Low-resistance high-reproducibility PTC over-current protection element

A technology for protecting components and overcurrents, applied in electrical components, resistors and circuits that respond to currents, etc., can solve the problems of abnormal rise and resistance of polymer PTC products, affecting performance, and PTC products getting wet, etc., to improve environmental reliability and performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Preparation of polymer PTC composite sheet:

[0049] The base layer of conductive polymer composite material with positive temperature coefficient of resistance effect is composed of high-density polyethylene and dispersed in the polymer. The volume resistivity is 0.1-100mΩ.cm, and the particle size is:

[0050] 0.1 μm ~ 50 μm conductive filler metal tungsten carbide, the two are mixed in a high-speed mixer in proportion for 30 minutes, and the mixture components are granulated in a twin-screw granulator at a temperature of 180 ° C, cooled, crushed, and then passed through a single After extrusion and calendering by the screw extruder, electrode foils are attached to the upper and lower surfaces of the polymer sheet, and pressed into an area of 400cm 2 , 0.3mm thick polymer composite base layer 5, after heat treatment in a vacuum oven at 120°C for 0.5 hours, use gamma rays (Co 60 ) irradiation with a dose of 16Mrad; after that, a polymer PTC composite sheet was obtai...

Embodiment 1

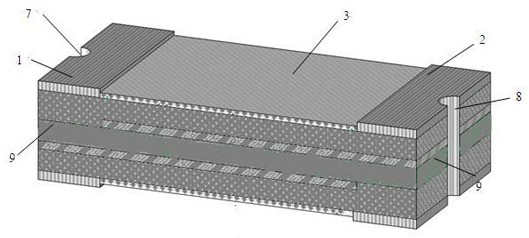

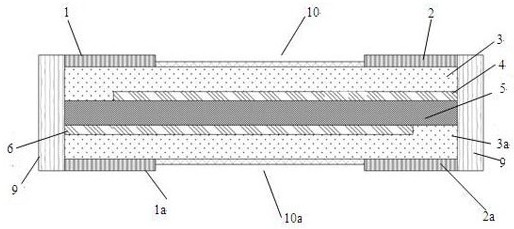

[0052] A low-resistance polymer PTC overcurrent protection component that can effectively increase the environmental reliability of the product. It is made of a surface-mounted polymer PTC overcurrent protection component using printed circuit board technology, including polymer PTC composite sheets and terminal electrodes. , conductive electrodes, insulating layers and conductive vias, where,

[0053] An encapsulation layer or plating layer is added on the side of the overcurrent protection element to isolate the polymer PTC composite sheet from the air, so as to improve the environmental reliability of the overcurrent protection element;

[0054] A polymer PTC composite sheet, composed of first and second conductive electrodes 4, 6 and a polymer composite material base layer 5;

[0055]The polymer PTC composite sheet is etched into insulating grooves on the first conductive electrode 4 and the second conductive electrode 6 respectively through PCB etching processing technolo...

Embodiment 2

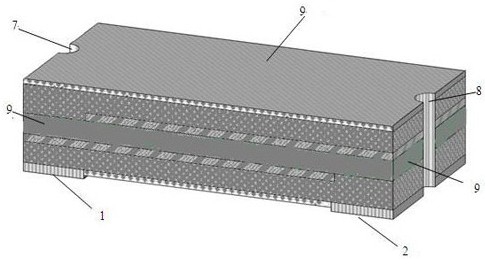

[0058] A low-resistance polymer PTC overcurrent protection element that can effectively increase the environmental reliability of the product is made of a surface-mounted polymer PTC overcurrent protection element using a printed circuit board process, which is similar to Example 1, wherein,

[0059] An encapsulation layer or coating is added to the side and front of the overcurrent protection element to isolate the polymer PTC composite sheet from the air, so as to improve the environmental reliability of the overcurrent protection element;

[0060] A polymer PTC composite sheet, composed of first and second conductive electrodes 4, 6 and a polymer composite material base layer 5;

[0061] The polymer PTC composite sheet is processed by PCB etching technology, so that the first conductive electrode 4 and the second conductive electrode 6 are respectively etched into insulating grooves, and then the upper insulating layer 3 is superimposed on the first conductive electrode 4, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com