Manufacturing method of fingerprint identification module

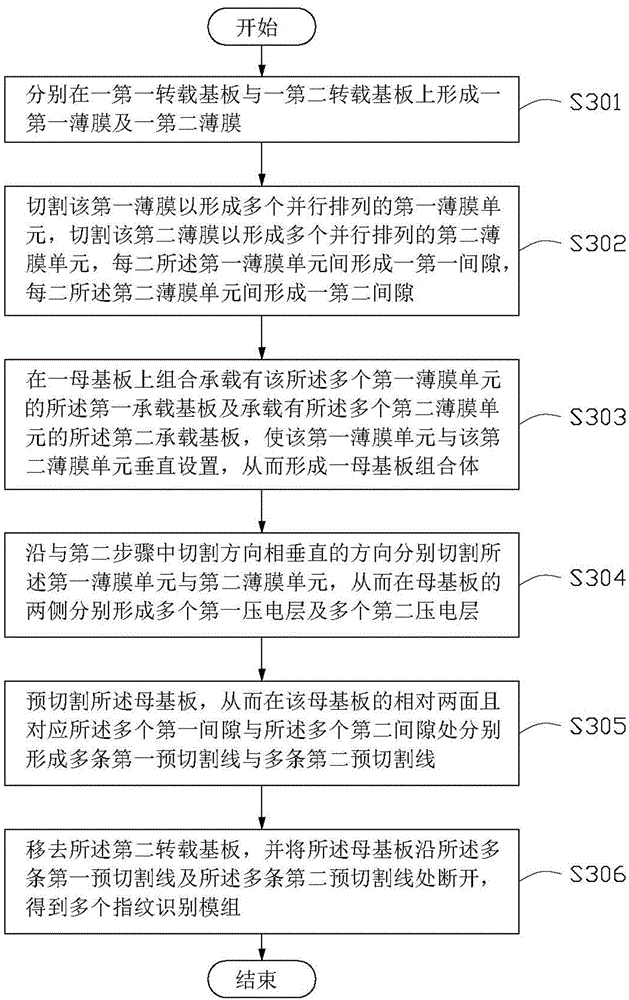

A technology of a fingerprint identification module and a manufacturing method, which are applied in character and pattern recognition, acquisition/organization of fingerprints/palmprints, manufacturing/assembly of piezoelectric/electrostrictive devices, etc., can solve high labor costs and large time costs and other problems, to achieve the effect of improving production speed, reducing time cost and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

