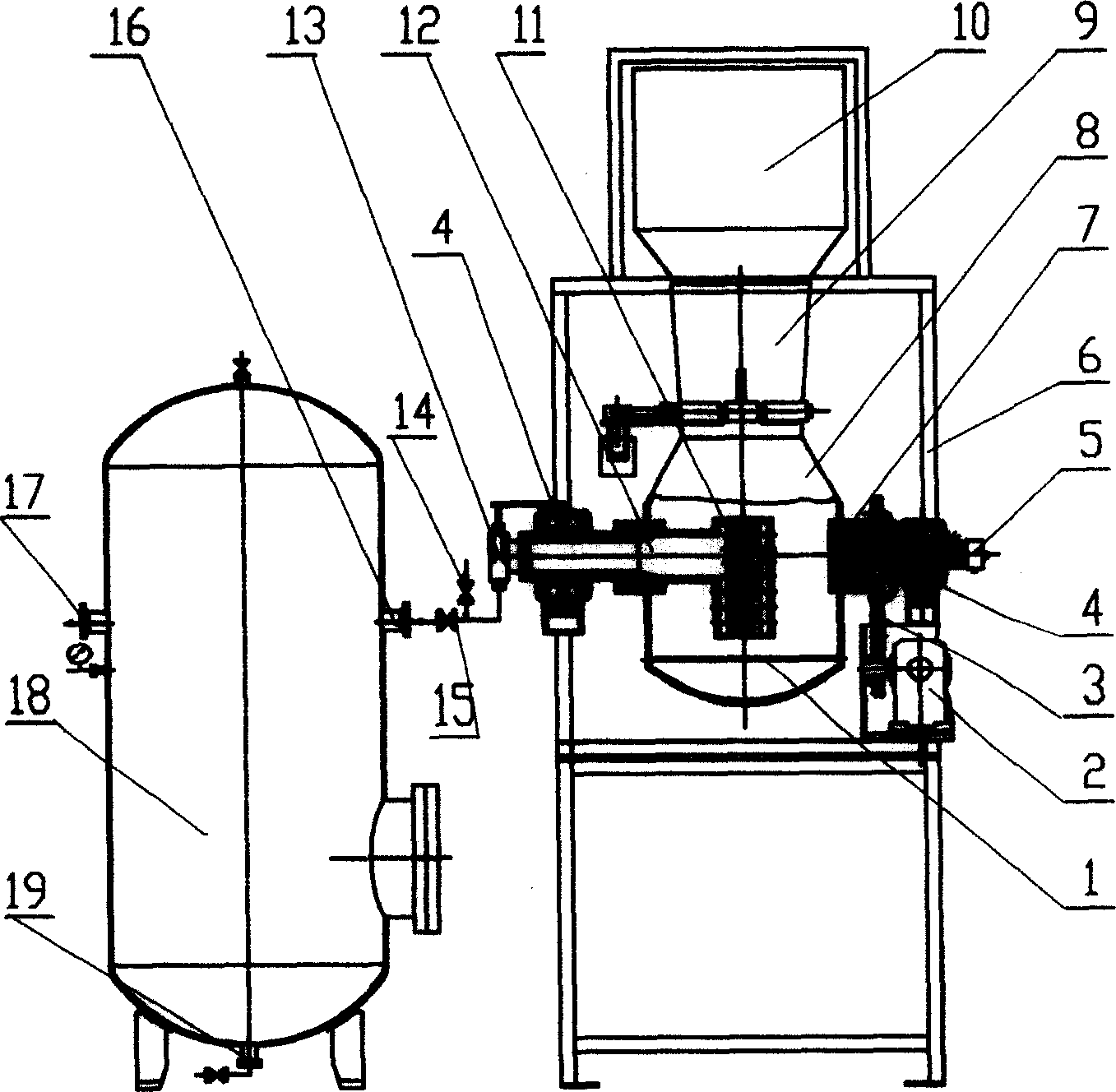

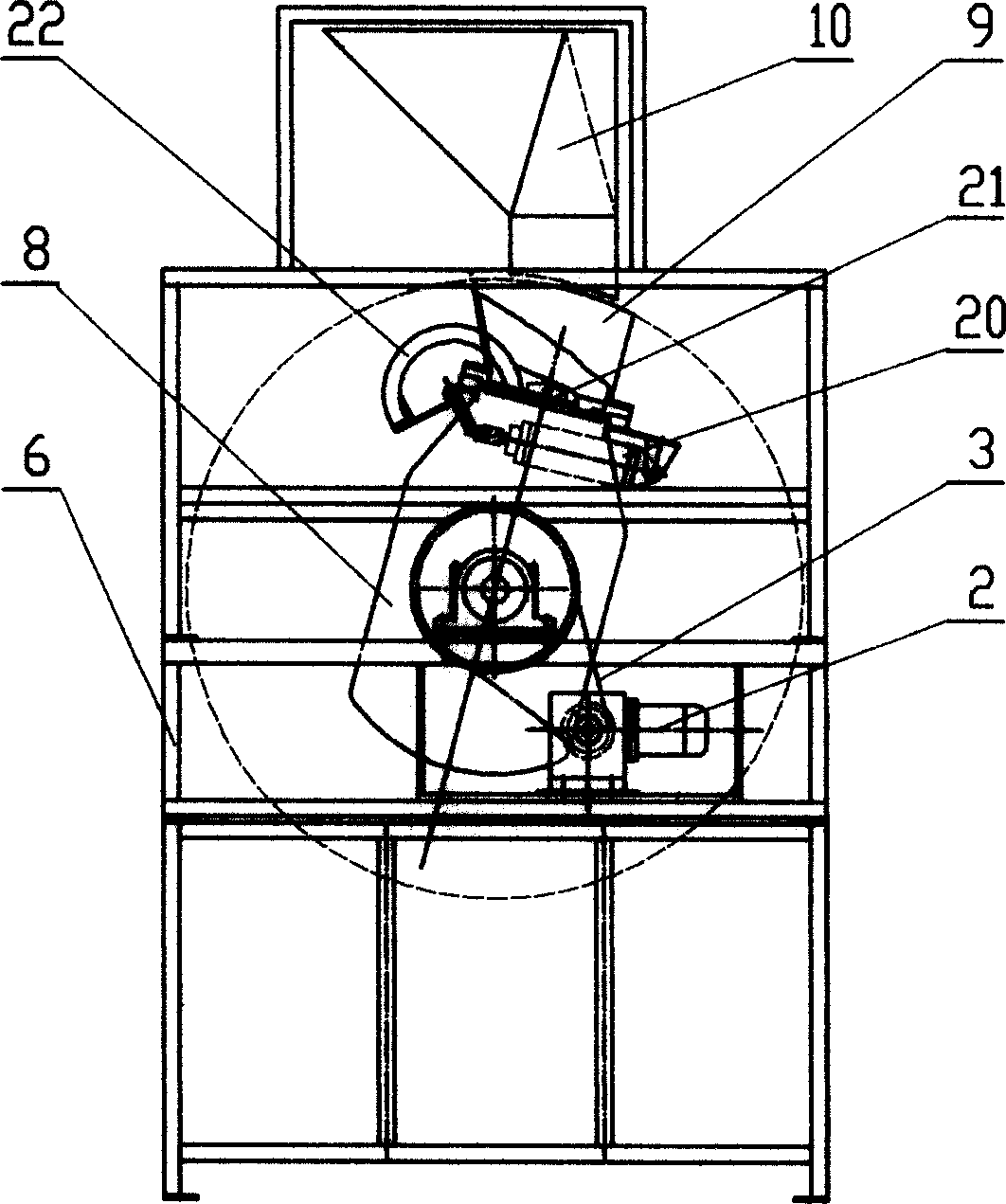

[0014] exist figure 1 , figure 2 In the rotary steam peeling machine shown, the left half shaft 12 and the right half shaft 7 are fixedly connected coaxially on both sides of the waist of the cooking pot 8 respectively, and the left half shaft 12 and the right half shaft 7 are symmetrically connected through the rolling bearing 4. Supported on the frame 6, the frame 6 adopts a frame structure. The left half shaft 12 is a hollow shaft, one end of which extends into the cooking tank 8. A steam shower 11 is installed at the inner end of the left half shaft 12. The steam shower 11 adopts an end cover structure, and the end cover A number of steam spray holes with different orientations are arranged on the top; the outer end of the tank of the left half shaft 12 is equipped with a steam rotary joint 13, and the steam rotary joint 13 communicates with the exhaust valve 15 and the steam inlet valve 14 which are connected in parallel. The steam valve 15 communicates with the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com