Self-precooling liquid nitrogen tunnel quick freezer

A self-precooling and quick-freezing machine technology, which is applied in household refrigeration equipment, cooling fluid circulation equipment, lighting and heating equipment, etc., and can solve the problem of liquid nitrogen waste and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

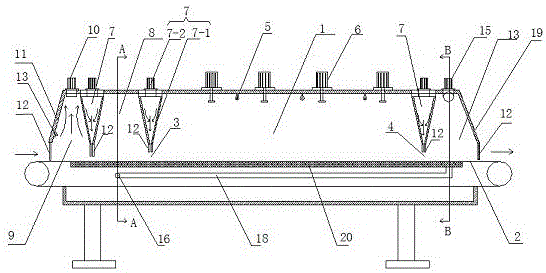

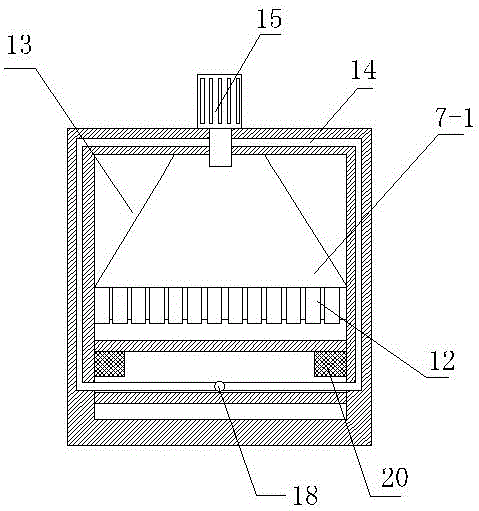

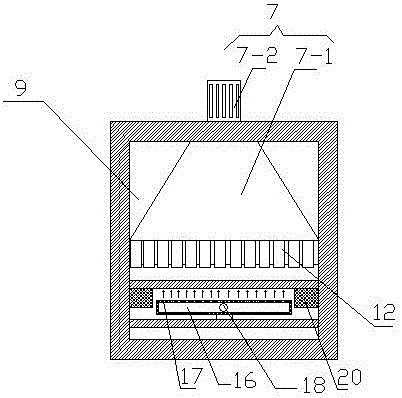

[0015] as attached figure 1 As shown, a self-precooling liquid nitrogen tunnel quick-freezing machine includes a tunnel-type freezing chamber 1 and a surrounding conveyor belt 2. The two ends of the freezing chamber are respectively a feed end 3 and a discharge end 4. The surrounding The type conveyor belt passes through the freezing chamber to form an upper and lower conveyor belt, and the two ends of the conveyor belt protrude from the feeding end and the discharging end of the freezing chamber respectively.

[0016] The structure of this freezing chamber 1 is consistent with the structure of the traditional liquid nitrogen tunnel type quick-freezing machine. The top of the freezing chamber is provided with a liquid nitrogen spray pipe 5, and the top wall of the freezing chamber is provided with a downward pressure diffusion fan 6. Its structure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com