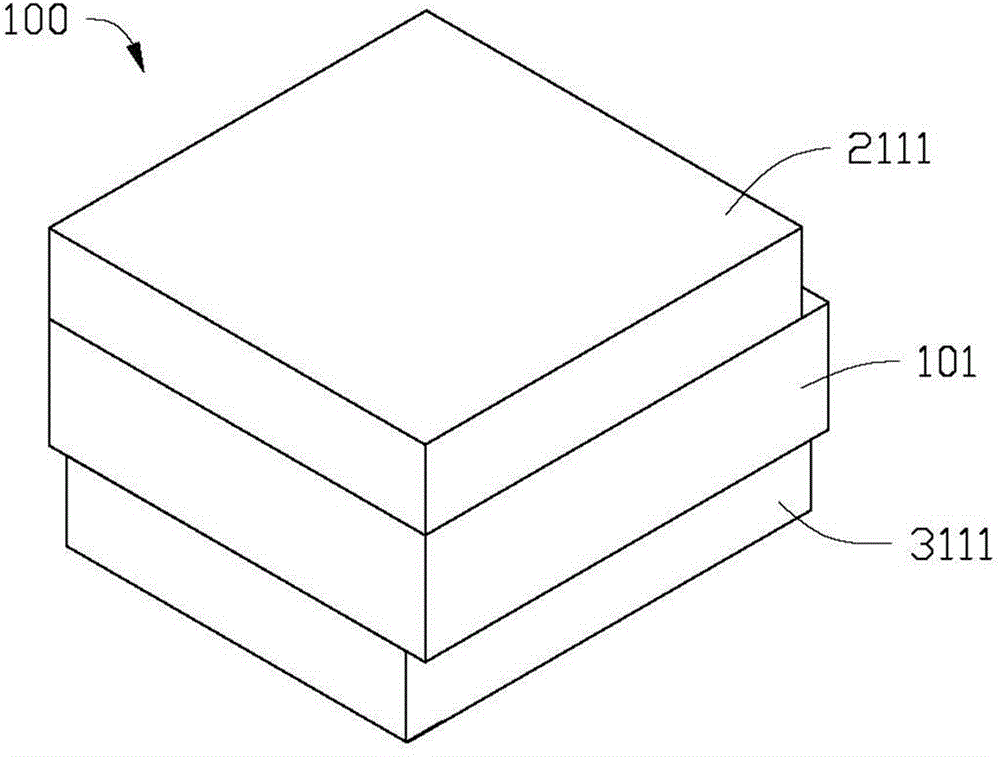

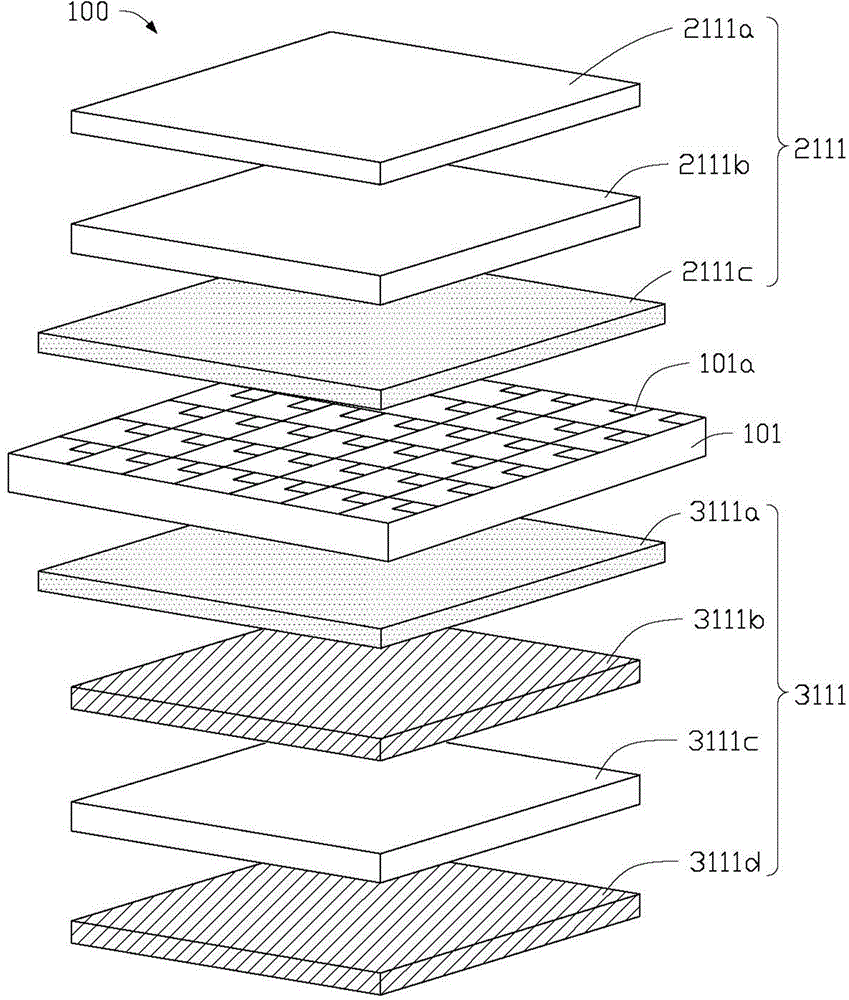

[0019] figure 1 is a perspective view of the fingerprint recognition module 100 provided by the present invention, figure 2 for figure 1 For an exploded schematic diagram of the fingerprint identification module 100 in China, please refer to figure 1 and figure 2 . The fingerprint identification module 100 is used to electrically connect with a signal transmission module (not shown), the fingerprint identification module 100 is used to identify fingerprints placed on its surface, and form image information corresponding to user fingerprints transmitted to the signal transmission module, and the signal transmission module outputs the image information received from the fingerprint identification module 100 to other external functional modules, such as an image display module and the like. In this embodiment, the fingerprint recognition module 100 is an ultrasonic fingerprint recognition module 100 .

[0020] The fingerprint identification module 100 includes a substrate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com