A kind of production method of electrical grade magnesium oxide powder

A technology of magnesium oxide powder and production method, which is applied in the direction of metal oxides, circuits, electrical components, etc., can solve the problems of high moisture absorption rate and hydration rate, leakage, and serious problems of electrical grade magnesium oxide, so as to improve the moisture-proof effect and prevent leakage Effect of current reduction and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

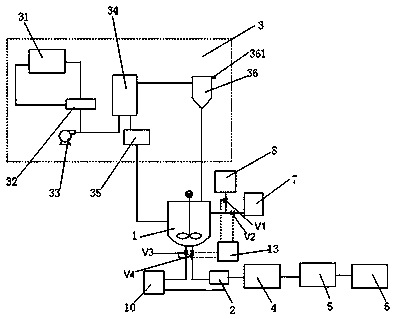

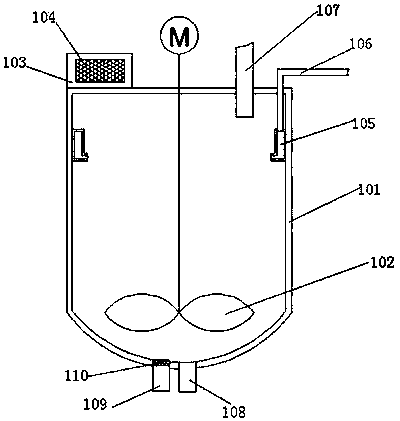

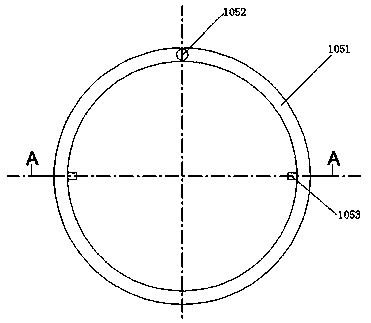

Method used

Image

Examples

preparation example Construction

[0060] According to an embodiment of the present invention, the preparation method of the inorganic filler includes: crushing the serpentine and kaolin separately, sieving to make a 40-325 mesh powder, mixing according to the ratio of 1:2, and then placing it in a box-type high-temperature furnace Roast at 900°C for 3 hours, then cool to room temperature after coming out of the furnace, and it will be an inorganic filler;

[0061] According to another embodiment of the present invention, the preparation method of the inorganic filler comprises: first placing the serpentine in a ladle, heating it with a three-phase electric arc, melting it at 1950-2150°C, and keeping it warm for 3-5 hours, After natural cooling, it is separated and crushed, and then mixed with calcined kaolin to prepare inorganic fillers. In the molten state, the layered crystal structure in the serpentine is changed, so that after the melt is cooled, the Fe element in the serpentine can be removed quickly and ...

Embodiment 1

[0097] A production method of electrical grade magnesium oxide powder: comprising the following steps:

[0098] (1) Pulverize the fused magnesium block, and sieve it into magnesium oxide powder with a particle size of 40-325 mesh;

[0099] (2) Step (1) magnesium oxide powder and sodium hydroxide solution (concentration is 10.0mol / L) are 600 with mass volume ratio (g / L), drop in alkali washing-washing still 1 and carry out alkali washing, pre-normal temperature Wash with alkali for 50 minutes, filter the alkali washing solution to obtain a precipitate, and wash the precipitate with water several times until the pH value is 6.9;

[0100] (3) drying the magnesium oxide powder obtained in step (2) in a rotary furnace at 400-500° C. for 45 minutes;

[0101] (4) Pulverize the inorganic filler, sieve to make 40-325 mesh powder, mix the magnesium oxide powder obtained in step (3) and the inorganic filler in a weight ratio of 100:1, and stir the mixture in a mixer for 15 minutes Amon...

Embodiment 2

[0106] A production method of electrical grade magnesium oxide powder: comprising the following steps:

[0107] (1) Pulverize the fused magnesium block, and sieve it into magnesium oxide powder with a particle size of 40-325 mesh;

[0108] (2) Step (1) magnesium oxide powder and sodium hydroxide solution (concentration is 6.0mol / L) are 900 with mass volume ratio (g / L), drop into alkali washing-washing still 1 and carry out alkali washing, pre-normal temperature Wash with alkali for 40 minutes, filter the alkali washing solution to obtain a precipitate, and wash the precipitate with water several times until the pH value is 7.3;

[0109] (3) drying the magnesium oxide powder obtained in step (2) in a rotary furnace at 400-500° C. for 30 minutes;

[0110] (4) Pulverize the inorganic filler, sieve to make 40-325 mesh powder, mix the magnesium oxide powder obtained in step (3) and the inorganic filler in a weight ratio of 100:1.5, and stir the mixture in a mixer for 20 minutes A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com