Dust blowing device for selective catalytic reduction (SCR) denitration reactor

A denitrification reactor and ash cleaning device technology, which is applied in the direction of chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of insufficient soot blowing strength, difficulty in overcoming, and affecting denitrification efficiency, etc., achieving significant economic benefits and improving The effect of service life and improvement of denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

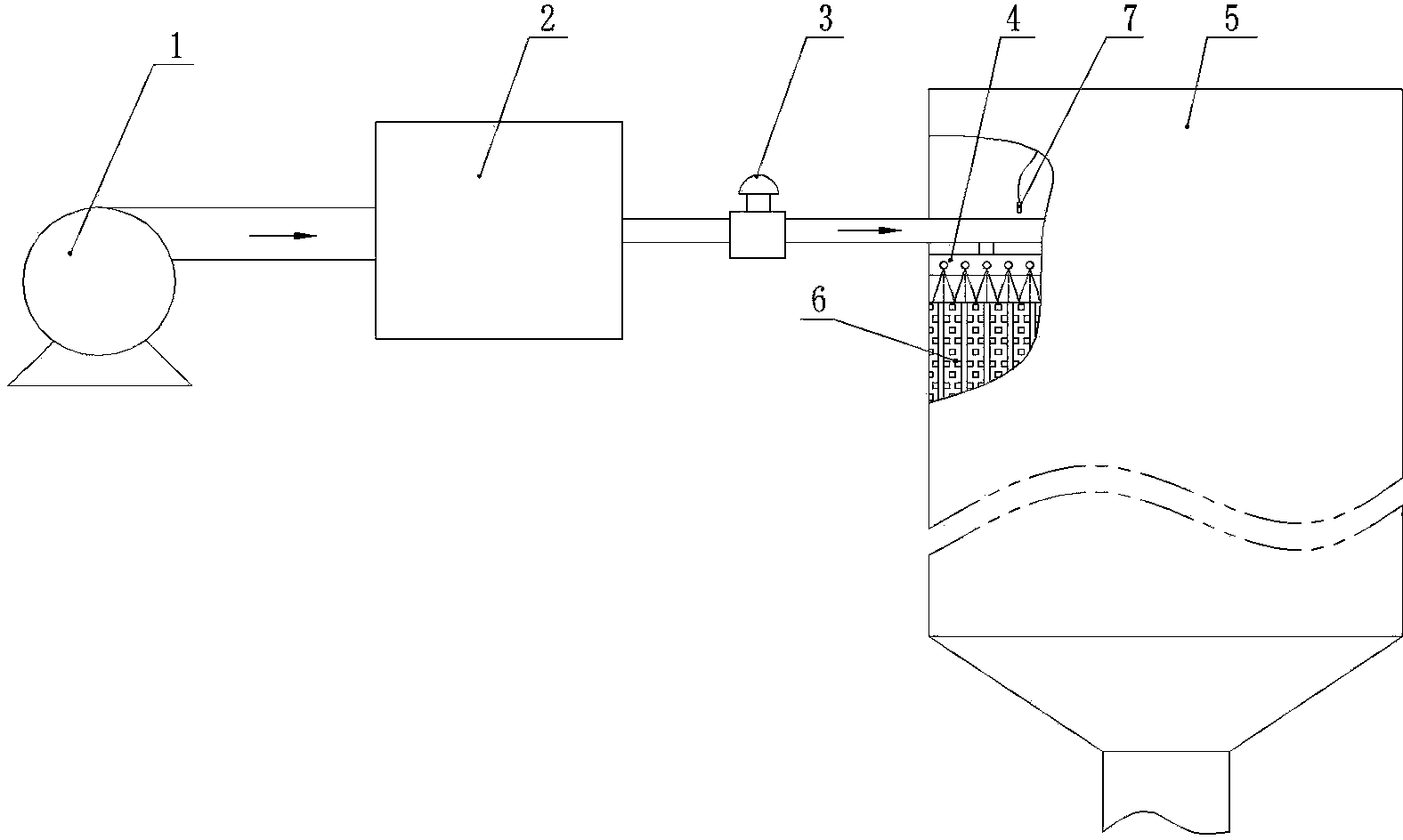

