Industrial robot center distance adjusting ring

A technology of industrial robots and center distance, applied in manipulators, manufacturing tools, etc., can solve problems such as low installation efficiency and poor transmission accuracy, and achieve the effects of improving installation efficiency, improving production convenience, and simplifying shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

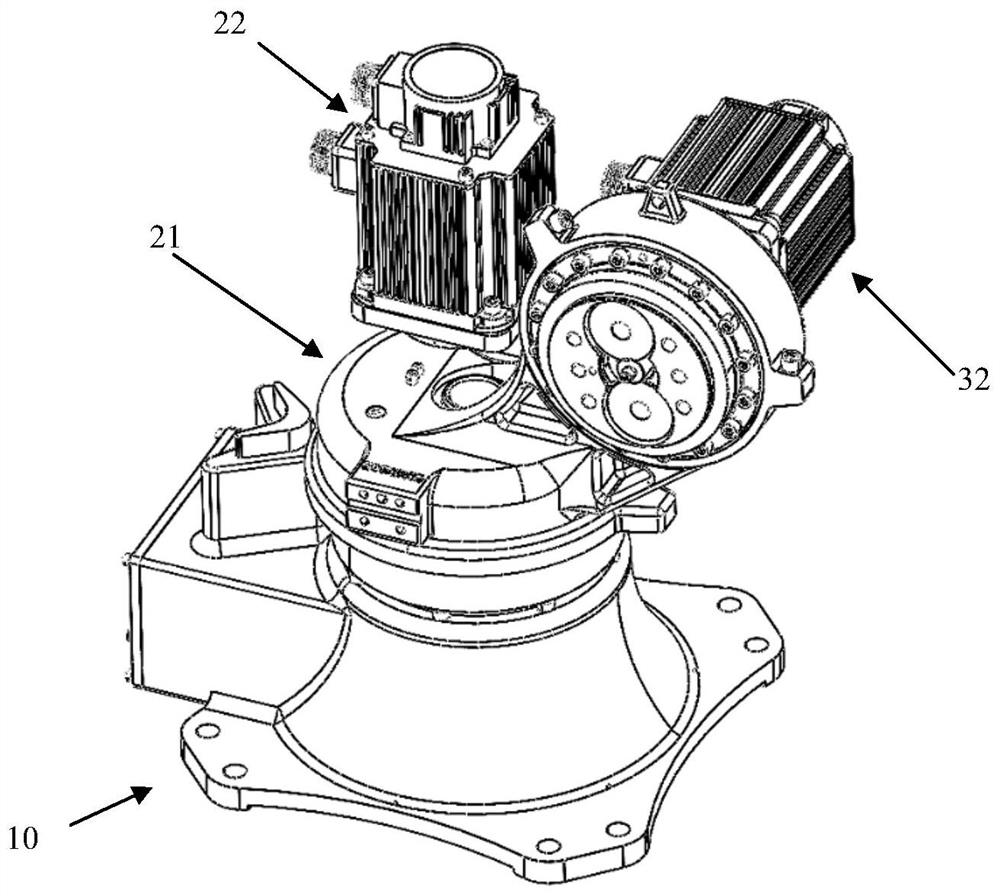

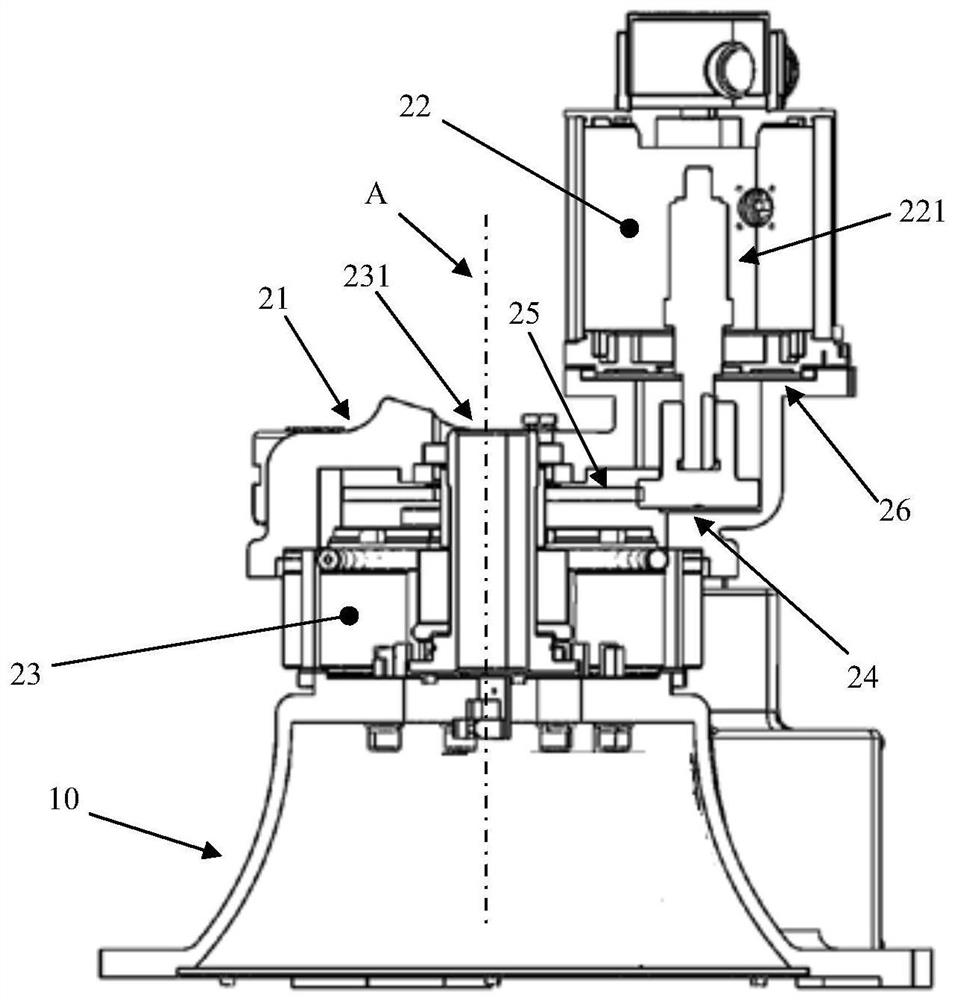

[0031] During the installation process of the components of each joint of the industrial robot, the machining error of each component and the installation error are progressive and finally affect the meshing parameters between the output gear of the motor and the input gear of the reducer, while