Patents

Literature

75results about How to "Reduce spray volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

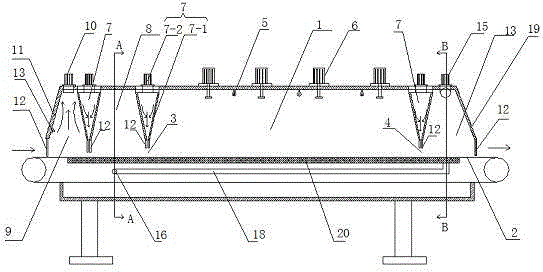

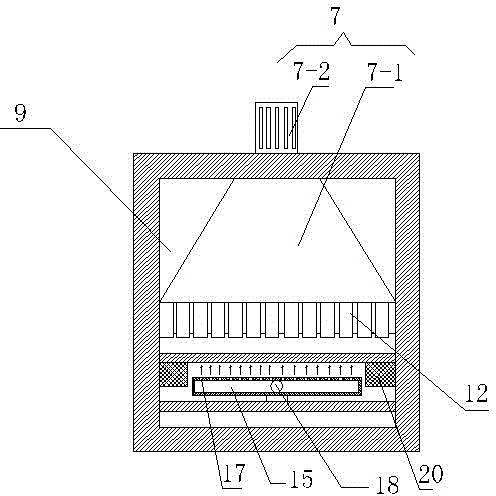

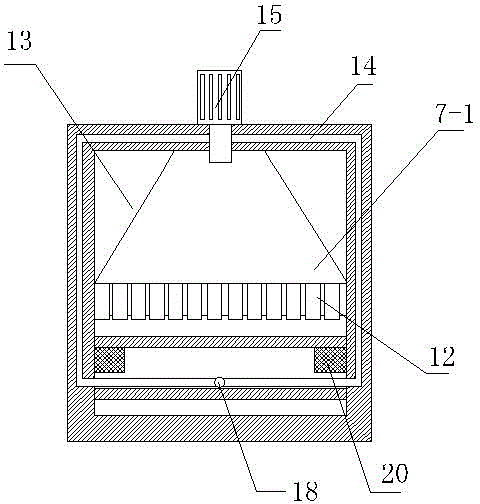

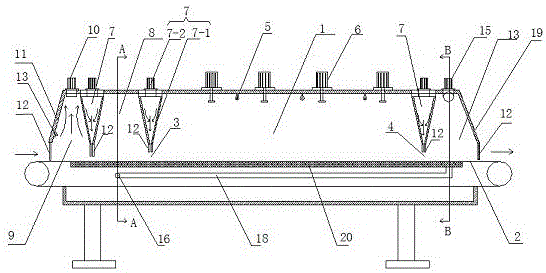

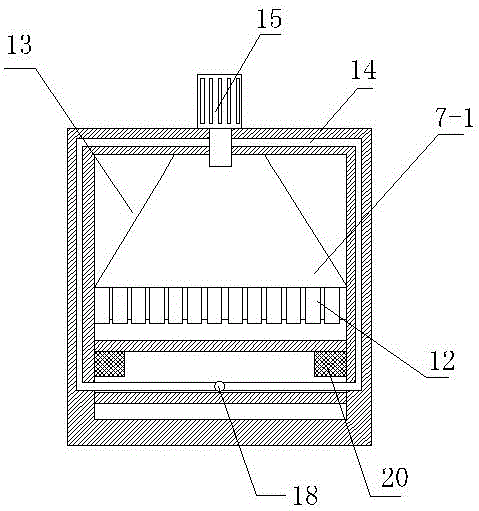

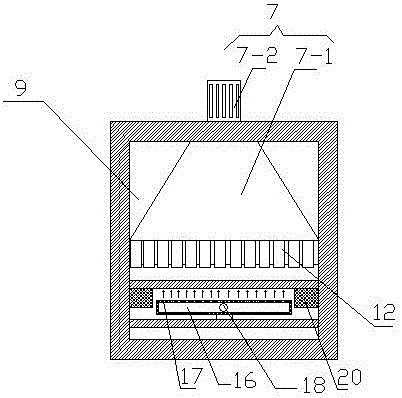

Self-prefreezing liquid nitrogen tunnel quick freezer

ActiveCN104697263AReduce spray volumeReduce usageLighting and heating apparatusCooling fluid circulationFreezing chamberMechanical engineering

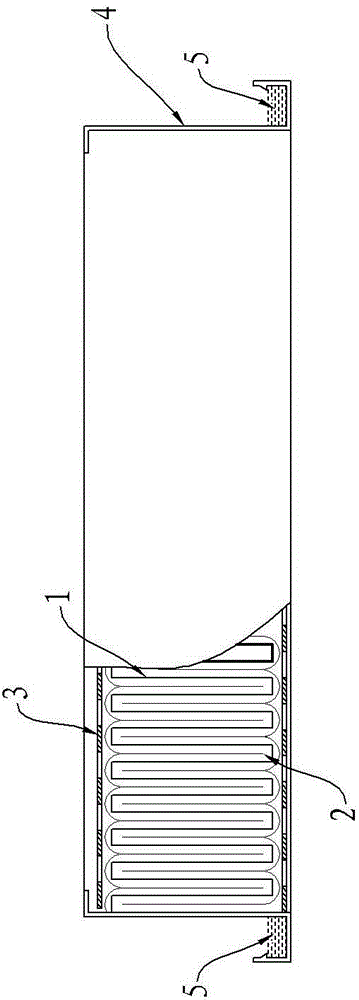

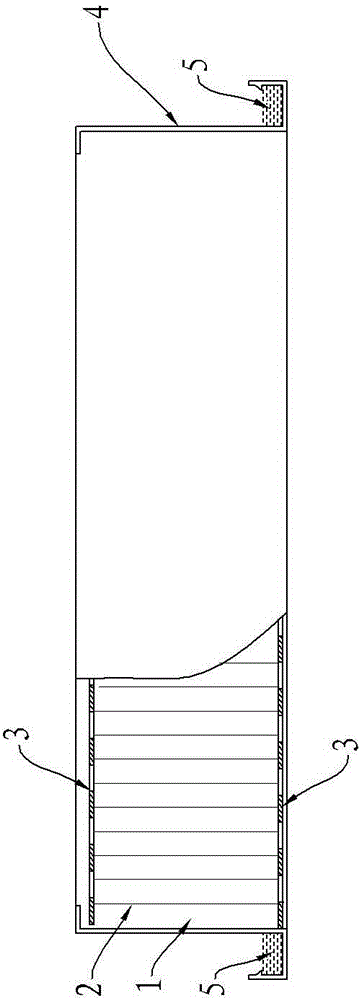

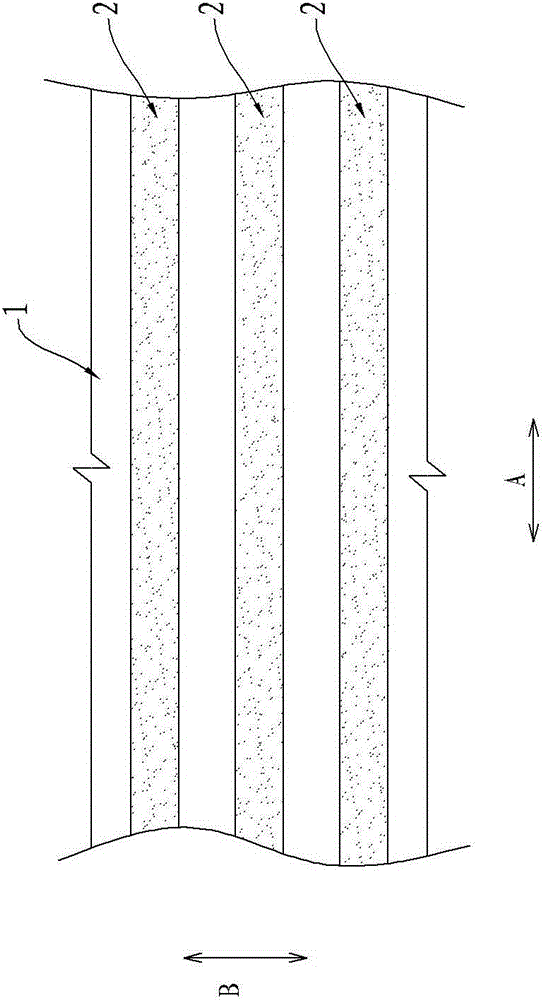

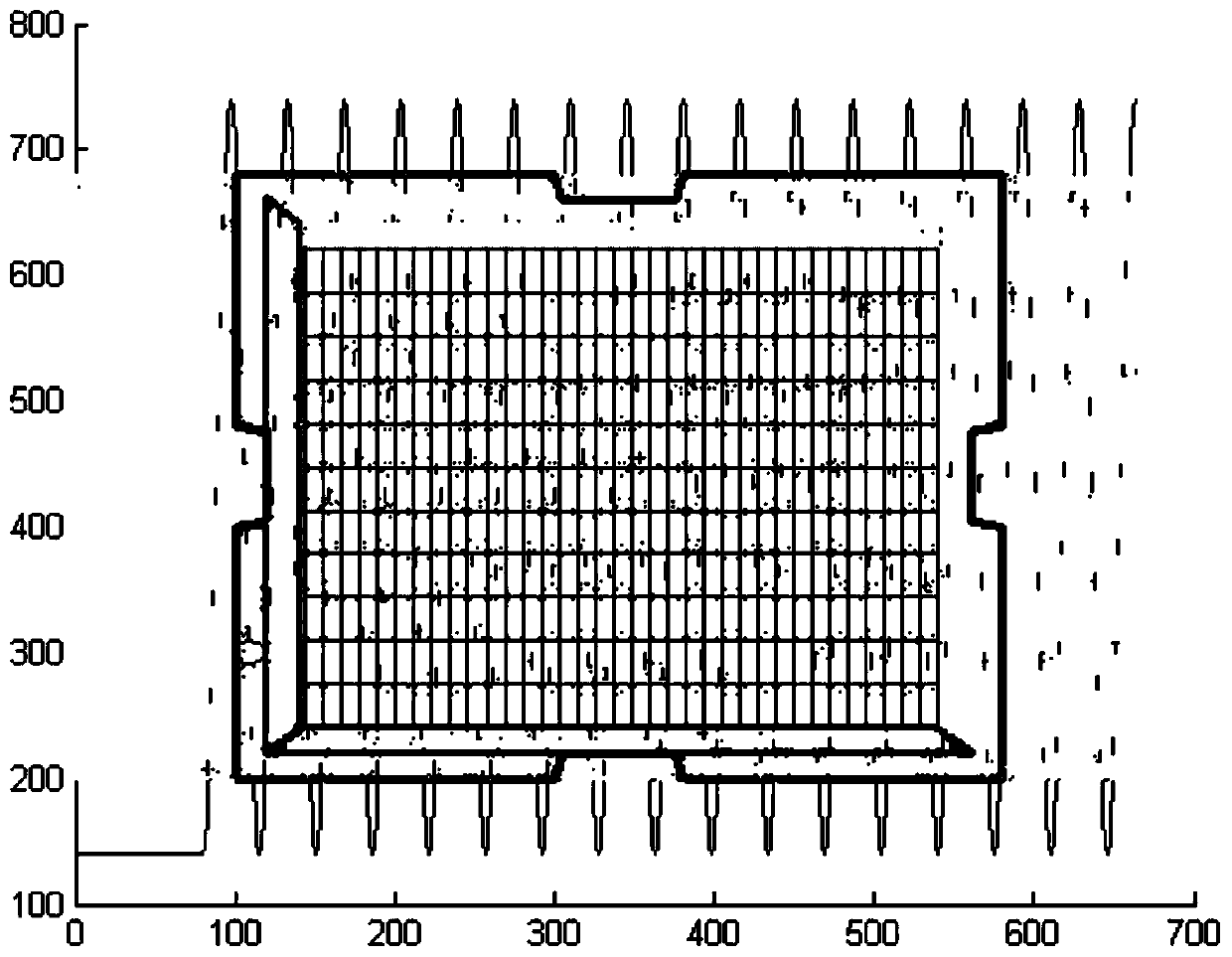

The invention relates to a quick freezer. In order to solve the technical problem of the waste of the liquid nitrogen in the prior art, the invention provides a self-prefreezing liquid nitrogen tunnel quick freezer. The self-prefreezing liquid nitrogen tunnel quick freezer comprises a tunnel freezing chamber and a surrounding type conveying belt, wherein liquid nitrogen sealing devices are arranged at the feeding end and the discharging end of the freezing chamber respectively; the quick freezer is characterized in that a prefreezing chamber is formed in the exterior of the feeding end of the freezing chamber; the chamber wall of the prefreezing chamber is fixedly connected to the chamber wall of the feeding end of the freezing chamber; the liquid nitrogen sealing device is arranged at an end opening of the outer side of the prefreezing chamber; the conveying belt penetrates through the prefreezing chamber; the side end of the conveying belt stretches out of the exterior of the prefreezing chamber. The self-prefreezing liquid nitrogen tunnel quick freezer is reasonable in structure, simple and convenient to operate and high in quick freezing efficiency; the production cost can be effectively reduced; the self-prefreezing liquid nitrogen tunnel quick freezer has a wide market prospect.

Owner:荣成市同福机械制造有限公司

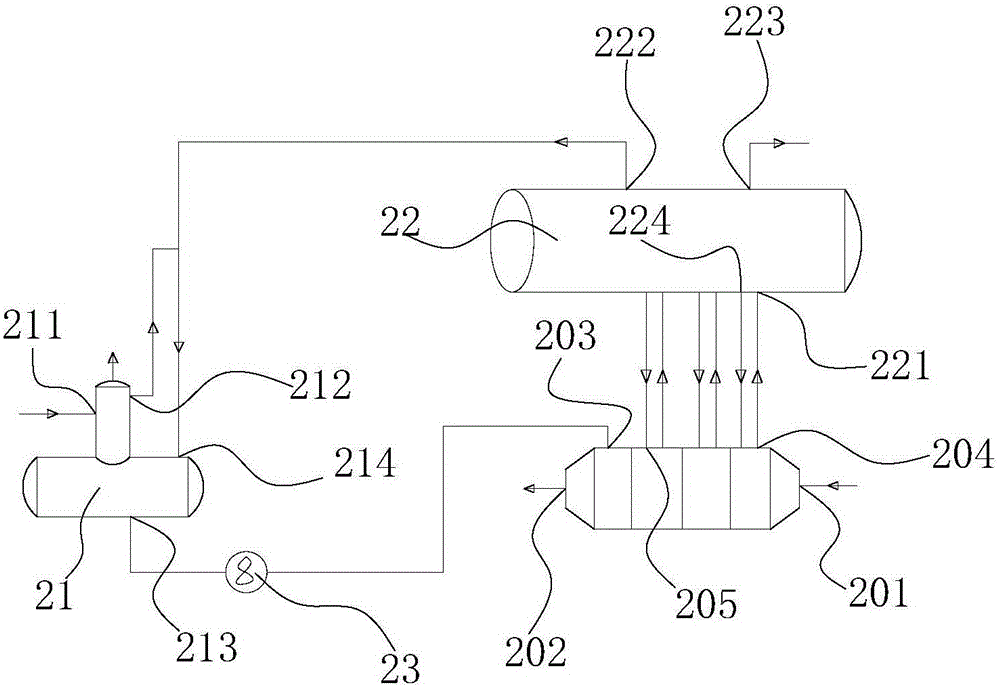

Titanium dioxide production process calcining tail gas processing method

ActiveCN105561721AHigh utilization rate of waste heat recoveryReduce consumptionCombination devicesGas treatmentProduction lineUtilization rate

The present invention discloses a titanium dioxide production process calcining tail gas processing method comprising the following steps: 1) dust removal; 2) preliminary heat exchange, to be more specific, calcining tail gas after the dust removal is discharged into a waste heat boiler system for heat exchange with process water, and the calcining tail gas is preliminarily calcined; 3) further heat exchange, to be more specific, the preliminarily-calcined calcining tail gas enters a venturi system and further cooled by spraying with spent sulfuric acid; and 4) desulfurization. According to the titanium dioxide production process calcining tail gas processing method, waste heat boiler system with high heat recovery utilization rate is used, and by step-by-step heat exchange, heat can be efficiently recovered from the calcining tail gas, and can be used for other processes in a titanium dioxide production line, energy and water consumption can be greatly saved, and by the desulfurization, desulfurization rate of the calcining tail gas is significantly increased.

Owner:SHANGHAI TITANOS IND

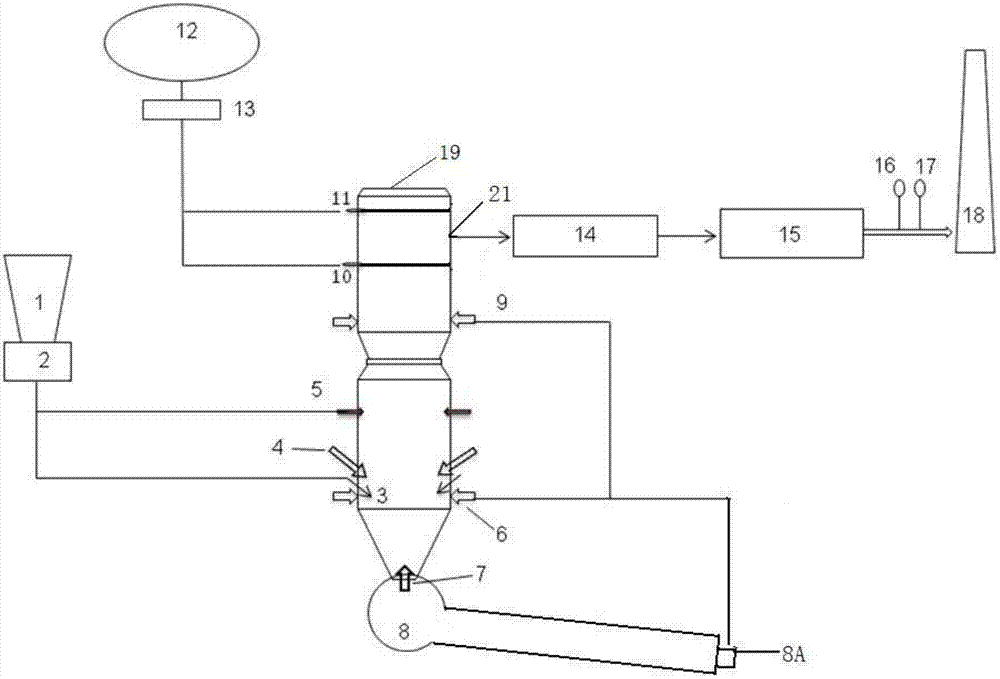

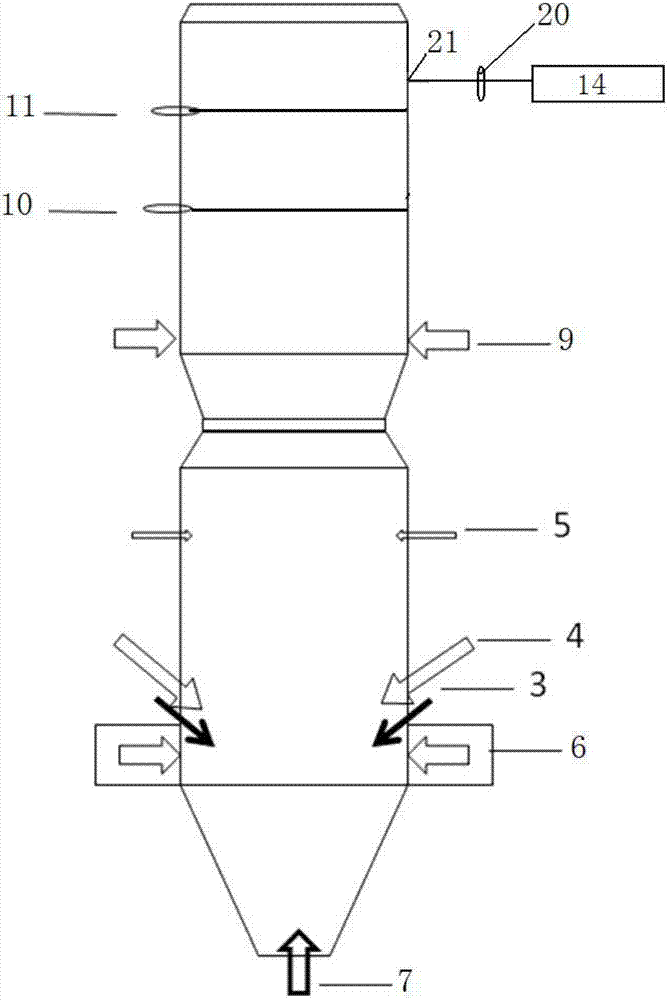

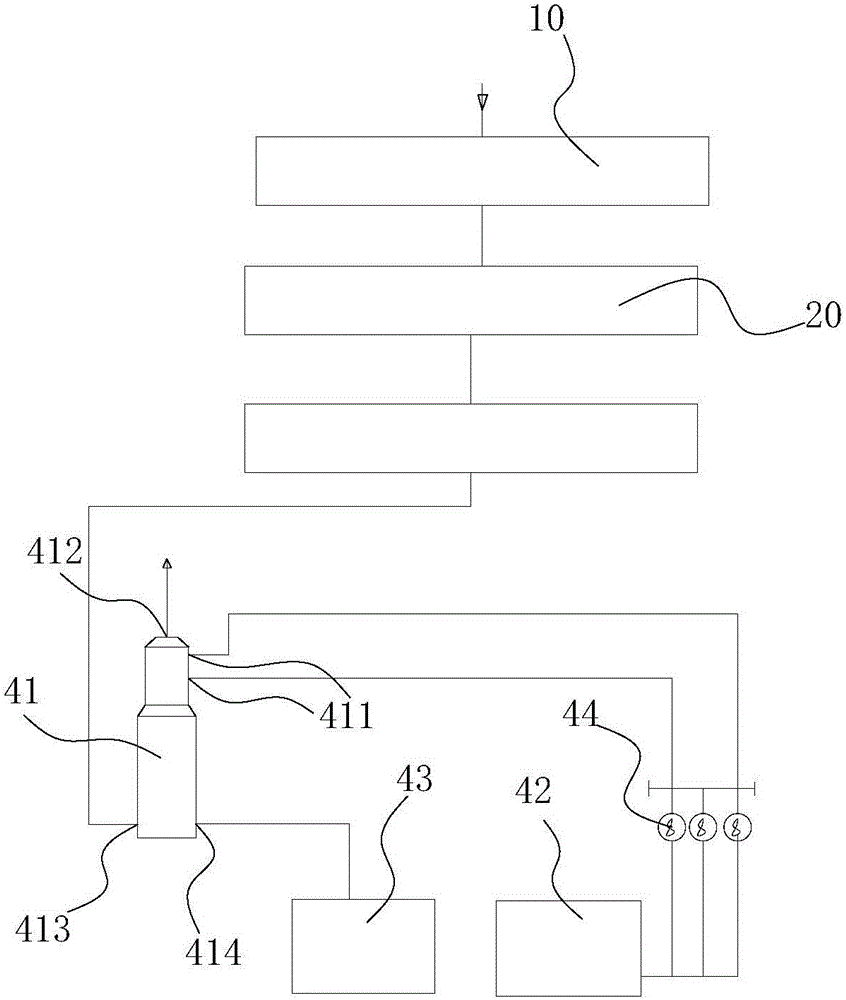

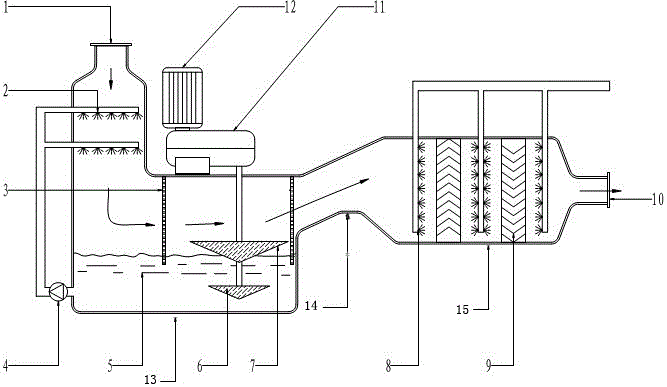

Efficient reburning denitrification device and technical method

ActiveCN103206865AImprove removal efficiencyMeet emission standardsIncreasing energy efficiencyWaste heat treatmentWater storage tankEngineering

The invention discloses an efficient reburning denitrification device which comprises a decomposing furnace. The bottom of the decomposing furnace is provided with a secondary air inlet and is connected with a rotary cement kiln. The decomposing furnace comprises a main low-nitrogen burner and a reburning burner on the lower portion from bottom to top, and a raw material inlet is arranged at the position of the main low-nitrogen burner. Coal powder in a coal powder bunker enters the decomposing furnace from the main low-nitrogen burner and the reburning burner. A tertiary air inlet is arranged below the raw material inlet and connected with a cooler of the rotary cement kiln. The decomposing furnace comprises an overfire air inlet and an SNCR (selective non-catalytic reduction) spray gun on the upper portion from bottom to top. The overfire air inlet is connected with the tertiary air inlet and the cooler of the rotary cement kiln. The SNCR spray gun is connected with a centrifugal pump and an ammonia water storage tank device. A smoke outlet is arranged at the upper section of the decomposing furnace and connected with a cyclone preheater, an electric dust collector and a chimney. The invention further provides a technical reburning denitrification method by the efficient reburning denitrification device. By the efficient reburning denitrification device and the technical reburning denitrification method, NOx removal efficiency can be improved, sprayed ammonia water is reduced, and denitrification cost of cement enterprises is lowered.

