Patents

Literature

51 results about "Viscosity solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, the viscosity solution concept was introduced in the early 1980s by Pierre-Louis Lions and Michael G. Crandall as a generalization of the classical concept of what is meant by a 'solution' to a partial differential equation (PDE). It has been found that the viscosity solution is the natural solution concept to use in many applications of PDE's, including for example first order equations arising in optimal control (the Hamilton–Jacobi–Bellman equation), differential games (the Hamilton–Jacobi–Isaacs equation) or front evolution problems, as well as second-order equations such as the ones arising in stochastic optimal control or stochastic differential games.

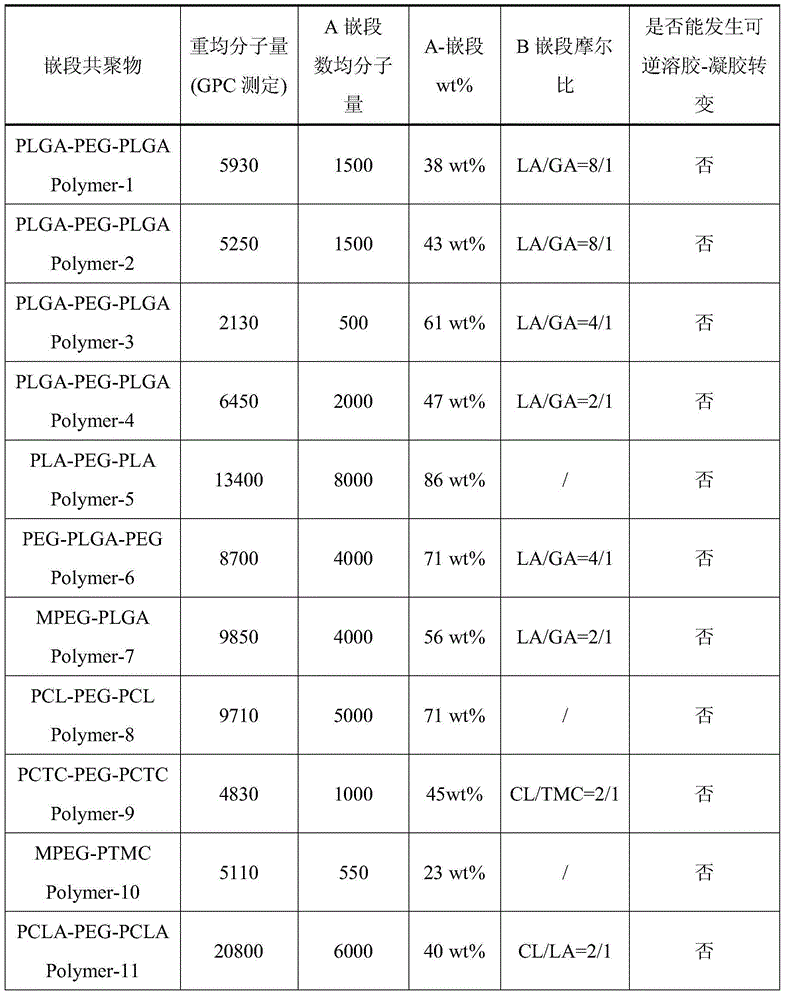

Submucous injection material composed of physical cross-linked hydrogel and application thereof

