A kind of photosensitive resin and its preparation method and application

A photosensitive resin and photoinitiator technology, applied in the field of 3D printing materials, can solve the problems of complex formula and preparation process, unfavorable environmental protection, poor printing accuracy, etc., and achieve improved solid content and sintering compactness, low viscosity, and printing accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

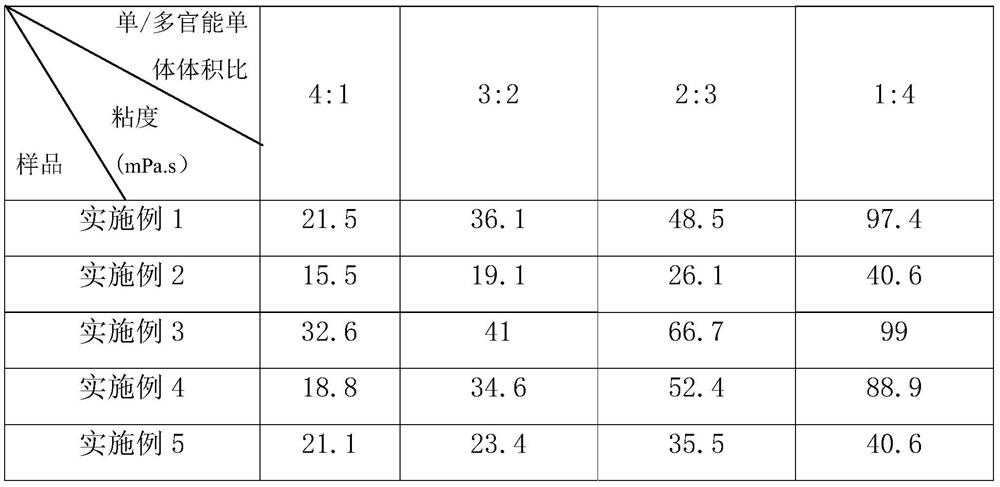

Embodiment 1

[0021] Measure 60ml of isobornyl acrylate, add it to a 150ml beaker, add 40ml of ethoxylated pentaerythritol tetraacrylate, that is, the volume ratio of monofunctional monomer to multifunctional monomer is 3:2, stir magnetically for 1h to obtain a uniform mixture, use The mass of the mixed solution was weighed by a precision balance to 106 g, and 0.53 g of photoinitiator TPO, 0.5 g of UVAbsorber 1205 were sequentially added to the obtained uniform mixed solution, the stirring speed was 600 r / min, and the heating temperature was 50 °C. Magnetic stirring for 2 hours ensures that TPO and UV Absorber 1205 are fully Dissolved in the mixed solution to obtain a photosensitive resin mixed solution A for photocuring ceramic slurry 1 . Among them, UVAbsorber 1205 (purchased from Qingdao Jadejia New Material Technology Co., Ltd.) is a nitrogen heterocyclic compound, which is a solid absorber with an efficient absorption peak at 350-440 nm.

[0022] In addition, take 80ml of isobornyl ac...

Embodiment 2

[0026] Measure 20ml of isobornyl acrylate, add it to a 150ml beaker, add 80ml of polyethylene glycol diacrylate, that is, the volume ratio of monofunctional monomer to multifunctional monomer is 1:4, and magnetically stir for 1h to obtain a uniform mixture. The mass of the mixed solution was weighed by a precision balance to 109 g, and 1.09 g of photoinitiator TPO, 0.55 g of UVAbsorber LQ01 were added to the obtained uniform mixed solution in turn, the stirring speed was 600 r / min, and the heating temperature was 50 °C. Magnetic stirring for 2h ensures that TPO and UV Absorber LQ01 are Fully dissolved in the mixed solution to obtain the photosensitive resin mixed solution B for photocuring ceramic slurry 1 . Among them, UVAbsorber LQ01 (purchased from Qingdao Jadejia New Material Technology Co., Ltd.) is a nano-dispersed material, which is a liquid absorbent with an efficient absorption peak at 310-440 nm.

[0027] In addition, take 80ml of isobornyl acrylate and 20ml of poly...

Embodiment 3

[0031] Measure 80ml of acryloyl morpholine, add it to a 150ml beaker, add 20ml of ethoxylated trimethylolpropane triacrylate, that is, the volume ratio of monofunctional monomer to multifunctional monomer is 4:1, and magnetically stir for 1h to obtain a uniform The mixed solution was weighed with a precision balance to be 112 g, and 0.56 g of photoinitiator TPO, 0.56 g of UVAbsorber 1205 were added to the obtained uniform mixed solution in turn, the stirring speed was 600 r / min, and the heating temperature was 50 °C with magnetic stirring for 2 h to ensure TPO. and UV Absorber1205 fully dissolved in the mixed solution to obtain the photosensitive resin mixed solution C for photocuring ceramic slurry 1 .

[0032] In addition, take 60ml of acryloyl morpholine and 40ml of ethoxylated trimethylolpropane triacrylate (that is, the volume ratio of monofunctional monomer to multifunctional monomer is 3:2), other conditions remain unchanged, according to the above preparation method, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com