Compound ultrasonic fusion deposition additive-manufacturing device and compound ultrasonic fusion deposition additive-manufacturing method

A technology of additive manufacturing and fused deposition, which is applied in the field of additive manufacturing, can solve the problems of high temperature requirements in the forming room, poor shear resistance of formed parts, and weak mechanical strength, so as to improve comprehensive mechanical properties and enhance comprehensive mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

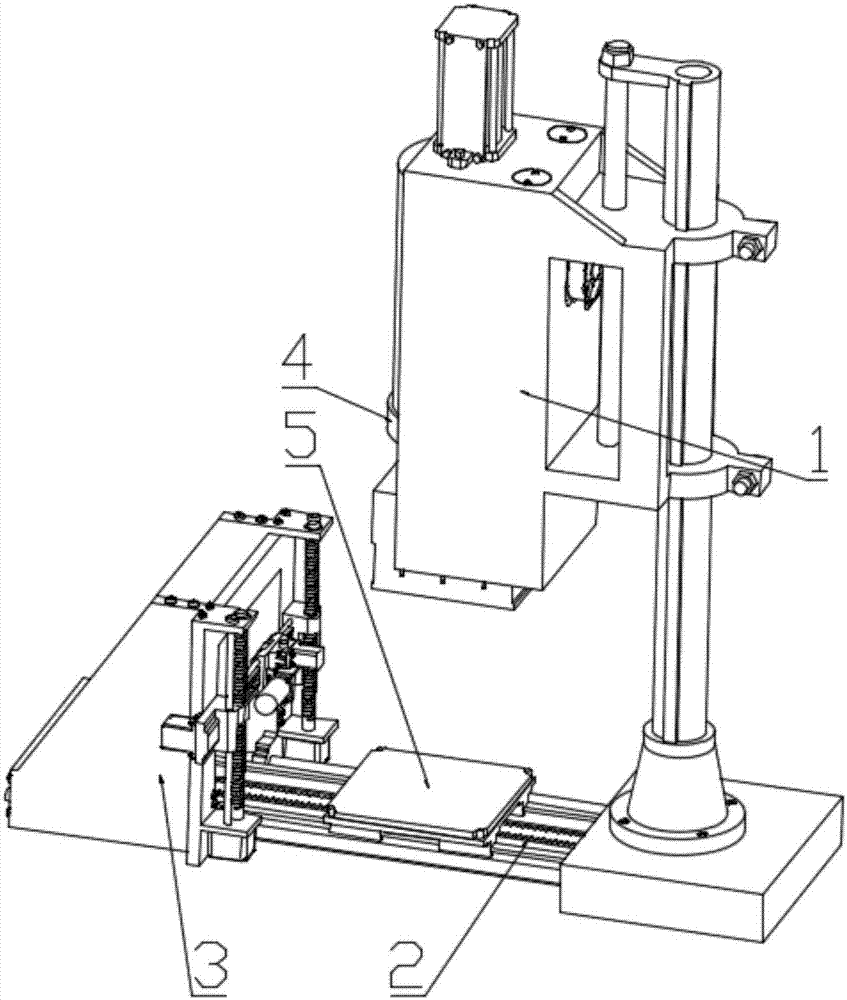

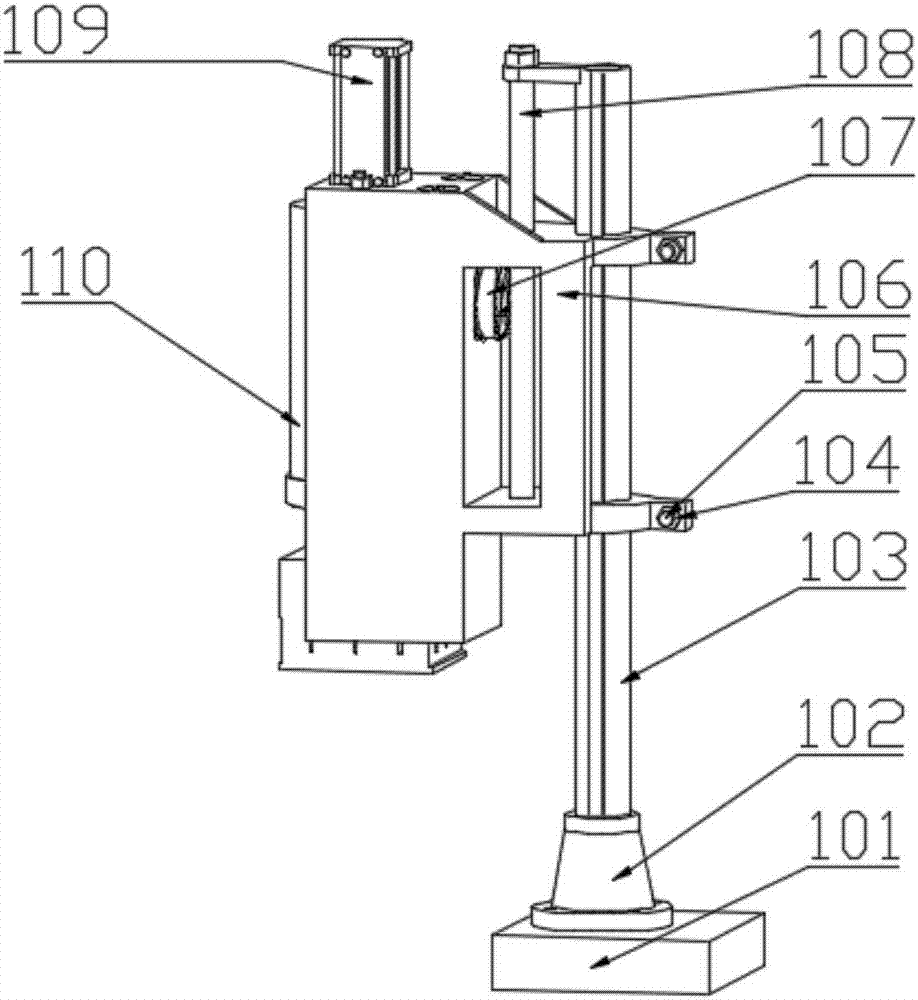

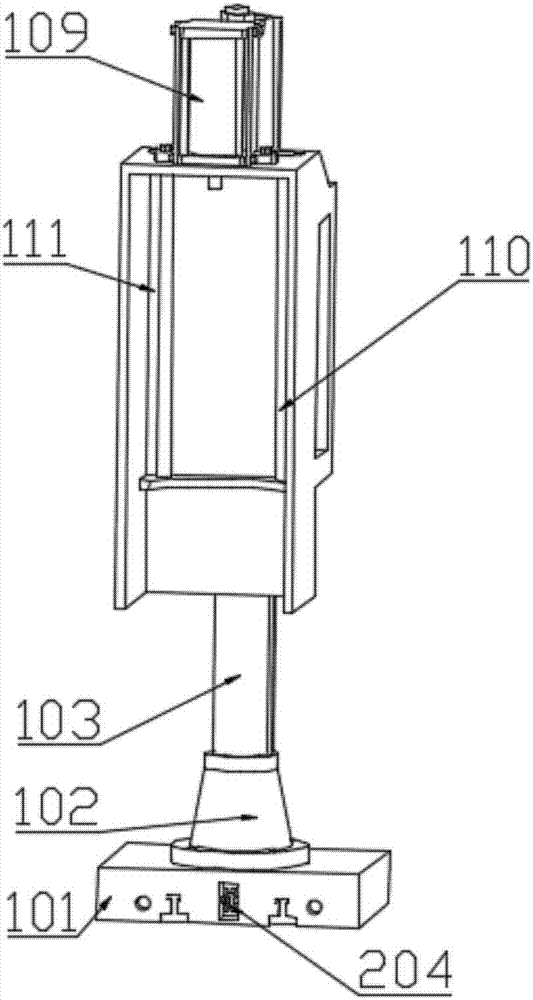

[0035] It includes an ultrasonic support platform 1, an X-direction guiding connection system 2, a fused deposition additive manufacturing system 3, an ultrasonic strengthening device 4 and a moving substrate 5, and the ultrasonic strengthening device 4 is fixed on the guide bar 110 and the guide bar of the ultrasonic support platform 1 On the second 111, the moving substrate 5 is installed on the guide rail 1 202 and the guide rail 2 205 of the X-direction guiding connection system 2, and is fixed on the timing belt 203 at the same time, and the moving substrate 5 is driven by the motor 208 in the X direction to move. The fused deposition additive manufacturing system 3 and the ultrasonic support platform 1 are connected to the connecting rod 2 206 through the connecting rod one 201 in the X-direction guiding connection system 2;

[0036] The ultrasonic support platform 1 is composed of a counterweight table 101, a base 102, a mounting rod 103, an ultrasonic strengthening devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com