Low-temperature difference air heat power generation method

A technology of air heat energy and normal temperature air, which is applied in the direction of machines/engines, mechanisms for generating mechanical power, mechanical equipment, etc., and can solve problems such as high cost of electric power remote transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

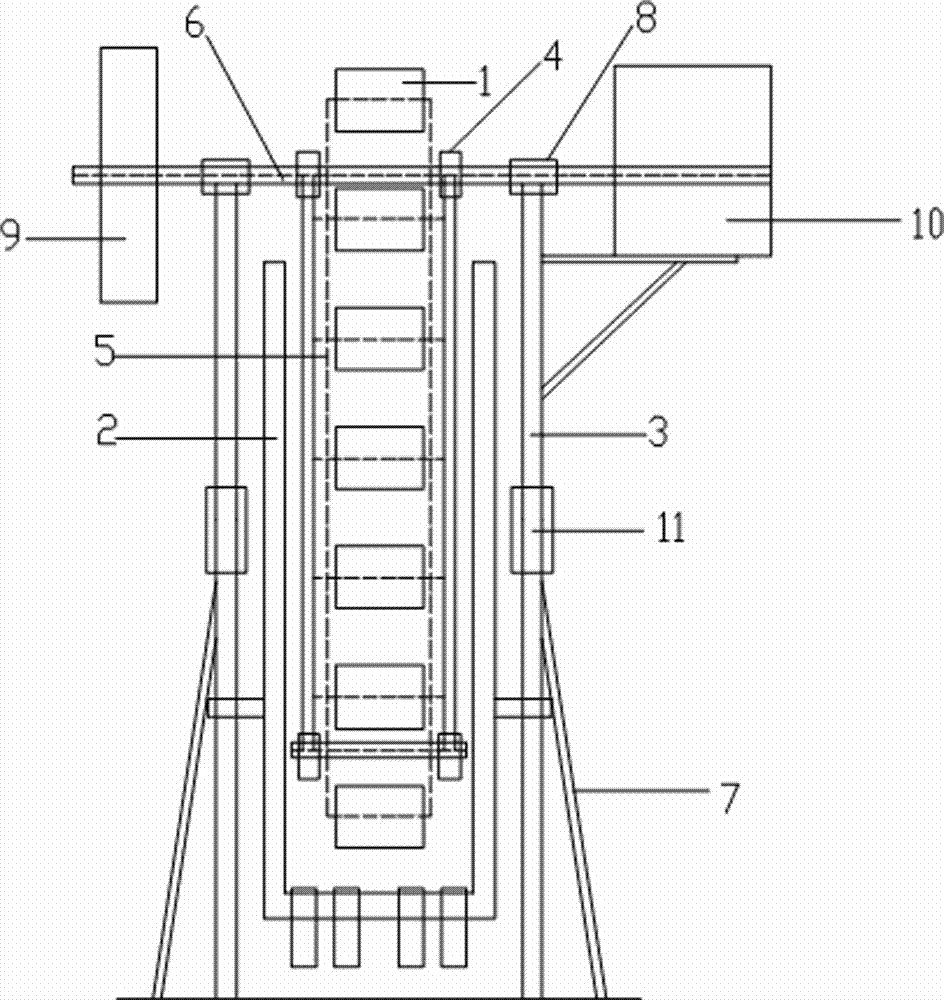

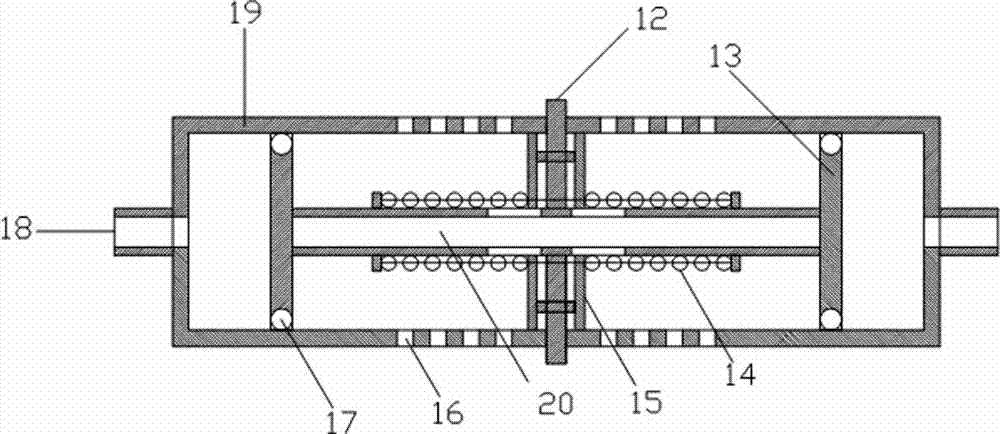

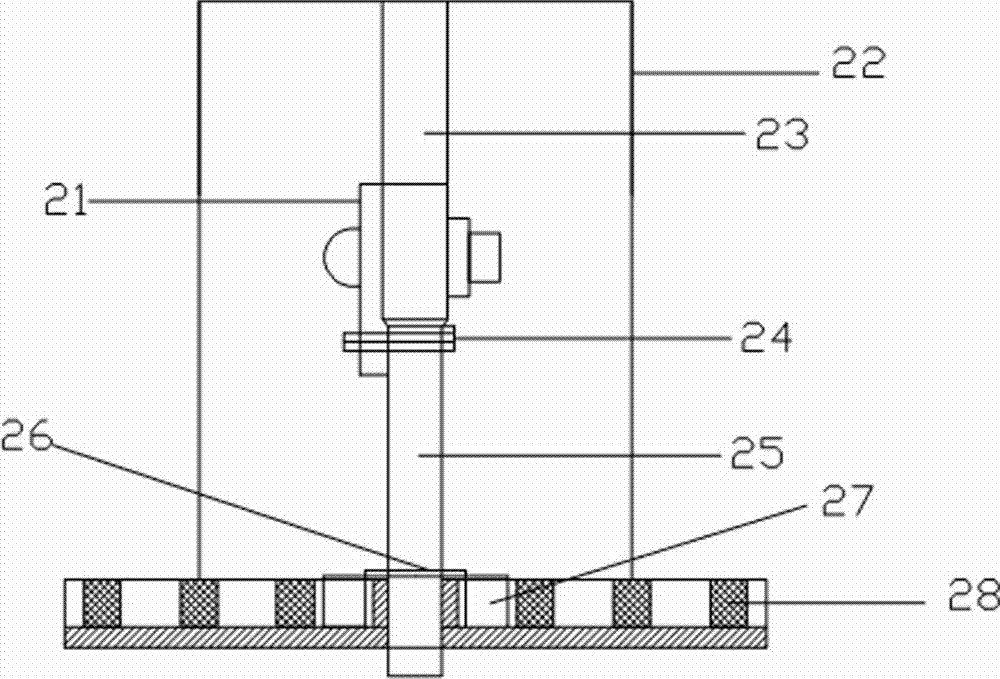

[0018] The air at normal temperature is absorbed from the atmosphere, and the hot gas is raised to 65 degrees by the heat pump, and then sent into the thermal insulation water tank with a specific height, so that the temperature of the water tank reaches 60 degrees. The rotating structure device installed in the water tank is equipped with a thermal actuator 1, and the laminated memory alloy butterfly spring in the thermal actuator 1 sinks from the martensitic configuration at room temperature into the hot water at 60 degrees, and changes to austenitic when heated. body configuration to move the variable capacity valve 13 of the thermal actuator 1, so that the buoyancy of the transducing cylinder 19 increases, and it floats out of the water. Memory alloy belleville spring changes to martensitic configuration and enters the hot water again. Its up and down process reciprocates in circles, thereby generating mechanical rotation and driving the generator to generate electricity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com