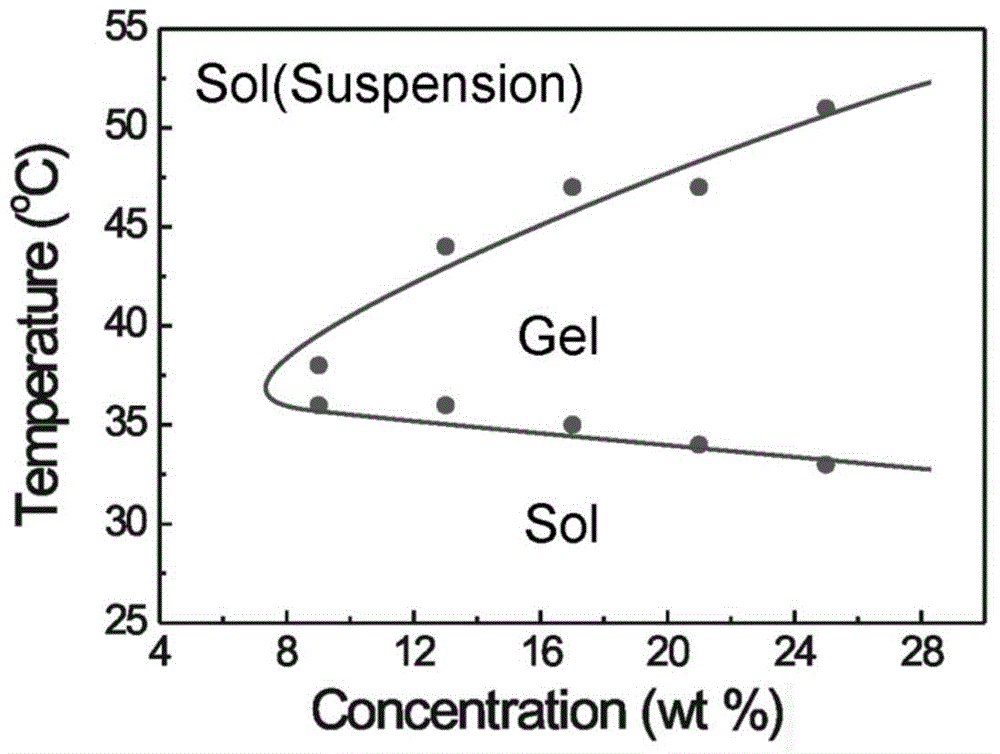

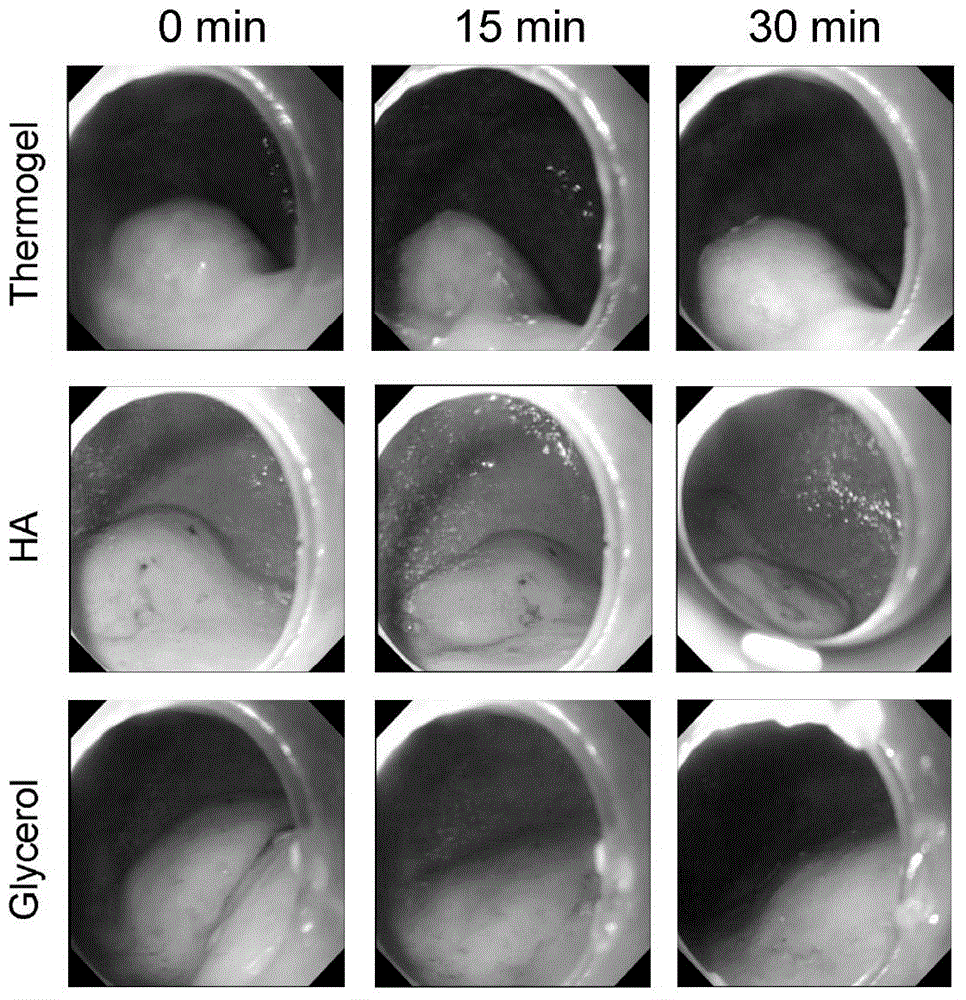

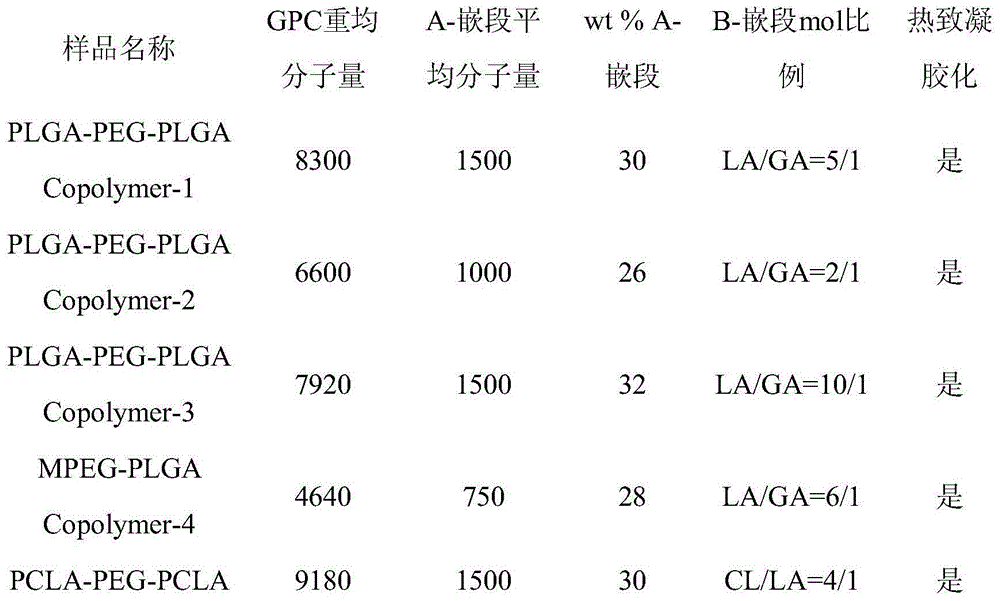

The invention belongs to the fields of high polymer materials and medical equipment and relates to a submucous injection material composed of physical cross-linked hydrogel and an application thereof to preparing injection materials for endoscopic submucosal dissection. The submucous injection material consists of an amphiphilic block copolymer, a solvent which takes water as a main body, and a coloring indicator, wherein the amphiphilic block copolymer is formed by taking polyethylene glycol (PEG) as a hydrophilic block and taking degradable polyester as a hydrophobic block. The material has thermal induced gel-forming properties; when the temperature is lower than a sol-gel transition temperature, a water system presents low-viscosity solution, has good injectable property, and can be subjected to endoscopic injection to the submucosal position so as to spontaneously form in-situ physical hydrogel under the body temperature, good gel morphology is maintained during an ESD operation, the uplift height and duration of the submucous injection material are superior to those of an existing pure liquid material, and the ESD operation is smoothly performed.

Owner:FUDAN UNIV

