Spray nozzle and coating system using the same

A spray nozzle and coating technology, used in spray discharge devices, liquid spraying equipment, coatings, etc., can solve problems such as limited and difficult mass production process applications, and achieve increased spray volume, improved material consumption, and improved adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

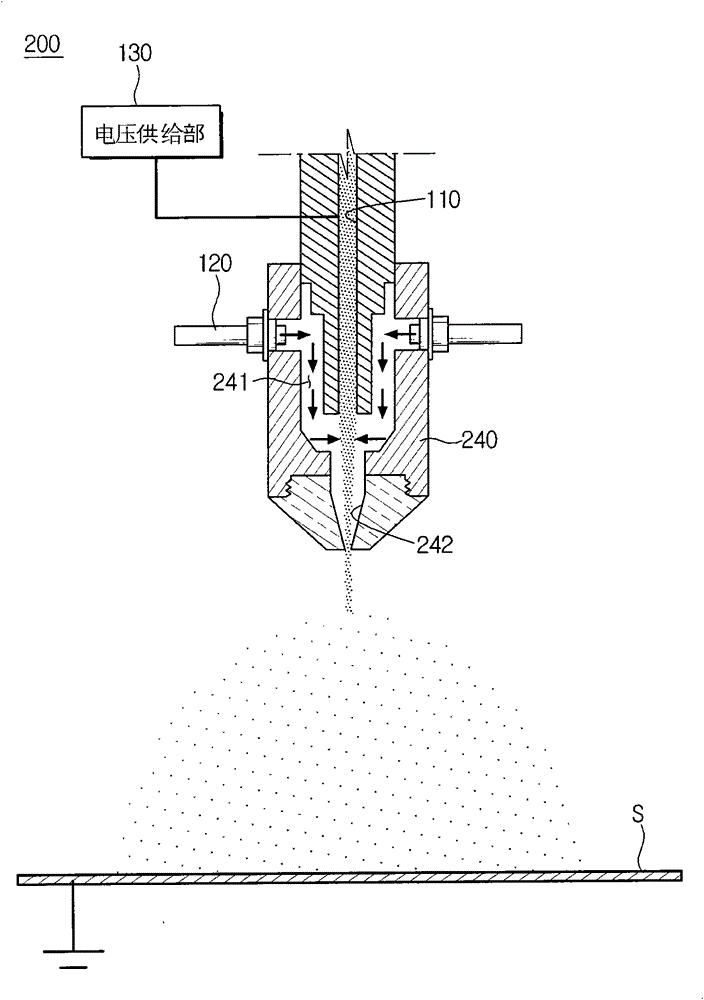

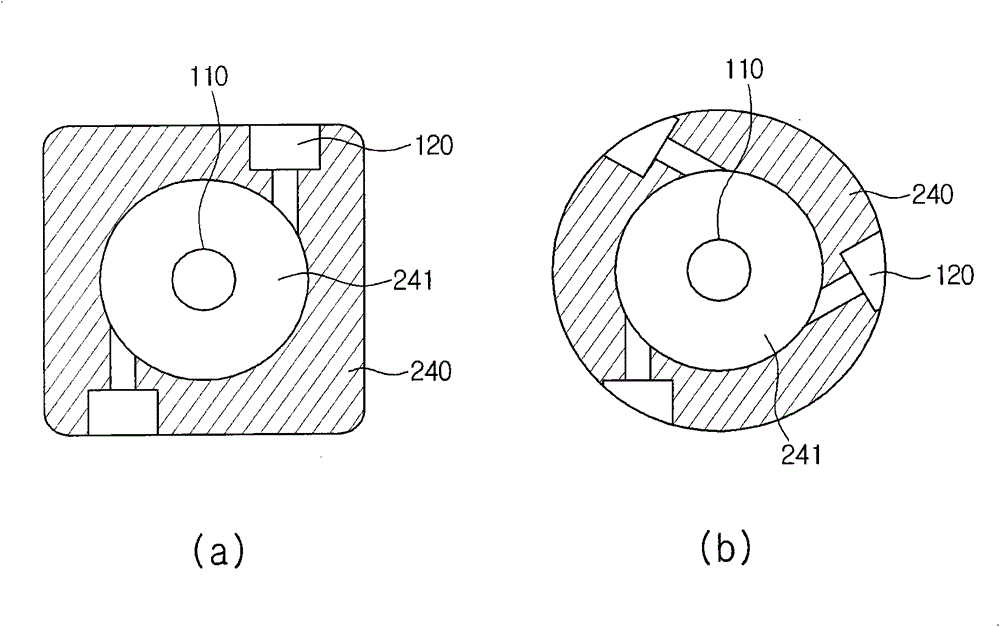

[0061] Before the description, it needs to be emphasized that in multiple embodiments, the same reference signs are used for the structural elements with the same structure, and a representative description is made in the first embodiment, and the description in other embodiments is similar to that in the first embodiment. A different structure of an embodiment.

