Carbon-ceramic composite brake disc and preparation method thereof

A carbon-ceramic composite material and brake disc technology, which is applied in the field of carbon-ceramic composite material and brake disc preparation, can solve the limitations of carbon-ceramic composite brake disc manufacturing and popularization and application, long preparation process cycle, and low material mechanical properties And other problems, to achieve the effect of improving anti-oxidation performance, reducing wear, and pedal feeling comfortable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

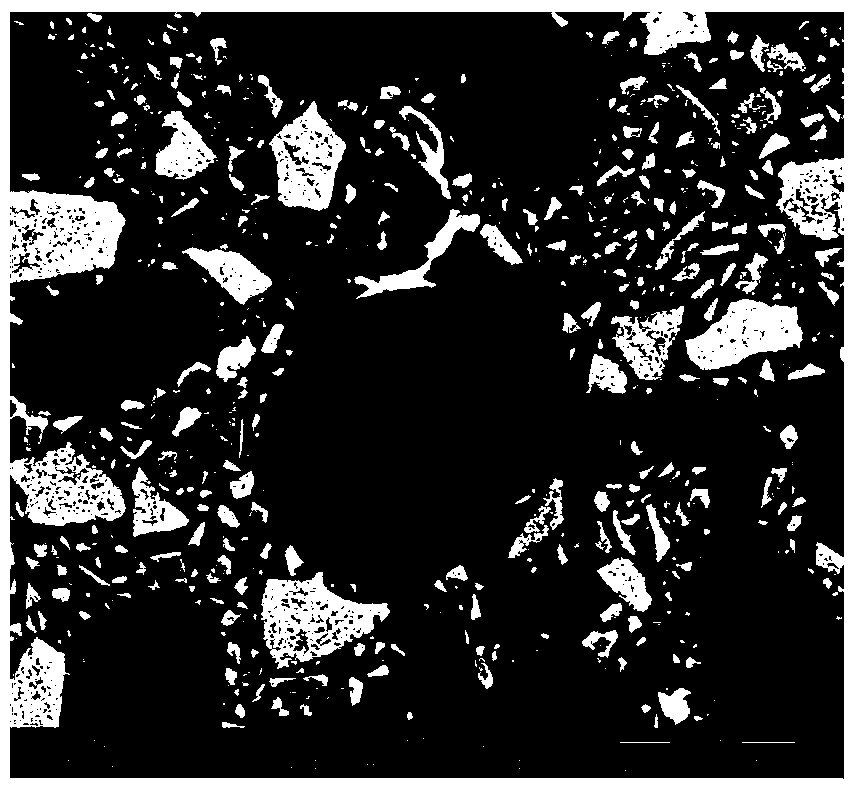

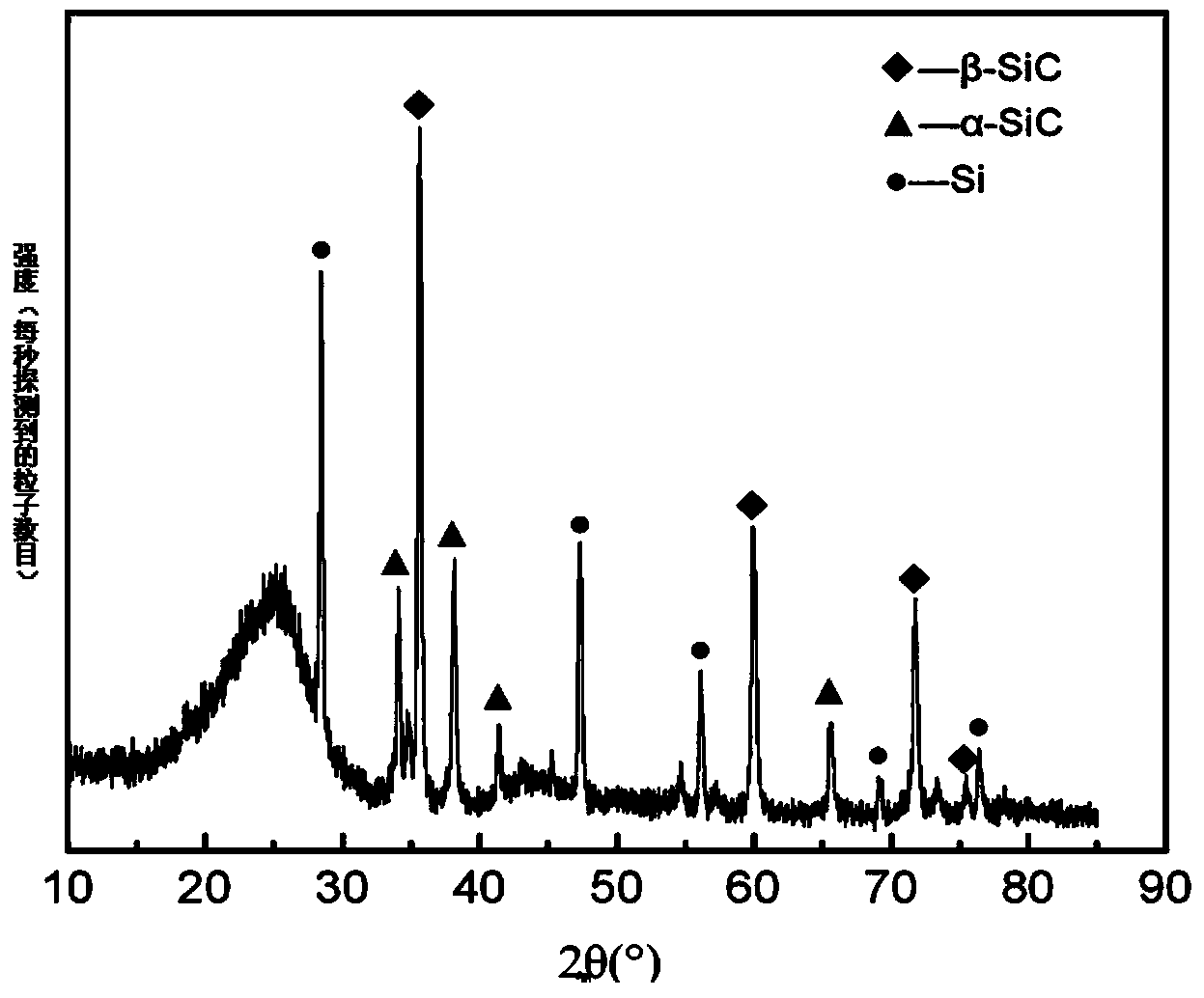

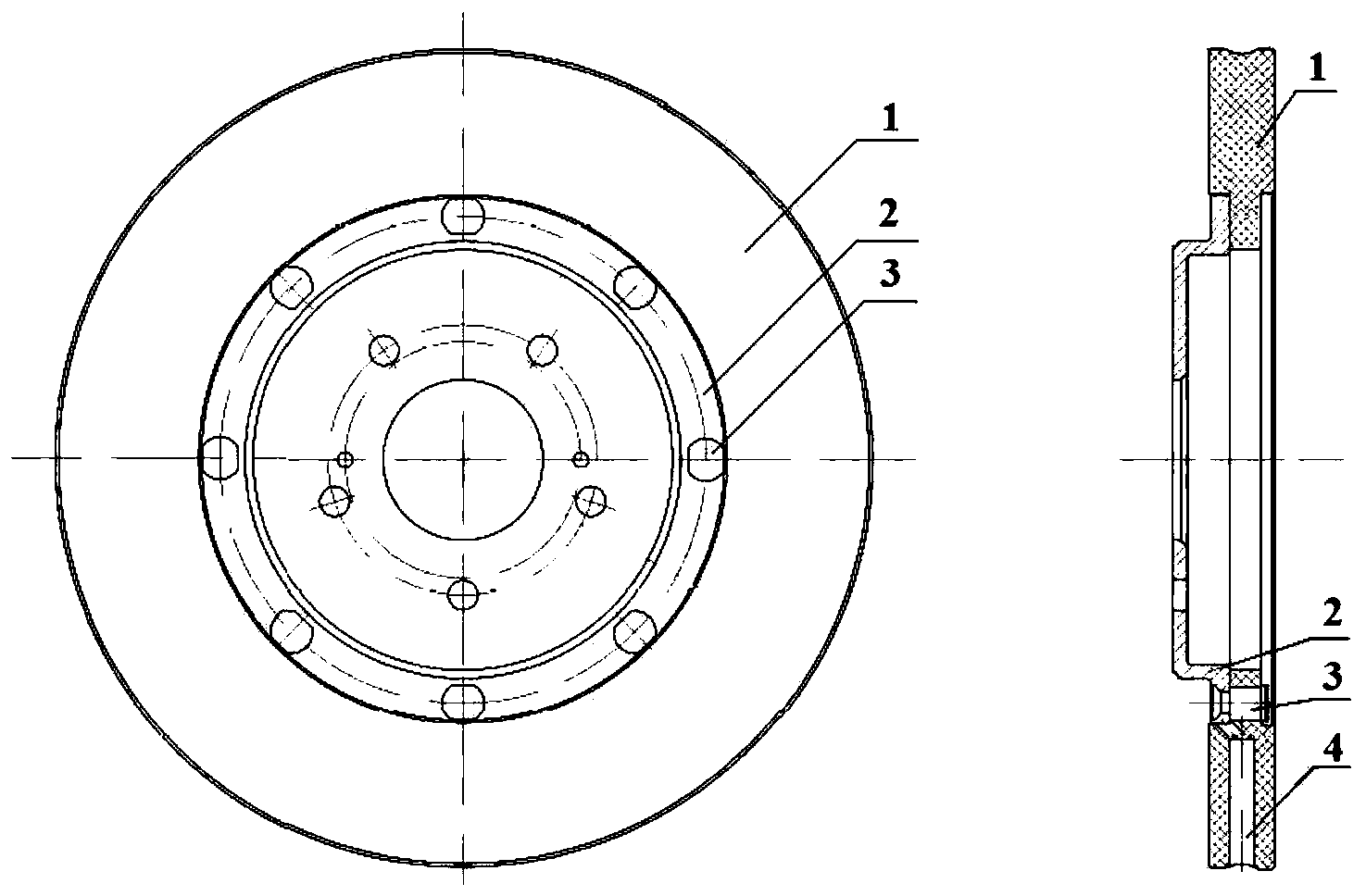

Embodiment 1

[0054] The PAN-type T700 (12K) carbon fiber bundles produced by Japan Toray Co., Ltd. (Toray) were used, and the carbon fiber bundles were passed through the liquid furan resin at a wire speed of 20mm / s, dried and cut to obtain a modified 15mm length. carbon fiber. Phenolic resin powder with particle size 99.5%, silicon powder with average particle size of 30nm, short carbon fiber with 15mm and absolute ethanol by mass percentage: 30% carbon fiber, 9% silicon powder, 51% After mixing the phenolic resin and 10% absolute ethanol