Low VOC (volatile organic compounds), dimethyl-2-piperidone solvent-based, PVC and CPVC pipe and component adhesives and primers containing minimal or no tetrahydrofuran

Novel low VOC solvent-based adhesives are provided, comprising a mixture of low vapor pressure, isomeric dimethyl-2-piperidones (DMPD) blended with (1) a non-solvent diluent, specifically, acetone (a VOC-exempt compound), or with mixtures of acetone and other known ketonic solvents such as methyl ethyl ketone (MEK), diethyl ketone (DEK), methyl propyl ketone (MPK), and methyl iso-butyl ketone (MIBK), cyclohexanone, and (2) thermoplastic PVC or CPVC resins. Omission of the resin provides a novel primer for pipes. The blended mixture yields PVC or CPVC pipe adhesives and primers that: (1) result in low VOC formulas (e.g., less than 510 g / l for PVC pipe and less than 490 g / l for CPVC pipe); (2) are very economical in the industry; (3) yield strong, quick setting, durable pipe joints that meet the required standards and performance criteria (e.g., ASTM D-2564 lap shear for PVC); (4) yield stable, low viscosity solutions that, in the case of adhesives, can be readily adjusted with thixotropes (e.g., Aerosil 200) to give desirable flow characteristics and body, as well as primers for solvent welding PVC and CPVC pipe and components; and (5) can be formulated with minimal (10 wt %) or no cyclic ethers such as THF.

