Interlayer reinforcing agent for papermaking as well as raw material composition and preparation method thereof

A technology of raw material composition and interlayer reinforcement, applied in the direction of reinforcing agent addition, papermaking, paper coating, etc., to achieve the effect of easy operation of preparation steps, realization of simple resources and raw material formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

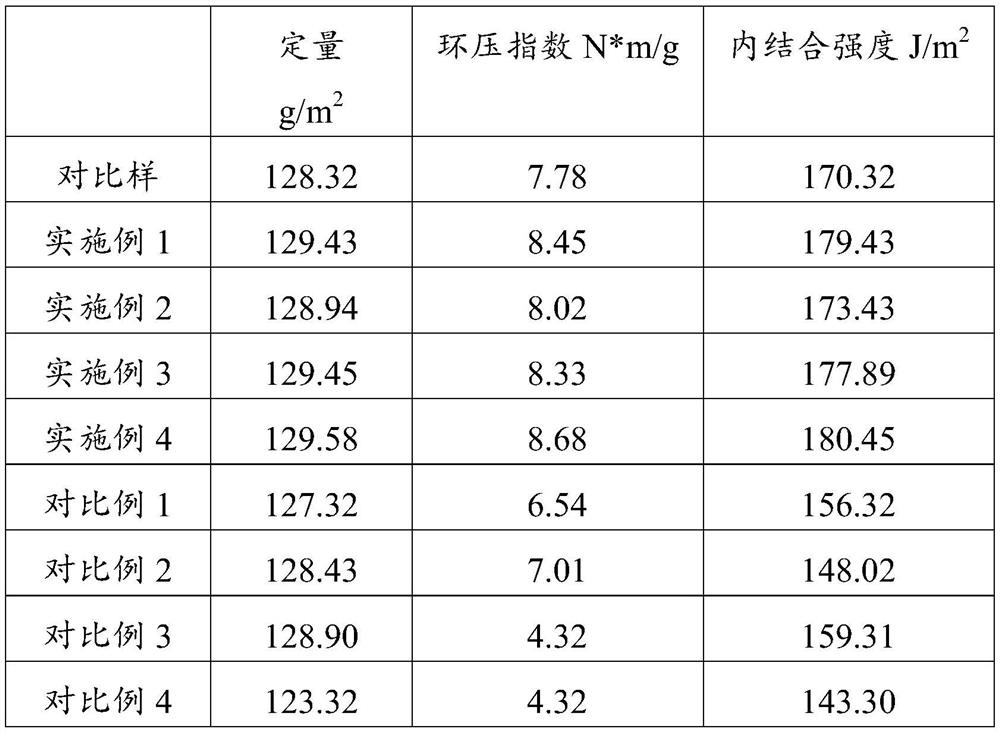

Examples

Embodiment 1

[0033] (1) get dissolving pulp pre-hydrolyzate 400g in 1L glass reactor, stir and disperse, add 80g cornstarch and 0.8g tetrasodium EDTA in the reactor, stir and disperse, start to heat up simultaneously, temperature rises to 50 ℃ ℃, add 4g of 1mol / L sulfuric acid, dropwise add a liquid mixed with 16g of glutaraldehyde and 20g of water, the dropwise addition time is 40min, the dropwise addition is completed and the insulation is completed for 120min to obtain material A;

[0034] (2) 8g potassium hydroxide was added to the material A obtained in step (1), 80g 10% ammonium persulfate solution and 40g acrylamide were added dropwise and 60g water mixture was added dropwise, and the sodium persulfate was added dropwise for 80min, acrylamide The dropwise addition time of the mixed solution is 60min, the reaction temperature is 50°C, and the temperature is kept for 90min after all dropwise additions are completed.

Embodiment 2

[0036] (1) get dissolving pulp pre-hydrolyzate 400g in 1L glass reactor, stir and disperse, in reactor, add 40g tapioca starch and 0.4g disodium EDTA, stir and disperse, start to heat up simultaneously, temperature rises to 60 ℃ ℃, add 2g of 1mol / L hydrochloric acid, dropwise add a liquid mixed with 10g of glyoxal and 10g of water, the dropwise addition time is 20min, the dropwise addition is completed and the insulation is completed for 90min to obtain material A;

[0037](2) add 4g sodium hydroxide to the material A obtained in step (1), add 32g 10% sodium persulfate solution and 20g acrylamide dropwise respectively and add 20g water mixture, sodium persulfate dropping time 60min, acrylamide The dropwise addition time of the mixed solution is 40min, the reaction temperature is 55°C, and the temperature is kept for 60min after all dropwise additions are completed.

Embodiment 3

[0039] (1) get dissolving pulp pre-hydrolyzate 400g in 1L glass reactor, stir and disperse, add 20g cornstarch, 20g potato starch and 0.7g disodium EDTA in the reactor, stir and disperse, start to heat up simultaneously, The temperature was raised to 55°C, 4g of 2mol / L acetic acid was added, a liquid mixed with 12g of glutaraldehyde and 12g of water was added dropwise, the dropwise addition time was 30min, and the dropwise addition was completed for 90min of insulation to obtain material A;

[0040] (2) add 5g sodium hydroxide to the material A obtained in step (1), add 60g 10% benzoyl peroxide and 30g acrylamide dropwise respectively and add 30g water mixture, sodium persulfate dropping time 60min, propylene The dropwise addition time of the amide mixed solution is 50min, the reaction temperature is 60°C, and the temperature is kept for 90min after all the dropwise additions are completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com