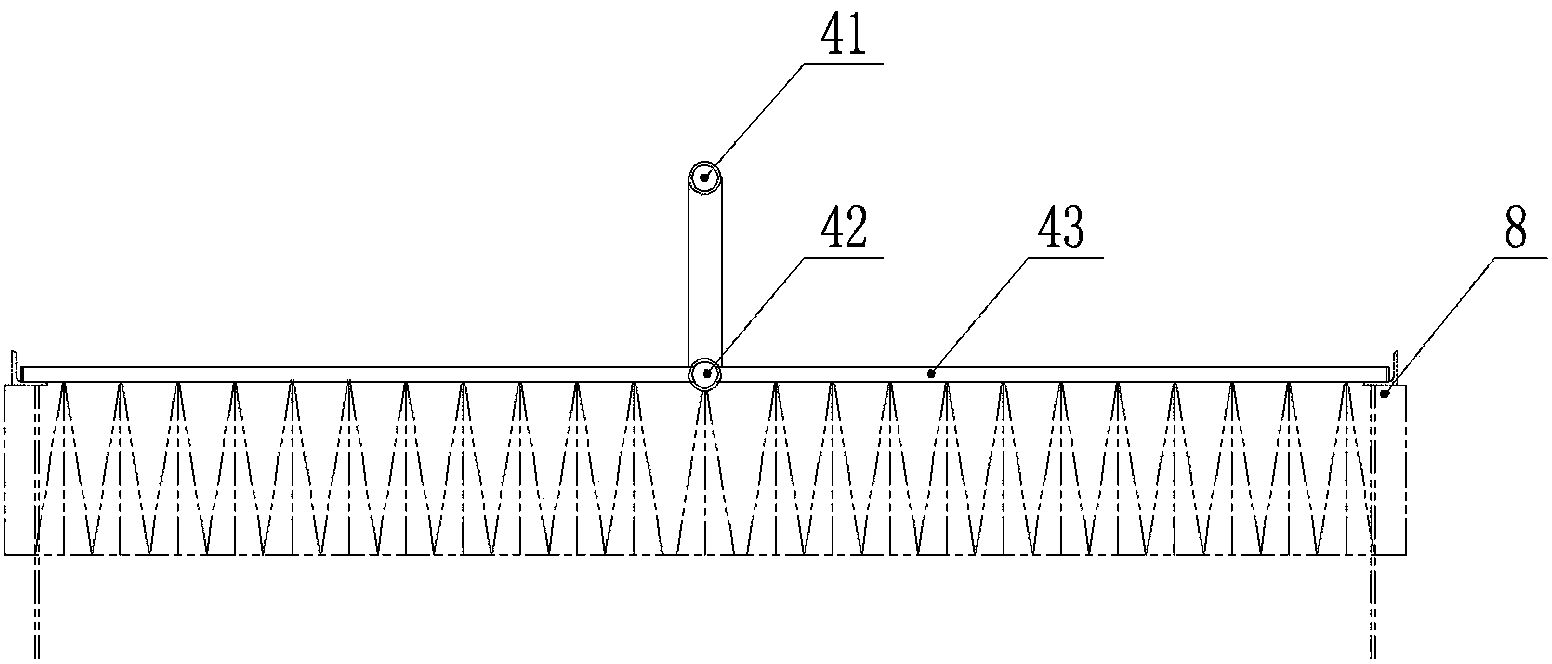

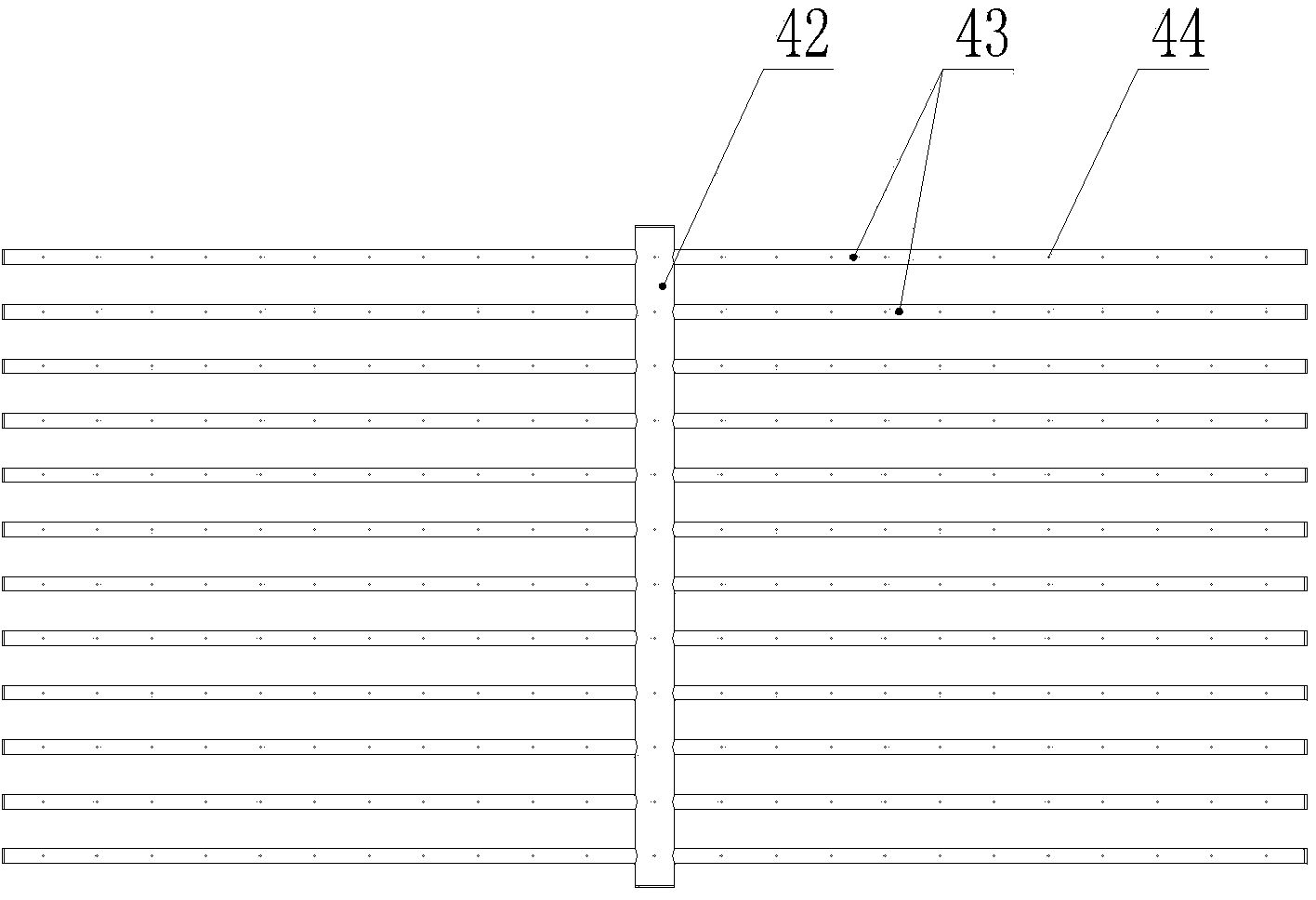

[0014] Such as Figure 1 to Figure 3 As shown, the soot blowing device for the SCR denitrification reactor disclosed by the present invention includes an air compressor 1, a buffer tank 2, a solenoid valve 3 and a soot blowing pipe network unit module 4, and the soot blowing pipe network unit module 4 is located in The top of the catalyst unit 6 in the SCR denitration reactor 5 is arranged in one-to-one correspondence with the catalyst unit 6 . The soot blowing pipe network unit module 4 includes an air supply main pipe 41 , a main air distribution conduit 42 and several air jet soot blowing branch pipes 43 . The main air distribution conduit 42 is connected to the bottom of the air supply main pipe 41, the air distribution branch pipes 43 are evenly distributed on the longitudinal sides of the main air distribution pipe 42, and the lower side of the air distribution soot blowing branch pipes 43 are evenly distributed with air injection holes 44. The compressed air outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com