Owner:IPS

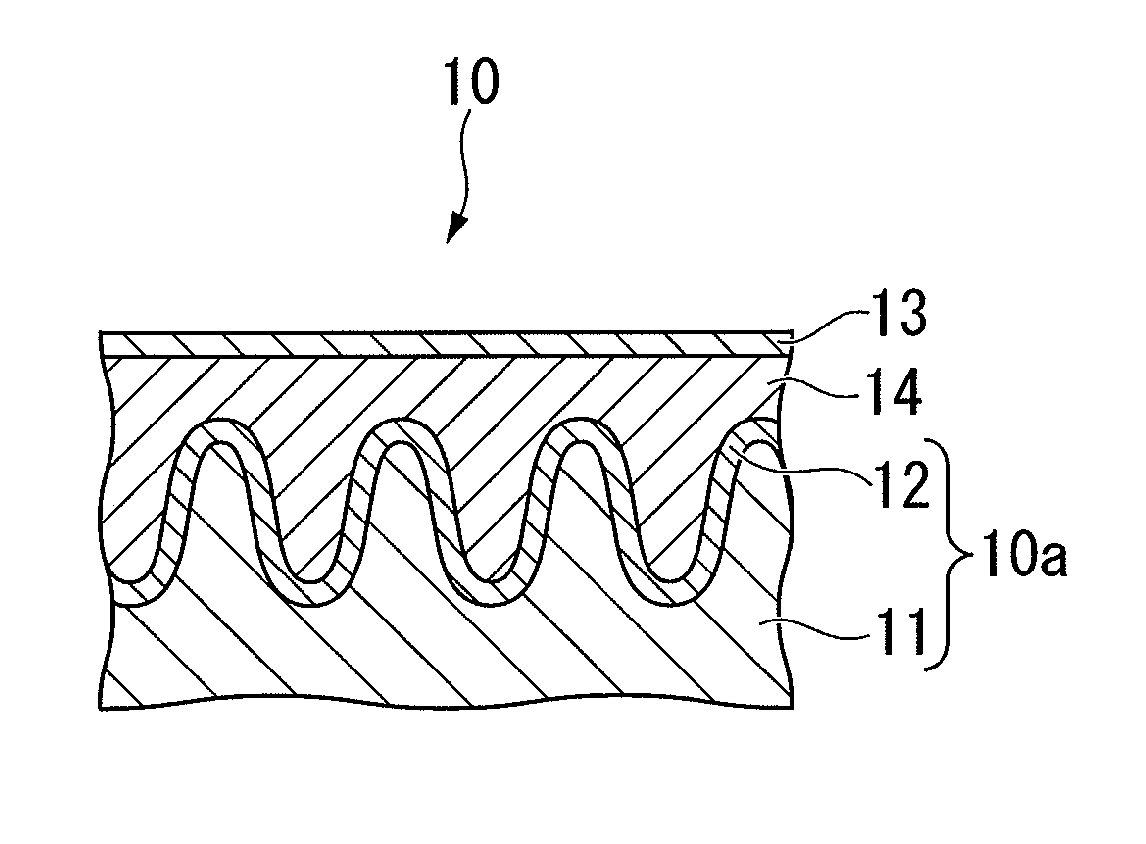

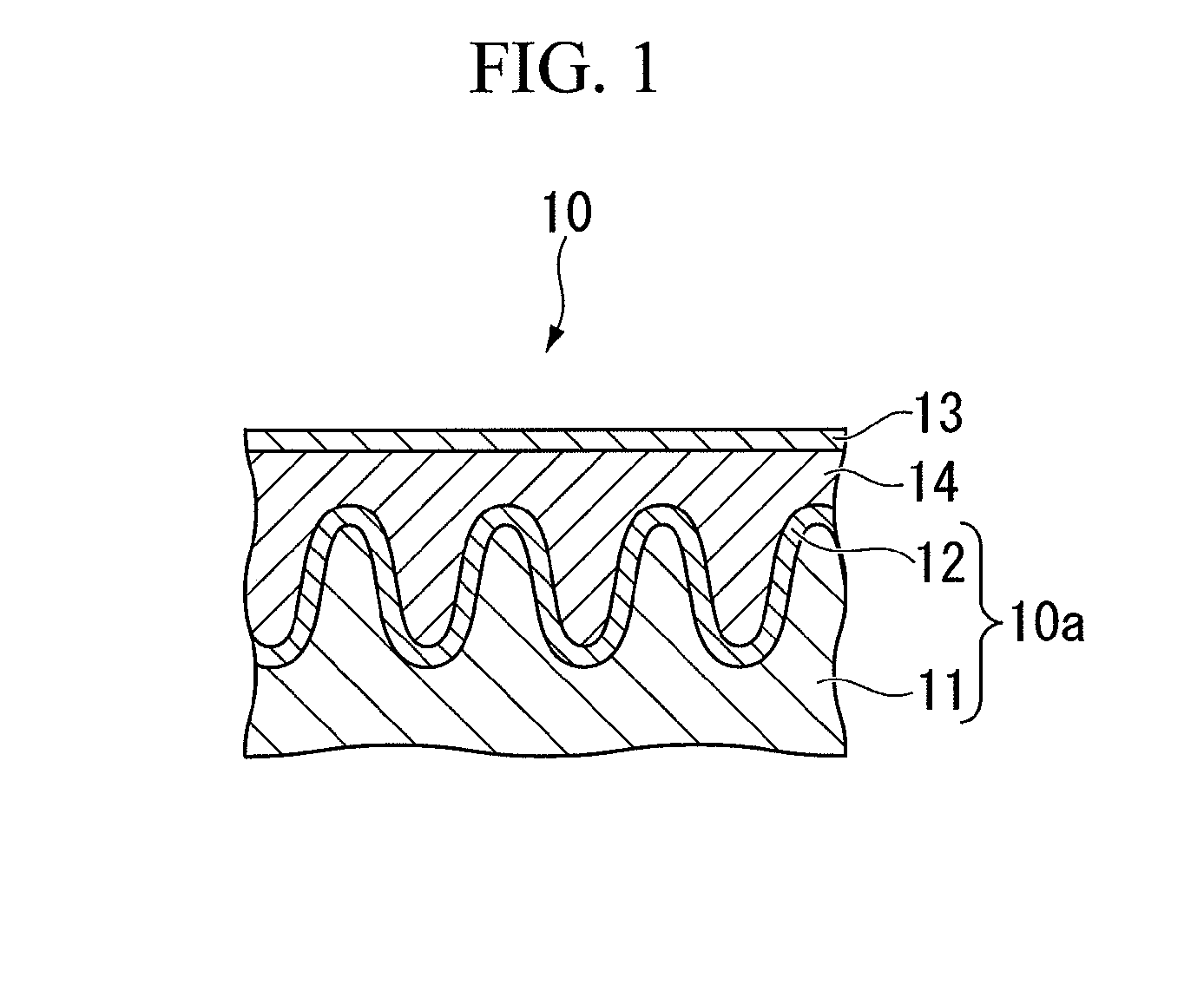

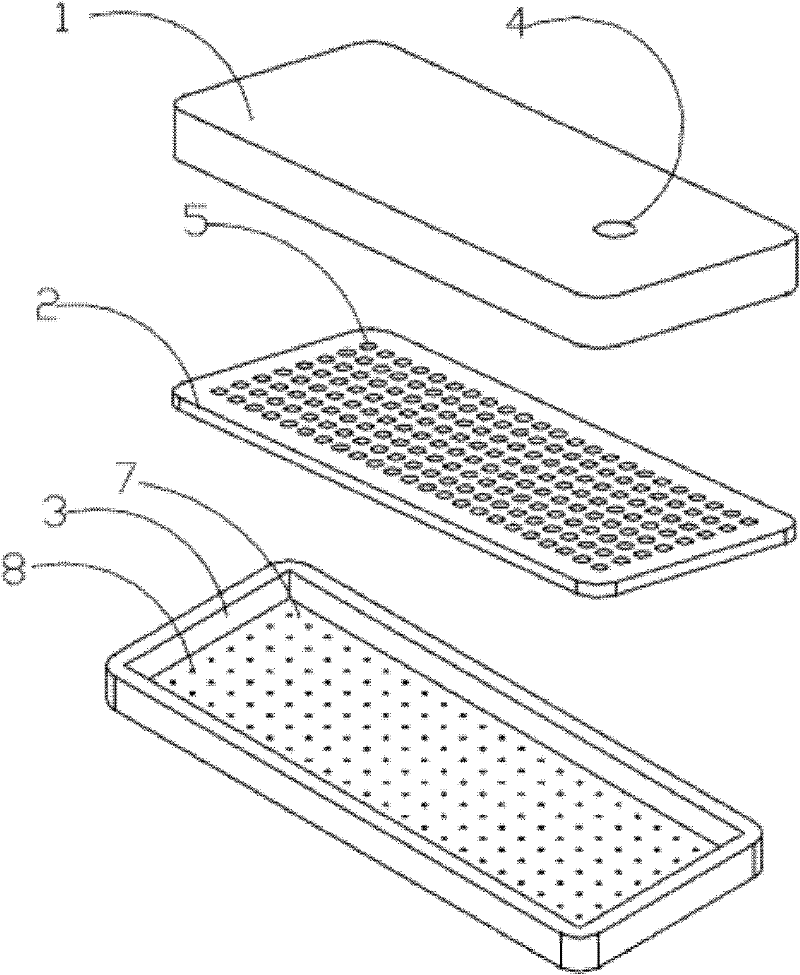

Capacitor manufacturing method

InactiveUS20110171366A1Improve pressure resistanceHigh capacitanceHybrid capacitor electrolytesSolid electrolytic capacitorsCapacitanceProduction rate

A capacitor manufacturing method that enables a capacitor having a high withstand voltage, a high electrostatic capacitance and a satisfactorily small ESR to be manufactured simply and at a high level of productivity. In the capacitor manufacturing method, a film-formation treatment of applying a conductive polymer solution containing a π-conjugated conductive polymer, a polyanion and a solvent to the dielectric layer side of a capacitor substrate having a dielectric layer formed on the surface of an anode, and then performing drying to form a conductive polymer film, is performed at least twice, and the conductive polymer solution used in at least one film-formation treatment among the second film-formation treatment and subsequent film-formation treatments is a high-viscosity solution having a higher viscosity than the conductive polymer solution used in the first film-formation treatment.

