Preform sterilization method and content filling method and device

A preform and sterilizing device technology, which is applied in packaging, bottling machines, liquid bottling, etc., can solve the problems of bactericide corrosion in forming machines, achieve simple filling and increase manufacturing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

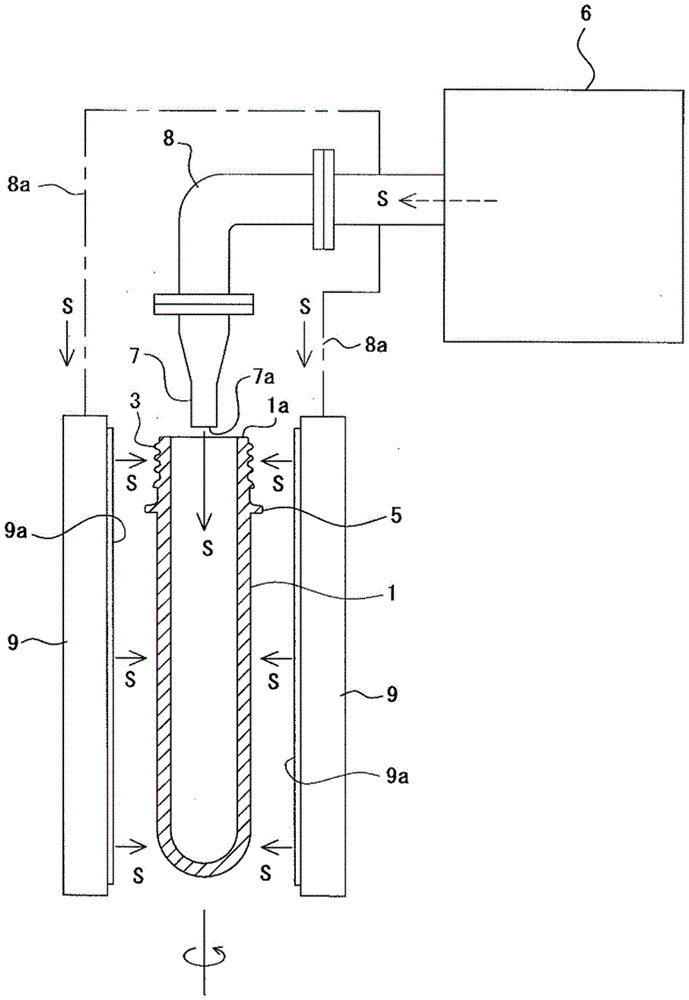

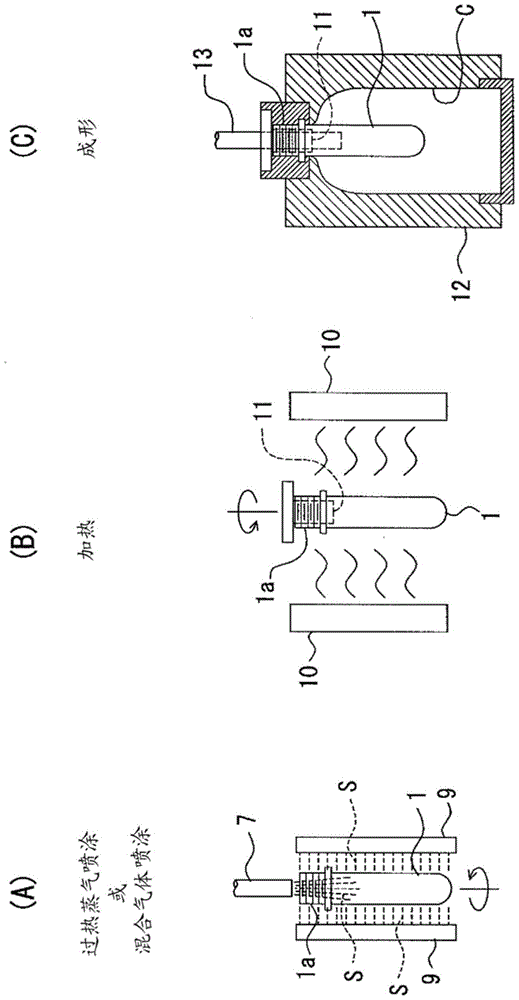

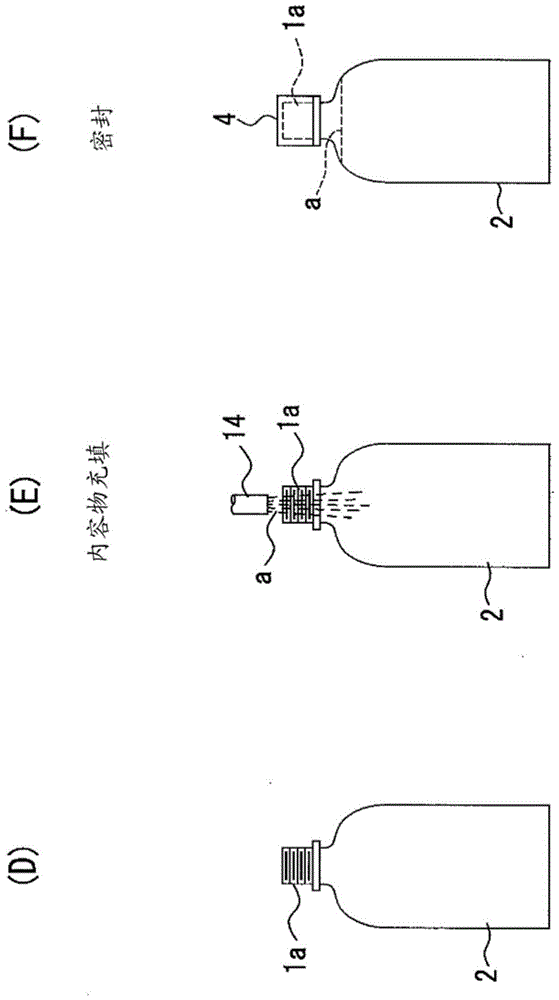

[0046] Such as figure 1 As shown, the preform 1 is sterilized by spraying water on the inner and outer surfaces of the preform as a whole including the mouth portion 1a of the preform 1 with superheated steam S whose pressure is higher than the atmospheric pressure of 200°C to 500°C.

[0047] The temperature of the superheated steam sprayed on the preform is preferably 200°C to 500°C, more preferably 250°C to 400°C. In the temperature range of 200° C. to 500° C., by exposing only the surface of the preform to high temperature, bacteria adhering to the surface of the preform can be sterilized in a short time. If the temperature of the superheated steam S is lower than 200° C., spraying for a long time is required for sterilization, PET itself constituting the preform becomes high temperature, and the deformation of the preform increases. Moreover, if it exceeds 500 degreeC, even in a short time, the temperature of PET itself which comprises a preform rises, and it becomes easy...

Embodiment 1

[0115] The superheated steam with a flow rate of 0.7g / s generated by heating water with a superheated steam generator according to the medium heating method is blown from a nozzle with an inner diameter of 8mmφ, and the preform for a 500mL (milliliter) PET bottle and a 2LPET bottle are injected at a temperature of 300°C. Each inner surface of the preform was sprayed for 5 seconds.

