Film roller for metallized film slitter

A metallized film, slitting machine technology, applied in thin material processing, capacitor manufacturing, winding strips, etc., can solve the problems of static electricity, low friction, single, etc., to increase friction and reduce wrinkles , Improve the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

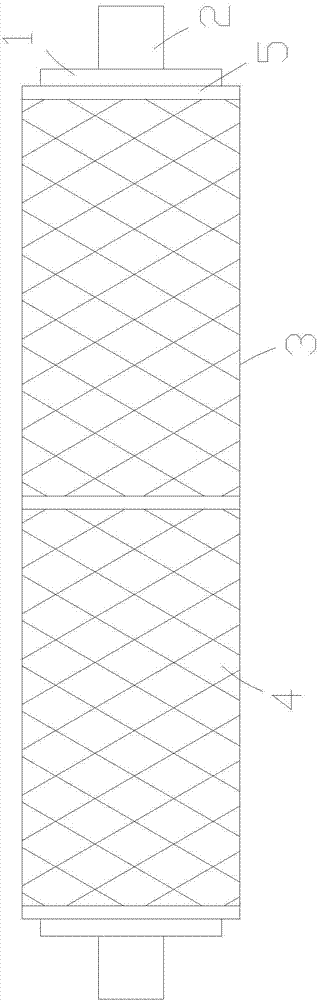

[0011] Such as figure 1 As shown, a film roll for a metallized film slitting machine includes a metal roll body 1, a central rotating shaft 2 is arranged in the metal roll body 1, and a roll sleeve 3 is set outside the metal roll body 1. The surface of the surface is printed with rhombus lines 4 which are connected together, and the rhombus lines 4 cover the entire circumferential surface of the roller sleeve 3, and the diamond-shaped area in the middle of the rhombic lines 4 protrudes upwards, and the roll sleeve 3 is made of methyl vinyl silicone rubber. As a result, strip-shaped grooves 5 are provided on both sides and the middle position of the roller cover 3 along the circumferential direction.

[0012] The basic principles and main featur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com