Owner:上海三融环保工程有限公司

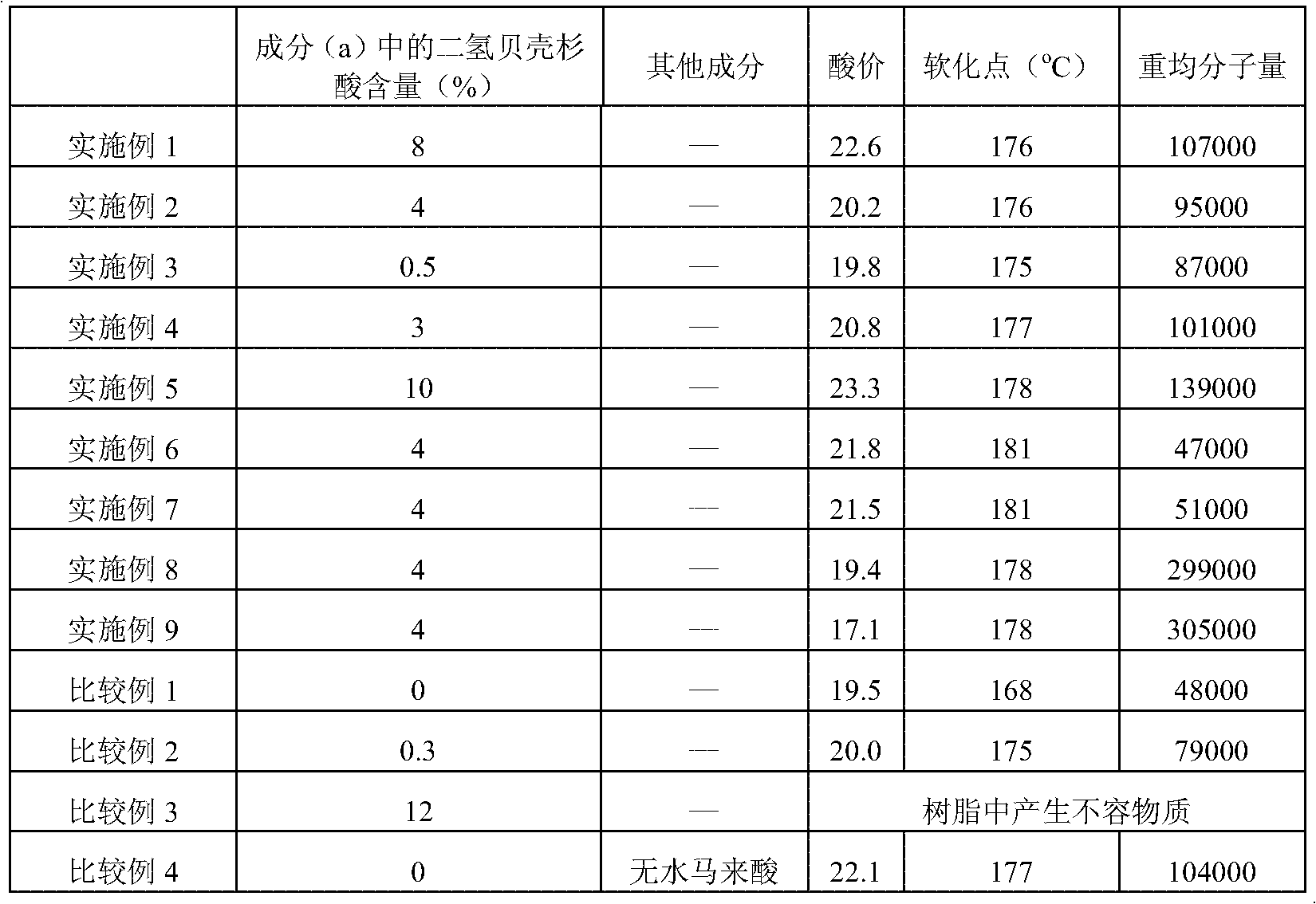

Rosin-modified phenol resin, manufacturing method thereof, and printing ink

A rosin-modified phenol resin is obtained by reacting (a) rosins containing 0.4-10% of dihydroagathic acid, (b) a condensation product of phenols and formaldehyde, and (c) a polyol. The rosin-modified phenol resin is suitable for printing ink applications, and the amount of printing ink mist can be reduced without the luster of the printed material being diminished while maintaining various ink capabilities (drying properties, emulsifying properties, etc.).

Owner:ARAKAWA CHEM IND LTD

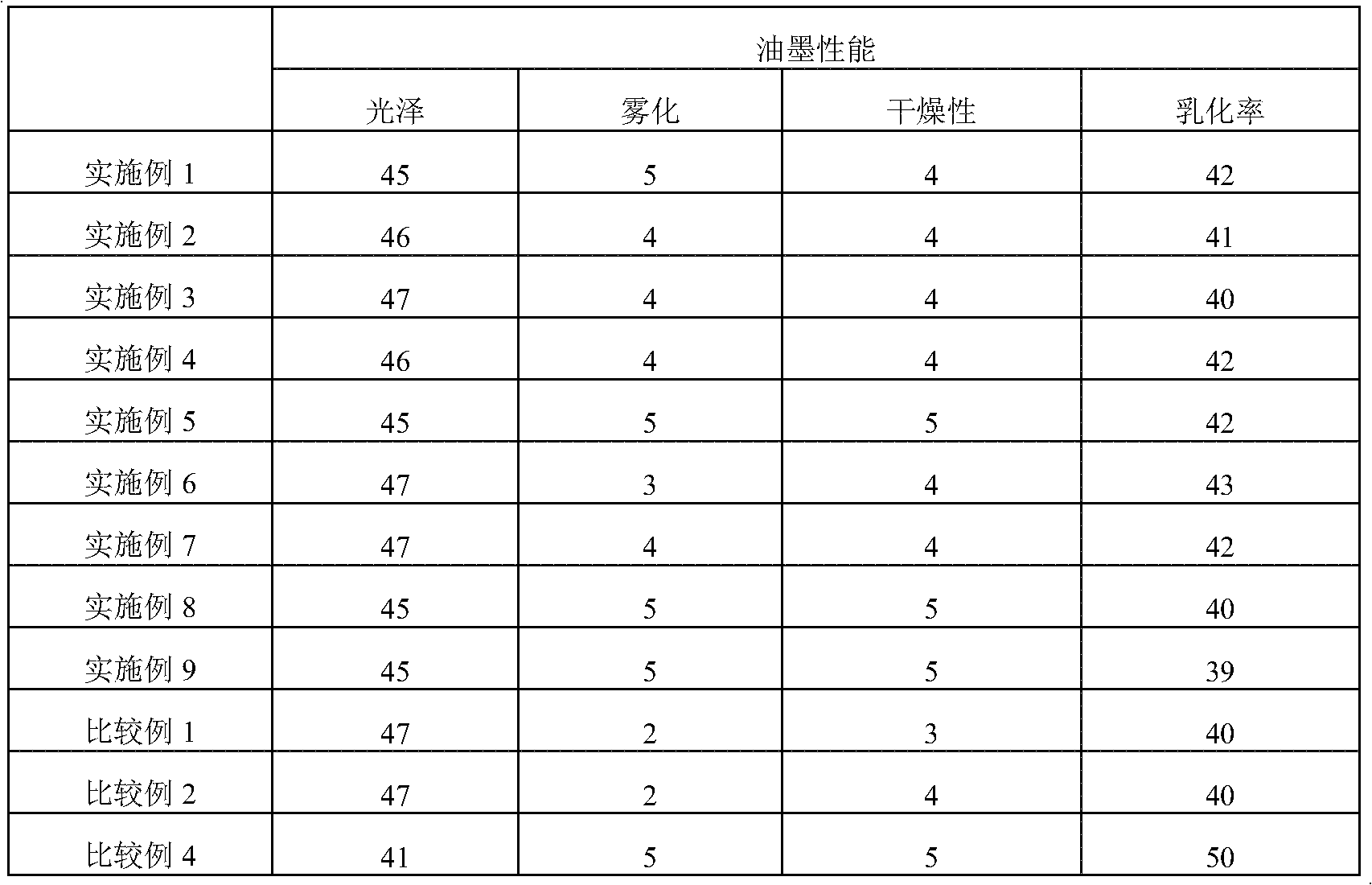

Household waste incineration fly ash cyclic utilization method

ActiveCN108273825AFlexible control of the amount of fly ashContinuous industrial productionSolid waste disposalTransportation and packagingPrillPhosphate

The invention relates to a household waste incineration fly ash cyclic utilization method. A flow distributing device is installed at the lower end of a dust remover of a waste incineration smoke treatment system and controls the amount of fly ash circularly entering a non-medium grinding machine, and therefore the phenomenon that since the fly ash agglomerates at a grinding medium or adheres to the inner wall of the grinding machine, the grinding effect is influenced is avoided. After the fly ash is smashed in a grinding bin, a high-pressure centrifugal fan brings the grinded powder materialsinto a powder selecting machine, fine powder meeting the fineness requirement enters a circulatory system along with airflow, and coarse particle materials incapable of meeting the fineness requirement return to the grinding bin to continue to be grinded. It is guaranteed that the particle sizes of the grinded fine powder are uniform and kept within a certain range, unreacted calcium hydroxide isfully exposed, the specific surface area of the fly ash is increased, the utilization rate of the calcium hydroxide in the fly ash can be improved to be 80% or over, and continuous industrial production can be achieved. Meanwhile, phosphate is fed into the non-medium grinding machine so as to pre-stabilize heavy metal and reduce the application amount of follow-up deacidification agents, and thephosphate also has the grinding assistance function. A strong oxidant is added and achieves the desulfurization and denitration function and the function of promoting dioxin to decompose.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

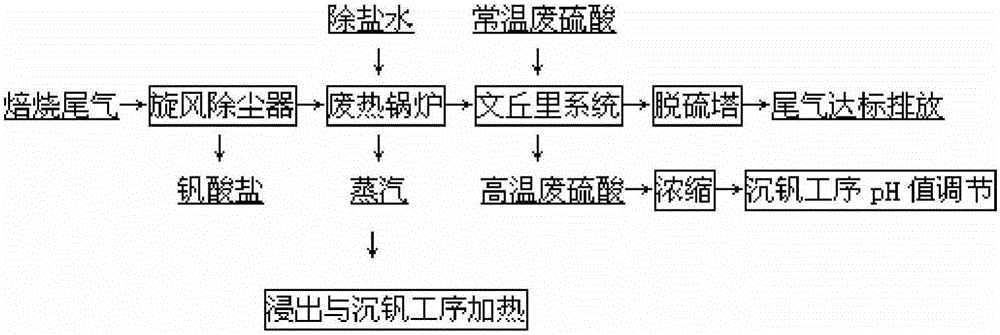

Treating method for vanadium slag roasting tail gas

InactiveCN105727727AReduce coal consumptionImprove waste heat utilization efficiencyGas treatmentDispersed particle separationSlagSulfide

The invention belongs to the field of production of vanadium pentoxide, and particularly relates to a treating method for tail gas produced after vanadium slat is roasted through a rotary kiln. The method comprises the following steps that a, vanadium slag roasting tail gas enters a dust removal system and is separated to obtain vanadate and tail gas I, wherein the vanadate is transferred into a pulping groove; b, the tail gas I enters a waste heat boiler system and exchanges heat with process water supplied externally to be cooled, tail gas II is obtained, and the process water is changed into saturated vapor to be supplied externally; c, the tail gas II enters a Venturi system to be cooled further, and tail gas III is obtained; d, the tail gas III enters a desulfurizing tower from the bottom and makes countercurrent contact with alkali liquor sprayed on the top, defogging is carried out, up-to-standard emission is carried out, and the alkali liquor enters a sewage treating system. By means of the method, the vanadium pentoxide rotary kiln roasting tail gas waste heat utilization rate can be improved, sulfide in the roasting gas can be discharged on standard completely, and therefore a new technological process of clean production of a vanadium pentoxide roasting tail gas system is achieved.

Owner:PANZHIHUA UNIV

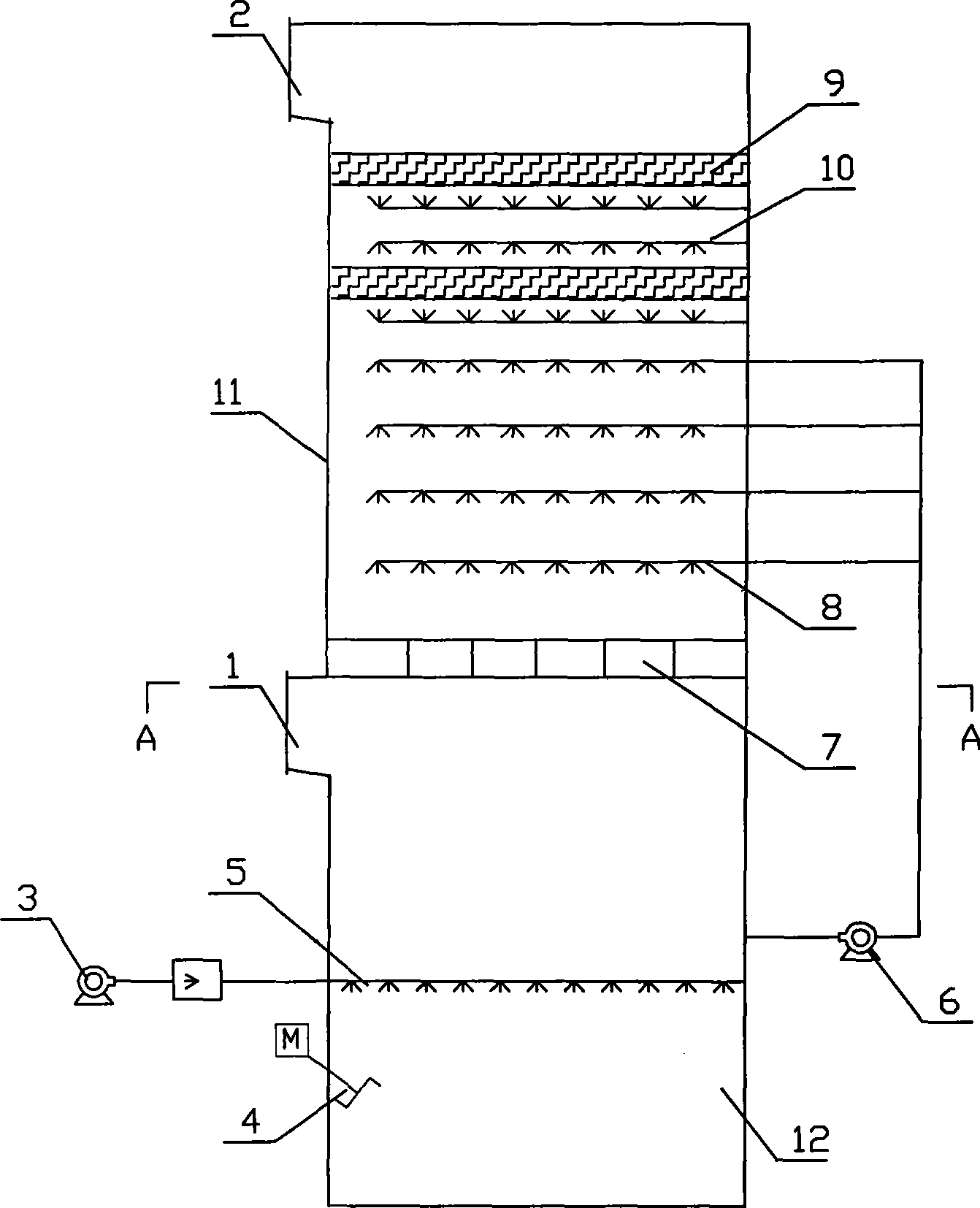

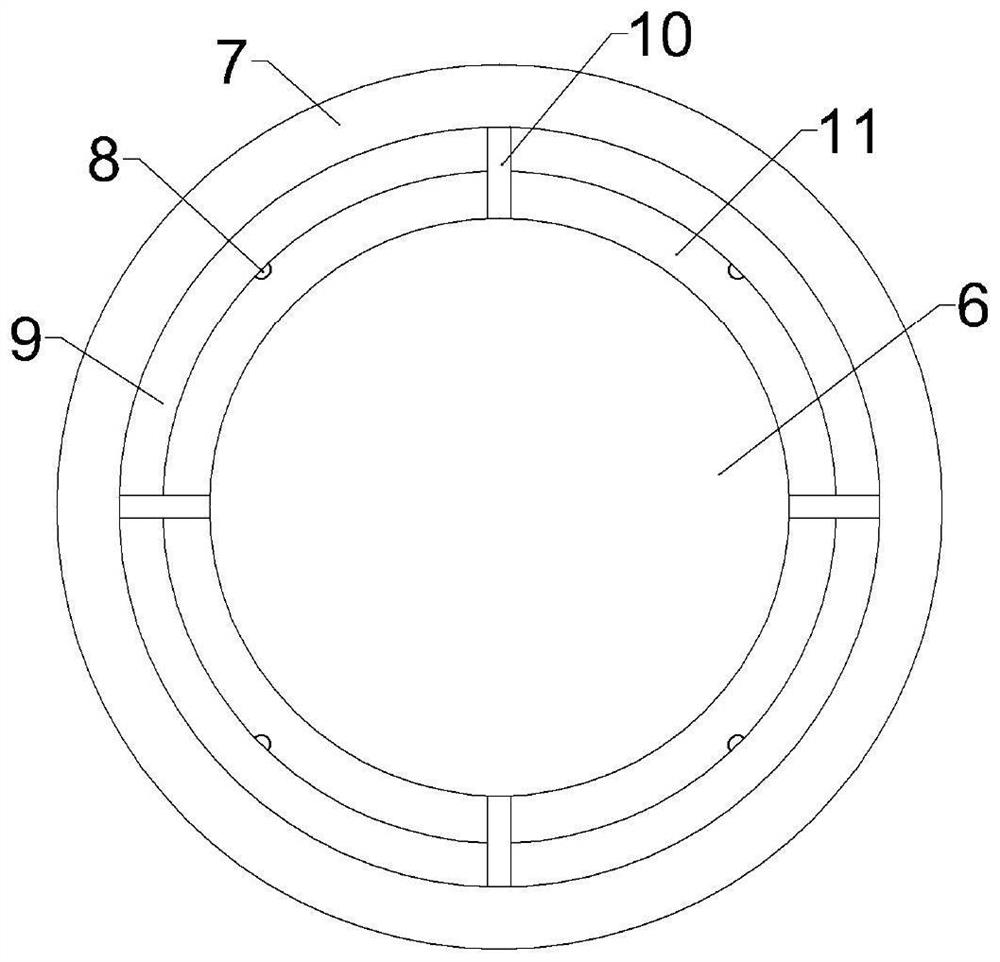

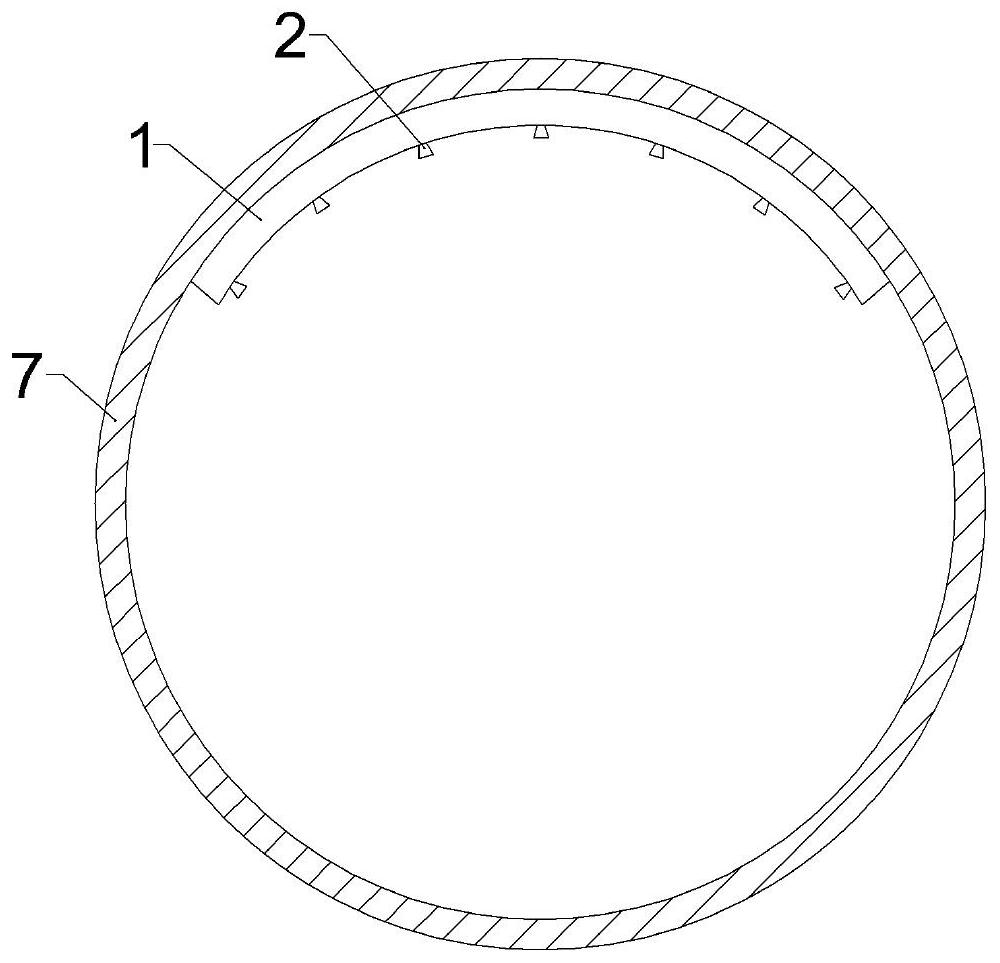

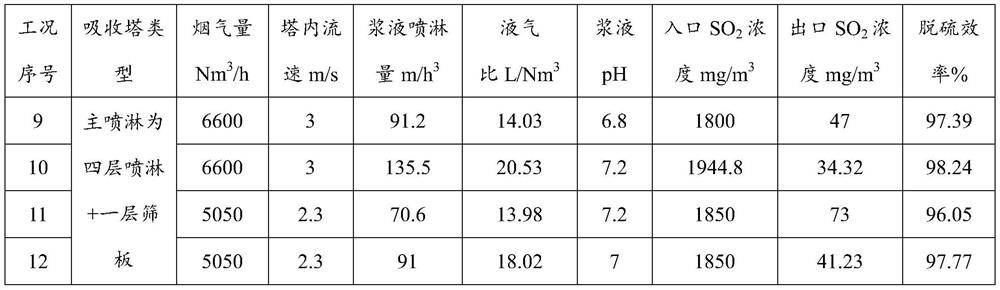

Rectifying desulphurization system

InactiveCN101474535AImprove mass transfer effectReduce spray volumeDispersed particle separationFlue gasProcess engineering

