Porous graphene enhanced supercapacitor and preparation method thereof

A porous graphene and supercapacitor technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of inability to provide charges, low specific capacity, and low specific surface area of graphene, so as to improve the volumetric energy density , short preparation time and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A kind of supercapacitor preparation method reinforced by porous graphene of the present invention, comprises the following steps:

[0037] S1. After mixing activated carbon, porous graphene and polyvinylidene fluoride (PVDF), add N-methylpyrrolidone (NMP) solvent, stir evenly through a ball mill tank to make electrode slurry, and coat it on carbon-coated aluminum foil;

[0038] The mass percentage of activated carbon, porous graphene and PVDF is (80%~89%): (1%~10%): 10%, the mass ratio of solute to solvent is 1: (4~6), and the ball milling speed is 300~ 400rpm, the thickness of the carbon-coated aluminum foil is 15-20 microns, and the thickness of the coating is 150-200 microns.

[0039] S2. Put the coated carbon-coated aluminum foil into a blast oven for drying treatment, put the dried carbon-coated aluminum foil into a vacuum oven to continue processing, and put it on an electric double-roller machine and roll it tightly to form a pole piece;

[0040] The temperatur...

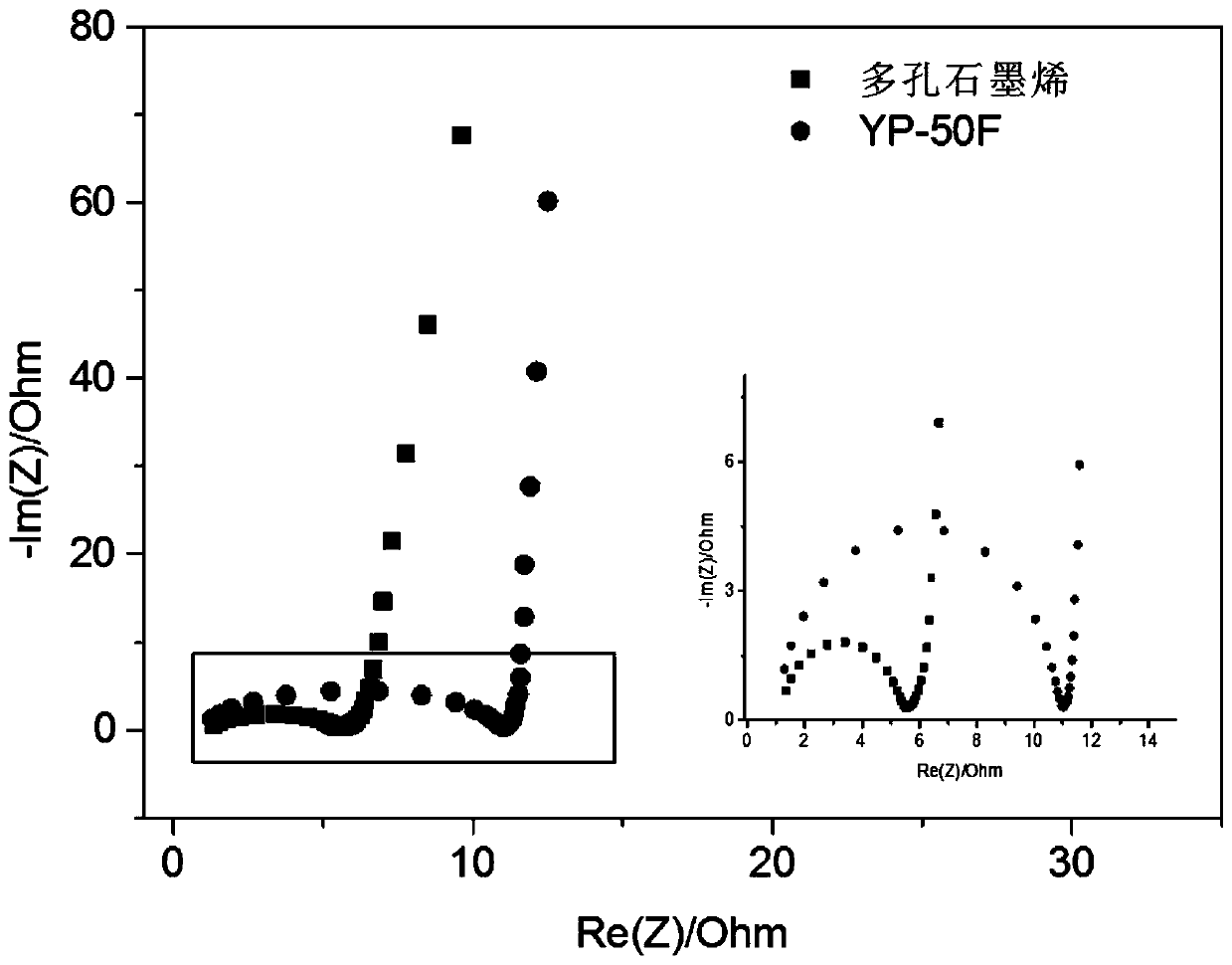

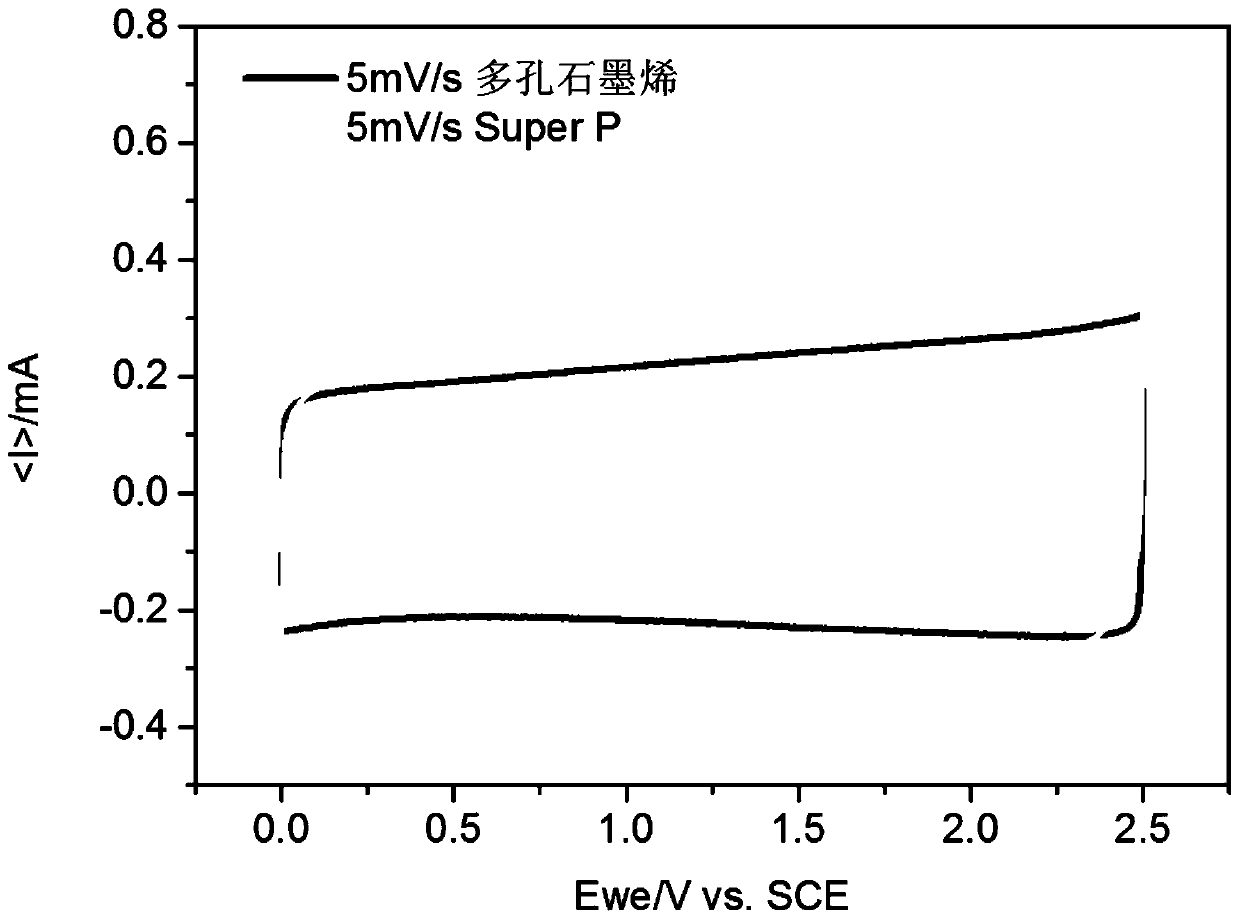

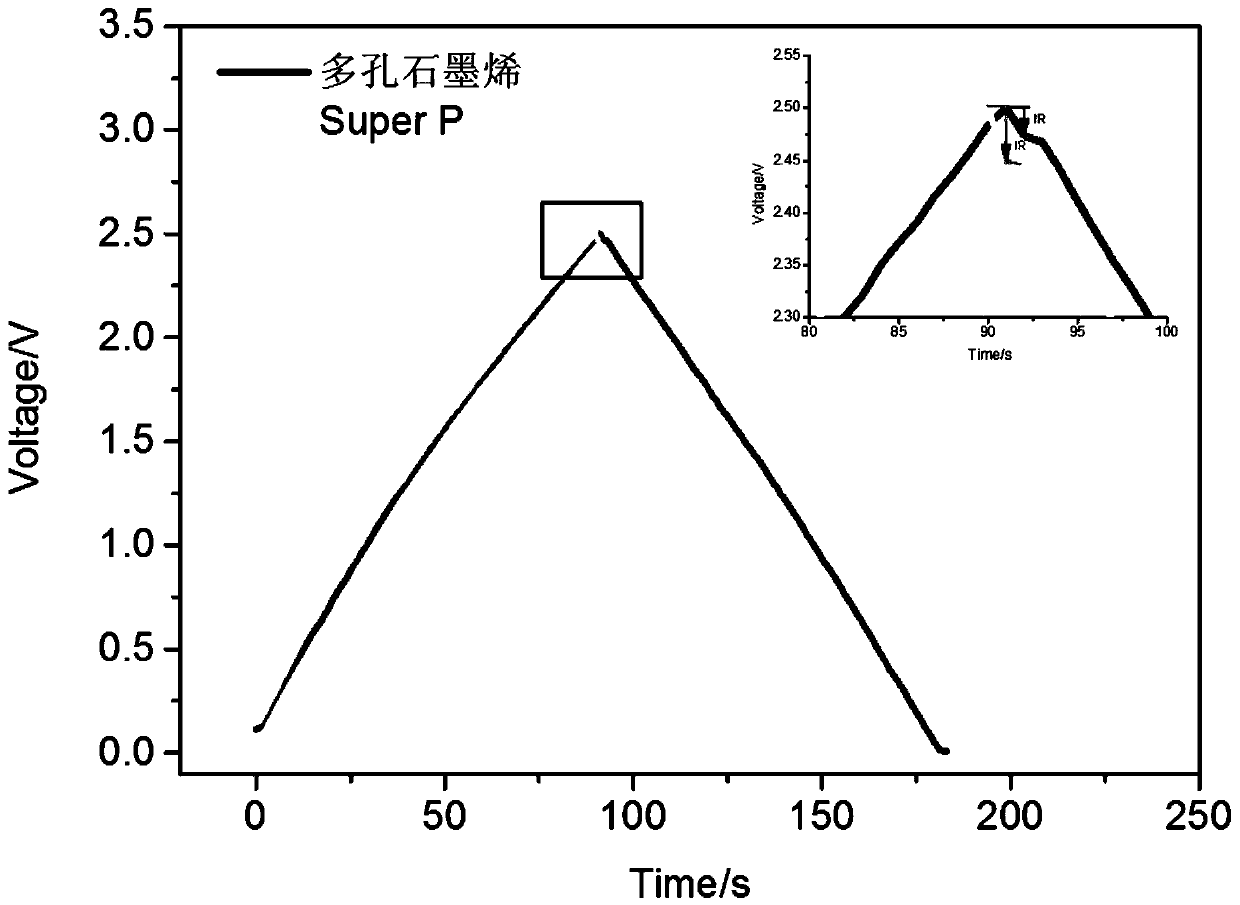

Embodiment 1

[0048] Take 0.8g of activated carbon, 0.1g of porous graphene, 0.1g of PVDF, add 3.5ml of NMP solvent through a ball mill and stir at a speed of 400rpm to form an electrode slurry, and coat it on a 20μm thick carbon-coated aluminum foil with a 150μm scraper;

[0049] Put the coated carbon-coated aluminum foil in a blast oven for 3 hours at 80°C, then put the dried carbon-coated aluminum foil in a vacuum oven at 70°C for 10 hours, take it out, put it on an electric double-roller machine, and roll it tightly. Pole piece, so that the thickness is 80% of that before rolling;

[0050] Cut the prepared pole piece and package the button battery for electrochemical test and charge-discharge test.

Embodiment 2

[0052] Take 0.85g of activated carbon, 0.05g of porous graphene, 0.1g of PVDF, add 3.0ml of NMP solvent through a ball mill and stir at a speed of 350rpm to form an electrode slurry, and use a 100μm scraper to coat it on a 18μm thick carbon-coated aluminum foil;

[0053] Put the coated carbon-coated aluminum foil in a blast oven at 90°C for 3 hours, put the dried carbon-coated aluminum foil in a vacuum oven at 100°C for 10 hours, take it out, put it on an electric roller machine and roll it tightly to make it Pole piece, the thickness is 90% of that before rolling;

[0054] Cut the prepared pole piece and package the button battery for electrochemical test and charge-discharge test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com