Method for improving circuitboard welding quality and air knife device therefor

A technology for welding quality and circuit boards, which is applied to cleaning methods and appliances, cleaning methods using gas flow, auxiliary devices, etc. The effect of environmental reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

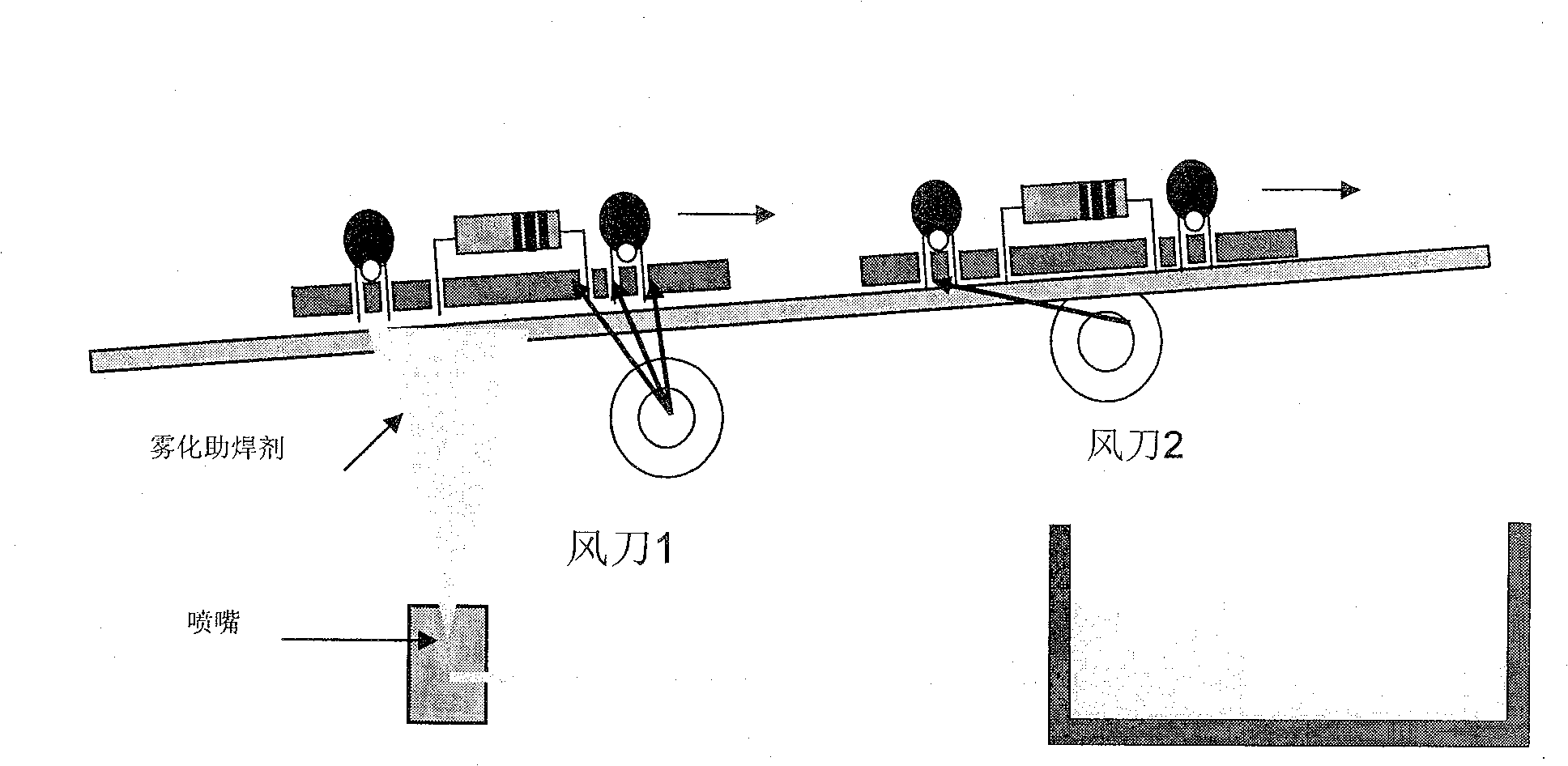

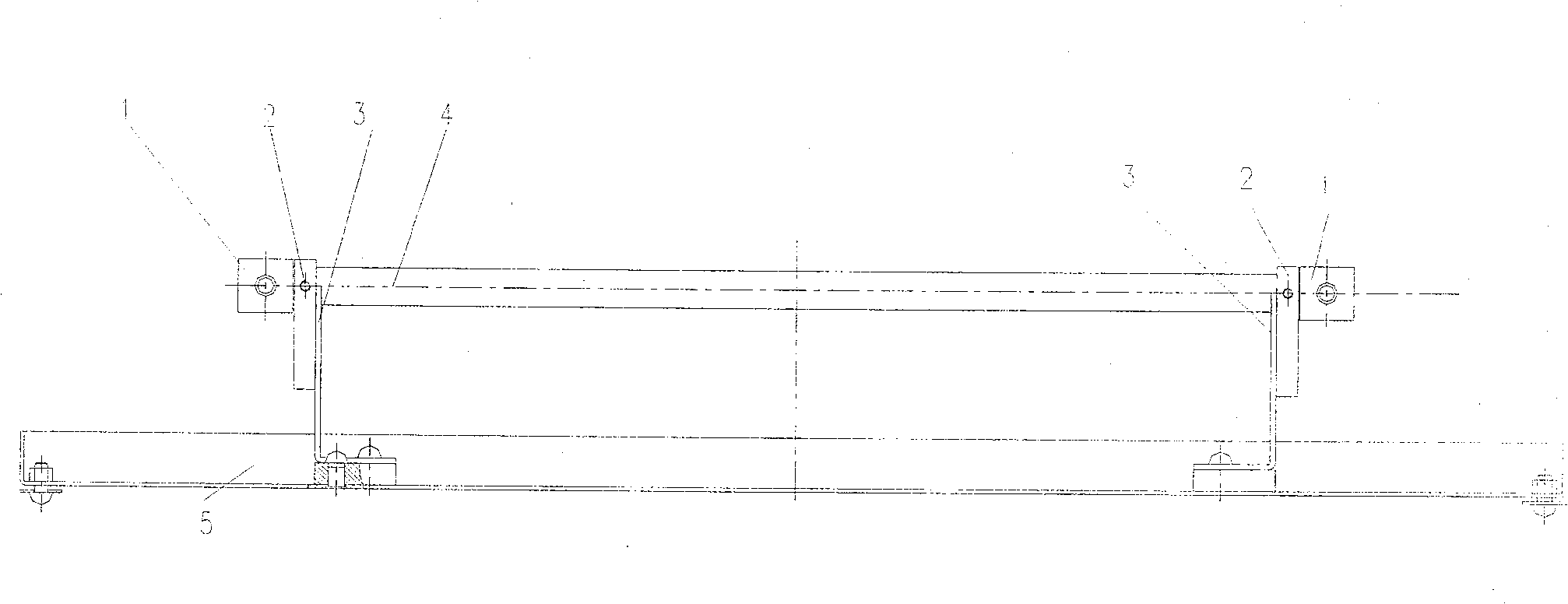

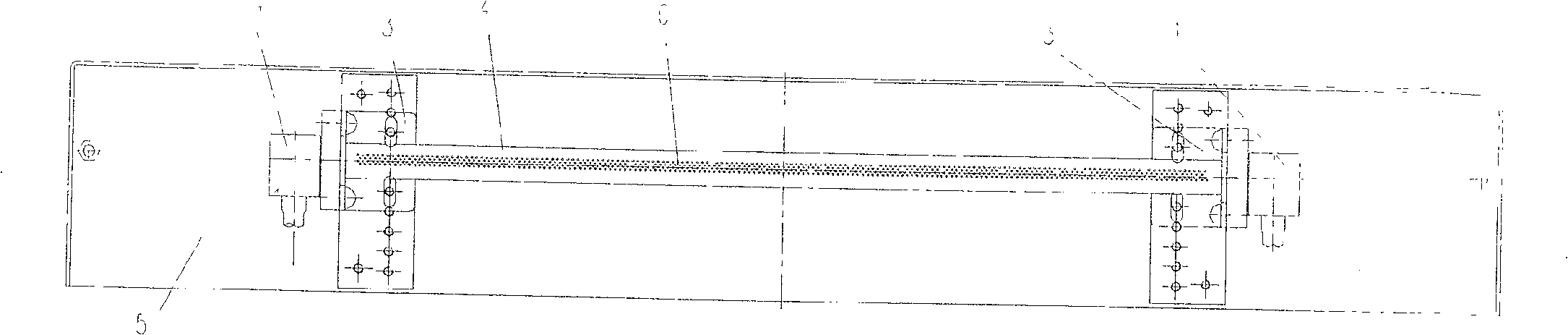

[0027] refer to figure 1 As shown, a circuit board wave soldering method is provided, the method includes the steps of: 1, spraying flux on the circuit board; 2, blowing the flux sprayed on the lower surface of the circuit board into the through hole in the circuit board, To increase the amount of flux coating in the through hole and flush the OSP coating on the hole wall, improve the solderability of the hole wall, and improve the tin penetration ability of through hole welding; 3. The flux sprayed on the solder mask on the lower surface of the circuit board Remove it, reduce the ion residue after the circuit board is soldered, and improve the environmental reliability of the circuit board; 4. Preheat the circuit board; 5. Solder the circuit board through a wave soldering machine to complete the welding process.

[0028] In the above circuit board wave soldering method, in the step of blowing the flux sprayed on the lower surface of the circuit board into the through hole of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com