Radiating module

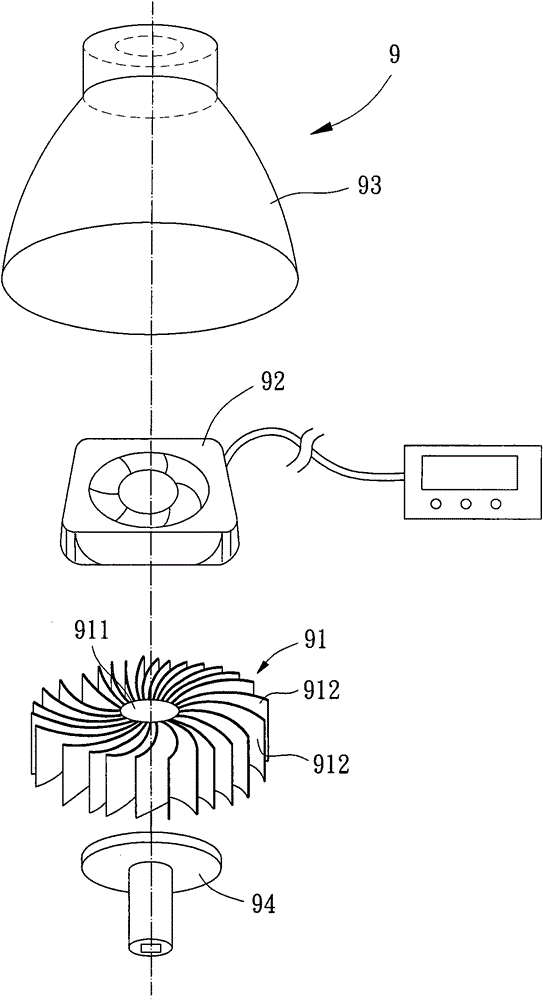

A technology of heat dissipation module and radiator, which is applied in the direction of instruments, electrical digital data processing, electrical components, etc., can solve the problems of reducing the air-displacement effect of the fan 92, easy to produce looseness, and the heat dissipation effect of the heat dissipation module 9 is reduced, and achieves a high level of improvement. The effect of making convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

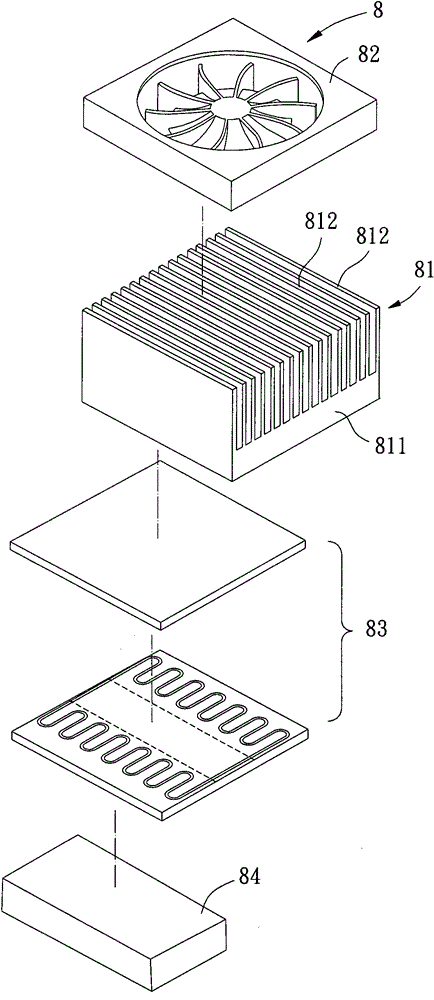

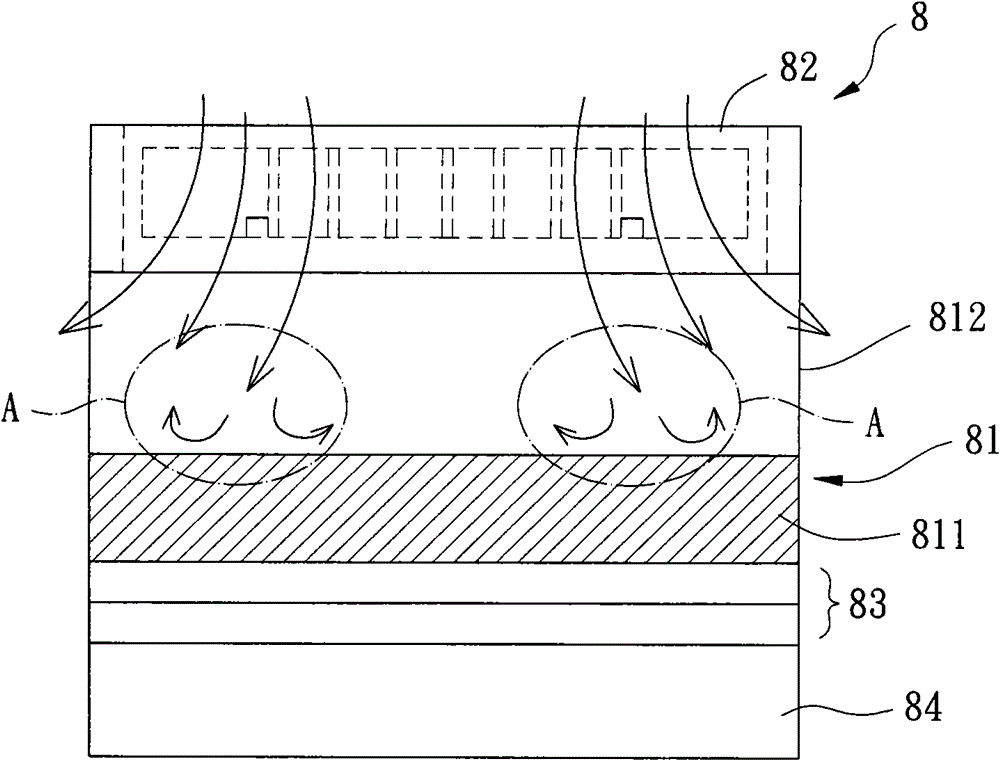

[0039] Please refer to Figure 4 and 5 As shown, the heat dissipation module of the preferred embodiment of the present invention includes a radiator 1 , a fan 2 and a heat spreader 3 . The fan 2 is combined with one end of the radiator 1 , and the heat spreader 3 is combined with the other end of the radiator 1 , so that the radiator 1 can be located between the fan 2 and the heat spreader 3 .

[0040] The heat sink 1 has a central body 11, the central body 11 is provided with a first end surface 111 and a second end surface 112 in the axial direction, and the outer peripheral surface of the central body 11 is provided with several fins 12, each of the fins 12 extends radially outward and is located between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com