evenly, put it into a mold designed according to the size of Changfeng CS6 brake disc for automobiles, hot-pressing at a pressure of 2.0Mpa and a temperature of 140°C, and the pressure holding time is 30min. After curing at 120°C for 24h, the density was 1.26g / cm 3 The carbon fiber reinforced blank (CFRP) has 32 cooling channels. The obtained carbon fiber reinforced green body (CFRP) was then carbonized for 38 hours under an argon protective atmosphere...

Embodiment 2

[0058] The PAN-type T700 (12K) carbon fiber bundles produced by Toray Corporation of Japan were used, and the carbon fiber bundles were passed through the liquid phenolic resin at a wire speed of 18mm / s, dried and cut to obtain a modified 25mm length. carbon fiber. Phenolic resin powder with particle size 99.5%, silicon powder with average particle size of 30nm, short carbon fiber with 25mm and absolute ethanol by mass percentage: 36% carbon fiber, 5% silicon powder, 57% After the phenolic resin and 2% absolute ethanol are mixed evenly, they are put into the designed mold, and the pressure is 2.0Mpa and the temperature is 140℃. 1.24g / cm 3 The carbon fiber reinforced blank (CFRP) has 36 cooling channels. The carbon fiber reinforced green body (CFRP) was carbonized for 60h under nitrogen protection, the pressure was 0.1Mpa, and the maximum temperature was 600°C to obtain a C / C porous body; then the C / C porous body was machined to obtain countersunk holes and then put into Imm...

Embodiment 3

[0061] The PAN type XK-24-1 (24K) carbon fiber bundle produced by Dalian Xingke Carbon Fiber Co., Ltd. was used, and the carbon fiber bundle was passed through the liquid resin at a wire speed of 15mm / s, dried and cut to obtain a length of 30mm. Modified carbon fiber, the liquid resin is composed of liquid furan resin and liquid epoxy resin in a mass ratio of 1:1. Asphalt powder with an average particle size of 0.3mm, silicon powder with a purity of ≥99.5%, an average particle size of 50nm, a short carbon fiber of 30mm and anhydrous ethanol by mass percentage: 24% carbon fiber, 7% silicon powder, 65% % asphalt powder and 4% anhydrous ethanol are mixed evenly, then put into the designed mold, hot-pressed under the conditions of pressure of 5.0Mpa and temperature of 100℃, holding time of 20min, and then cured at 180℃ for 22h to obtain the density 1.18g / cm 3 The carbon fiber reinforced blank (CFRP) has 32 cooling channels. The carbon fiber reinforced green body is carbonized fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com