the output gear of the motor and the input gear of the reducer The error between the gears can be eliminated by adjusting the center distance. Therefore, adjusting the distance between the output shaft of the motor and the input shaft of the reducer can correct various errors and adjust the output gear of the motor and the input gear of the reducer to the designed meshing state.

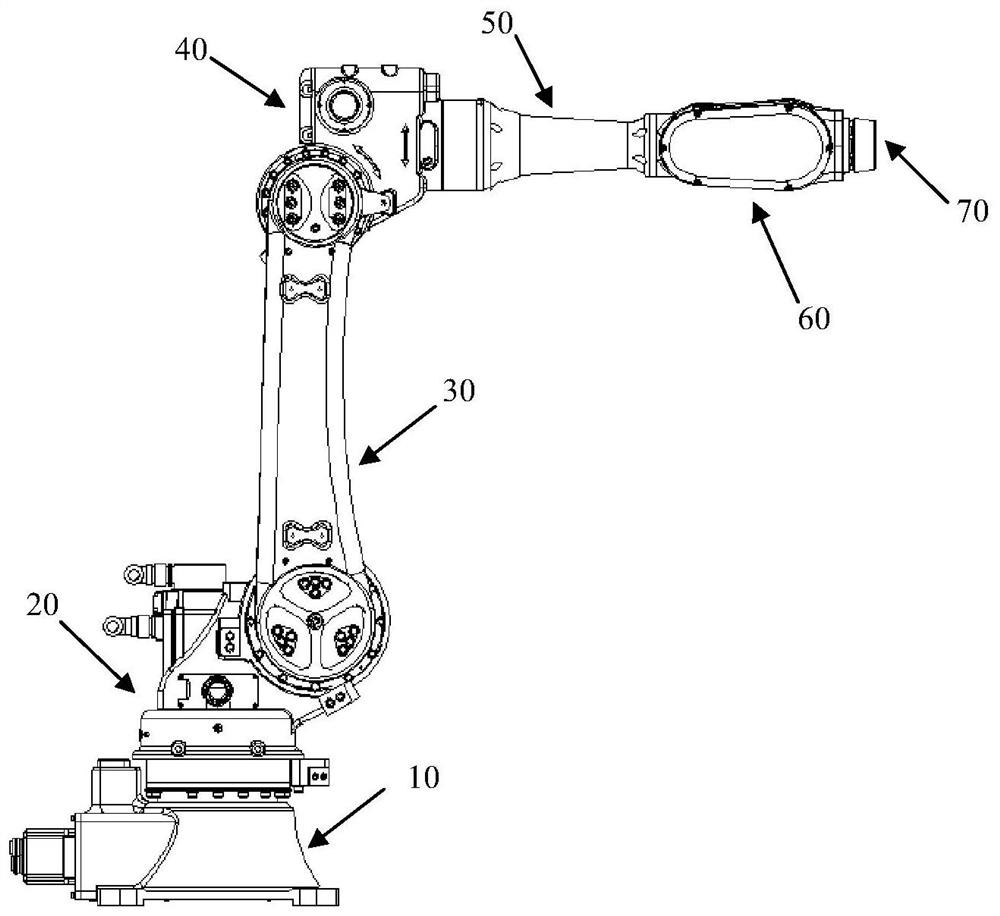

[0032] To this end, the present invention provides an industrial robot, which includes one or more joints equipped with center distance adjusting rings. Install the center distance adjusting ring into the joint to adjust the center distance between the output shaft of the joint motor and the input shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com