Baffle-free high-efficiency filter

A high-efficiency filter without partition technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of self-heavy, small effective ventilation area, and high processing cost, so as to reduce resistance and improve effective Ventilation area, dust accumulation, and the effect of reducing the amount of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

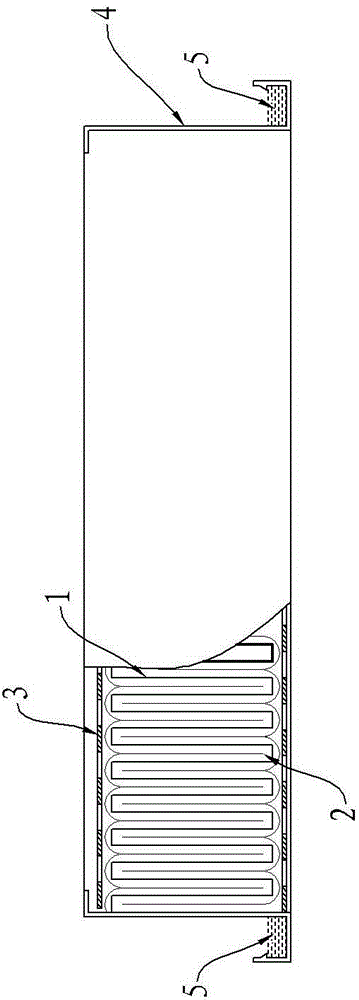

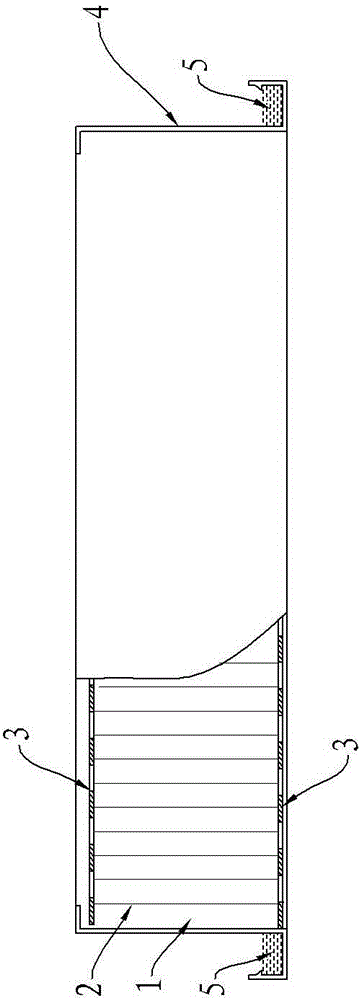

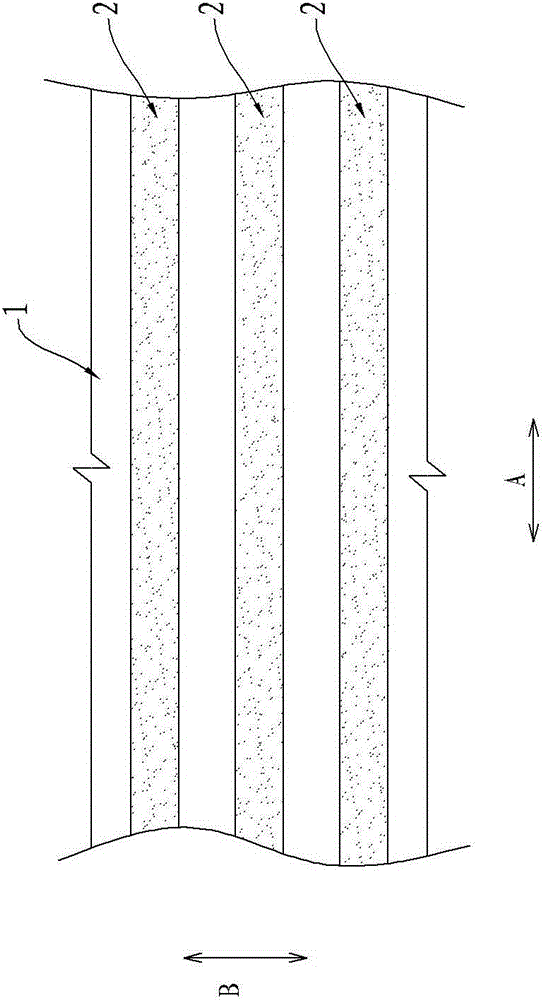

[0013] See Figure 4 and Figure 5 The high-efficiency filter without clapboard of the present invention includes a box body 10, and a filter element 20 is installed in the box body 10. The filter element 20 includes a filter paper 21, and the front and back sides of the filter paper 21 are symmetrically sprayed with several hot-melt adhesive strips 22 in the shape of rectangular strips. ,See Figure 6 , and some hot-melt adhesive strips 22 in the shape of rectangular strips are evenly distributed in a rectangular array, and the filter paper with several hot-melt adhesive strips 22 symmetrically sprayed on the front and back sides forms a filter core 20 through repeated folding; It is divided into the rubber strip row 22-1 at the folding part and the rubber strip row 22-2 at the middle part, the rubber strip row 22-2 at the middle part is located between two adjacent rows of rubber strips 22-1 at the folding part, and the filter paper 21 is folded repeatedly At this time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com