Zeolite film and process for producing zeolite film

A manufacturing method and zeolite membrane technology, applied in separation methods, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve problems such as high separation performance, inability to provide large-scale membranes, and membrane defects, and achieve high separation performance, Yield improvement and defect reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] [2] Preparation of raw material solution (sol)

[0068] Next, a raw material solution having a predetermined composition containing 1-adamantanamine dissolved in ethylenediamine was prepared.

[0069] Since 1-adamantanamine is the SDA (structure-directing agent) in the synthesis of DDR-type zeolite, that is, the substance (structure-directing agent) used as a mold to form the crystal structure of DDR-type zeolite, it is the same as the raw material of DDR-type zeolite. SiO 2 (Silicon dioxide) molar ratio is important. 1-Adamantadine / SiO 2 The molar ratio must be in the range of 0.002~0.5, preferably in the range of 0.002~0.4, more preferably in the range of 0.002~0.3. 1-Adamantadine / SiO 2 If the molar ratio is less than this range, the 1-adamantanamine in SDA will be insufficient, and it will be difficult to form a DDR type zeolite. On the other hand, if it exceeds this range, 1-adamantanamine will be added in more than the necessary amount, which is not preferable...

Embodiment 1~4)

[0086] According to the following (1)-(4), the samples of Examples 1-4 were produced.

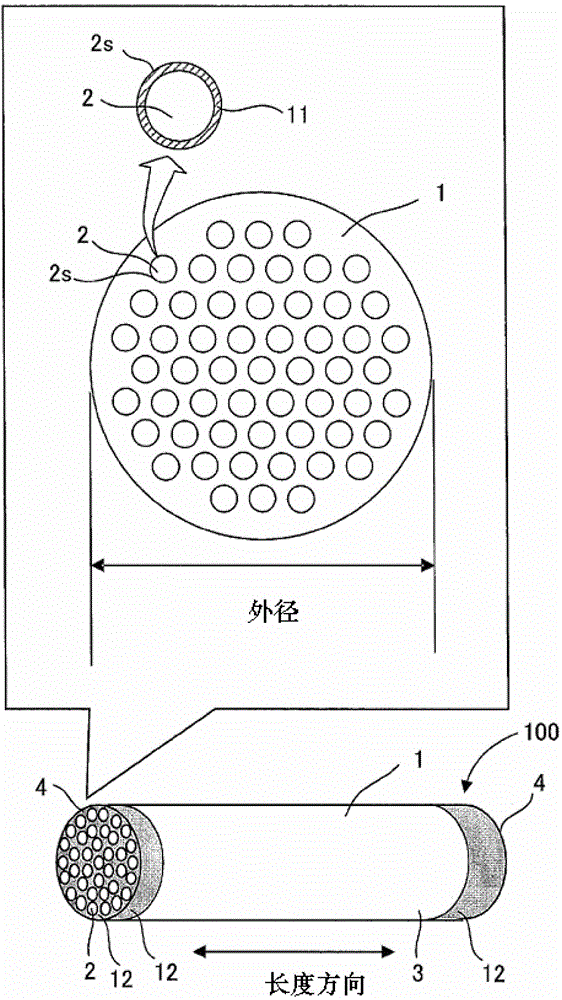

[0087] (1) Introduction of seed crystals (particle attachment process)