The invention provides a rectification desulphurization system. The interior of an absorption tower of the system has uniform flue gas distribution, good gas-liquid mass transferring effect and higher desulphurization effect. The rectification desulphurization system comprises a tower body of the absorption tower. The lower part of the tower body of the absorption tower is provided with a stock tank, the middle part is provided with a flue gas inlet, and the upper part is provided with a flue gas outlet. The tower body of the absorption tower is internally and sequentially provided with a grout spraying system and a defogging system from the flue gas inlet through the flue gas outlet. A rectification device is arranged between the flue gas inlet and the grout spraying system. Compared with the prior art, the system has the following advantages that the system is provided with the rectification device, which causes that the interior of the tower has uniform flue gas distribution, good gas-liquid mass transferring effect; the height of the absorption can be lowered; the quantity of spaying layers and the spraying amount of grout is reduced; the power consumption of a grout circulation pump is reduced; based on the power consumption reduction, the higher desulphurization efficiency is realized.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

Comprehensive control method for dragon fruit canker

The invention discloses a comprehensive control method for a dragon fruit canker, and belongs to the technical field of plant protection and fruit culture. The method comprises the steps that for a newly-built orchard, the disease-free nursery stock and disease-resistant variety are selected to be cultivated; a bactericide is sprayed in spring in the morbidity orchard to restrain germination of pathogen spores; summer is the key control period, the phenomenon that pathogenic bacteria circularly infect a medium is reduced by cut off novel tender branches in time, and bactericide is sprayed; clipping, orchard cleaning and medicament spraying are performed in time in autumn and winter, and a pathogenic spore hibernacle is removed. All medicaments are organic silicone additives, the medicaments are promoted to extension and absorption on the surfaces of branches, and the control effect is enhanced. By implementing the comprehensive control method for the dragon fruit canker, damage to the canker can be completely controlled for the morbidity orchard, and the good prevention effect can be achieved for a non-attacked orchard.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

Herbicide composition

InactiveUS7060659B2Reduce spray volumeGood curative effectBiocideDead animal preservationChemical MoietySurface-active agents

There is provided an essentially non-aqueous homogeneous liquid herbicide composition comprising: a) a lipophilic solvent soluble complex comprising the reaction product of: i) not in excess of about 35% by weight of one or more lipophobic herbicides having an acidic moiety; and ii) not in excess of about 99% by weight of one or more tertiary dimethylamines of the structure (CH3)2N—R wherein R contains an alkyl group of at least 8 carbon atoms and may contain other chemical moieties and wherein is at least one mole equivalent of such amine to each mole of lipophobic herbicide; b) not in excess of about 60% by weight of one or more essentially non-aqueous polar solvents having low volatility; c) not in excess of about 90% by weight of one or more additional solvents selected from the group consisting of low to medium HLB surfactants; and d) not in excess of about 99% by weight of one or more lipophilic carriers.

Owner:VICTORIAN CHEM INT

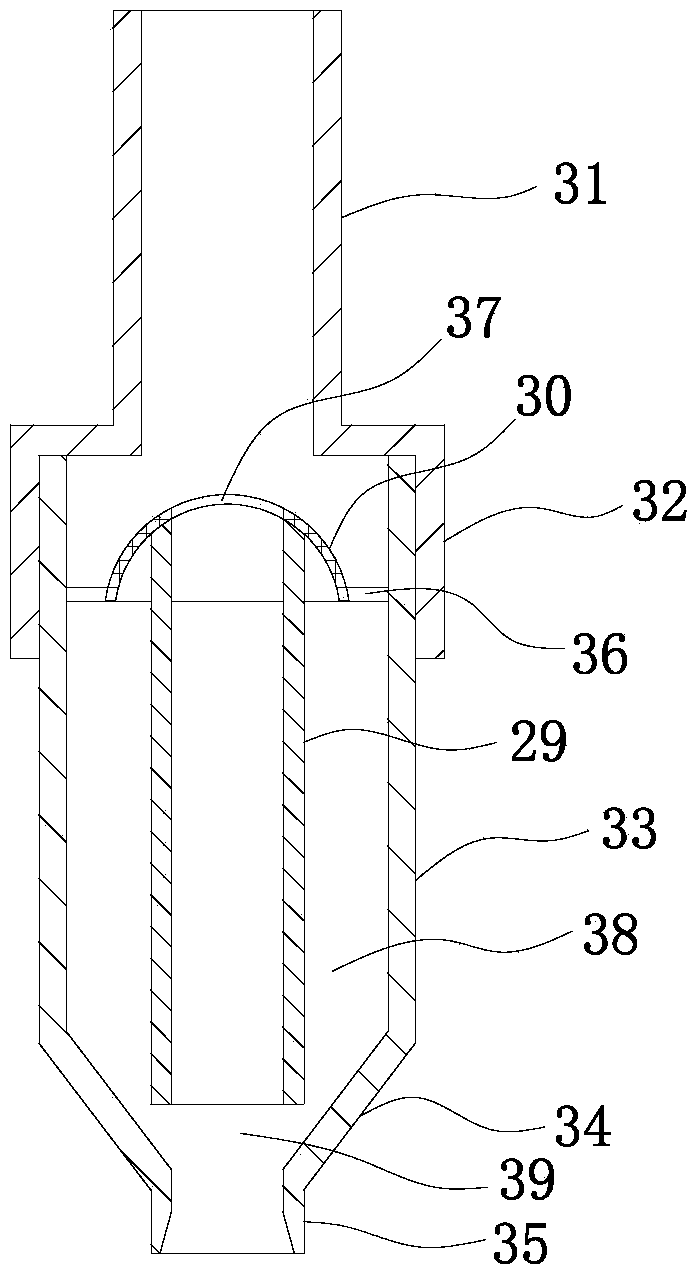

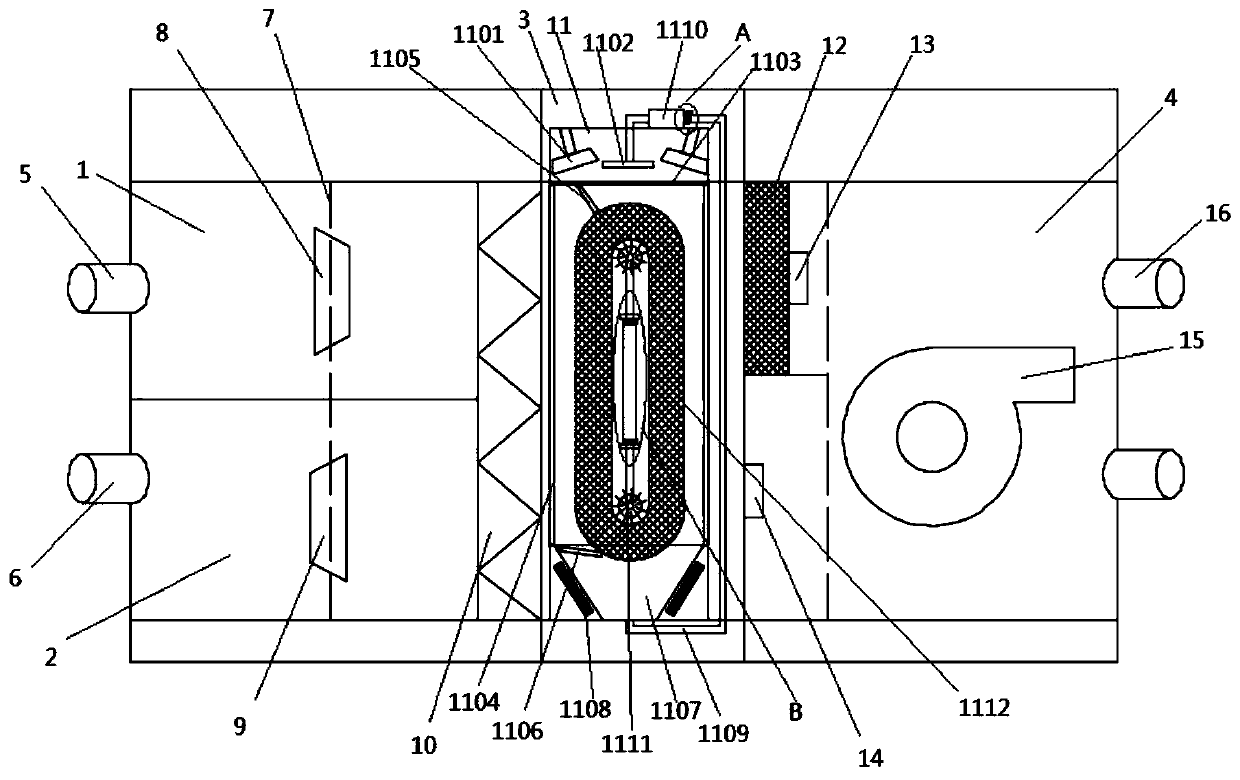

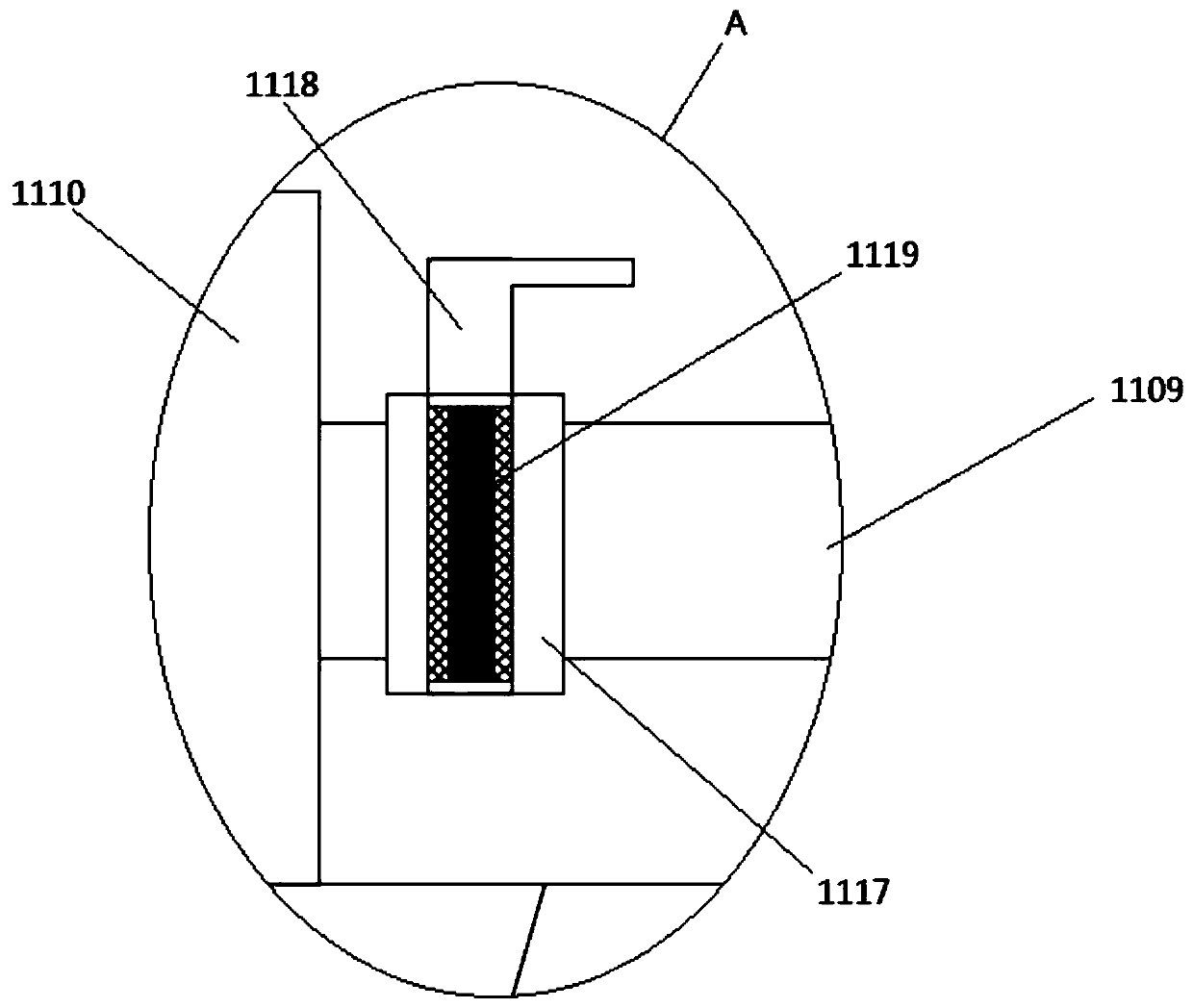

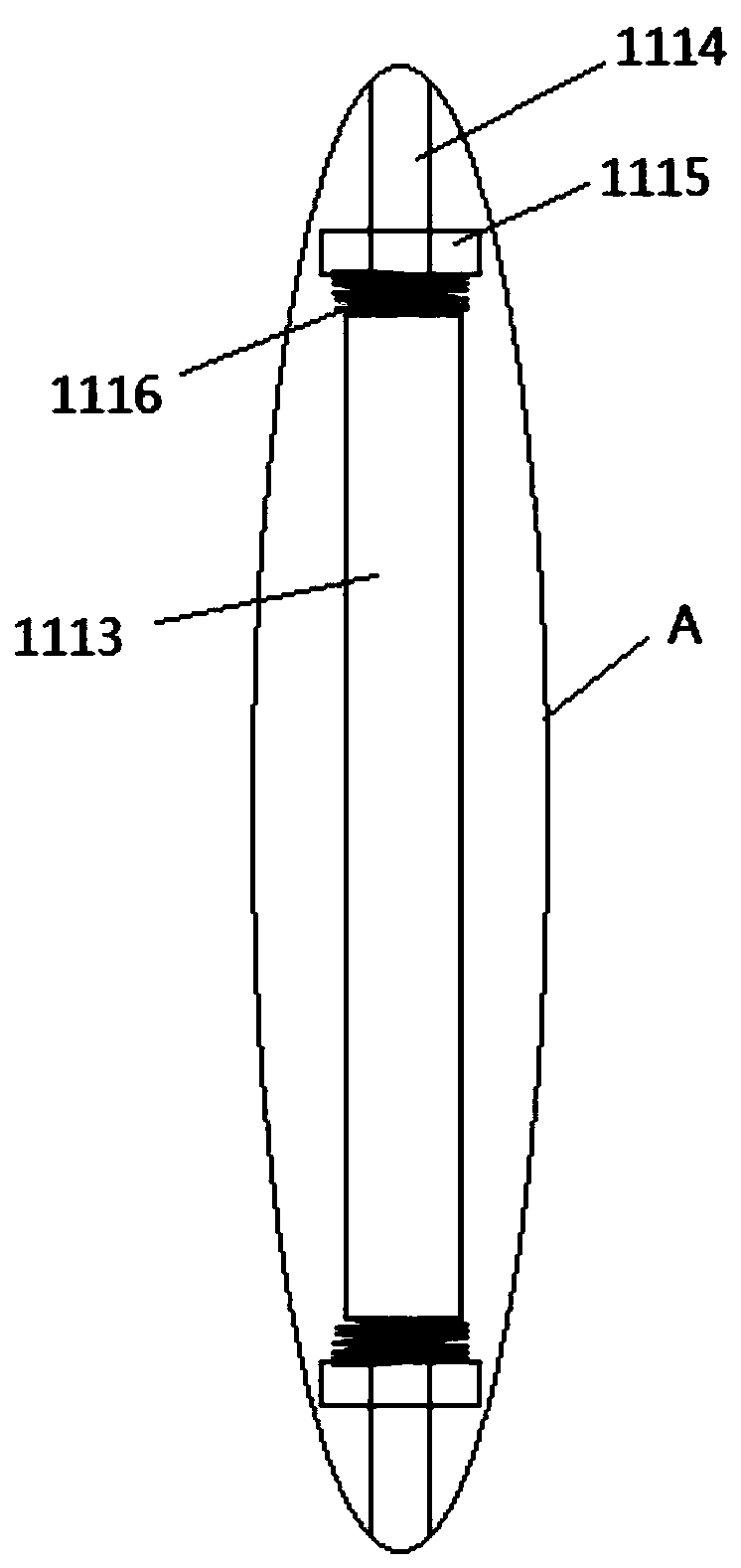

Integrated atmospheric pollutant purifier

InactiveCN106823720ACompact structureSmall footprintGas treatmentDispersed particle separationOrifice plateAtmospheric pollutants

An integrated atmospheric pollutant purifier is disclosed. The bottom of the equipment is externally connected to a circulating pump. By the utilization of the circulating pump, an absorbent is sent to an absorbent spray device arranged below a flue gas inlet, and the absorbent sprayed out of the spray device reacts with pollutants in flue gas. In addition, the purifier also comprises a dispersion atomizing device. The dispersion atomizing device stirs up water sprays to form a water film on an orifice plate, and a turbulent flow vapor-liquid exchange layer is formed. The purifier belongs to a desulphurization, denitration and demercuration integrated device, and has advantages of small floor space, high removal efficiency, low cost of investment and operation, large handling capacity of flue gas and good purification effect. As the inside of the purifier is continuously washed out by circulating slurry, scaling or obstruction will be avoided. With the existence of mixing blades, deposition of the absorbent can be effectively avoided.

