Combined biological treatment method for pharmaceutical and chemical sewage and organic waste gas

A technology for organic waste gas and chemical sewage, which is applied in water/sewage treatment, special compound water treatment, water/sewage multi-stage treatment, etc. It can solve the problems of high daily maintenance requirements, low treatment efficiency, deflagration risk, etc. The effect of chemical consumption, improving processing efficiency and reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

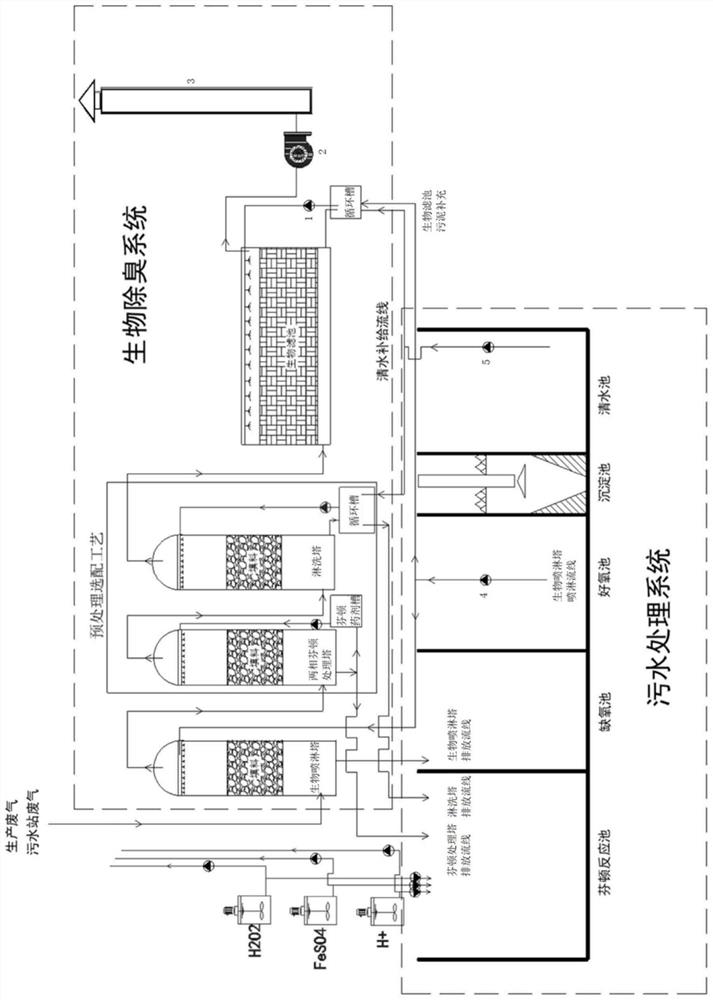

[0026] figure 1 It is a simplified schematic diagram of the CBPP process. The system treatment process of the sewage station is simplified. Only the sewage station and the functional area of waste gas purification involved in CBPP are listed to facilitate the description of the process content of CBPP.

[0027] figure 1 Shown, a method for combined biological treatment of pharmaceutical and chemical sewage and organic waste gas, comprising the following steps:

[0028] (1) After the production waste gas and the waste gas from the sewage station are collected, they are transported into the biological spray tower through the exhaust gas inlet through the Roots blower, and the aerobic pool return pump 4 of the sewage treatment system pumps the activated sludge mud-water mixture in the aerobic pool into the biological spraying tower. Spray tower, the top-down mud-water mixture fully contacts the bottom-up organic waste gas in the spray tower packing layer, dissolves and absorbs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com