Preparation method of nanofiber

A technology of nanofibers and solutions, applied in the field of nanometers, can solve the problems that hinder the development and application of nanobiomedicine, hinder the industrial application of nanofibers, and make nanofibers difficult to prepare, and achieve the effects of simple structure, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 A preparation method of nanofibers, comprising the following steps:

[0033] (1) Prepare the solution: mix polyvinylpyrrolidone and alcohol at a mass ratio of 5:100, and stir for 3 to 4 hours to obtain a transparent viscous solution; put the viscous solution into a storage bottle.

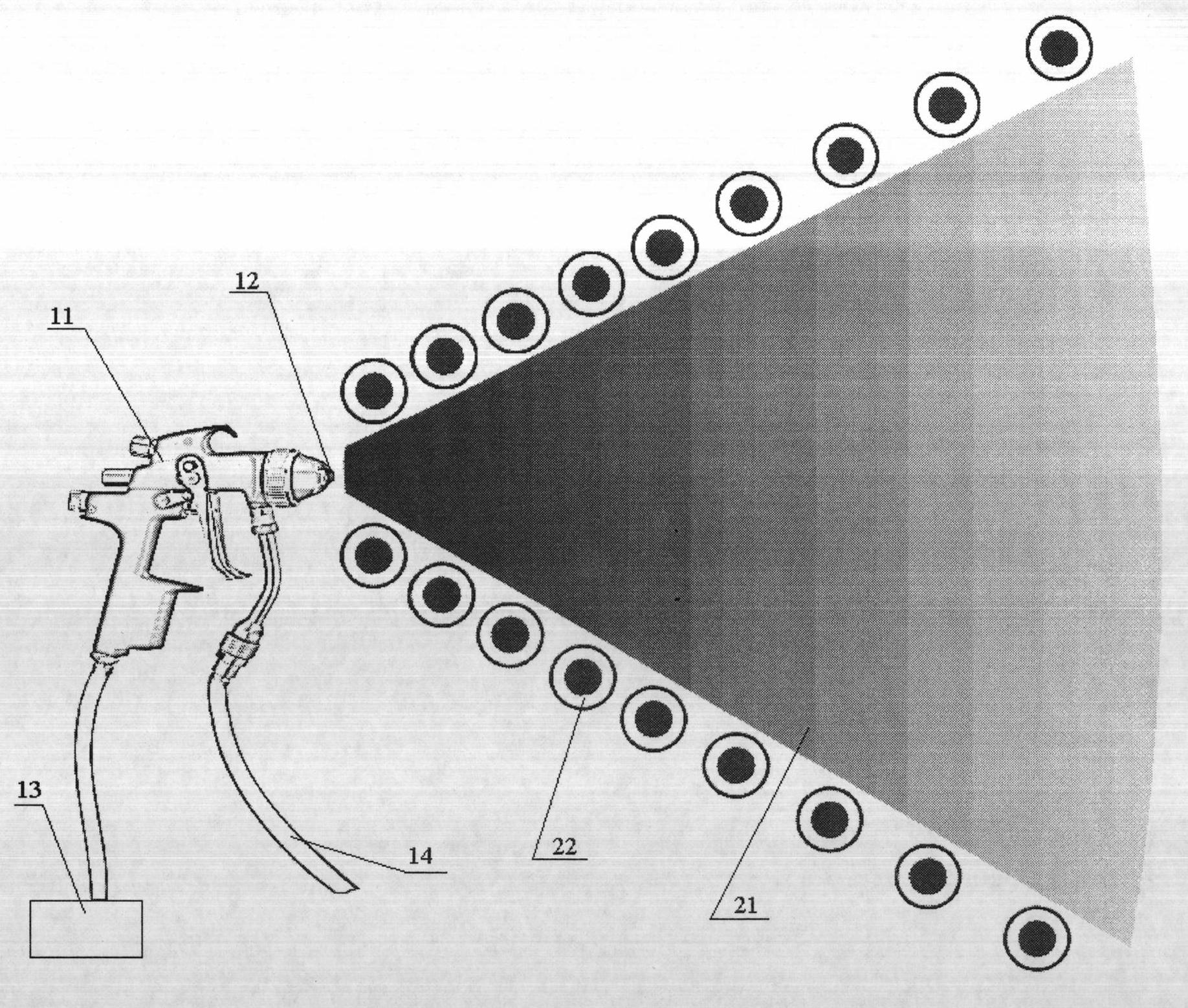

[0034] (2) The liquid storage bottle is connected to the liquid infusion port of the spray gun 11 with an aperture of 1.5 mm through the solution input pipe 14, and the air supply port of the spray gun 11 is connected to the air compressor 13 whose pressure is 5 bar.

[0035] (3) The nozzle of the spray gun 11 is facing the front end of the drawing chamber 21, and the air compressor 13 is started to spray the viscous solution into the drawing chamber 21. Fiber; this nanofiber falls into the collection device of net from the silk outlet of drawing cavity 21 (seeing figure 1 ).

Embodiment 2

[0036] Embodiment 2 A preparation method of nanofibers, comprising the following steps:

[0037] (1) Preparation of solution: mix polyvinylpyrrolidone and alcohol at a mass ratio of 20:100, and stir for 3 to 4 hours to obtain a transparent viscous solution; put the viscous solution into a storage bottle.

[0038] (2) The liquid storage bottle is connected to the infusion port of the spray gun 11 with an aperture of 1.5 mm through the solution input pipe 14, and the air delivery port of the spray gun 11 is connected to the air compressor 13 whose pressure is 8 bar.

[0039] (3) The nozzle of the spray gun 11 is facing the front end of the drawing chamber 21, and the air compressor 13 is started to spray the viscous solution into the drawing chamber 21. Fiber; this nanofiber falls into the collection device of net from the silk outlet of drawing cavity 21 (seeing figure 1 ).

Embodiment 3

[0040] Embodiment 3 A kind of preparation method of nanofiber, comprises the following steps:

[0041] (1) Prepare the solution: mix polyvinylpyrrolidone and alcohol at a mass ratio of 10:100, and stir for 3 to 4 hours to obtain a transparent viscous solution; put the viscous solution into a storage bottle.

[0042] (2) The liquid storage bottle is connected to the liquid infusion port of the spray gun 11 with an aperture of 1.5 mm through the solution input pipe 14, and the air supply port of the spray gun 11 is connected to the air compressor 13 whose pressure is 6 bar.

[0043] (3) The nozzle of the spray gun 11 is facing the front end of the drawing chamber 21, and the air compressor 13 is started to spray the viscous solution into the drawing chamber 21. Fiber; this nanofiber falls into the collection device of net from the silk outlet of drawing cavity 21 (seeing figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com