Owner:山东三融环保工程有限公司

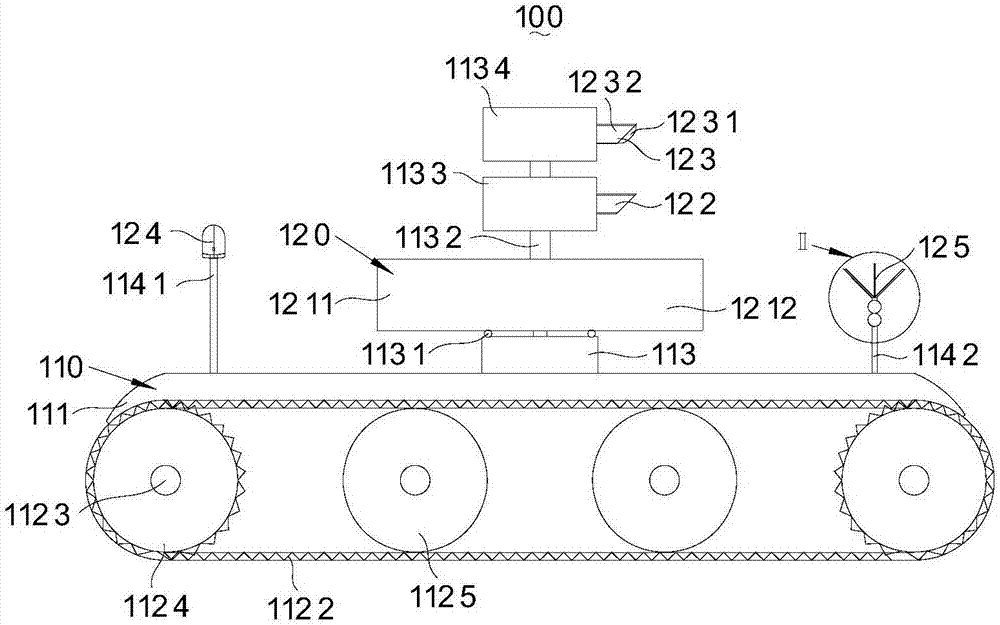

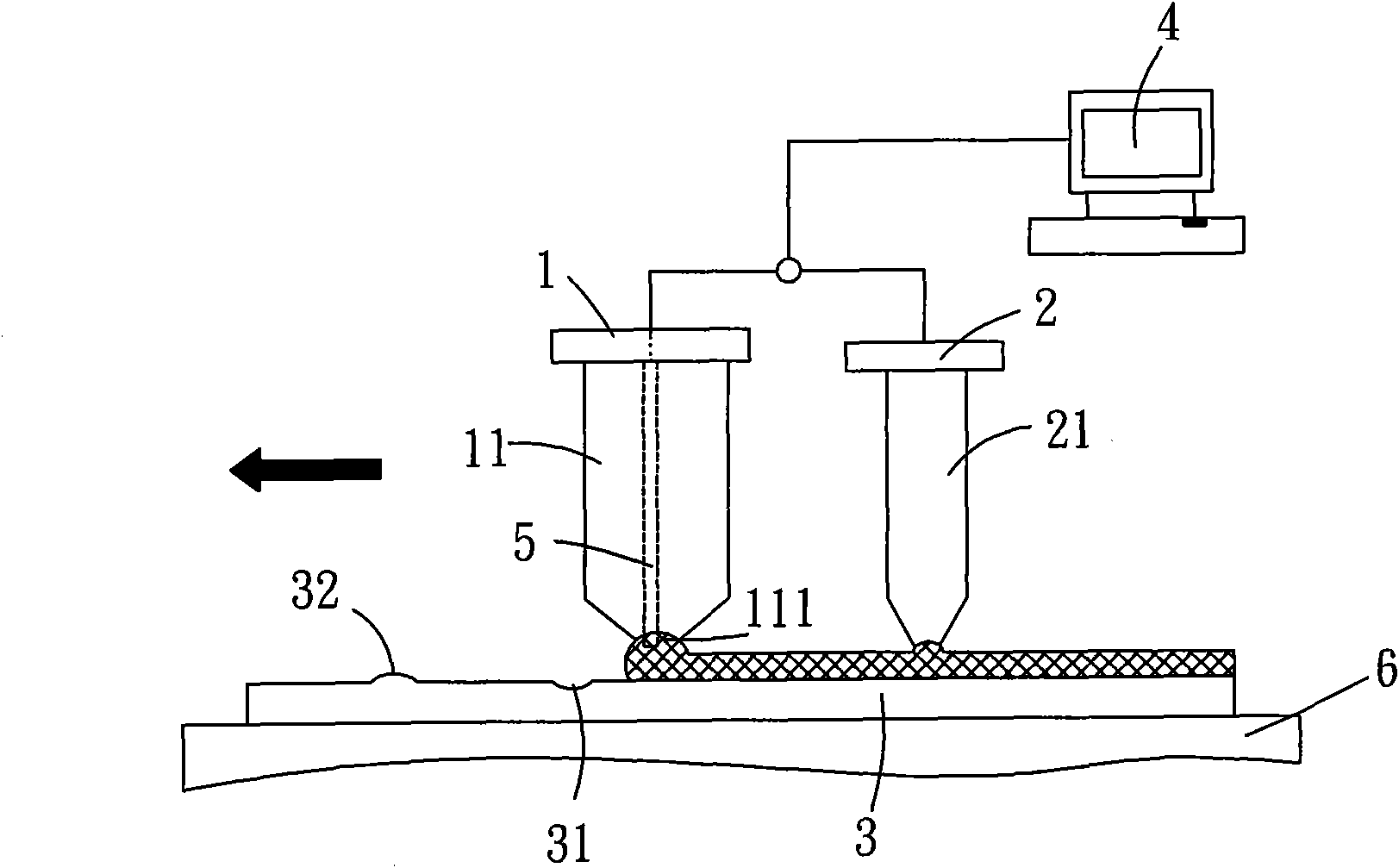

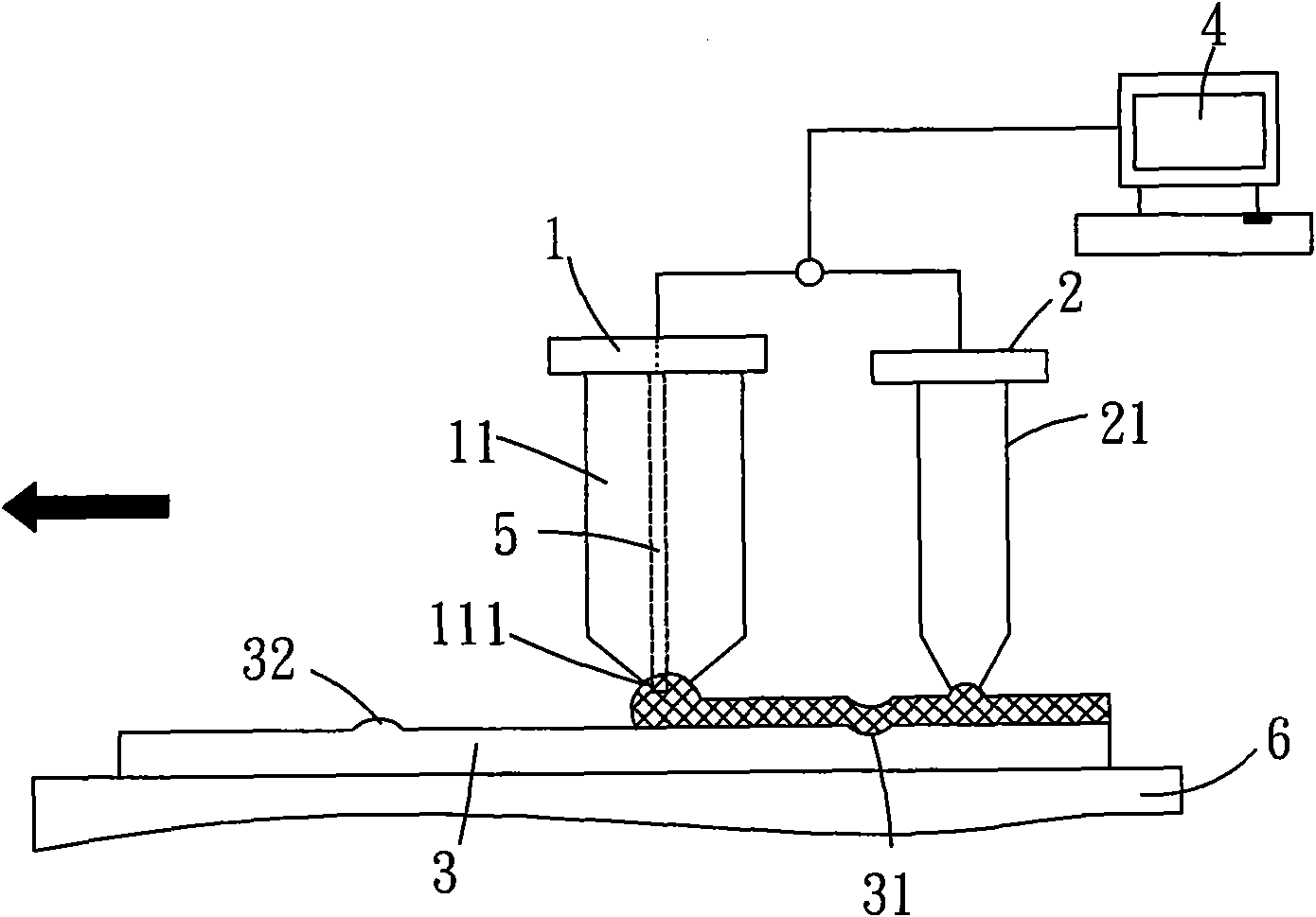

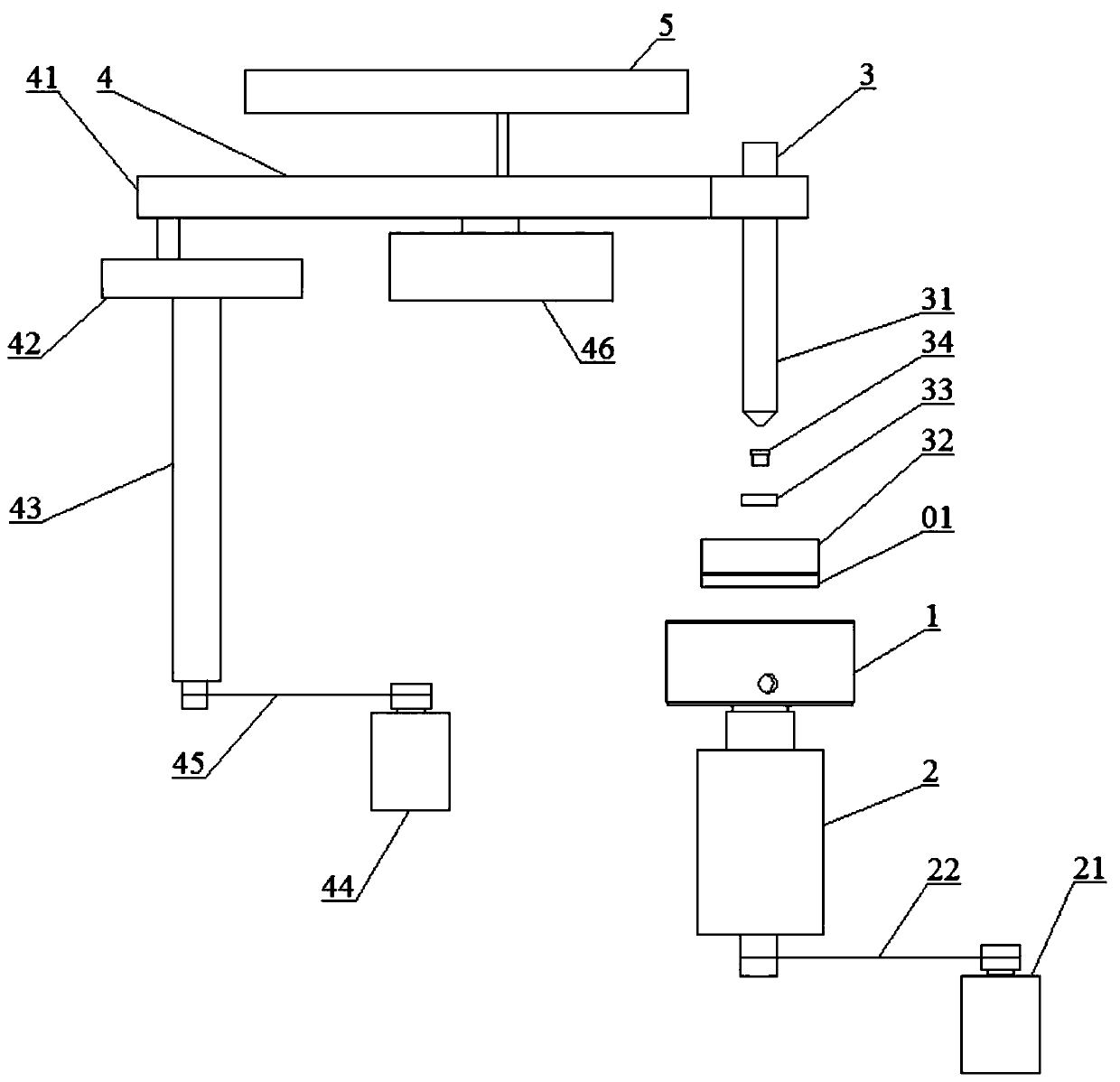

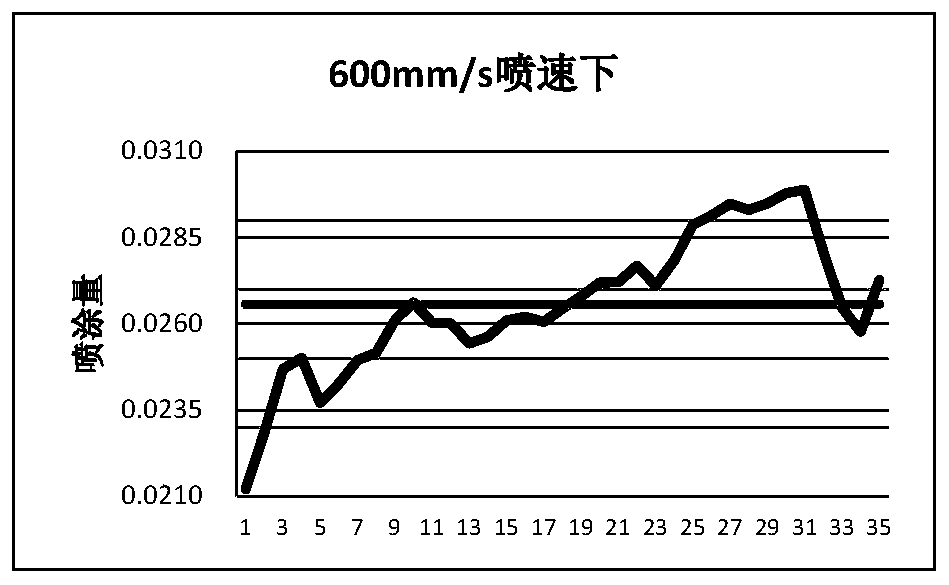

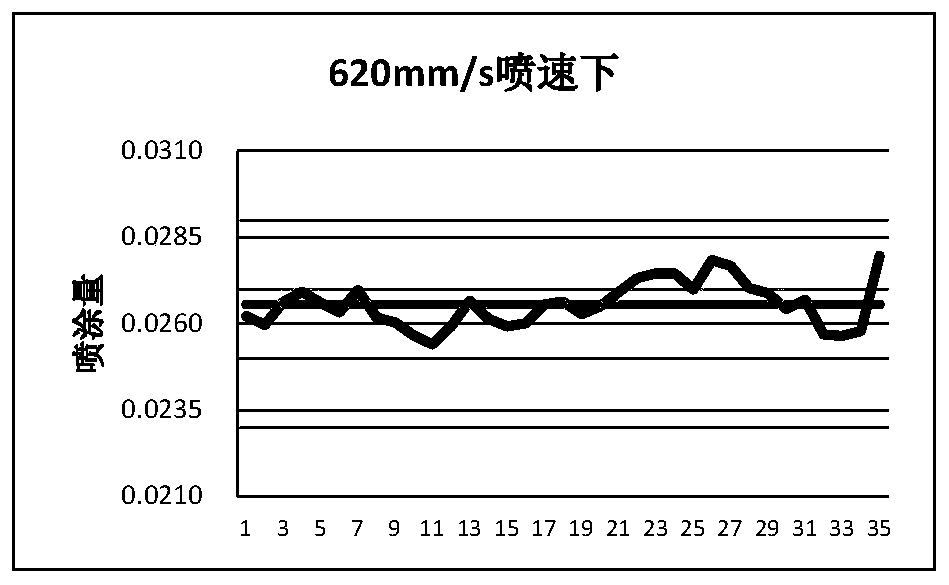

Reciprocating type automatic spraying machine and control method thereof

ActiveCN105499025AReduce spray volumeSmall thickness errorSpraying apparatusReciprocating motionEngineering

The invention discloses a reciprocating type automatic spraying machine and a control method thereof. The reciprocating type automatic spraying machine comprises a stander and a gun frame, wherein the gun frame is provided with a spray gun and a guide rail; the spray gun is arranged on the stander, a swinging head device capable of moving along the guide rail is arranged on the guide rail, and the spray gun is rotatably connected to the swinging head device along the movement direction of the swinging head device. According to the reciprocating type automatic spraying machine, the reciprocating horizontal movement and the rotation of a swinging head of the spray gun can be synchronously realized, the thickness of the coating on to-be-coated surfaces corresponding to two ends of the guide rail can be reduced, and the spraying thickness is relatively uniform.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

Patrol device and spray system

PendingCN107507290APrevention and control of fireSave water spray volumeChecking time patrolsFire rescueElectricityLiving body

The invention provides a patrol device and a spray system, relating to the field of baijiu storage. The patrol device comprises a patrol device body, and a detection module, a communication module and a control module which are arranged on the body, wherein the detection module comprises a biological recognition module and an environment sensing module; the control module is electrically connected with the communication module, the biological recognition module and the environment sensing module; the biological recognition module is used for recognizing a living body and transmitting the detected biological signal to the control module; the environment sensing module is used for detecting temperature and rainfall, and transmitting detected temperature signal and rainfall signal to the control module; the control module is used for transmitting the biological signal, the temperature signal and the rainfall signal to a server linked with the communication module through the communication module. The device can realize automatic detection for a distilled liquor storage area.

