Permanent-magnet motor assembling production line

A technology for assembling production lines and permanent magnet motors, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc. It can solve problems such as affecting motor production capacity, increasing motor manufacturing costs, and inaccurate data, improving automation and production. Convenience, the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

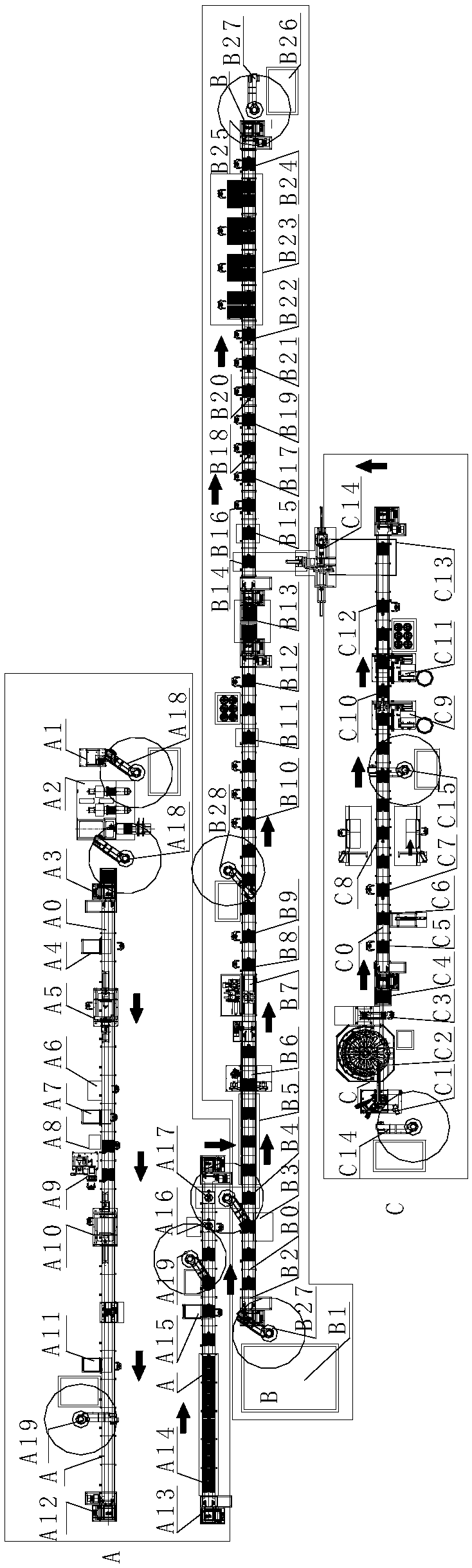

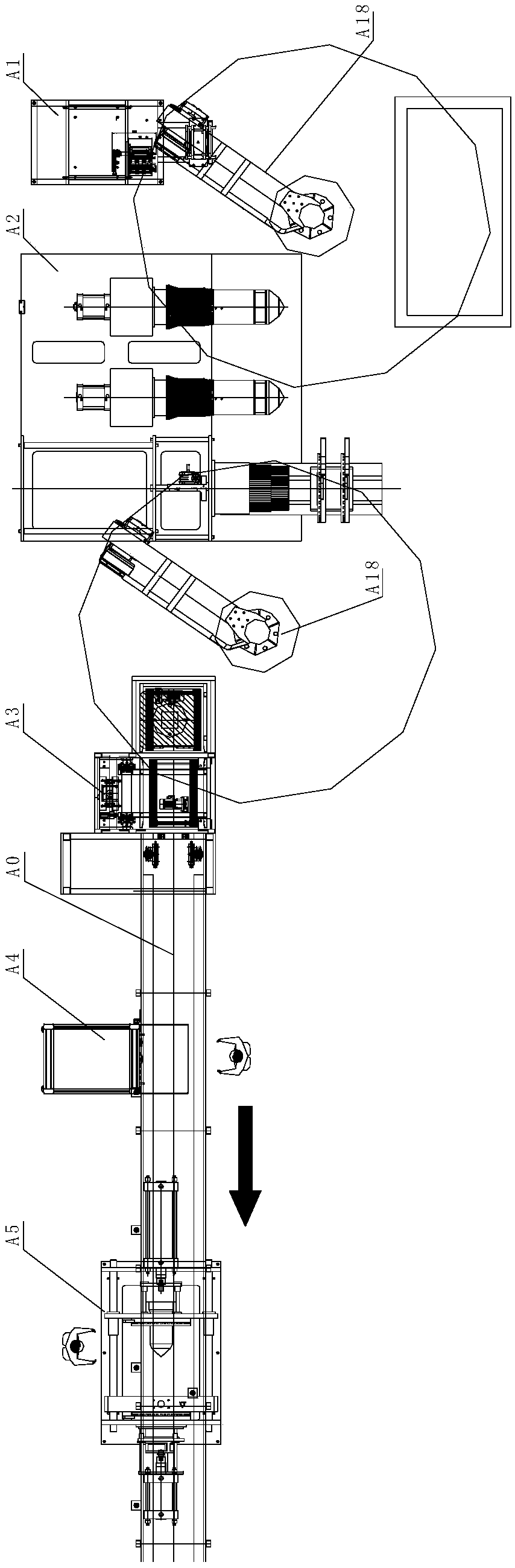

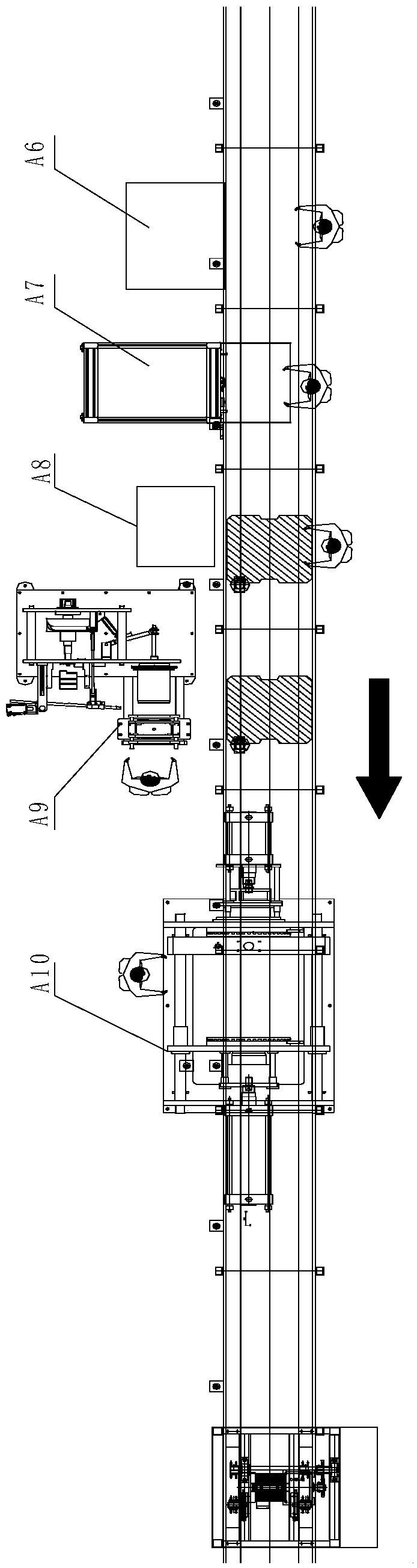

[0042] see Figure 1-9 , the permanent magnet motor assembly production line of the present invention includes a general assembly assembly section B and a stator assembly section A and a rotor assembly section C that transport the stator and the rotor for the general assembly assembly section; the stator assembly section A includes a stator assembly transmission line A0, and the stator The assembly transmission line A0 is equipped in sequence along the way: stator paper inserting machine A1, embedding and expanding integrated machine A2, stator on-line buffer table A3, coil shaping table A5, first paint stripping table A6, star point extrusion table A8, binding table A9, Final shaping station A10, paint dipping station A12, sampling station A13, stator air cooling channel A14, second paint stripping station A16 and stator transfer preparation station A17; the rotor assembly section C includes a rotor assembly transmission line C0, and the rotor assembly transmission line C0 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com