[0116]The bactericidal effect of the spraying of superheated steam was confirmed on the basis of the index bacteria planted on the inner surface. As shown in Table 1, it was found that the bactericidal effect is suitable for filling with mineral water and the like.

[0117] [Table 1]

[0118] B.sub. A. nig. For 500mL 3.1D 6.0D or above For 2L 3.0D 6.0D or above

[0119] In addition, in Table 1, "B.sub." is the abbreviation of Bacillus subtilis (Bacillus subtilis), and "A.nig." is the abbreviation of Aspergillus niger (Aspergillus niger). "D" is a D value indicati...

Embodiment 2

[0124] The inner surface of the preform for a 500mL PET bottle is sprayed from a nozzle with an inner diameter of 8mmφ at various blowing temperatures ranging from 180°C to 550°C for various times ranging from 10 seconds to 3 seconds. Generation of superheated steam by means of medium heating The device heats water to generate superheated steam with a flow rate of 0.7g / s.

[0125] Table 3 shows the bactericidal effect and the deformation of the inner diameter of the preform by the spraying of the superheated steam.

[0126] [table 3]

[0127] Ejection temperature (°C) Ejection time (seconds) Bactericidal effect out of shape 180 10 × × 250 6 ○ ○ 350 4 ○ ○ 450 3 ○ ○ 550 3 ○ ×

[0128] However, in Table 3, regarding the bactericidal effect, the D value relative to Bacillus subtilis is 3 or more, and the D value relative to Aspergillus niger is 6 or more. Set to "×" (impossible). Regarding the deformation, the case where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com