Piezoelectric composite material capable of being subjected to 3D printing/hot press molding and preparation method thereof

A piezoelectric composite material and hot-press forming technology, applied in the field of materials, can solve the problems of inability to provide piezoelectric activity, complex process, difficult degradation, etc., and achieve moderate piezoelectricity, simple preparation process, and good biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

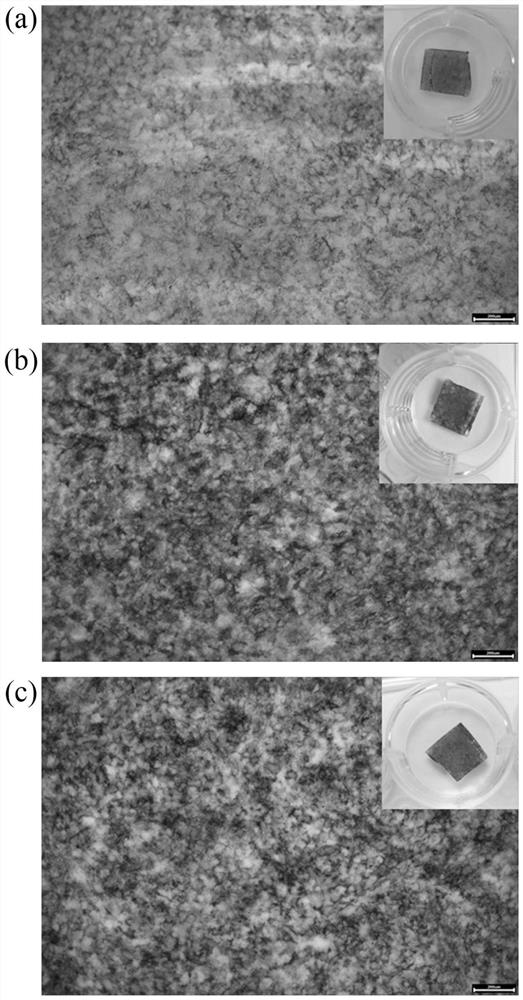

[0063] The preparation method of the piezoelectric composite material in this example is as follows:

[0064] 200 parts by mass of barium titanate, 900 parts by mass of ethanol, and 100 parts by mass of water were added to the reaction flask. Ultrasonic dispersion for 0.5 h, magnetic stirring for 0.5 h, repeat this 3 times, then add 4 parts by mass of KH550, heat to 45°C and mechanically stir for 12 h. Centrifuge, wash, and repeat three times to obtain the dried modified barium titanate (BT).

[0065] 24.3 parts by mass of modified BT, 200 parts by mass of methylene chloride, and 7.5 parts by mass of 3-hydroxybutyrate and 3-hydroxyvalerate copolymer (PHBV) were added to the beaker. Ultrasonic dispersion for 0.5h, magnetic stirring for 0.5h, repeated 3 times, magnetic stirring for 4h, adding ethanol precipitant to precipitate the composite material, filter and dry.

[0066] After the composite material is hot-pressed (heating temperature is 175°C, pre-pressing pressure is 8MP...

Embodiment 2

[0068] The preparation method of the piezoelectric composite material in this example is as follows:

[0069] 200 parts by mass of barium titanate, 1000 parts by mass of water, and Trish-HCl solution were added into the reaction flask to make pH = 7.4. Ultrasonic dispersion for 0.5 h and magnetic stirring for 0.5 h were repeated three times, then 4 parts by mass of dopamine hydrochloride was added and heated to 45° C. and mechanically stirred for 12 h. Dopamine hydrochloride self-polymerized to embed barium titanate particles. Centrifuge, wash, and repeat three times to obtain the dried modified barium titanate.

[0070] 18.2 parts by mass of modified BT, 200 parts by mass of methylene chloride and 7.1 parts by mass of polycaprolactone (PCL) were added to the beaker. Ultrasonic dispersion for 0.5h, magnetic stirring for 0.5h, repeated 3 times, magnetic stirring for 4h, adding ethanol precipitant to precipitate the composite material, filter and dry.

[0071] After the compos...

Embodiment 3

[0073] The preparation method of the piezoelectric composite material in this example is as follows:

