Method for realizing stable output of laser device, and laser device system

A stable output and laser technology, applied in the field of lasers, can solve problems such as loss of focus, reduced processing accuracy, and deteriorated processing quality, and achieve the effects of improving reliability, improving output laser stability, and improving environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

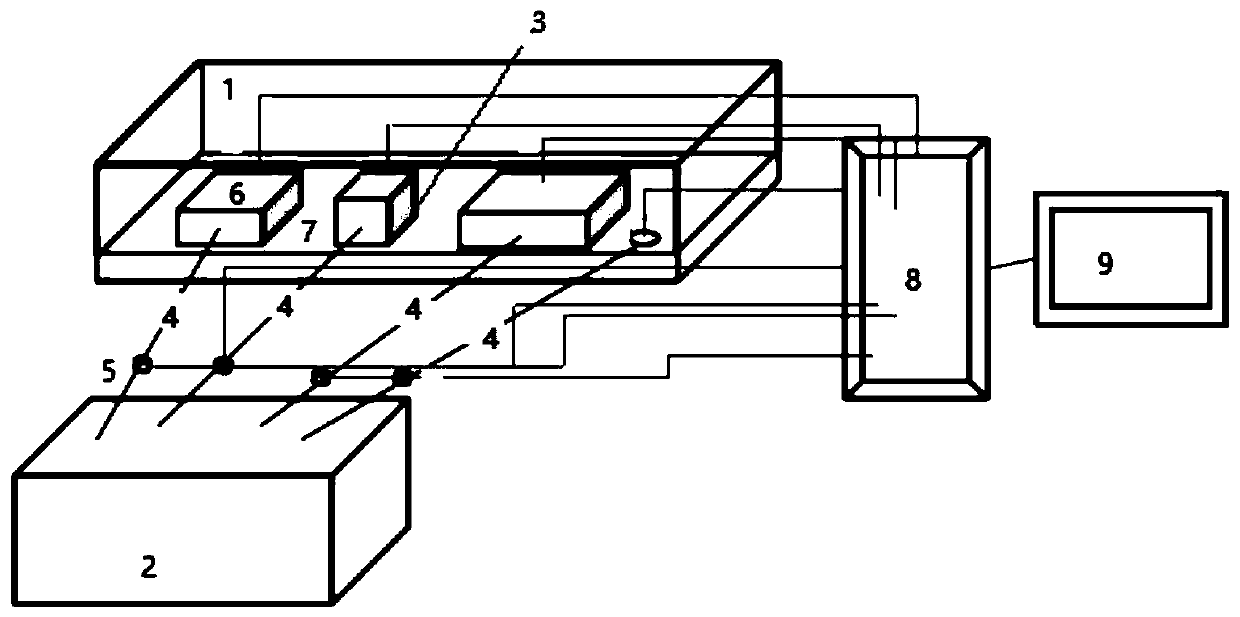

[0080] This embodiment provides a water-cooled solution to further describe the present invention in detail.

