Automatic spraying deodorization device and treatment method thereof

A treatment method and automatic technology, applied in separation methods, gas treatment, mixture post-treatment, etc., can solve problems such as difficulty in matching spray volume with actual demand, high labor intensity of batching operators, adaptability to changes in production line start and stop, etc., to achieve The effect of reducing labor intensity, improving the accuracy of proportioning, and reducing the amount of spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

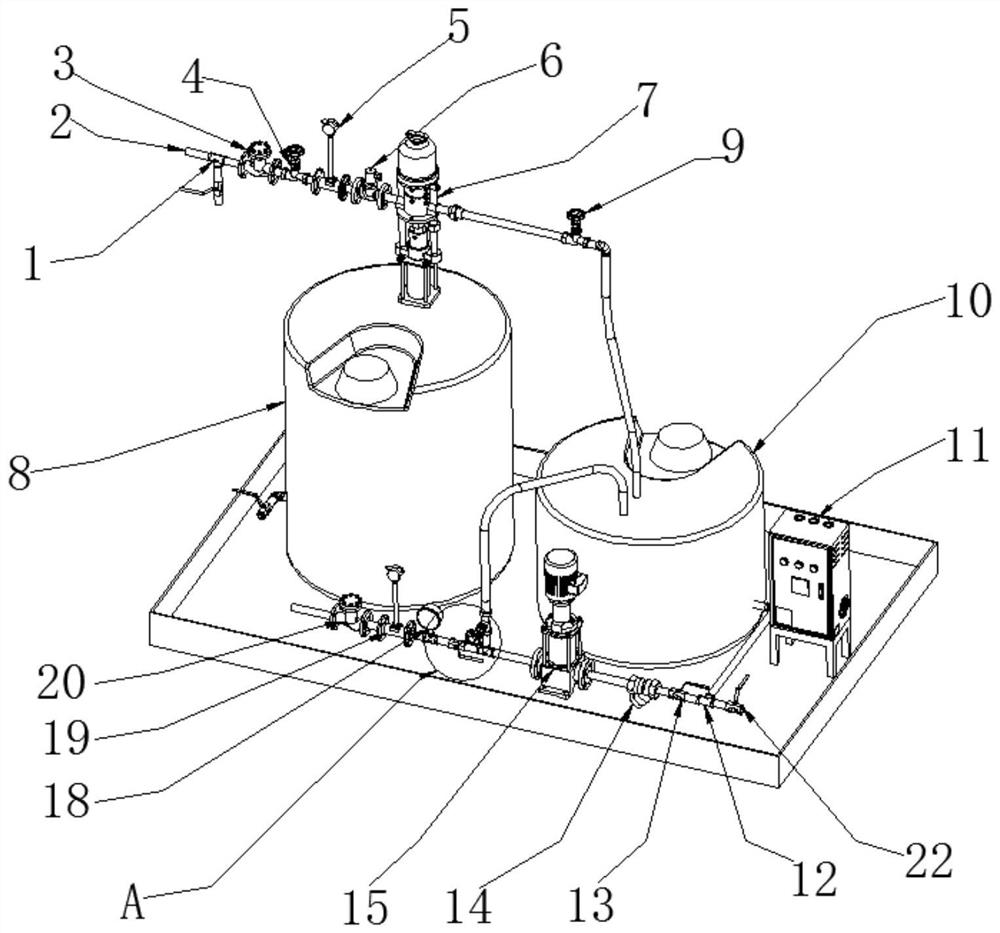

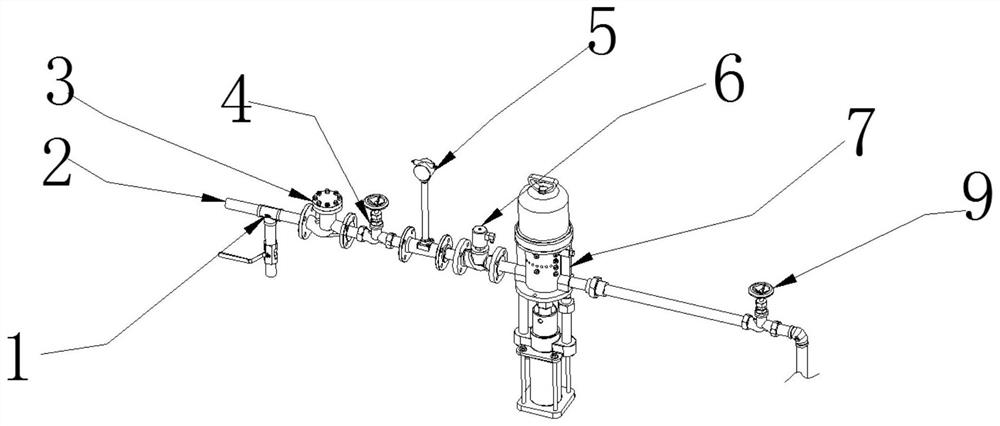

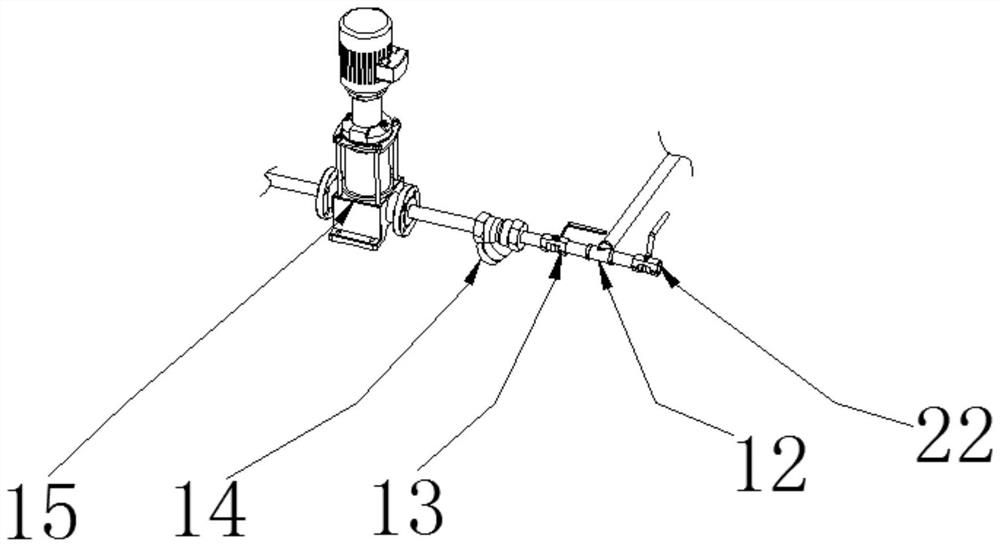

[0032] see Figure 1 to Figure 5 , the present invention provides a technical solution: an automatic spray deodorization device and a processing method thereof, comprising a first three-way pipe 1 and a raw material barrel 8, one end of the first three-way pipe 1 is provided with a water inlet 2, and the first three-way pipe 1 is provided with a water inlet 2, and the first The other end of the three-way pipe 1 is sequentially connected with a first check valve 3, a first ball valve 4, a first flow meter 5, a first solenoid valve 6 and a proportional pump 7 through a pipeline, and the raw material barrel 8 is connected to the proportional pump through a hose At the bottom of 7, the side of the proportional pump 7 away from the first solenoid valve 6 is connected with a second ball valve 9 through a pipeline, and the other end of the second ball valve 9 is connected with a batching bucket 10 through a pipeline, and one side of the batching bucket 10 is arranged with a control C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com