Owner:LUZHOU LAOJIAO GRP CO LTD

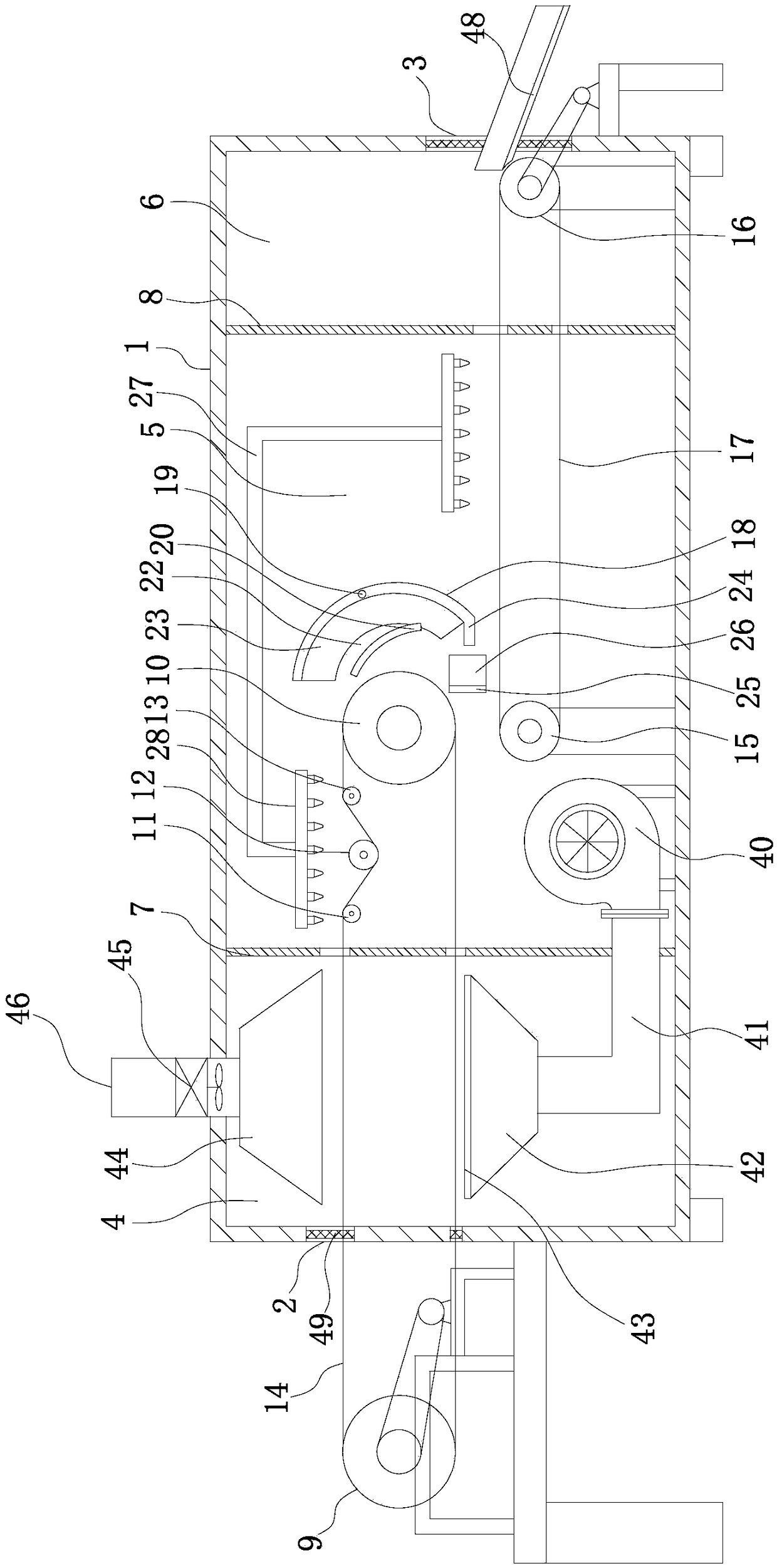

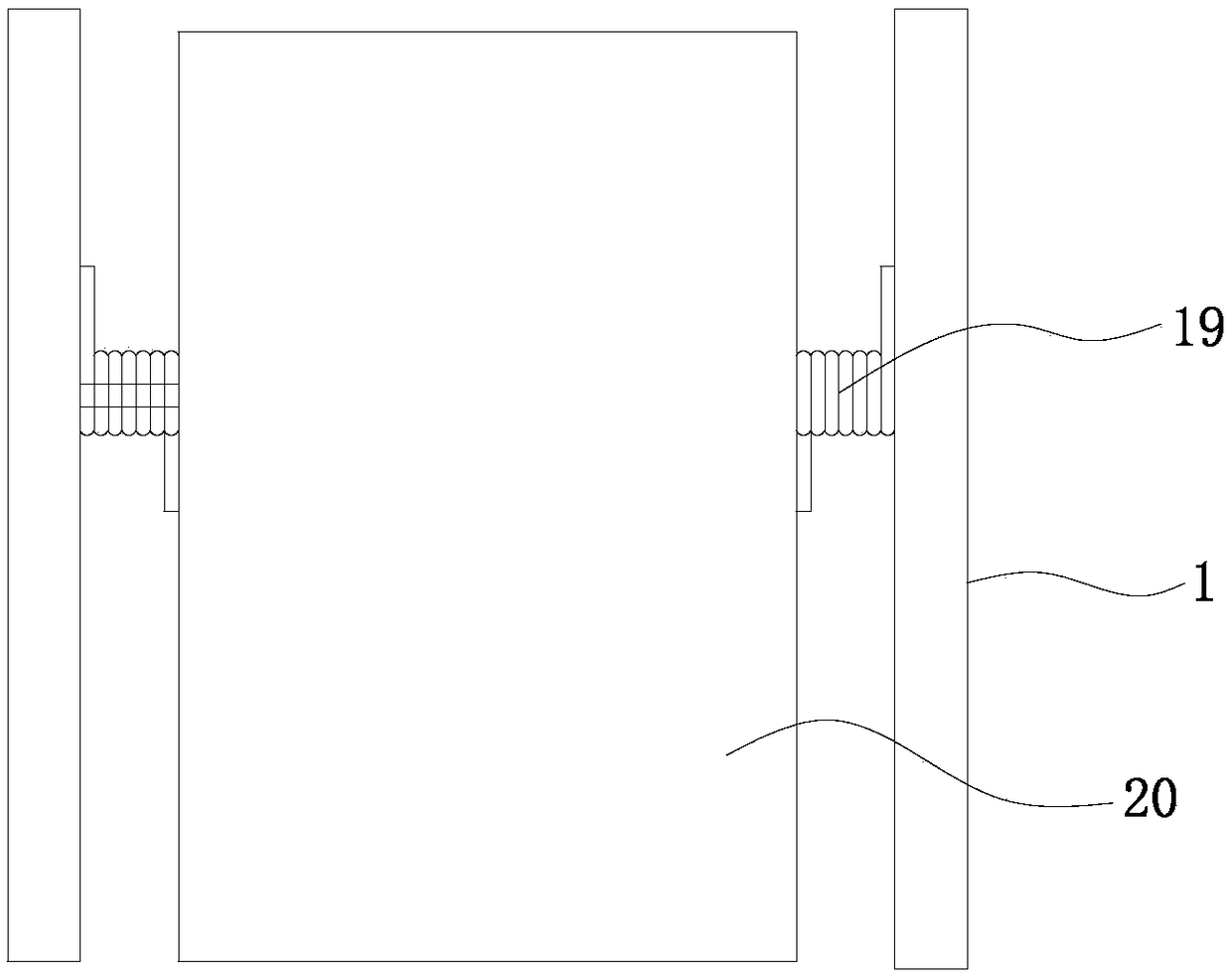

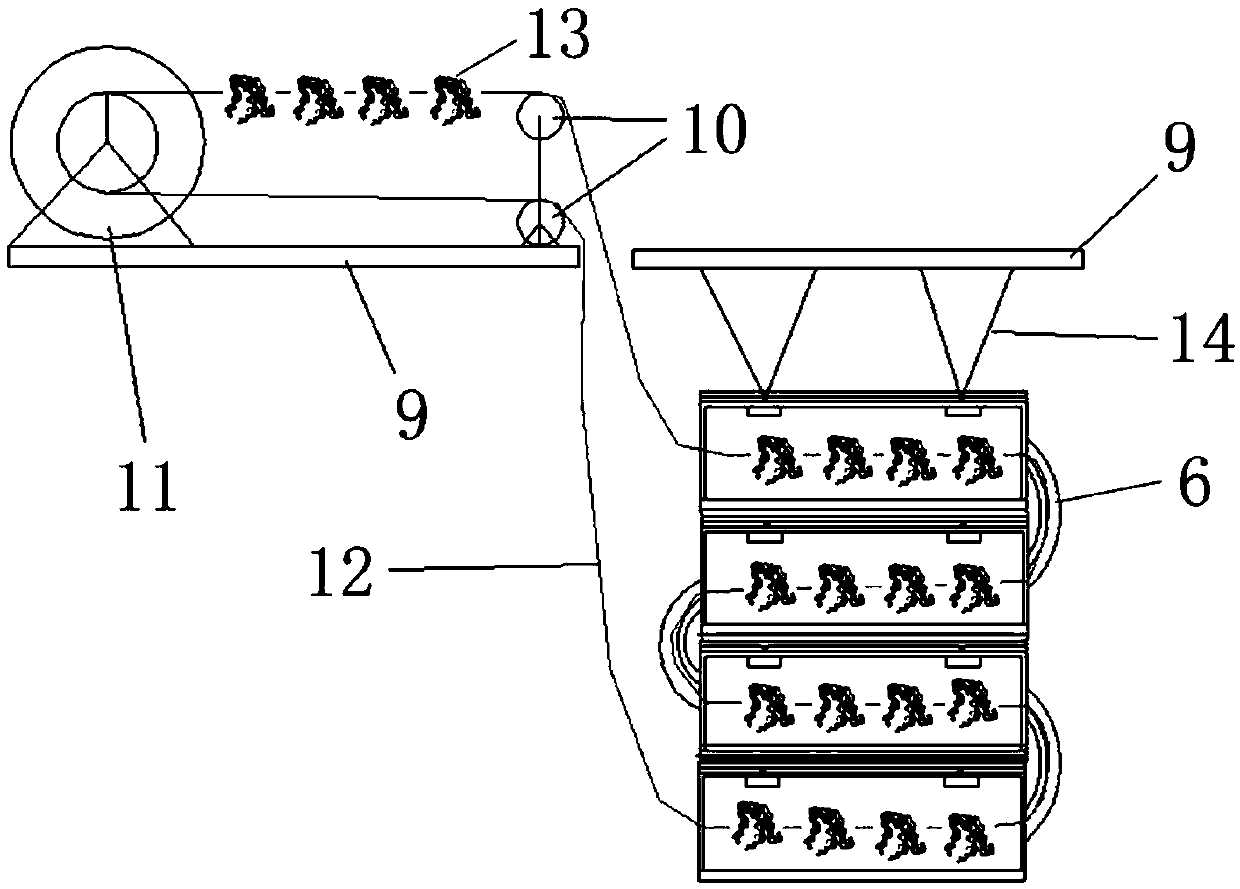

Liquid nitrogen quick-freezing equipment for swimming crabs

ActiveCN109393006APromote atomizationGood atomization effectMeat/fish preservation by freezing/coolingFreezing chamberLiquid nitrogen

The invention discloses liquid nitrogen quick-freezing equipment for swimming crabs. The liquid nitrogen quick-freezing equipment for the swimming crabs comprises a box, a material-feeding transmission mechanism and a material-discharging transmission mechanism; a material inlet and a material outlet are arranged at two ends of the box; a front clapboard and a rear clapboard are arranged inside the box; the material-feeding transmission mechanism comprises a driving feeding drum, a driven feeding drum, a front guide roller, a lower guide roller and a rear guide roller; a material-feeding conveyor belt is wound between the driving feeding drum and the driven feeding drum; the material-feeding conveyor belt sequentially passes downwards through the front guide roller, winds the lower guide roller and passes through the rear guide roller so as to form a recessed portion; the material-discharging transmission mechanism comprises a driven discharging drum and a driving discharging drum; a material-discharging conveyor belt is wound between the driving discharging drum and the driven discharging drum; the material-discharging conveyor belt and the material-feeding conveyor belt both moveclockwise; a turning-over mechanism is arranged outside a terminal of the material-feeding conveyor belt; and liquid nitrogen spraying mechanisms are arranged, inside a freezing chamber, above both the material-feeding conveyor belt and the material-discharging conveyor belt. The liquid nitrogen quick-freezing equipment for the swimming crabs is quick in freezing rate, so that, overall freezing efficiency and freezing quality of swimming crabs can be improved so as to have liquid nitrogen consumption reduced.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

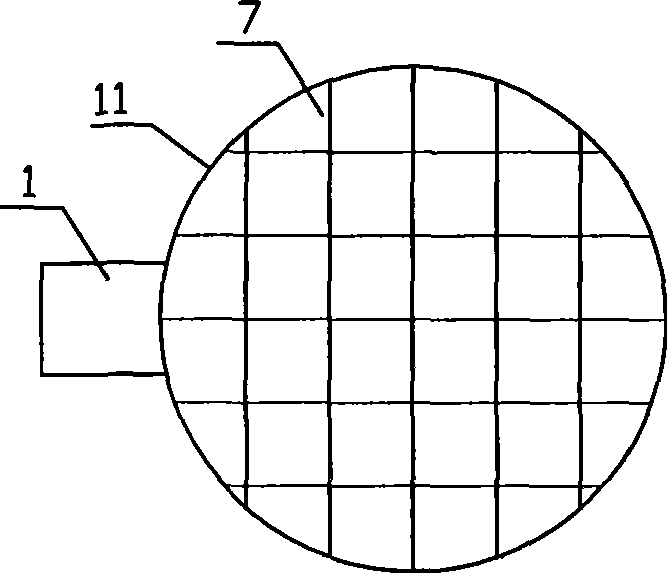

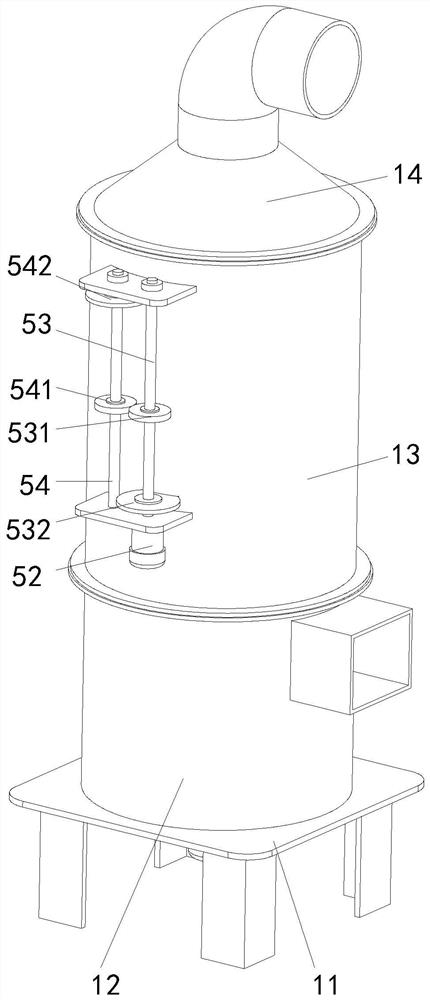

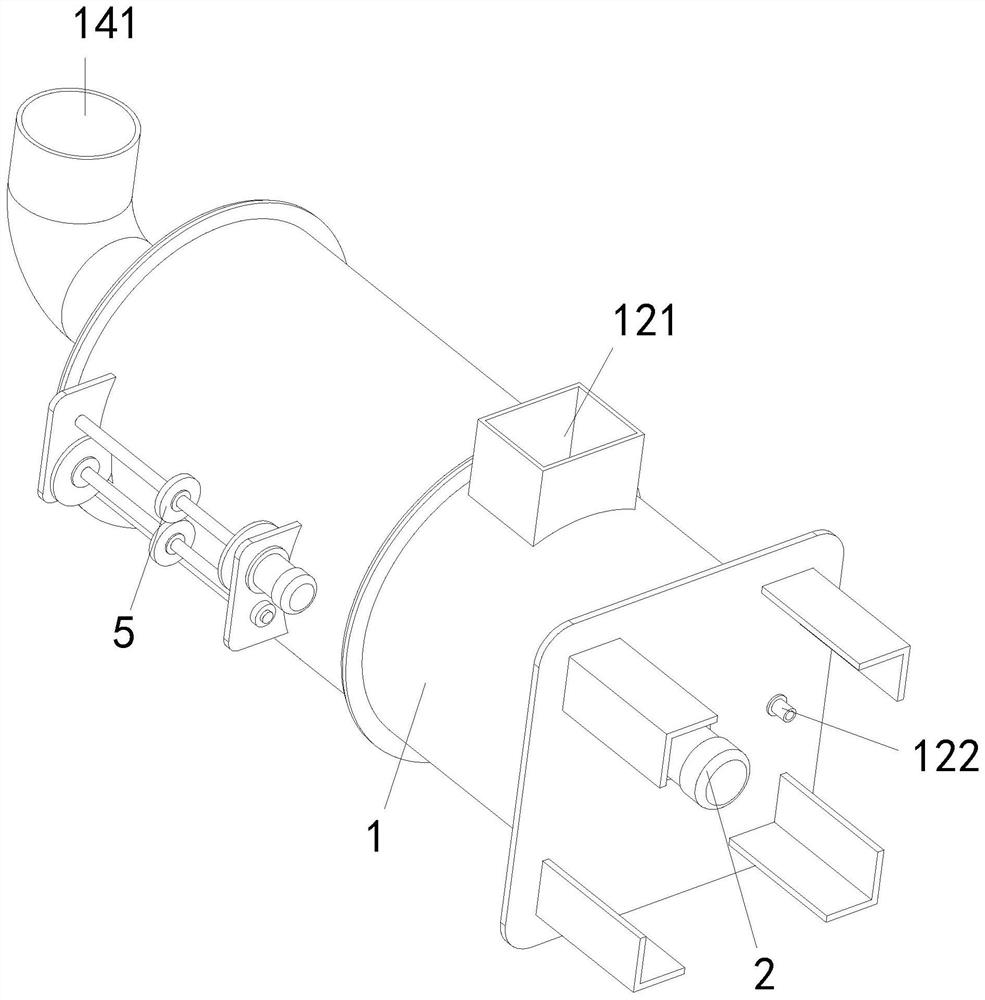

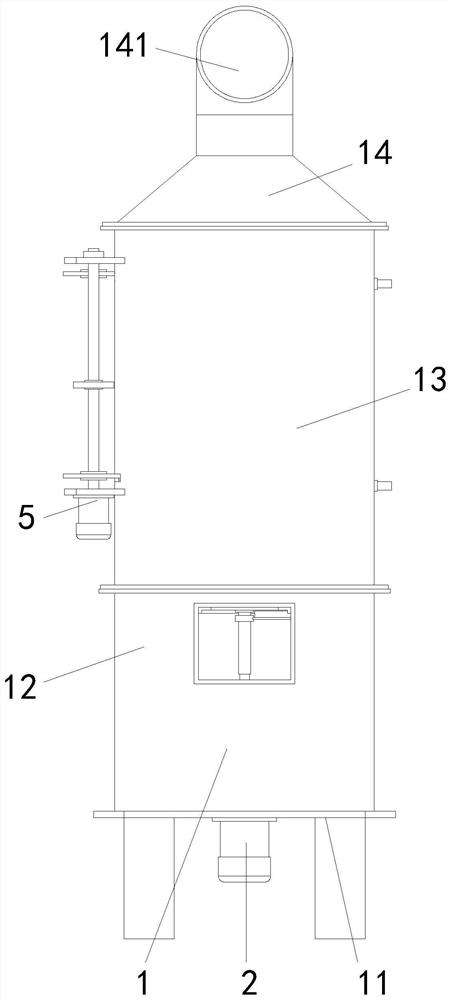

Circulating spray absorption tower for flue gas purification treatment

InactiveCN111821817AEvenly distributedAvoid formingGas treatmentDispersed particle separationFlue gasEngineering

The invention relates to a circulating spray absorption tower for flue gas purification treatment. The absorption tower comprises a cylindrical liquid storage tower body and a cylindrical spray towerbody connected with the top end of the liquid storage tower body; a cleaning and scraping mechanism is arranged on the liquid storage tower body; two spraying pipeline assemblies capable of horizontally rotating are vertically arranged in the spray tower body; and a rotation driving mechanism used for driving the two spraying pipeline assemblies to rotate is arranged on the outer side wall of thespray tower body. According to the absorption tower provided by the invention, a spraying medium liquid can be uniformly and widely distributed in the spraying space, so that flue gas flowing upwardscan be in contact exchange with the spraying medium liquid at equal probability, and the spraying absorption effect can be improved and guaranteed; in addition, solid precipitates can be continuouslyscraped off, and formation and accumulation of a precipitation layer are avoided.

Owner:杭州亿航环保科技有限公司

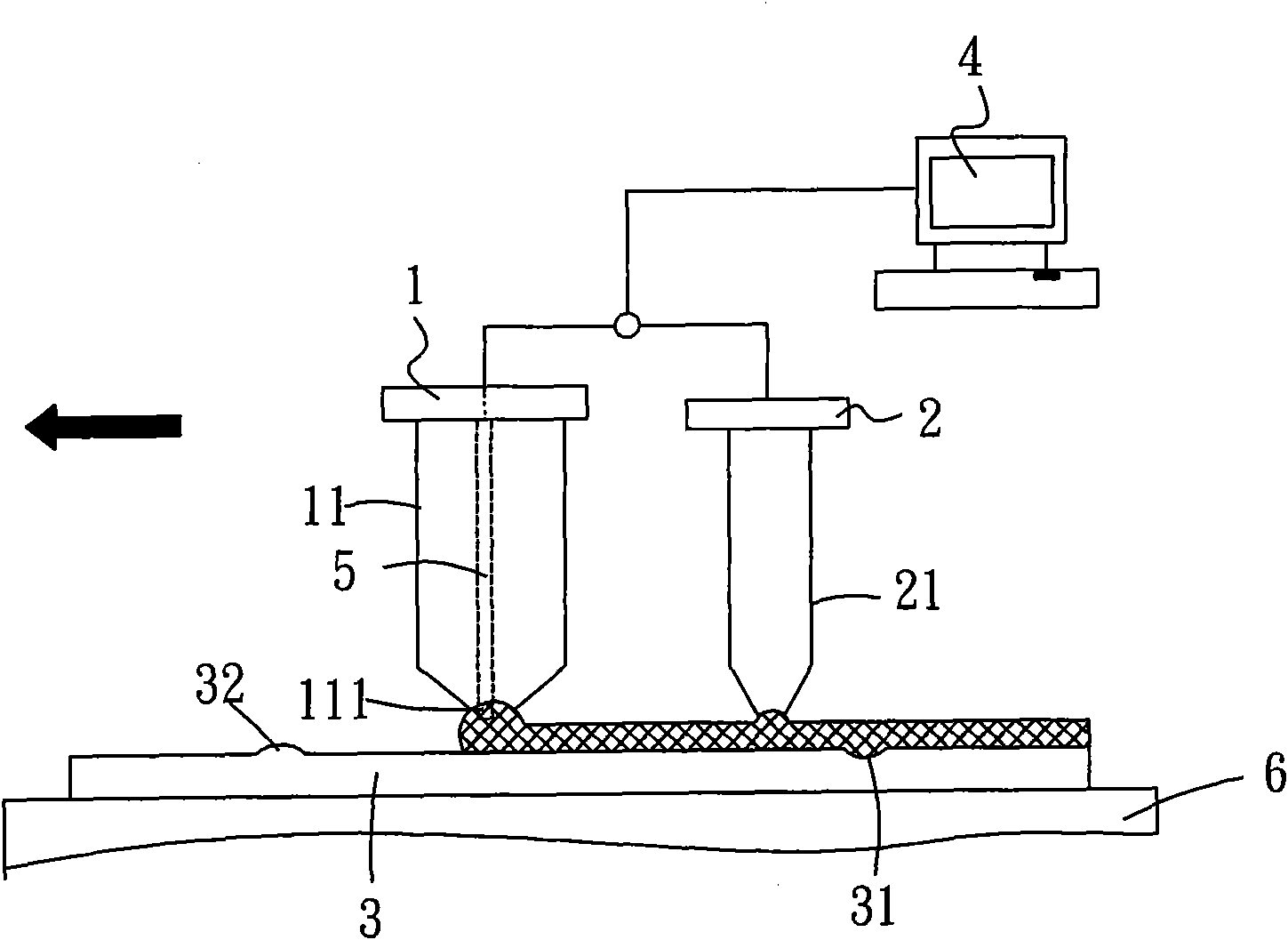

Film coating method

InactiveCN101524679AIncrease spray volumeReduce spray volumeLiquid surface applicatorsCoatingsLiquid ChangeFilm coating

The invention discloses a film coating method, which comprises the following steps: (1) controlling a first coating device and a second coating device by a control device to spray coating liquid on a base material simultaneously in the preset spraying amount; and (2) at the time of spraying the coating liquid on the base material, controlling a sensor by the control device to sense the adhesive force of the coating liquid between the first coating device and the base material; when sensing that the adhesive force of the coating liquid does not change, continuing executing the step (1); and when sensing that the adhesive force of the coating liquid changes, adjusting the spraying amount of the second coating device by the control device according to an adhesive force signal. In the film coating method, the control device adjusts the spraying amount of the second coating device according to the variation of the adhesive force of the coating liquid between the base material and the first coating device, so a smooth film is formed on the base material.

Owner:FUGANG ELECTRONICS DONGGUAN +1

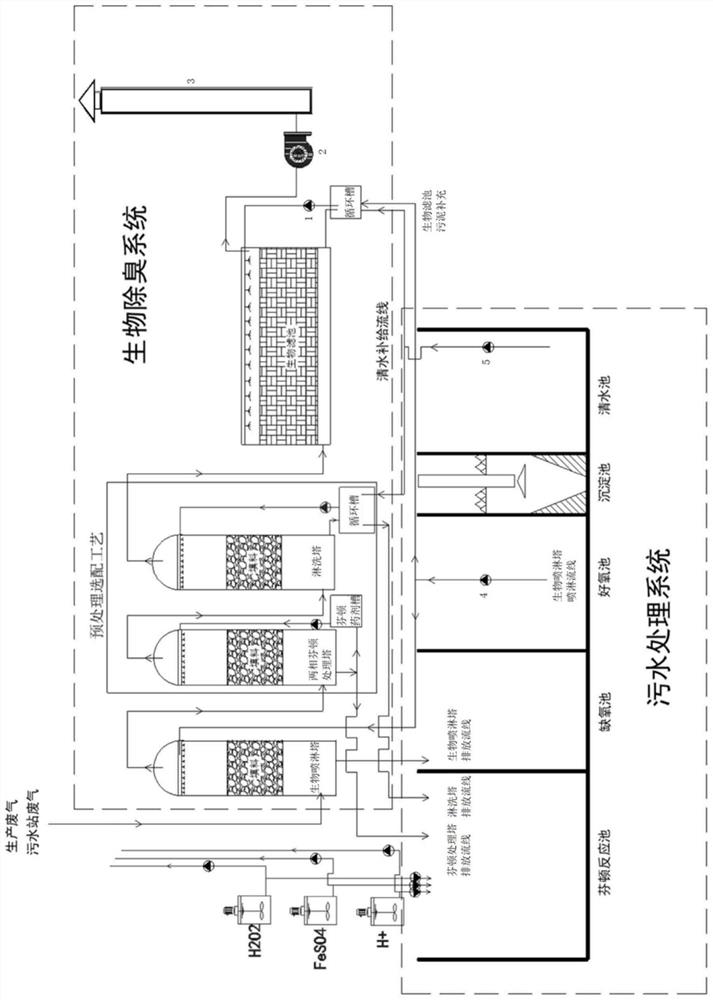

Combined biological treatment method for pharmaceutical and chemical sewage and organic waste gas

InactiveCN112007506AImprove processing efficiencyReduce consumptionWater treatment compoundsWater contaminantsBiological filterClean water

The invention discloses a combined biological treatment method for pharmaceutical and chemical sewage and organic waste gas. The method comprises the steps that waste gas is in countercurrent contactwith a mud-water mixture from an aerobic tank in virtue of a biological spray tower, so soluble organic matters in the waste gas are adsorbed; then the waste gas is subjected to Fenton treatment and aFenton reagent reaction, so degradation-resistant organic matters in the waste gas are oxidized and degraded; then the waste gas passes through a spray washing tower and is washed with clear water from a clear water tank; residual organic matters are removed from the washed waste gas through a biological filter, and then the waste gas is discharged through a chimney; after wastewater is treated by a Fenton reaction tank, an anoxic tank, an aerobic tank and a sedimentation tank, upper-layer clear water reaching a standard in the sedimentation tank enters the clear water tank; and washing liquid of a Fenton treatment tower is discharged into the Fenton reaction tank. The method integrates advanced oxidation, anaerobic and aerobic biological purification, a biological filter treatment process and other processes, and has the characteristics of high combined wastewater and waste gas treatment efficiency, low Fenton reagent consumption, low operating cost and the like.