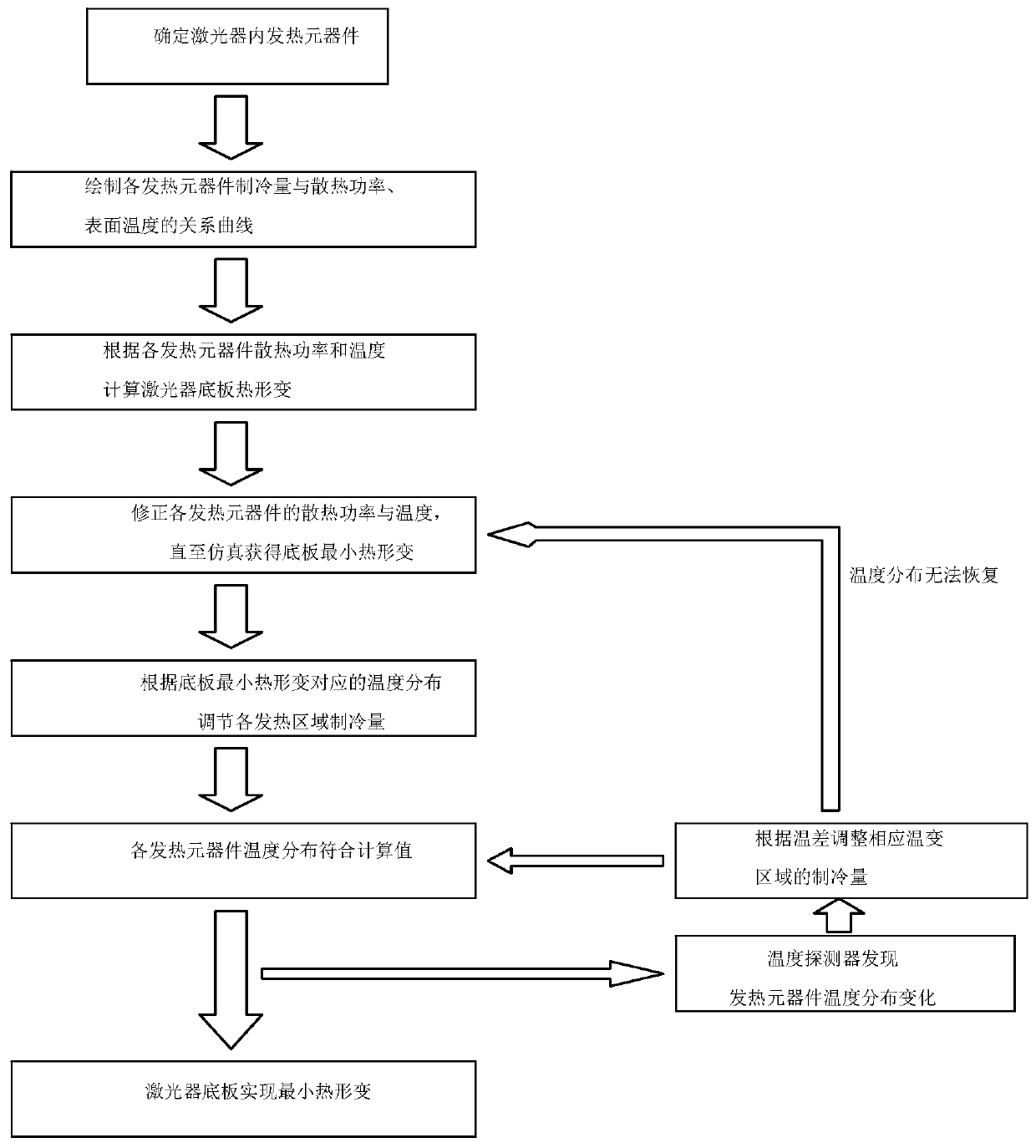

[0081] Step 1: Determine the heating components inside the main body of the laser; the heating components include LD pump modules, laser crystal modules, electro-optic or acousto-optic modulator modules, and various circuit control modules installed on the laser base plate;

[0082] Step 2: Install a water-cooled plate and corresponding flow valve and heat flow meter on each heating component, and unify the water temperature setting of the water cooler;

[0083] Step 3: Make each heating element work at the rated power, and obtain the heat dissipation power of the refrigeration component corresponding to each heating element;