[0062] Next, a spray nozzle and a coating system using the spray nozzle according to a first embodiment of the present invention will be described in detail with reference to the drawings.

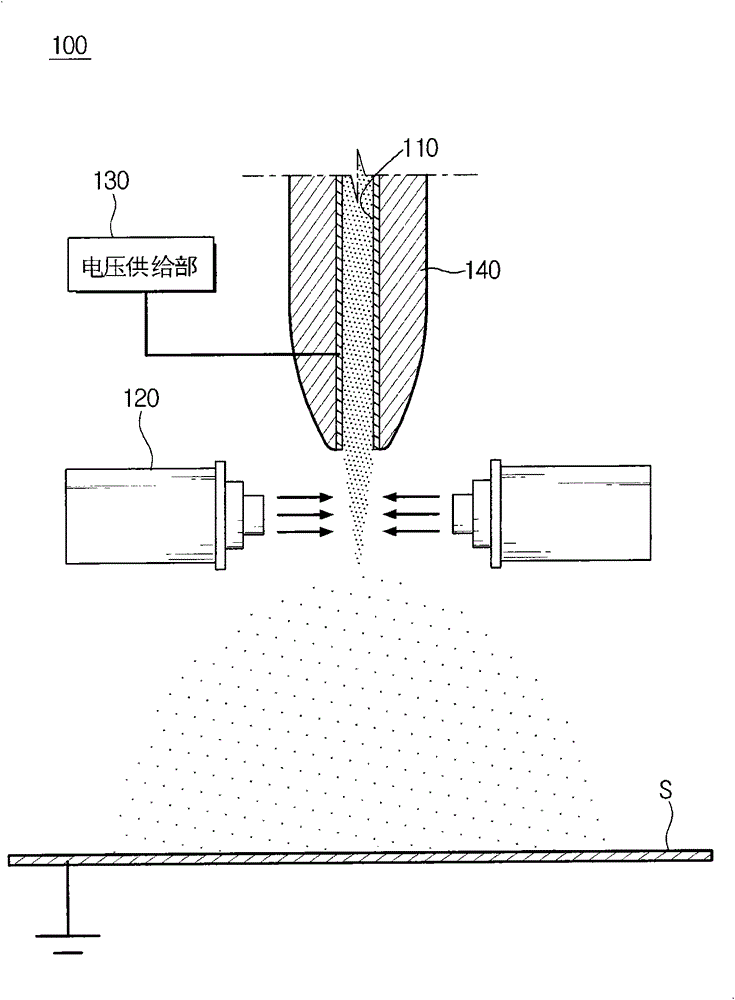

[0063] figure 1 It is a sectional view schematically showing the spray nozzle of the first embodiment of the present invention.

[0064] refer to figure 1 , the spray nozzle 100 of the first embodiment of the present invention collides the sprayed liquid with the gas so that the liquid is primary atomized, and an electric field is applied to the primary atomized liquid to cause the liquid to be secondary atomized, thereby The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com