Owner:成都达源环保工程有限公司

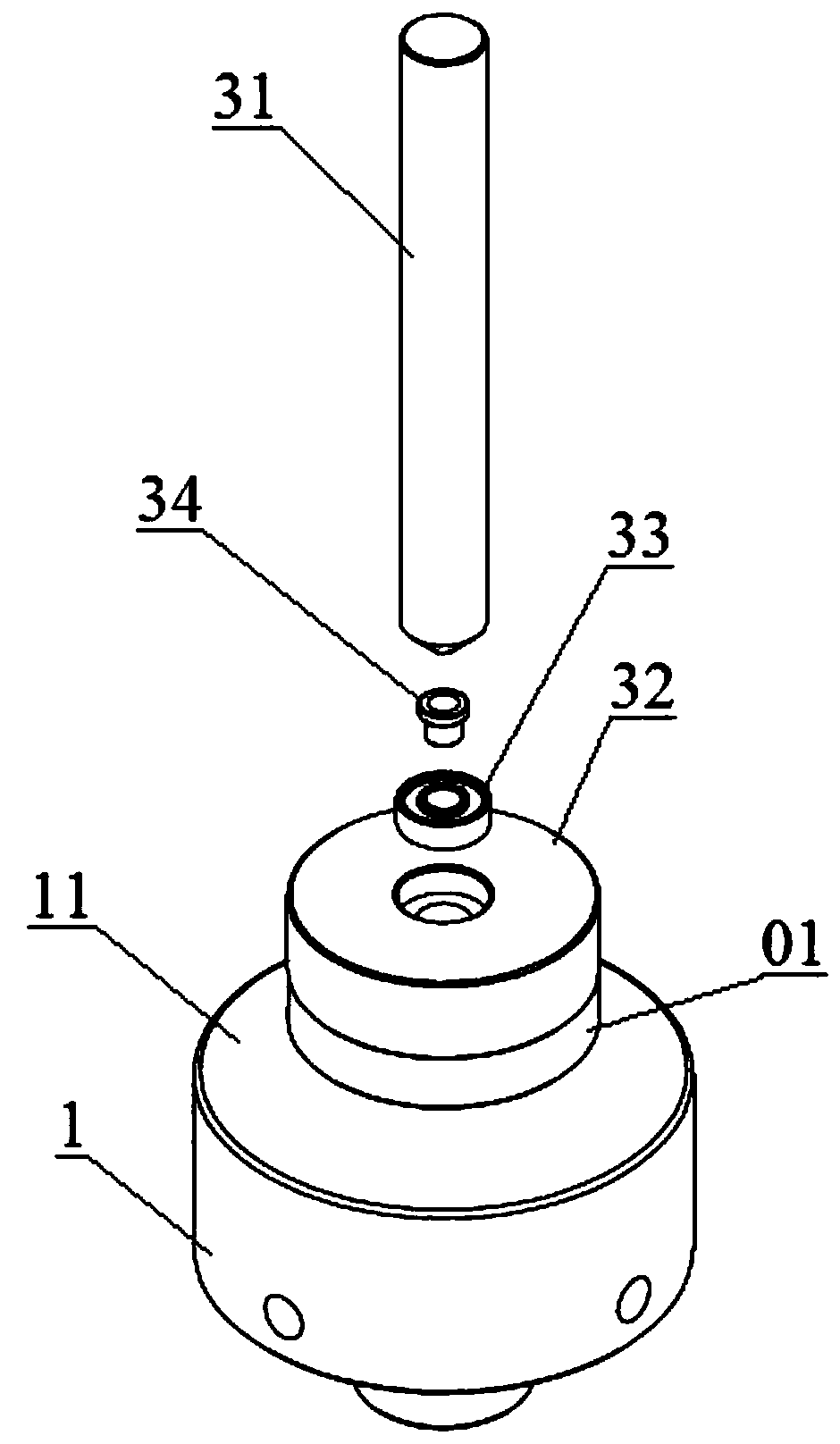

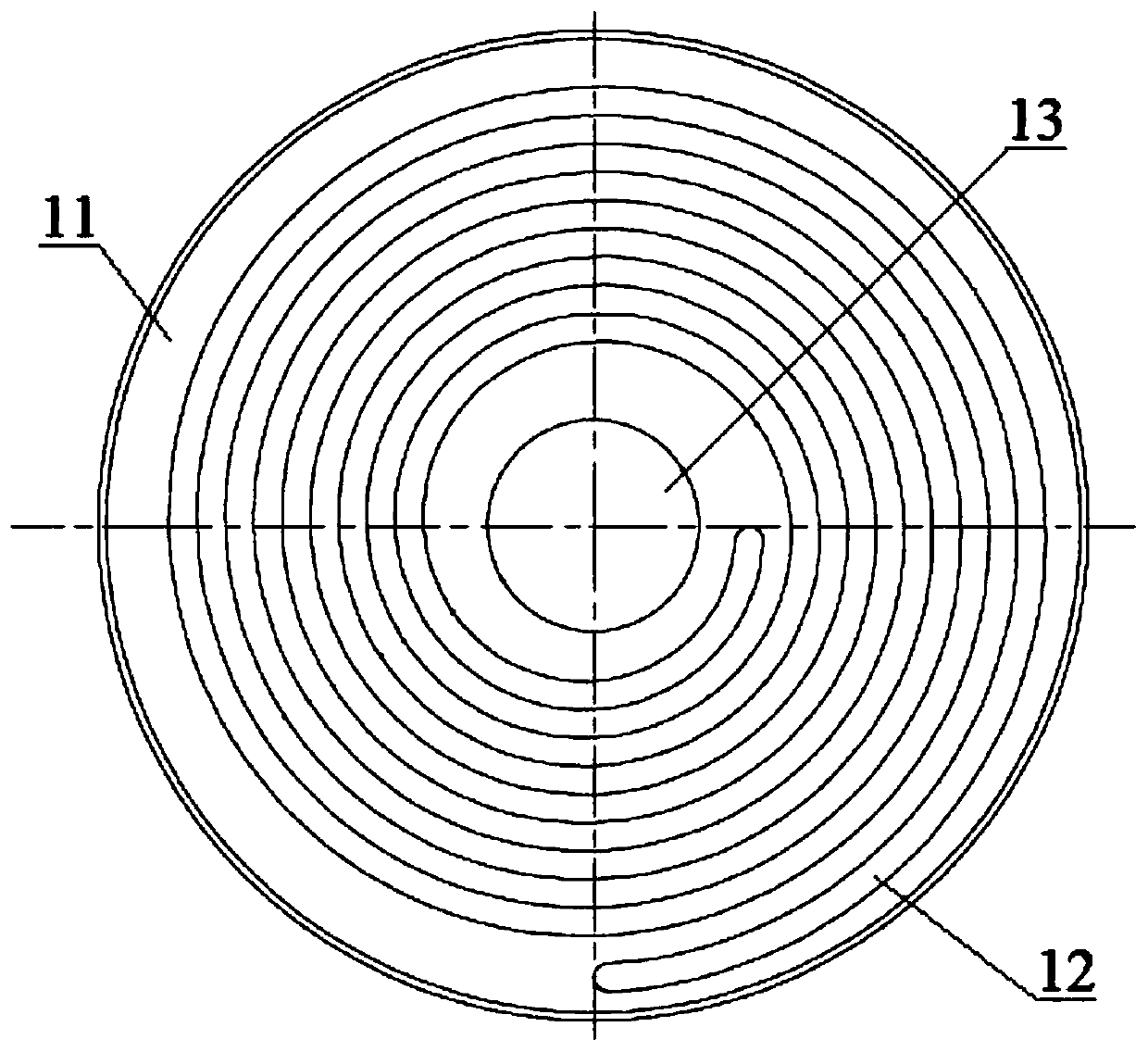

Polishing abrasive tool, polishing device comprising polishing abrasive tool, and polishing method

PendingCN110587464ASimple structureEasy to processGrinding wheel securing apparatusPolishing machinesMachined surfaceEngineering

The invention provides a polishing device. The polishing device comprises a rotary pedestal, a polishing abrasive tool, a positioning jig and a swing mechanism; the polishing abrasive tool is arrangedon the rotary pedestal and the polishing surface is upward; the polishing surface is provided with a spiral groove and an avoiding groove which is positioned in the center position of the spiral groove; the positioning jig is positioned above the polishing abrasive tool and comprises a vertical jacking rod and a product placing table which can be rotationally arranged at the lower end of the jacking rod; the positioning jig cooperates with a pressure load mechanism in order to closely press a product on the polishing surface of the polishing abrasive tool; the swing mechanism comprises a power source and a double-crank mechanism; one end of the double-crank mechanism is connected with the power source; and the other end of the double-crank mechanism is connected with the jacking rod so asto realize synchronous motion of the two ends. The invention further provides a method for polishing by utilizing the polishing device; and the rotary pedestal and the double-crank mechanism cooperate with each other to realize 360-degree self-rotation motion and periodic circular motion of a to-be-machined surface of the product on the polishing surface of the polishing abrasive tool, thereby guaranteeing that each position of the product is polished uniformly and the polishing surface is abraded uniformly.

Owner:LENS TECH CHANGSHA

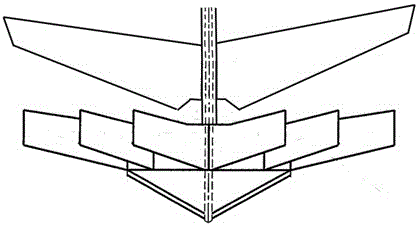

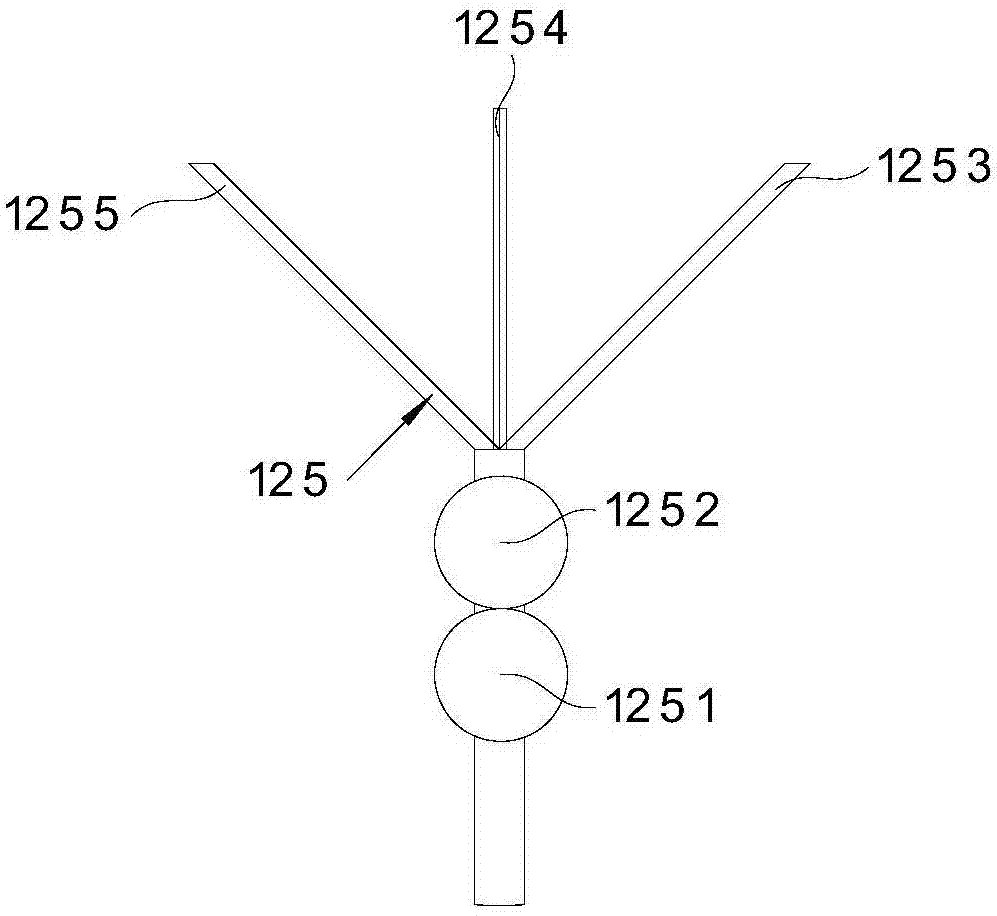

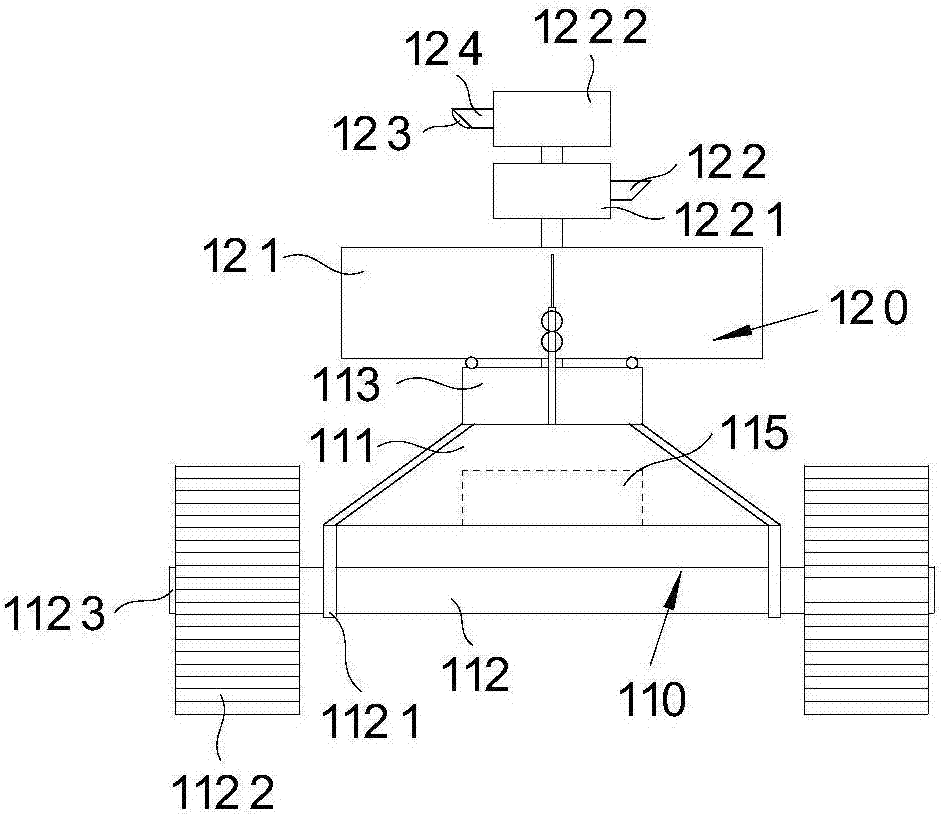

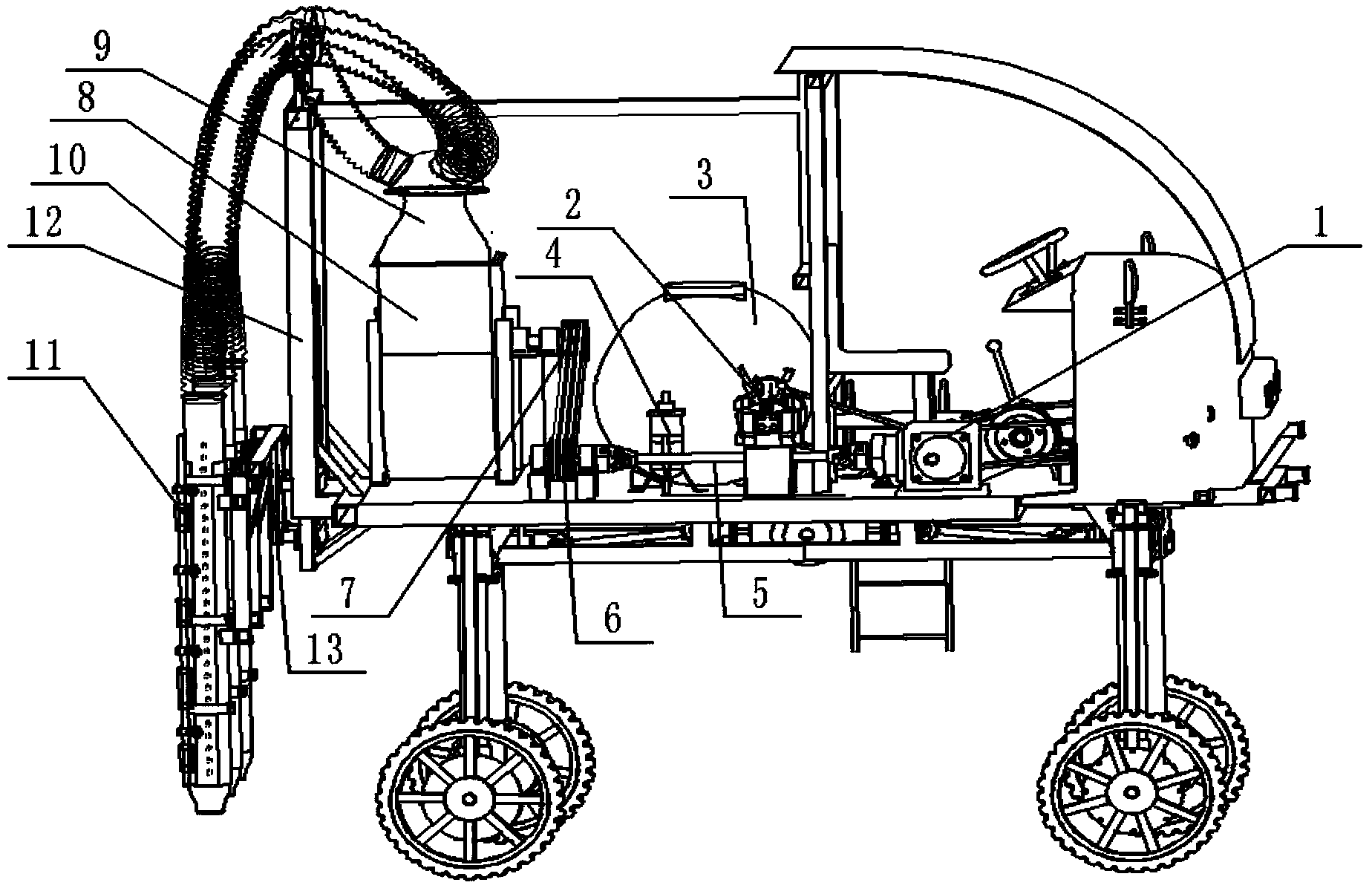

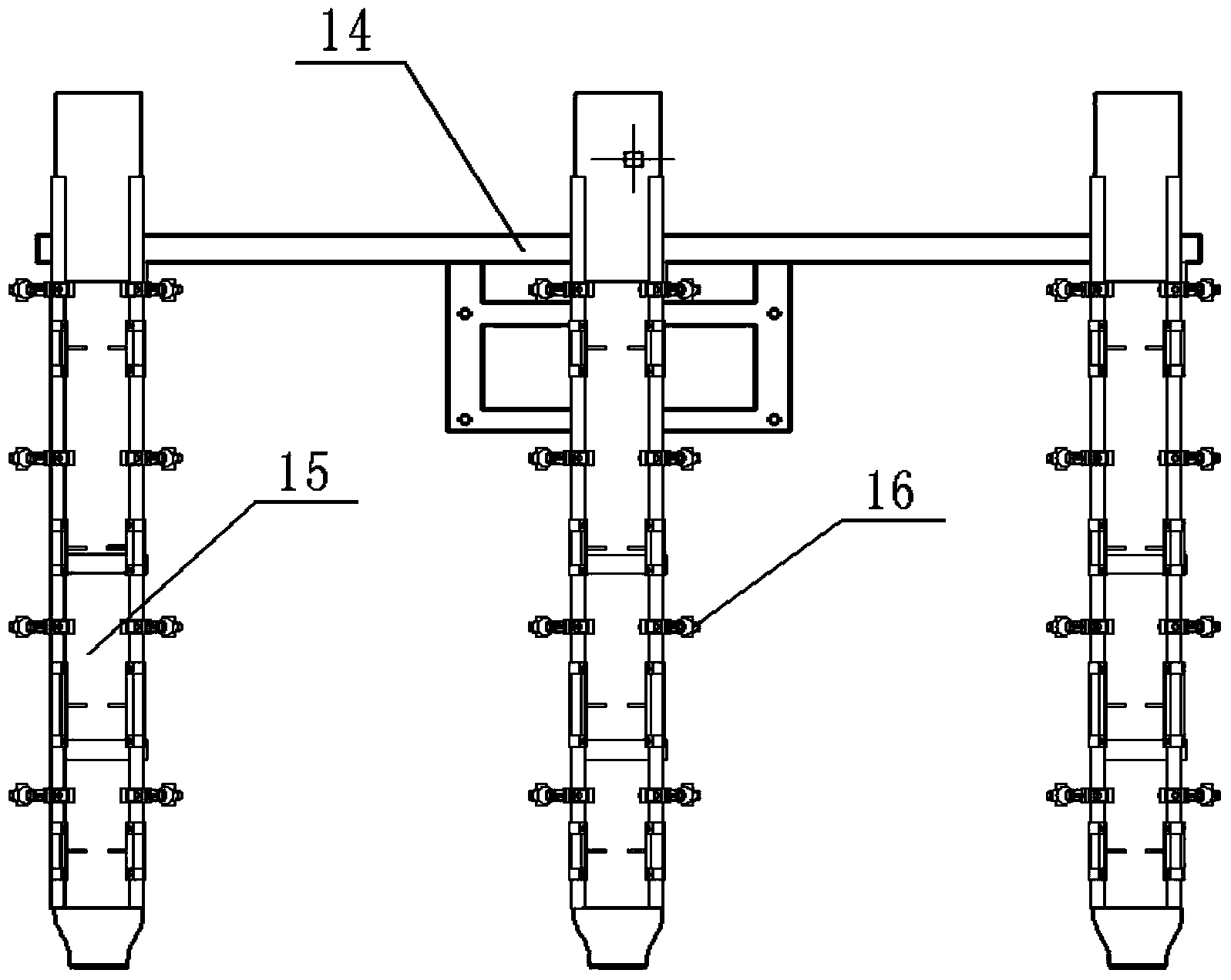

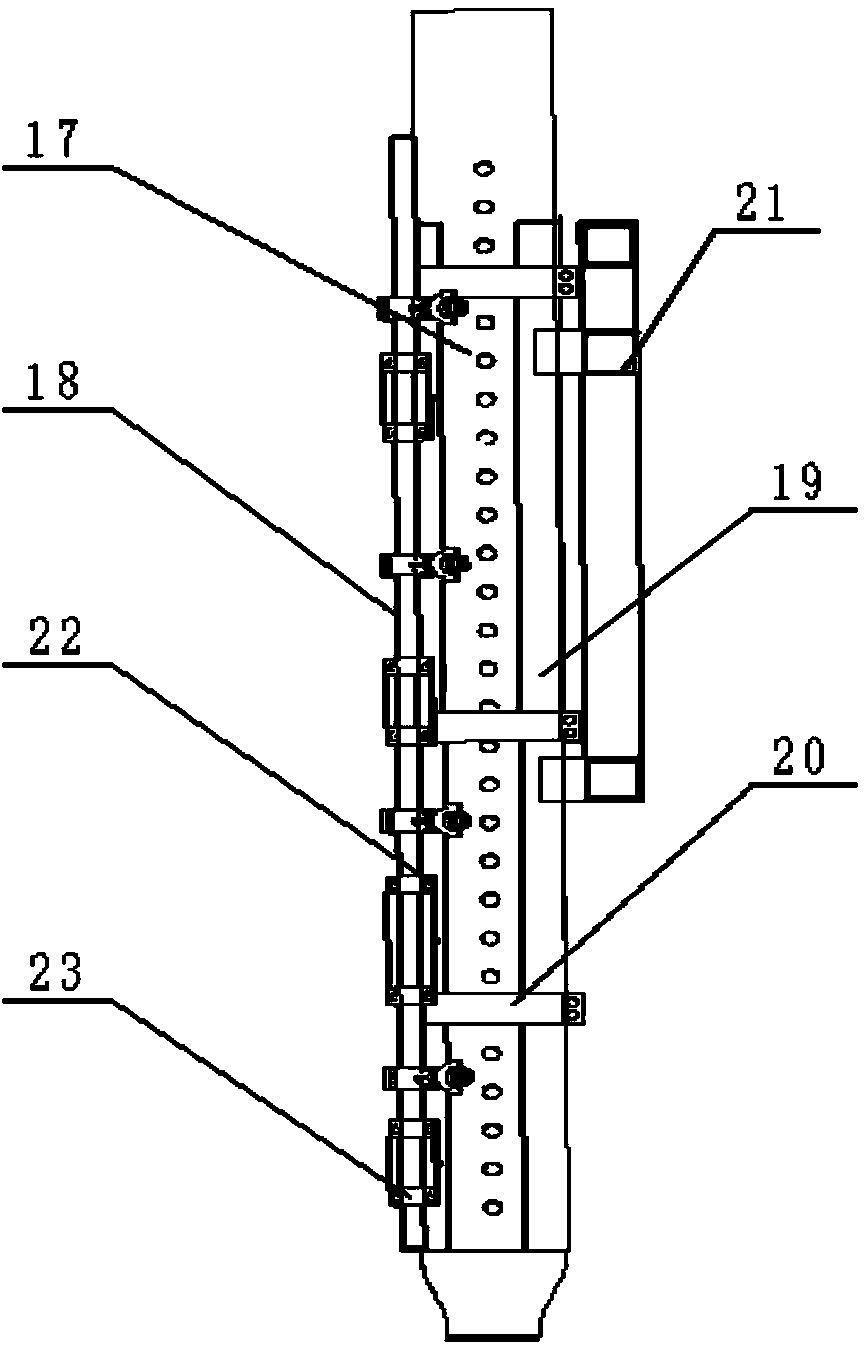

Pneumatic conveying type suspender profiling ripener spraying machine for cotton fields