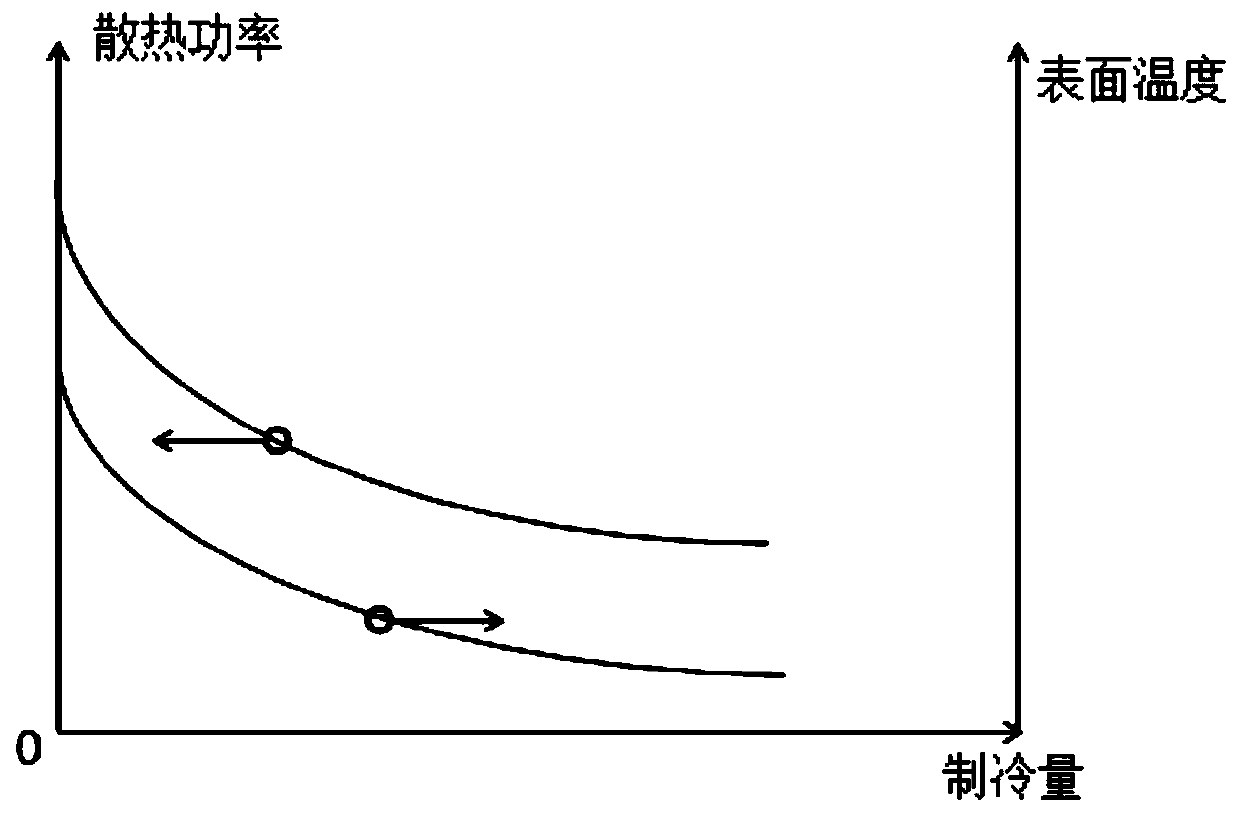

[0084] Step 4: Change the flow setting value of each flow valve separately, and measure the relationship curve between the cooling water flow value of each heating element and the heat dissipation power and surface temperature of the water cool...

Embodiment 2

[0100] This embodiment provides a solution in which the refrigeration component is electric refrigeration to further describe the present invention in detail,

[0101] Step 1: Determine the heating components inside the main body of the laser; the heating components include LD pump modules, laser crystal modules, electro-optic or acousto-optic modulator modules, and various circuit control modules installed on the laser base plate.

[0102] Step 2: Install a semiconductor cooling chip on each heating component, and set a thermostat to control the semiconductor cooling chip;

[0103] Step 3: Make each heating element work under the rated power, and obtain the heat dissipation power of the semiconductor refrigeration sheet corresponding to each heating element;

[0104] Step 4: Change the cooling capacity of each semiconductor cooling chip separately, and measure the relationship curve between the cooling capacity of each heating element and the heat dissipation power and surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com