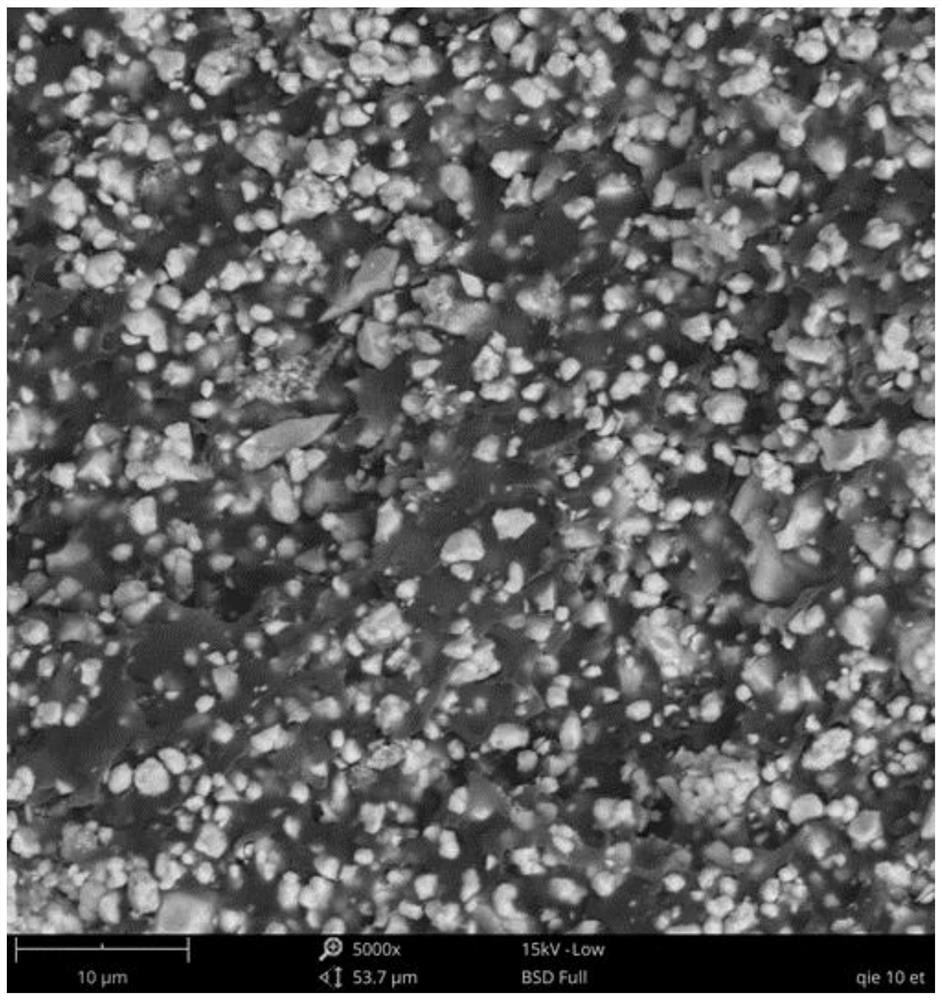

[0074] 200 parts by mass of barium titanate, 900 parts by mass of ethanol, and 100 parts by mass of water were added to the reaction flask. Ultrasonic dispersion for 0.5h, magnetic stirring for 0.5h, repeat 3 times, add 4 parts by mass of γ-aminopropyltriethoxysilane coupling agent, heat to 45°C and mechanically stir for 12h, centrifuge, wash, repeat three times to obtain dried Modified barium titanate.

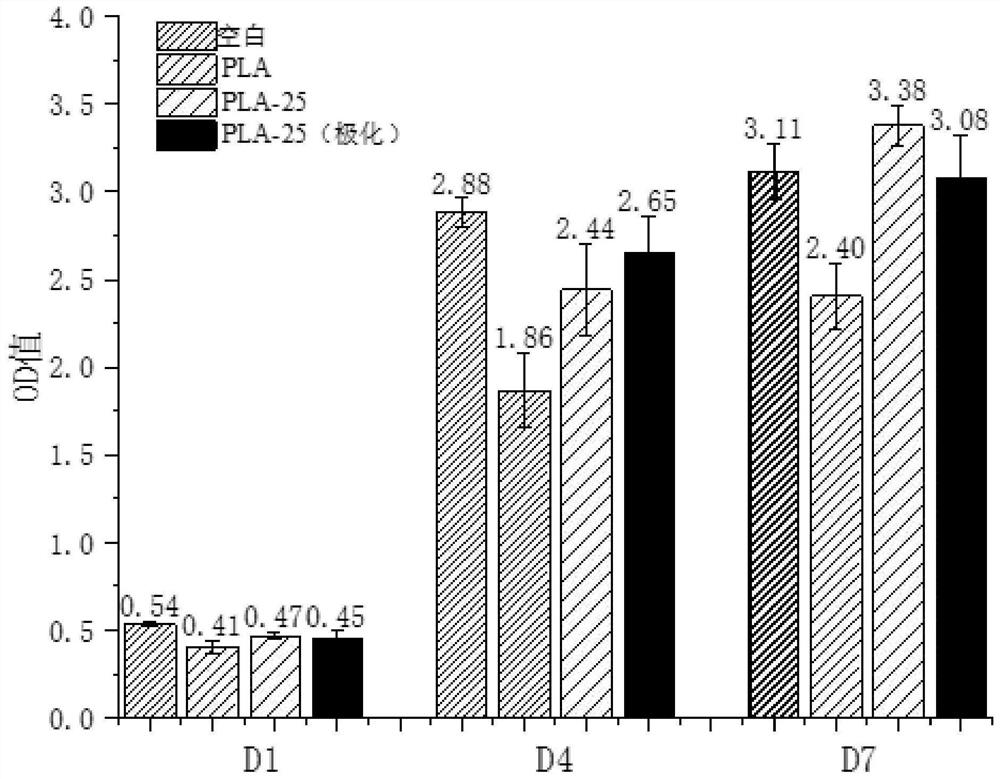

[0075] 15.2 parts by mass of modified BT, 200 parts by mass of methylene chloride and 9.4 parts by mass of polylactic acid (PLA) were added to the beaker. Ultrasonic dispersion for 0.5h, magnetic stirring for 0.5h, repeated 3 times, magnetic stirring for 6h, adding ethanol precipitant to precipitate the composite material, filter and dry.

[0076] After the composite material is thermoformed (heating temperature is 195°C, pre-pressing pressure is 8MPa, pre-pressing time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com