InactiveCN103521380AReduce spray volumeAvoid serious wasteSpraying apparatusHorticulture methodsPesticideEngineering

The invention relates to a pneumatic conveying type suspender profiling ripener spraying machine for cotton fields. The spraying machine is composed of a power drive device, a pesticide liquid spraying system, a pneumatic conveying system, a hydraulic lifting mechanism and a suspender profiling device. Wind outlets and a vertical pesticide rod are arranged on a multi-hole wind duct, jet stream fields are formed in the regions of the two sides of the wind duct, and then spraying fog drops are secondarily atomized, and the pesticide liquid adhesive rate is increased. The hydraulic lifting mechanism and the suspender rod profiling device are arranged, and then the suspender profiling device can meet operating requirements at different heights. Ripener can be evenly sprayed to the upper, the middle and the lower positions of cotton plants, the high defoliation rate and the high boll opening rate are achieved, and the spraying machine can be suitable for land parcels of different shapes and the cotton fields of different growth vigor.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for preventing ore heap hardening

InactiveCN105506279AIncrease convection intensityShort stayProcess efficiency improvementHigh concentrationPrecipitation

The invention belongs to the technical field of hydrometallurgy, particularly relates to a method for preventing ore heap hardening, and aims to prevent metals and impurities in leach liquor from forming insoluble precipitate in a heap and solve the problems of ore heap hardening, permeability lowering and the like by means of increasing the spraying amount and spraying acidity, optimizing a spraying system and the like. The method is characterized by comprising heap wetting, ore heap acidification period treatment, heap leaching medium-term treatment and leaching post-treatment. According to the method, ore is fully wetted with clear water before leaching, so that the residence time of an acidification-period high-concentration solution on the surface of ore is shortened, and secondary precipitation of leaching matters is relieved; high spraying strength is adopted at an ore heap acidification period, so that the thickness of a liquid film on the surface of the ore is reduced, and the ore leaching strength is enhanced; the sulfuric acid concentration of spraying liquid is kept constant at a heap leaching medium period, so that the spraying amount of a leaching agent is reduced gradually, the leaching process is enhanced, the metal concentration of the leaching liquor is increased, smooth proceeding of heap leaching is ensured, and the leaching period is shortened.

Owner:BEIJING RES INST OF CHEM ENG & METALLURGY

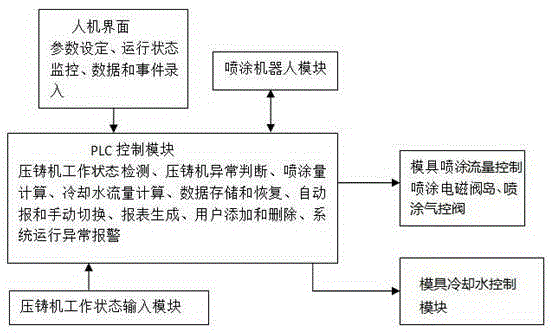

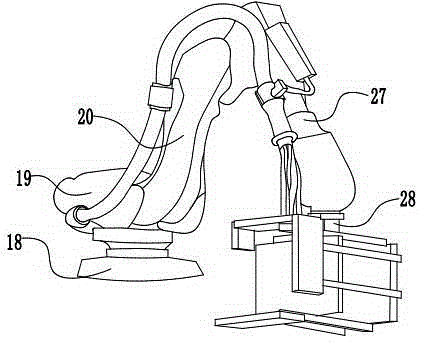

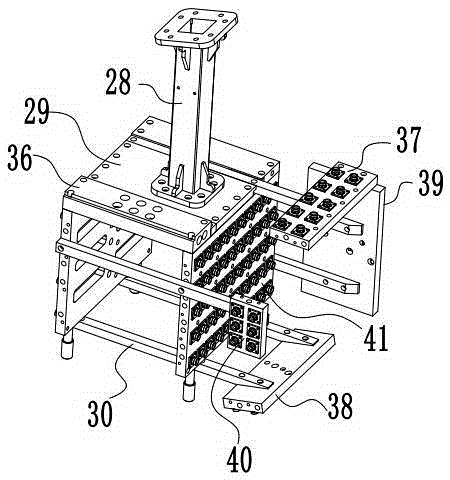

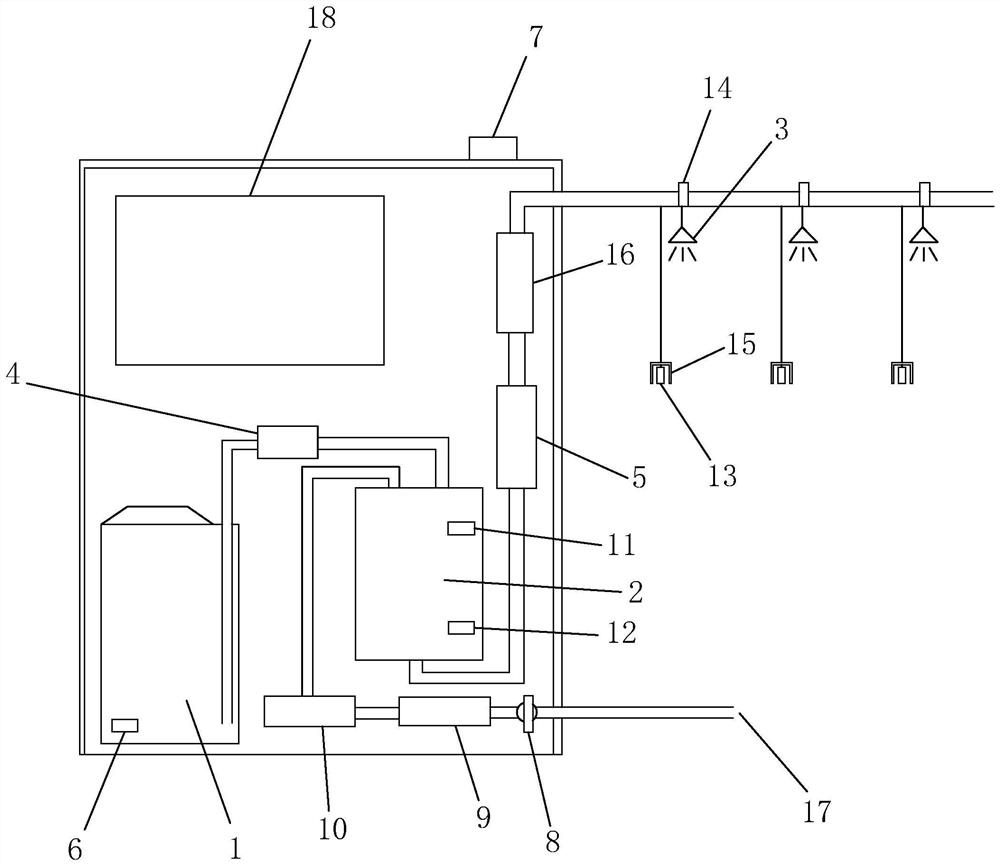

Die spraying system

The invention discloses a die spraying system. The die spraying system comprises a PLC control module, a human-machine interface, a die-casting machine work state input module, a spraying robot module, a die spraying flow control module and a die cooling water control module. The human-machine interface is connected with the PLC control module through one-way communication. The die-casting machine work state input module is in one-way communication with the PLC control module. The spraying robot module is in both-way communication with the PLC control module. The die spraying flow control module is in one-way communication with the PLC control module. The die cooling water control module is in one-way communication with the PLC control module. According to the die spraying system, the time, from a cold state to a normal production state, of a die casting machine can be greatly shortened, the number of disqualified products can be reduced to the maximum degree, the product yield is increased, and the production efficiency is improved.

Owner:CHONGQING NEWSTAR TECH CO LTD

Emergency treatment device for leakage of liquid ammonia storage tank

ActiveCN113154254APrevent leakageRealize blockingContainer filling methodsFluid handling accessoriesEmergency treatmentAir pump

The invention relates to the technical field of liquid ammonia safety protection, in particular to an emergency treatment device for the leakage of a liquid ammonia storage tank. The emergency treatment device comprises a detection mechanism for detecting ammonia gas and a spraying mechanism for diluting the ammonia gas, and the emergency treatment device further comprises a sleeve sleeved outside the liquid ammonia storage tank, one end of the sleeve is sealed, the other end of the sleeve is open, and a plurality of partition plates are axially arranged in the sleeve. The free ends of the partition plates are in sliding connection with the surface of the liquid ammonia storage tank, the partition plates divide the space between the sleeve and the liquid ammonia storage tank into a plurality of blocking cavities, an air bag is arranged in each blocking cavity, the air bags are fixed to the sleeve, each air bag communicates with an air pump, and the air pumps are used for inflating and deflating the air bags; and the detection mechanism comprises an ammonia gas detector, the ammonia gas detector is arranged on the face, close to the liquid ammonia storage tank, of the air bag, the ammonia gas detector is electrically connected with a controller, the controller is electrically connected with an alarm, and the controller is further electrically connected with the spraying mechanism and the air pump. According to the emergency treatment device, the air bags are inflated to block a leakage area, and further leakage of ammonia gas is effectively avoided.

Owner:重庆安全技术职业学院

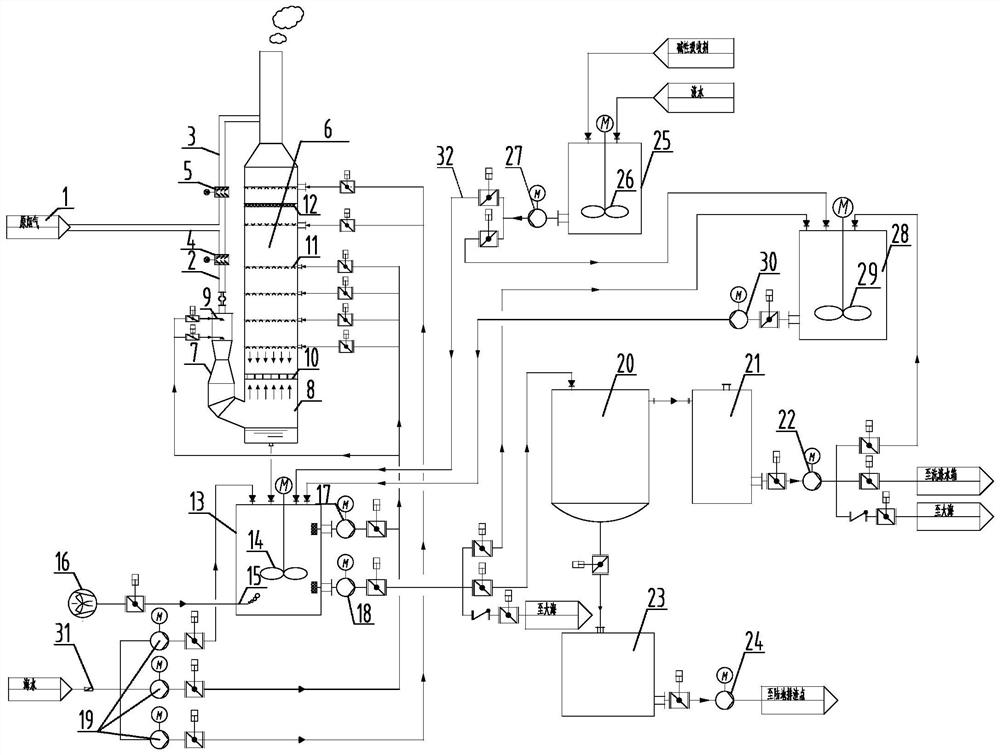

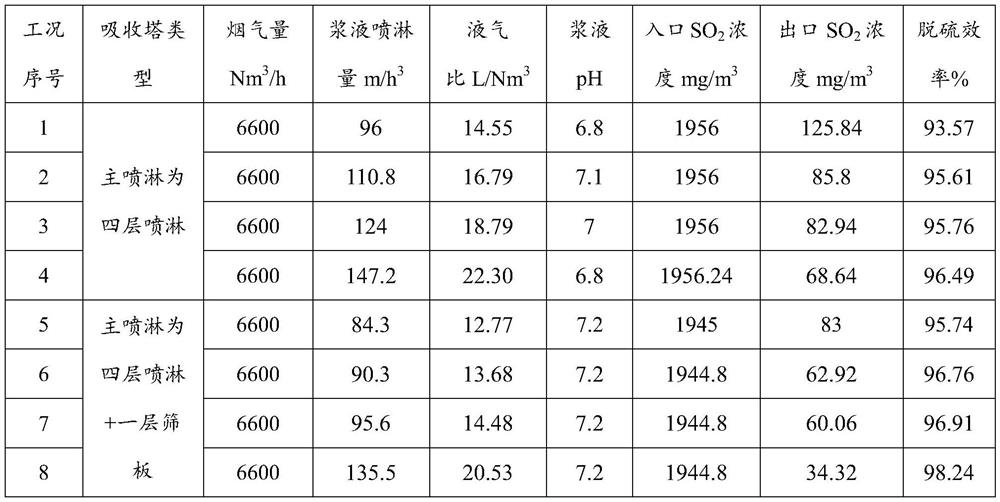

Marine hybrid desulfurization system and method

PendingCN111888905AFlexible operationEasy to operateGas treatmentDispersed particle separationWater treatment systemFlue gas

Owner:ZHEJIANG UNIV

Long-life fresh air ventilator

ActiveCN110567078AReduce spray volumeReduce use costMechanical apparatusSpace heating and ventilation safety systemsCouplingDifferential pressure

The invention discloses a long-life fresh air ventilator. The novel fresh air ventilator includes a return air bin, a fresh air bin, a filter adsorption bin, an air supply bin, an indoor return air inlet, an outdoor fresh air inlet, a coupling, a return air valve sheet, a fresh air valve sheet, a stainless steel wire mesh, a filtering self-cleaning device, a steel wire ball filter, a return air end differential pressure sensor, a fresh air mold end differential pressure sensor, a centrifugal fan and an indoor air outlet; the return air bin is located above the fresh air bin; the air supply binis arranged on the right of the return air bin and the fresh air bin, the stainless steel wire mesh, the filtering self-cleaning device, the steel wire ball filter, the return air end differential pressure sensor and the fresh air mold end differential pressure sensor are arranged between the return air bin, the fresh air bin and the air supply bins. The fresh air ventilator has the advantages that filtering and automatic cleaning are achieved, the service life of a filter element is prolonged, the purification ability is automatically recovered, the use cost is low and the ability is strong.

Owner:张和平

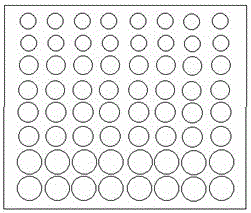

Baffle-free high-efficiency filter

InactiveCN105169847ALose weightReduce processing costsDispersed particle filtrationEngineeringHot melt

The invention provides a baffle-free high-efficiency filter and can solve the problems of small effective ventilation area, heavy deadweight and high manufacturing cost existing in the existing baffle-free high-efficiency filter. The baffle-free high-efficiency filter comprises a box body and filter paper, wherein a plurality of hot-melt rubber strips are symmetrically spray-coated onto the front and back sides of the filter paper, the filter paper with the plurality of hot-melt rubber strips which are spray-coated onto the front and back sides is repetitively folded to form a filter element and the filter element is arranged in the box body. The baffle-free high-efficiency filter is characterized in that the hot-melt rubber strips are rectangular and blocky, the length direction of the rectangular hot-melt rubber strips is consistent with the length direction of the filter paper and the plurality of hot-melt rubber strips are symmetrically spray-coated onto the front and back sides of the filter paper in the form of a regular rectangular array.

Owner:WUXI UNMIXED CLEANSE EQUIP

Spraying method of NdFeB rare earth permanent magnet surface diffusion source and magnet manufacturing method

InactiveCN111266273AEnsure consistencyImprove consistencySpraying apparatusPretreated surfacesEngineeringMechanical engineering

The invention discloses a spraying method of an NdFeB rare earth permanent magnet surface diffusion source. The diffusion source is sprayed on the surface of a magnetic through a spraying gun, the magnet is put on a tray to move, the spraying gun reciprocates to spray a solution of the diffusion source, and the moving velocity of the spraying gun, the moving velocity of the tray and the number oftimes of the spraying gun passing by the single magnet meet the following equation (please see the equation in the description), wherein l magnet represents the length of the magnet, N represents thenumber of times of the spraying gun passing by the single magnet, V tray represents the moving velocity of the tray, V spraying gun represents the moving velocity of the spraying gun and is perpendicular to the moving direction of the tray, V tray=2-5 cm / s, a=0.2-0.9, b=(1.1-3.2)*10^11, and c=450-800. By means of a manufacturing method of the NdFeB magnet, a magnet blank is manufactured, blasting,acid pickling and grinding are performed on the surface of the blank, heating treatment is performed on the blank, then spraying is performed according to the method, and finally ageing treatment isperformed. The spraying method has the advantages that the spraying consistency is ensured during spraying, the lower limit of the product is ensured, the spraying amount is reduced, meanwhile the performance consistency of the magnet is improved, and manufacturing cost is reduced.

Owner:ZHEJIANG INNUOVO MAGNETICS

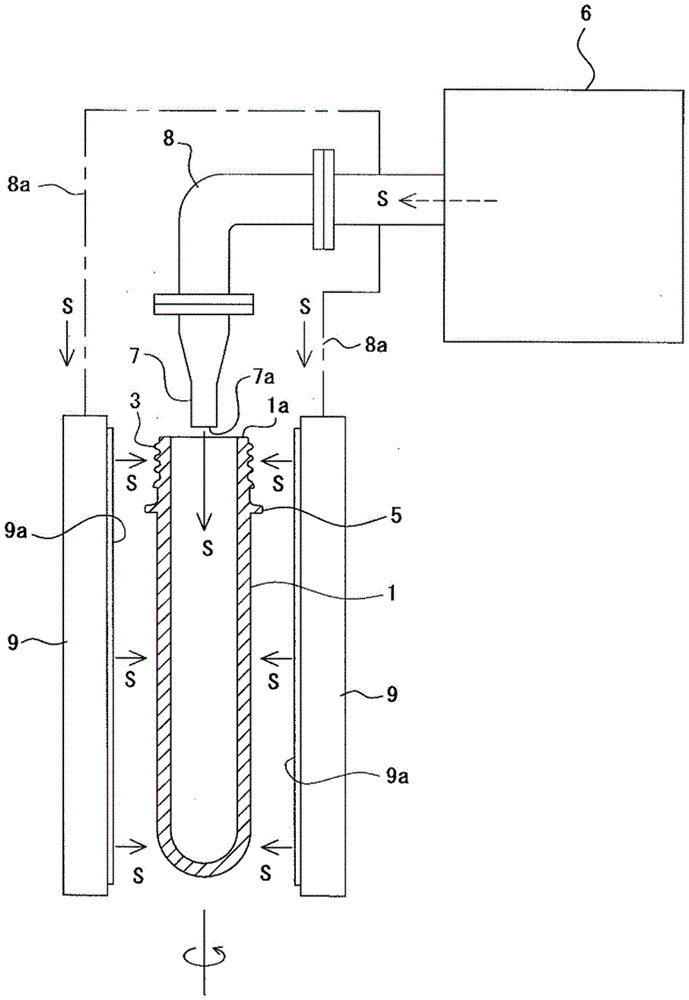

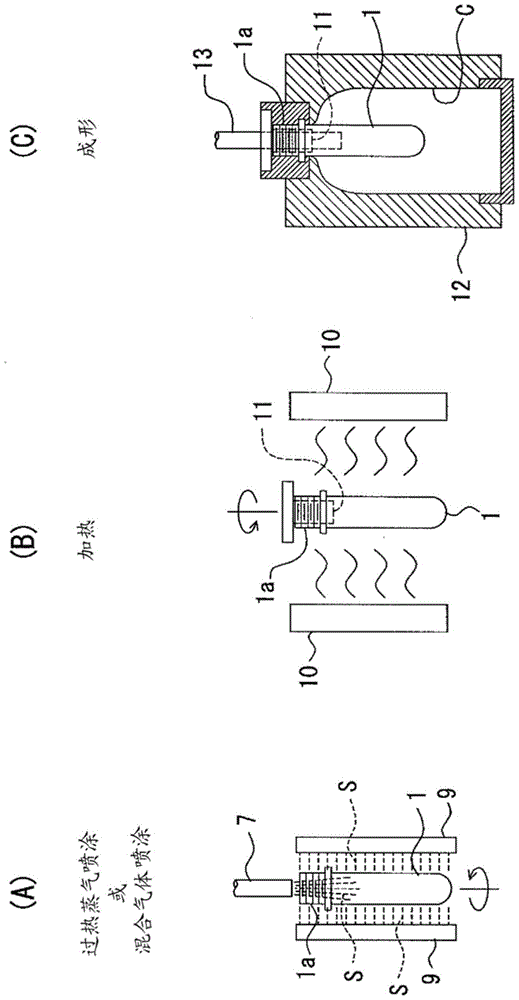

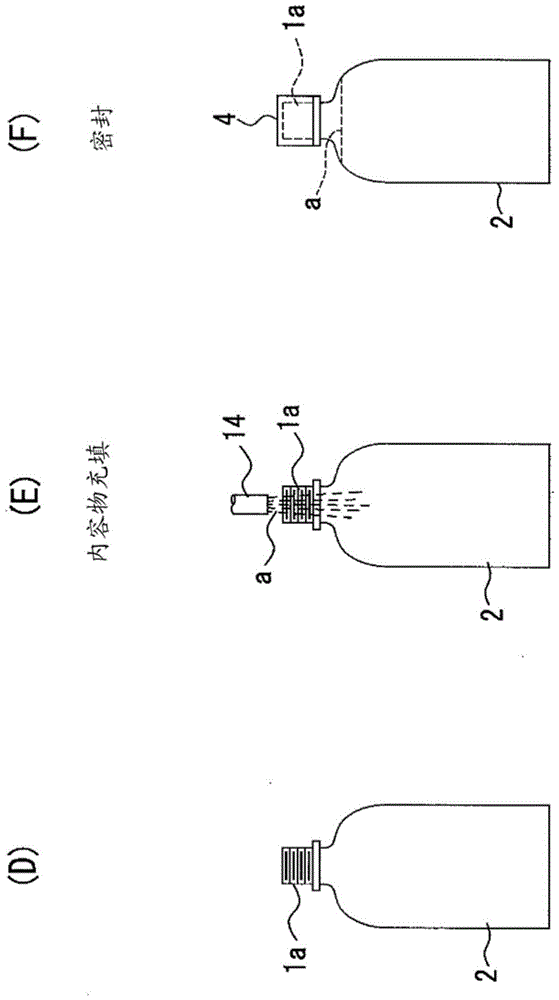

Preform sterilization method and content filling method and device

ActiveCN104169176BFast manufacturingEasy to fillPackage sterilisationDomestic articlesAtmospheric pressureMaterials science

The invention provides a method for sterilizing a preform, which can sterilize the preform simply and rapidly. Spraying superheated steam (S) made of water on the entire inner and outer surfaces including the mouth portion (1a) of the preform (1) with a pressure higher than the atmospheric pressure of 200° C. to 500° C. (1) Bacteria on the inner and outer surfaces are sterilized.

