Rectifying desulphurization system

A wet desulfurization and spray system technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory gas-liquid mass transfer effect, poor uniformity of flue gas distribution, and low desulfurization efficiency, etc. Achieve the effect of good gas-liquid mass transfer, reduce the amount of slurry spray, and reduce the number of spray layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

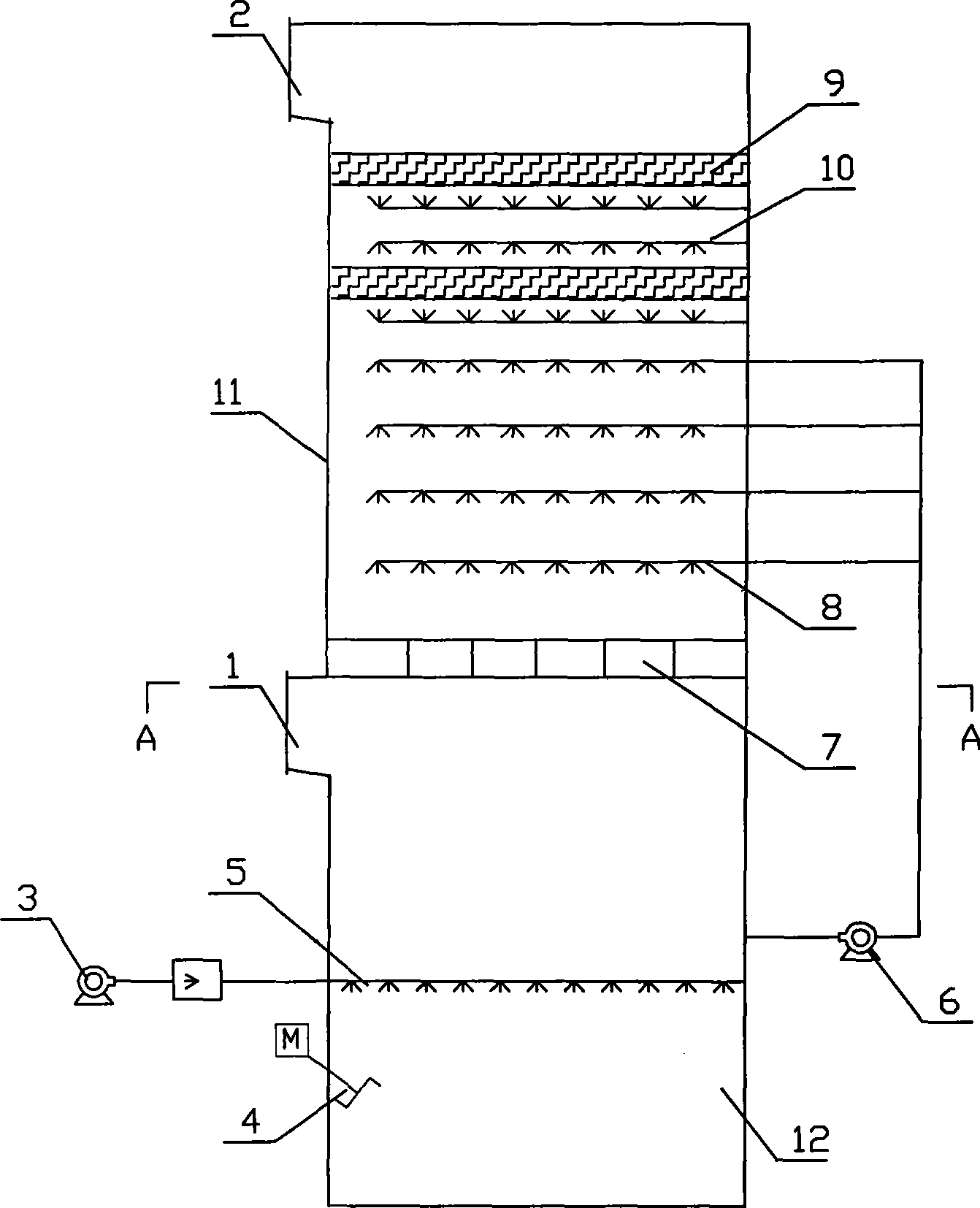

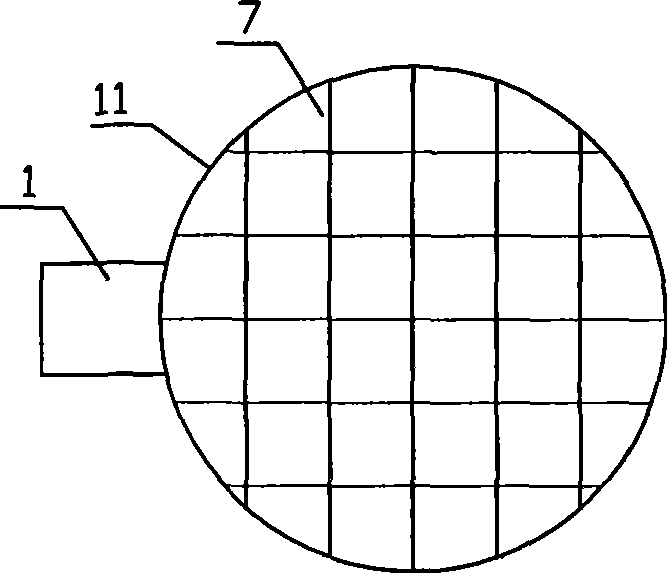

[0020] see figure 1 , the rectification and desulfurization system of this embodiment includes an absorption tower body 11, a slurry tank 12 is arranged at the bottom of the absorption tower body 11, and a stirring device 4 is arranged in the slurry tank 12; a flue gas is arranged in the middle part of the absorption tower body 11 Inlet 1, the upper part is provided with a flue gas outlet 2, and the absorption tower body 11 is sequentially provided with a slurry spray system 8 and a demisting system 9 from the flue gas inlet 1 to the flue gas outlet 2, and the demisting system 9 is provided with two stage, a shower water system 10 is arranged between the two-stage demisting systems 9, and the slurry spray system is provided with 4 layers. The flue gas wet desulfurization absorption tower also includes a circulating slurry pump 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com