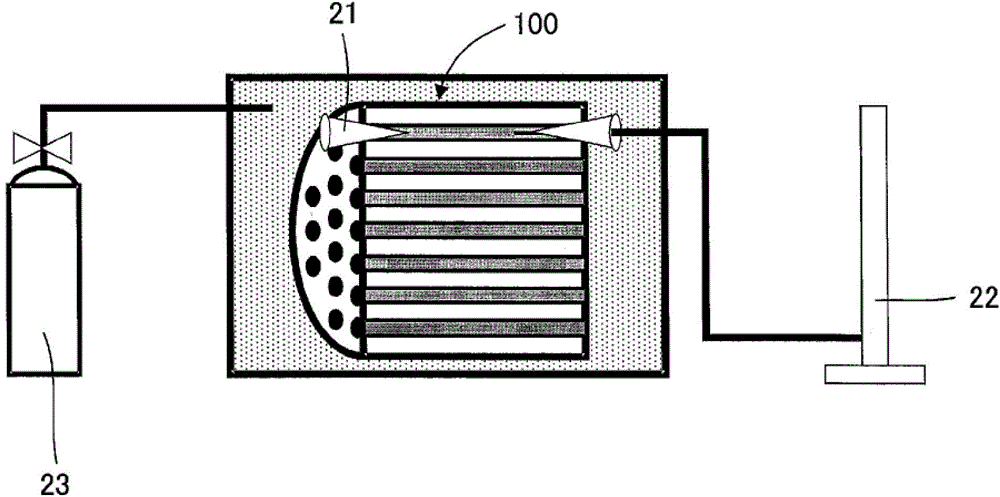

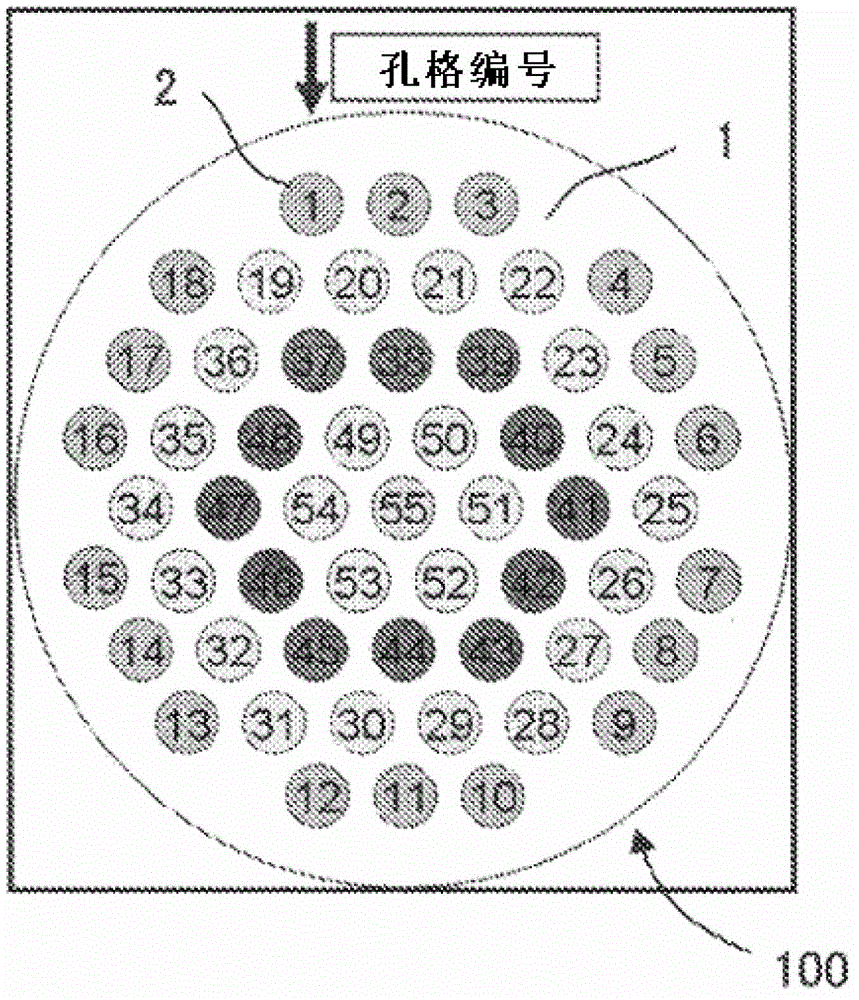

[0088] Dilute the seed crystal dispersion containing DDR-type zeolite particles with a particle size of 0.5 μm or less with ion-exchanged water or ethanol, adjust the seed crystal concentration to 0.001~0.36% by mass, stir with a stirrer at a speed of 300 rpm, and introduce the seed crystal Use a suspension. At the lower end of the wide-mouth funnel 32, a porous monolithic substrate 1 (having a diameter of 55 The outer diameter of the through-hole (well 2) Porous base material with a total length of 160 mm (refer to figure 1 , glass seals at both ends), the hole 2 in the unit area of the end face 4 is 7.8 cells / cm 2 ), so that 160mL of the suspension for seed crystal introduction flows from the upper part of the substrate and passes through the hole 2 (refer to image 3 ). Ventilate and dry the inside of the ...

Embodiment 5、6)

[0096] Using a porous monolithic substrate 1 (having a diameter of 2050 The outer diameter of the through-hole (well 2) Porous base material with a total length of 1000 mm (refer to figure 1 , glass seals at both ends)), according to the same method as in Examples 1-4 to produce Examples 5 and 6. That is, similarly to (1) to (3) above, the zeolite membrane 11 was synthesized by heat-treating (hydrothermal synthesis) at 135° C. for 52 or 62 hours using the ethanol-diluted suspension for introducing seed crystals. The He permeation of the membrane after hydrothermal synthesis is below the detection limit (2 kPa), it was confirmed that the cells 2 of the monolithic substrate 1 were covered with the DDR film. In the structure directing agent removal process of (4), while passing oxygen at 37 L / min, heat at 450°C for 50 hours to burn and remove 1-adamantanamine in the micropores as the structure directing agent. Furthermore, by passing oxygen at 37L / min, the O in the furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com