Natural polymer modified reinforcing agent and preparation method thereof

A technology of natural macromolecules and enhancers, which is applied in the addition of enhancers, non-polymer organic compounds, and non-fiber pulps, etc., can solve the problems of toxic price of human body and ungreen chemical reagents, and achieve sufficient supply and preparation steps. Easy operation, simple raw material formula effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

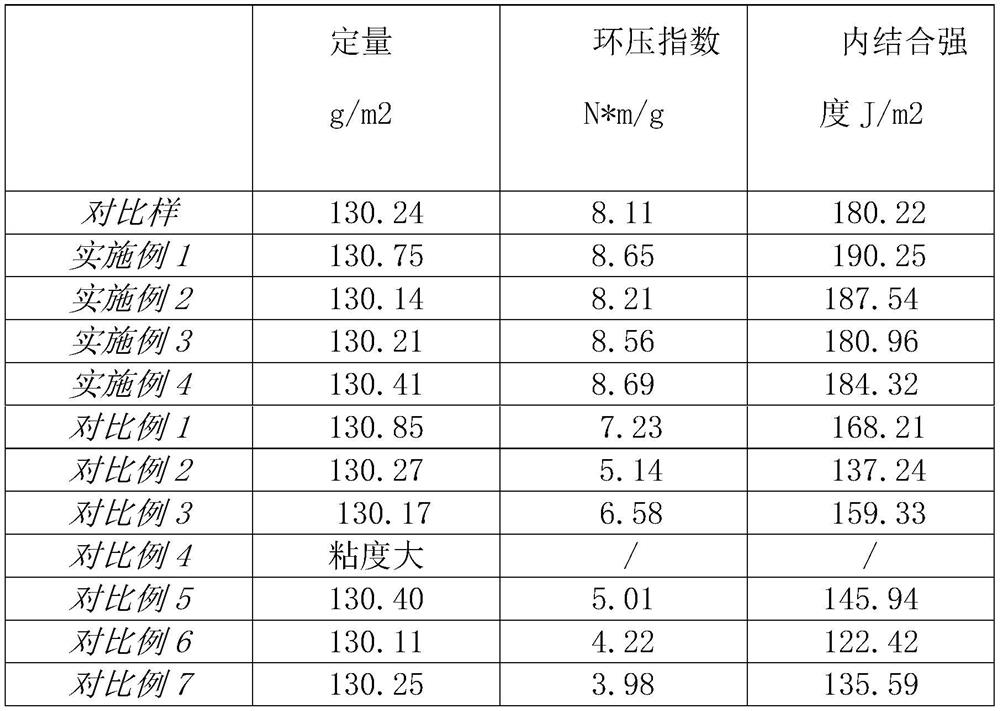

Examples

Embodiment 1

[0039] (1) Take 200g of hemicellulose and 650g of water in a 2L glass reactor, stir and disperse for 10min, add 15g of sodium hydroxide, and react at 25°C for 30min to obtain material A;

[0040] (2) Add 1 g of manganese dioxide and 10 g of hydrogen peroxide to the material A obtained in step (1) and react at 25° C. for 60 minutes to obtain material B;

[0041] (3) Add 120 g of cornstarch and 20 g of boric acid to the material B prepared in step (2), and stir at 25° C. for 10 min to obtain material C;

[0042] (4) Add 20 g of 10% sulfuric acid and 2 g of sodium bisulfite to the material B obtained in step (2), and stir at 25° C. for 10 min to obtain the product.

Embodiment 2

[0044] (1) Take 200 g of hemicellulose xylanase degradation product and 650 g of water in a 2L glass reactor, stir and disperse for 10 min, add 15 g of potassium hydroxide, and react at 25 ° C for 30 min to obtain material A;

[0045] (2) Add 2 g of ferric chloride and 10 g of hydrogen peroxide to the material A obtained in step (1) and react at 25° C. for 60 minutes to obtain material B;

[0046] (3) Add 150 g of cornstarch and 25 g of boric acid to the material B prepared in step (2), and stir at 25° C. for 10 min to obtain material C;

[0047] (4) Add 20 g of 10% sulfuric acid and 2 g of sodium sulfite to the material B prepared in step (2), and stir at 25° C. for 10 min to obtain the product.

Embodiment 3

[0049] (1) Take 220g of hemicellulose and 700g of water in a 2L glass reactor, stir and disperse for 15min, add 20g of sodium hydroxide, and react at 25°C for 30min to obtain material A;

[0050] (2) Add 2g of lithium chloride, 10g of hydrogen peroxide and 10g of sodium hypochlorite solution to the material A obtained in step (1) and react at 25°C for 90min to obtain material B;

[0051] (3) Add 200 g of potato starch and 20 g of borax to the material B prepared in step (2), and stir for 10 min at 25° C. to obtain material C;

[0052] (4) Add 20 g of 10% oxalic acid and 2 g of sodium thiosulfate to the material B prepared in step (2), and stir at 25° C. for 5 min to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com