Owner:DAI NIPPON PRINTING CO LTD

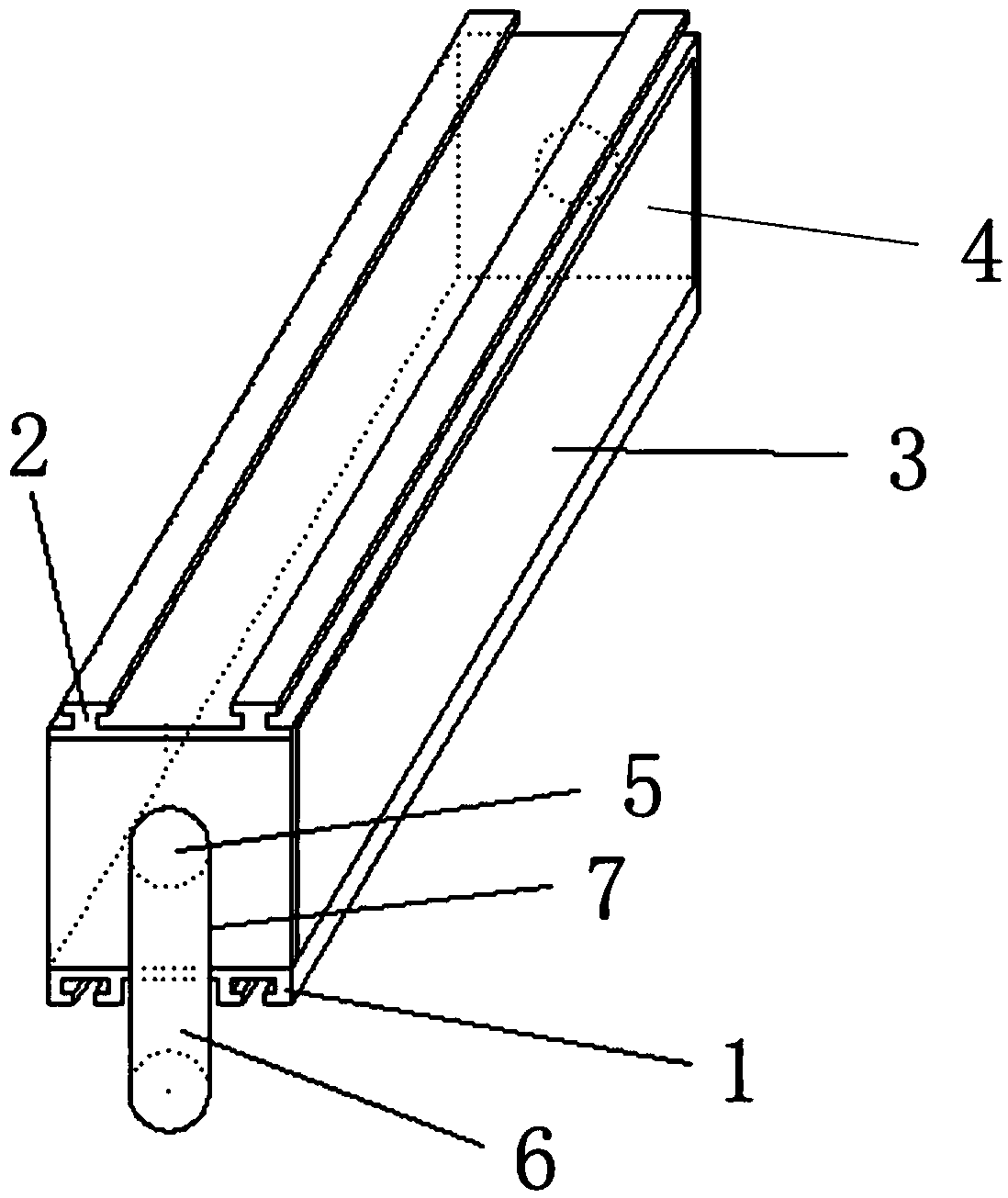

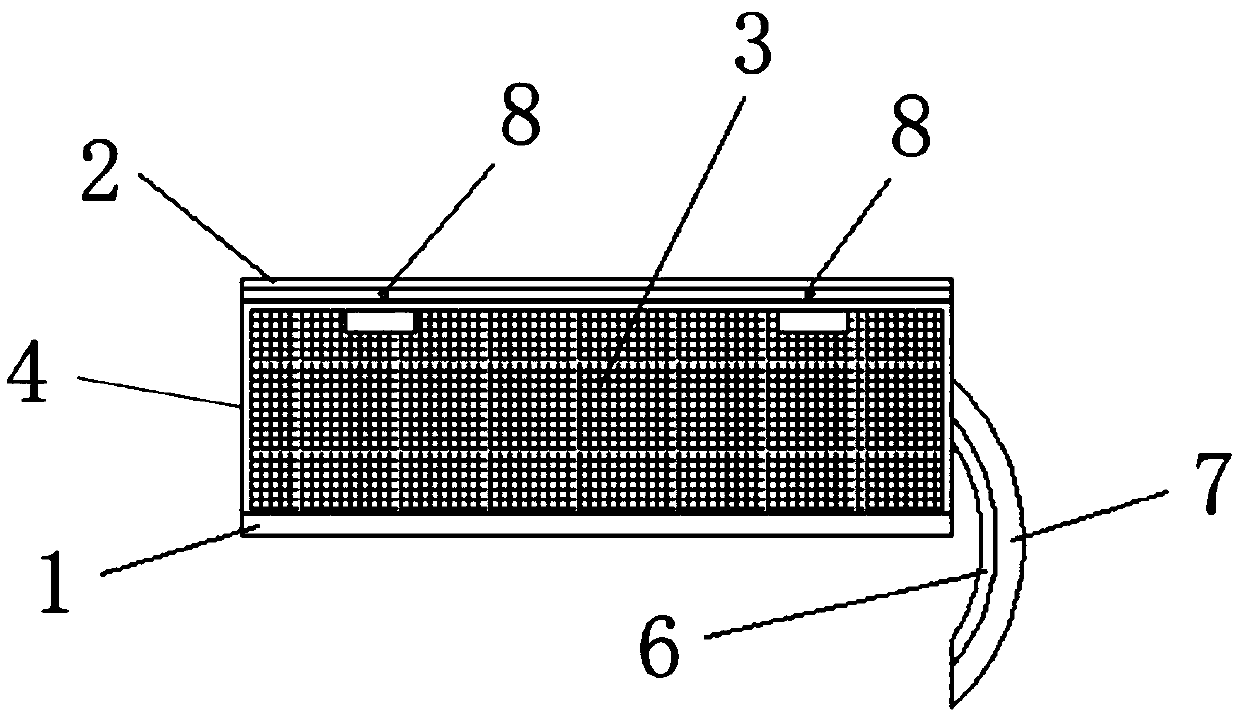

Breeding-transportation integrated encasement for marine products and application thereof

ActiveCN109511598ASimple structureReasonable designClimate change adaptationPisciculture and aquariaEngineeringMechanical engineering

The invention discloses a breeding-transportation integrated encasement for marine products and application thereof. The encasement comprises a box, which is composed of four long side-plates and twoshort side-plates. The two parallel long side-plates are respectively provided with a card track and a card slot, and the card track can be embedded in the card slot to form a stable structure. The side faces of the long side-plates provided with the card track are provided with lifting holes. The two short side-plates are both provided with penetrating round holes. One side of the round hole is provided with a detachable hose chute, which is sleeved with a detachable soft seal cartridge. The other end of the detachable hose chute can be embedded into the round hole of the other box. The application includes a floating aquaculture method based on the encasement and a cold seawater spray transportation method. The application requires no replacement of the box, improves the feeding mode, increases the feeding efficiency, and adopts cold sea water spray transportation to meet the transportation density.

Owner:YANCHENG INST OF TECH

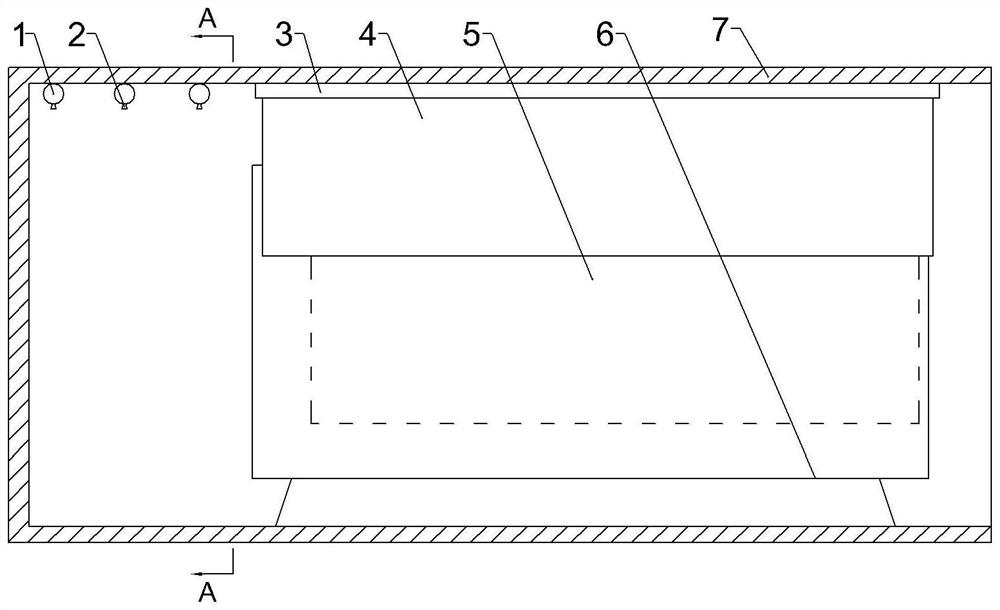

Self-precooling liquid nitrogen tunnel quick freezer

ActiveCN104697263BReduce spray volumeReduce usageLighting and heating apparatusCooling fluid circulationQuick FreezeEngineering

The invention relates to a quick freezer. In order to solve the technical problem of the waste of the liquid nitrogen in the prior art, the invention provides a self-prefreezing liquid nitrogen tunnel quick freezer. The self-prefreezing liquid nitrogen tunnel quick freezer comprises a tunnel freezing chamber and a surrounding type conveying belt, wherein liquid nitrogen sealing devices are arranged at the feeding end and the discharging end of the freezing chamber respectively; the quick freezer is characterized in that a prefreezing chamber is formed in the exterior of the feeding end of the freezing chamber; the chamber wall of the prefreezing chamber is fixedly connected to the chamber wall of the feeding end of the freezing chamber; the liquid nitrogen sealing device is arranged at an end opening of the outer side of the prefreezing chamber; the conveying belt penetrates through the prefreezing chamber; the side end of the conveying belt stretches out of the exterior of the prefreezing chamber. The self-prefreezing liquid nitrogen tunnel quick freezer is reasonable in structure, simple and convenient to operate and high in quick freezing efficiency; the production cost can be effectively reduced; the self-prefreezing liquid nitrogen tunnel quick freezer has a wide market prospect.

Owner:荣成市同福机械制造有限公司

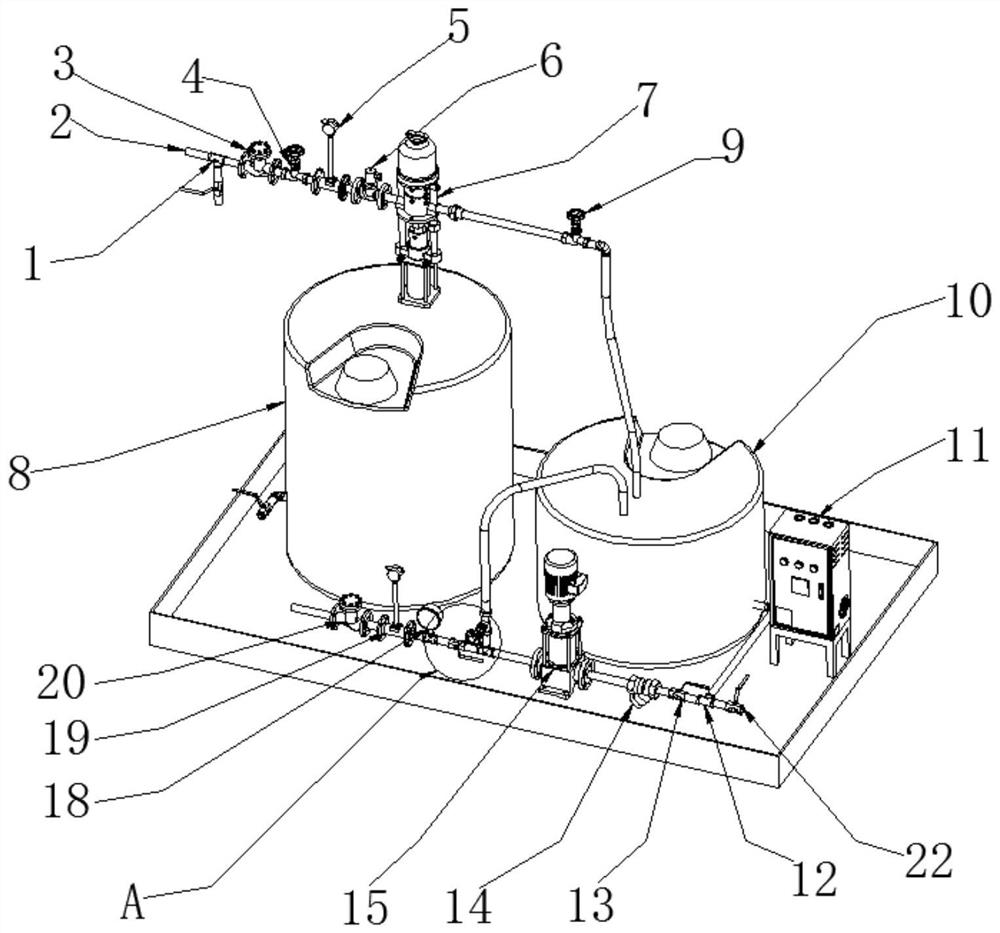

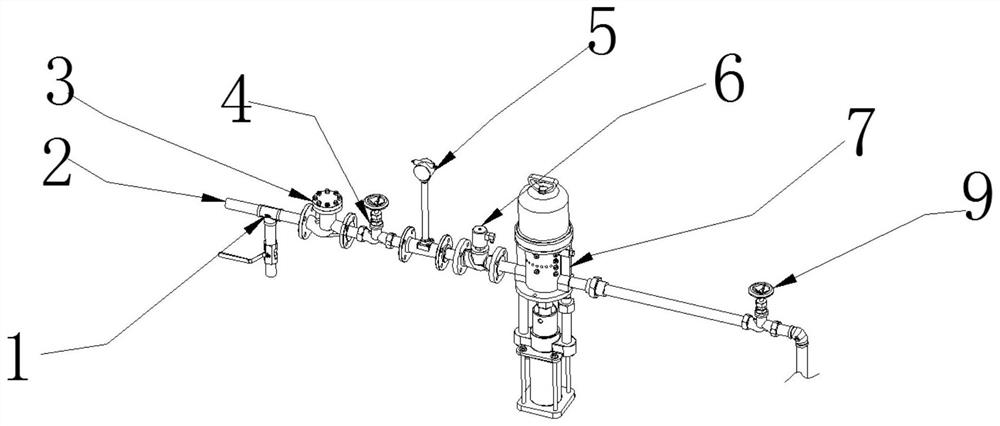

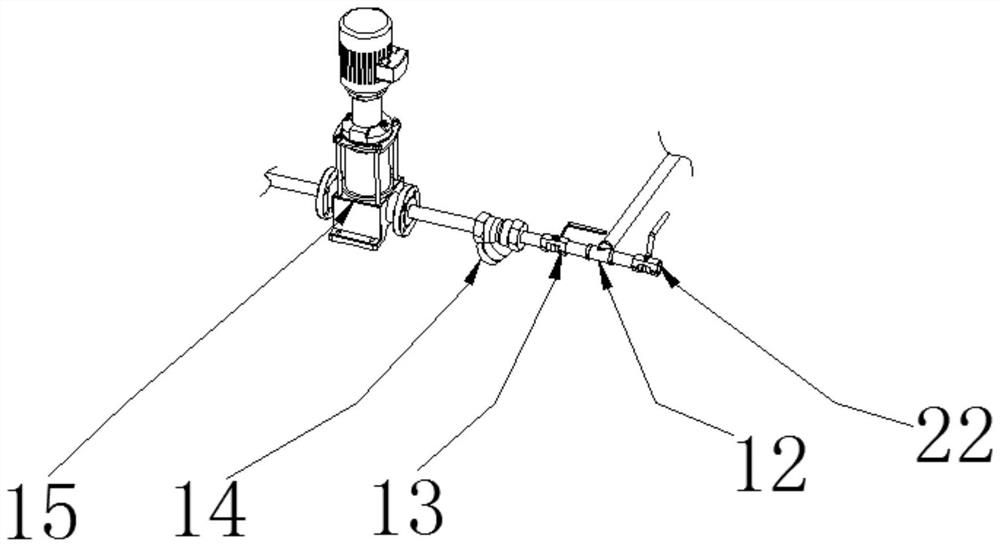

Mist spray equipment capable of automatically controlling deodorization with detection function

ActiveCN111686961AAchieve hybridControl concentrationGas treatmentDispersed particle separationSpray nozzleEnvironmental engineering

The invention relates to mist spray equipment capable of automatically controlling deodorization with a detection function. The mist spray equipment comprises a stock solution barrel, a liquid mixingbarrel and a plurality of spray nozzles, wherein a water pump is arranged between the stock solution barrel and the liquid mixing barrel; the liquid mixing barrel further communicates with a water inlet; a spray pump is arranged between the spray nozzles and the liquid mixing barrel; the water pump and the spray pump are respectively connected with a controller; the controller controls the water pump to pump liquid in the stock solution barrel into the liquid mixing barrel; and the controller controls the spray pump to pump the liquid in the stock solution barrel out to the spray nozzles to spray out. The water pump pumps a stock solution in the stock solution barrel into the liquid mixing barrel, and a water inlet feeds water into the stock solution barrel to achieve mixing of the stock solution and water; the concentration of mixed liquid is controlled by controlling the running time of the water pump; and the local mist spray amount is controlled by detecting the concentration valueof local odors, the mist spray amount to an odorous area is improved, the mist spray amount to a non-odorous area is reduced, and the mist spray amount is reasonably distributed, so that the treatment effect is improved; and the equipment is automatically opened and closed according to the highest odor concentration value, so that automatic opening and closing of the equipment is achieved.

Owner:宁波百竹环保科技有限公司

Automatic spraying deodorization device and treatment method thereof

PendingCN114669170AReduce labor intensityImprove the accuracy of the ratioGas treatmentTransportation and packagingCheck valveElectromagnetic valve

The invention discloses an automatic spraying deodorization device and a treatment method thereof, and relates to the technical field of environmental protection, in particular to a first three-way pipe and a raw material barrel, a water inlet is formed in one end of the first three-way pipe, and the raw material barrel is connected to the bottom of a proportioning pump through a hose; the side, away from the first electromagnetic valve, of the proportioning pump is connected with a second ball valve through a pipeline, a control cabinet is arranged on one side of the batching barrel, and the side face of the batching barrel is connected with a second three-way pipe through a pipeline; and the other end of the water pump is sequentially connected with a third three-way pipe, a fourth ball valve, a pressure gauge, a second flow meter, a second check valve and a spray head through a pipeline. According to the automatic spraying deodorization device and the treatment method thereof, through cooperative use of the liquid level meter and the proportioning pump, deodorization liquid and water can be automatically mixed according to a specific proportion when the liquid level is lower than a preset value, and the mixture is supplemented into the batching barrel, so that the labor intensity of manual proportioning of operators is greatly reduced, and the proportioning accuracy is also greatly improved.

Owner:苏州清初环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com