Snow blowing nozzle of jet snow remover

A technology of snow removal vehicles and nozzles, which is applied in snow surface cleaning, construction, cleaning methods, etc. It can solve the problems of unsatisfactory deicing effect, unadjustable grounding temperature and spray distance, and inability to concentrate heat, so as to achieve a good effect of baking ice , compact structure, less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

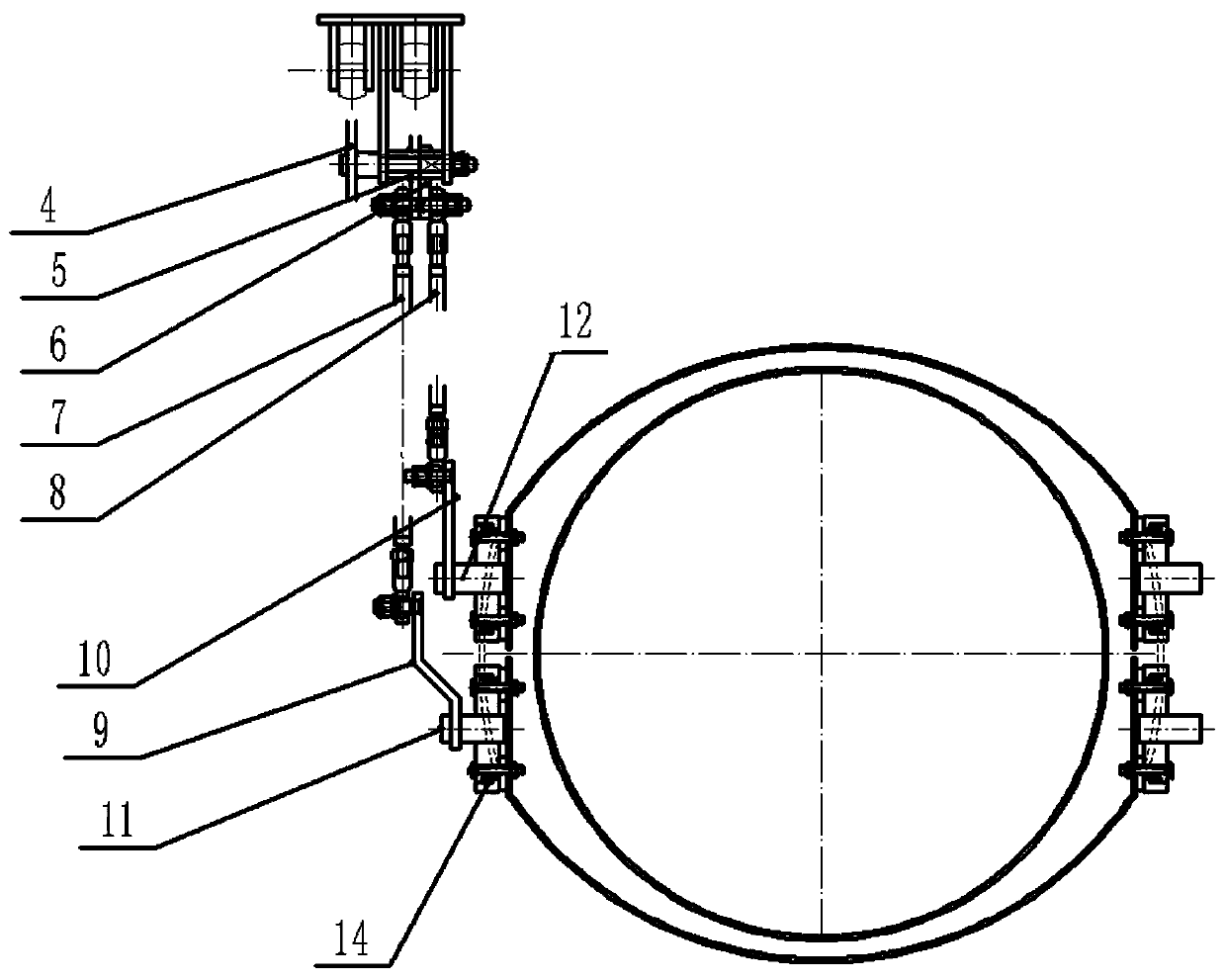

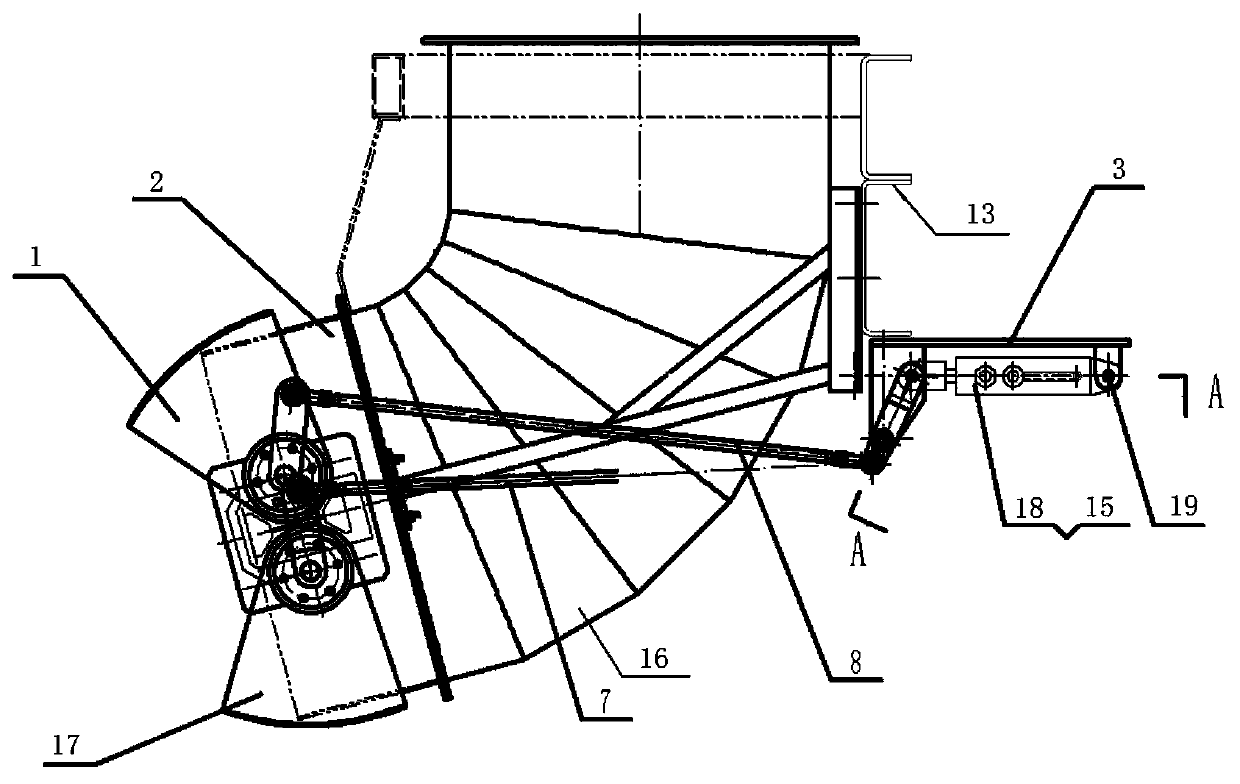

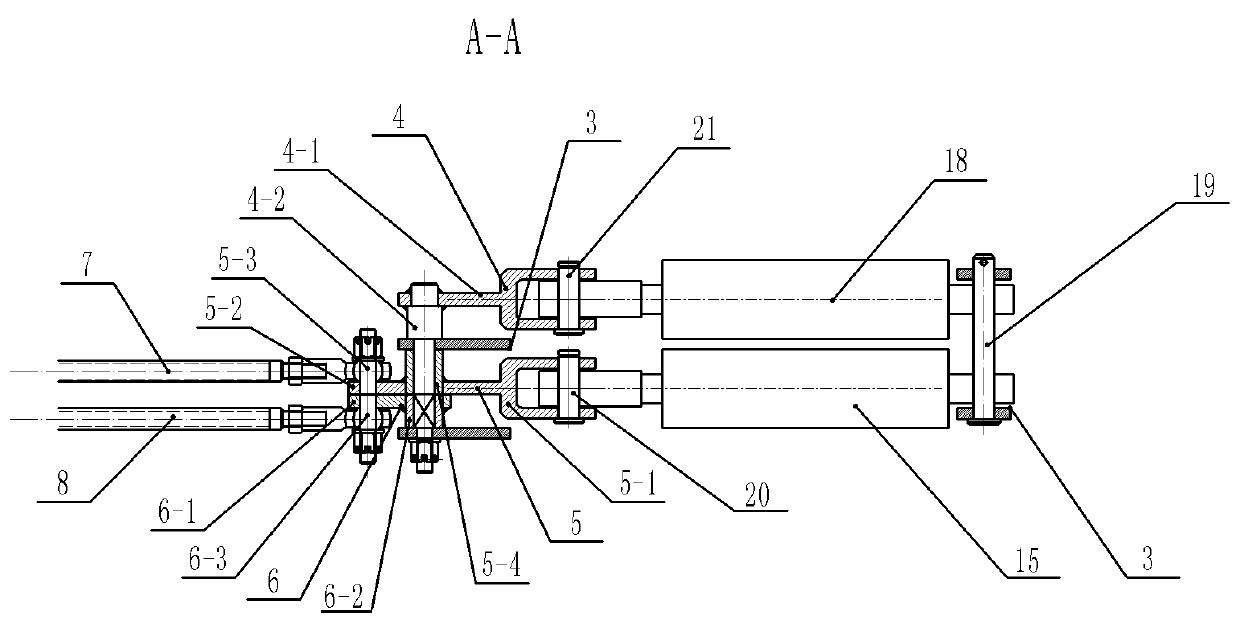

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] like Figure 1-3 As shown, the snow blowing nozzle of the jet snow blowing vehicle of the present invention is characterized in that it comprises a fixed nozzle 2 arranged on the nozzle pipe 16 of the jet snow blowing vehicle, and the upper nozzle adjusting piece 1 and the lower nozzle adjusting piece 1 and the lower nozzle 2 are connected with the fixed nozzle 2 through a sliding bearing 14 rotatably. The spout regulating piece 17, the upper fixed rotating shaft 12 fixedly connected with the upper spout regulating piece 1, the lower fixed rotating shaft 11 fixedly connected with the lower spout regulating piece 17, respectively connected with the upper fixed rotating shaft 12 and the lower fixed rotating shaft 11-phase welded drive mechanism,

[0026] The drive mechanism includes an oil cylinder fixing seat 3 arranged unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com