Owner:SHIN-ETSU POLYMER CO LTD

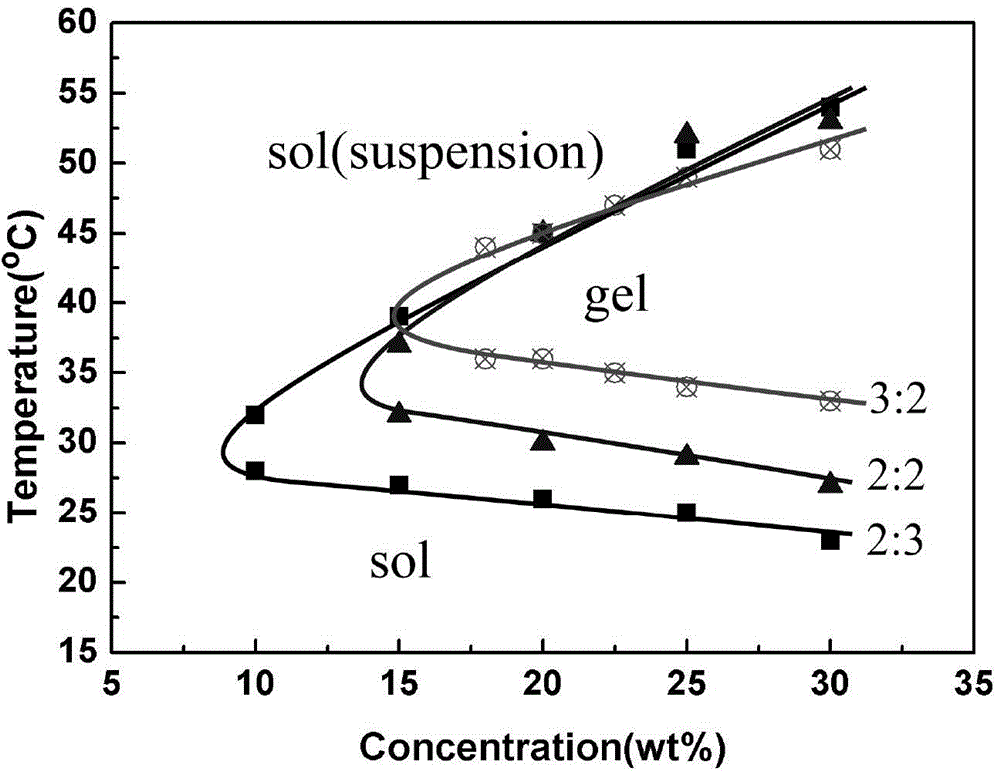

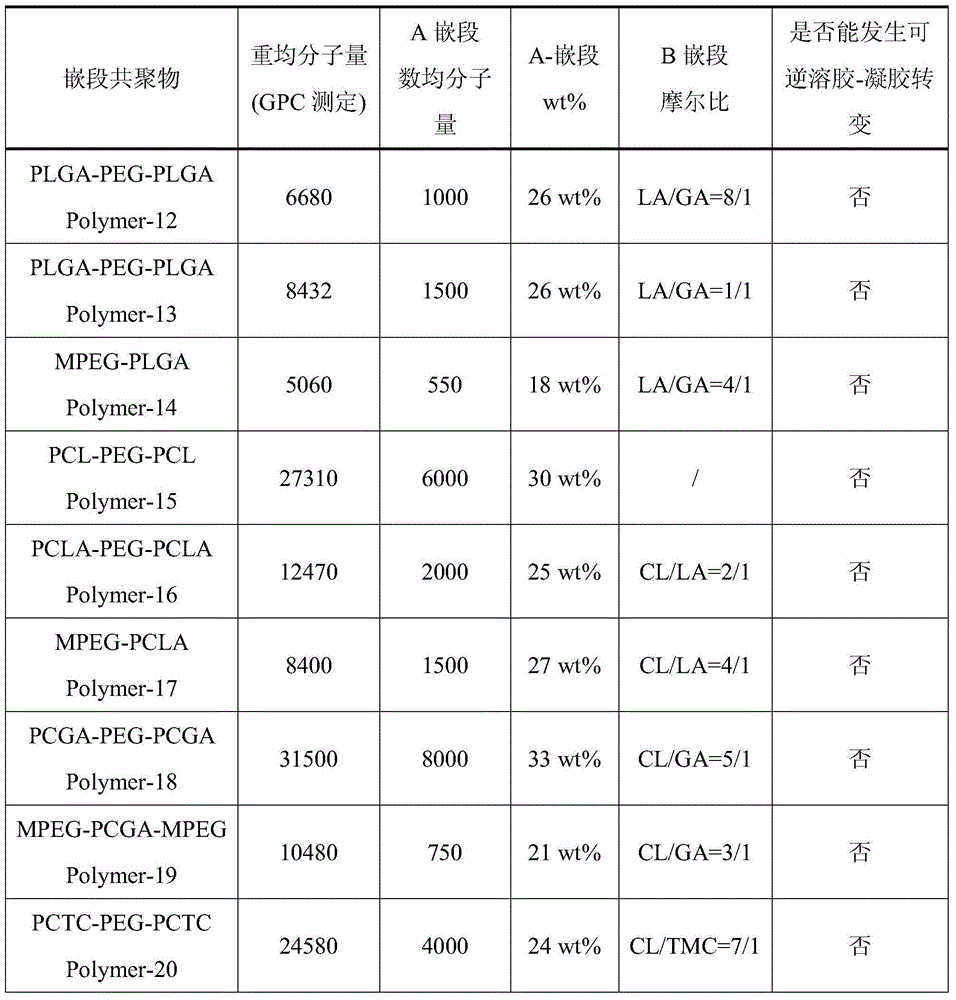

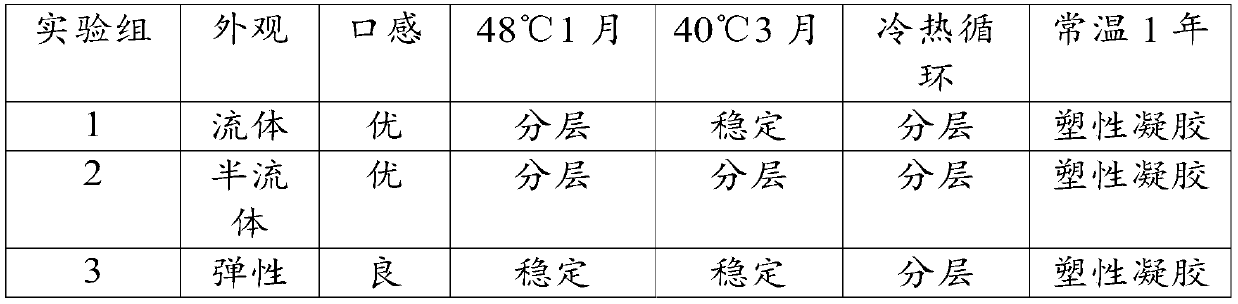

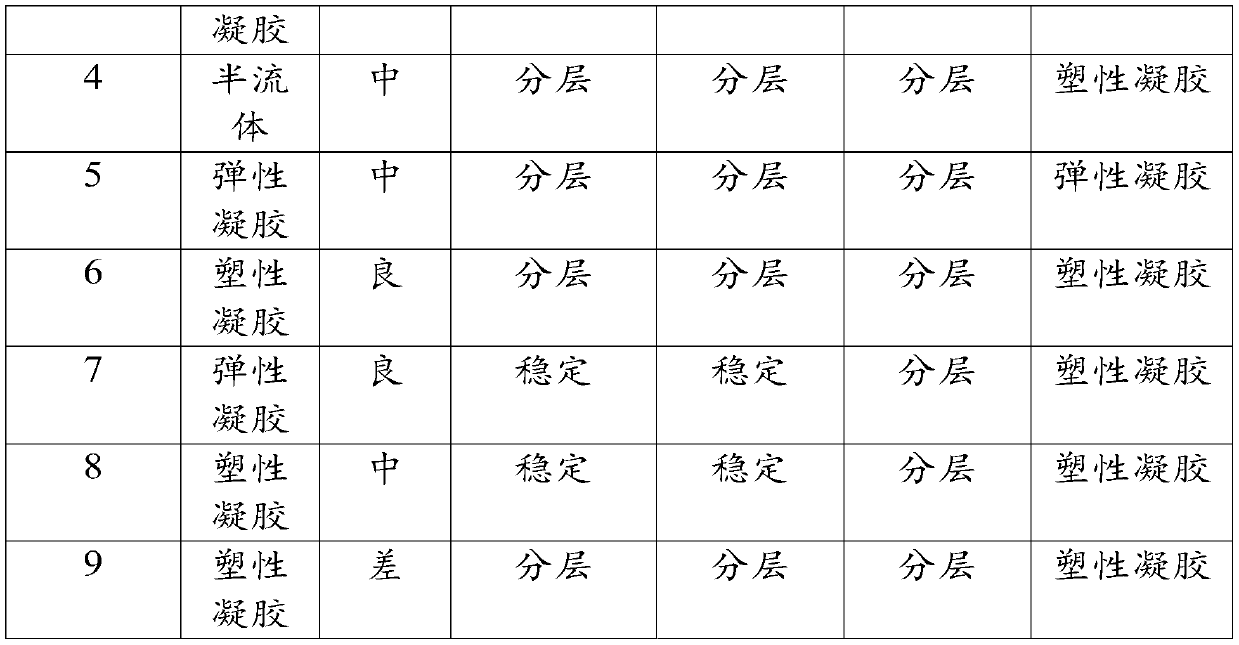

Hydrogel composition for gastrointestinal submucosal injection and application of hydrogel composition

The invention belongs to the fields of high polymer materials and mechanical instruments and relates to a hydrogel composition for gastrointestinal submucosal injection and an application of the hydrogel composition. The hydrogel composition provided by the invention is composed of a mixture, a solvent and a color indicator, wherein the mixture is composed of two or more segmented copolymers; water is taken as a main body by the solvent; a water solution of the hydrogel composition has thermotropic gelatinization property; a polymer mixture can be dissolved in water at a room temperature or a low temperature to form a low-viscosity solution; the water solution of the mixture can be subjected to reversible sol-gel transition along with temperature rise. The hydrogel composition material provided by the invention can be applied to preparation of the composition material for endoscopic submucosal dissection and is capable of reducing complications such as perforation and bleeding in an ESD operation when applied to ESD; the operation safety is improved; the operation difficulty is reduced; the time required for finishing operation is shortened; and convenience is provided for ESD diagnosis and treatment of cancers such as colon cancer and rectal cancer.

Owner:FUDAN UNIV

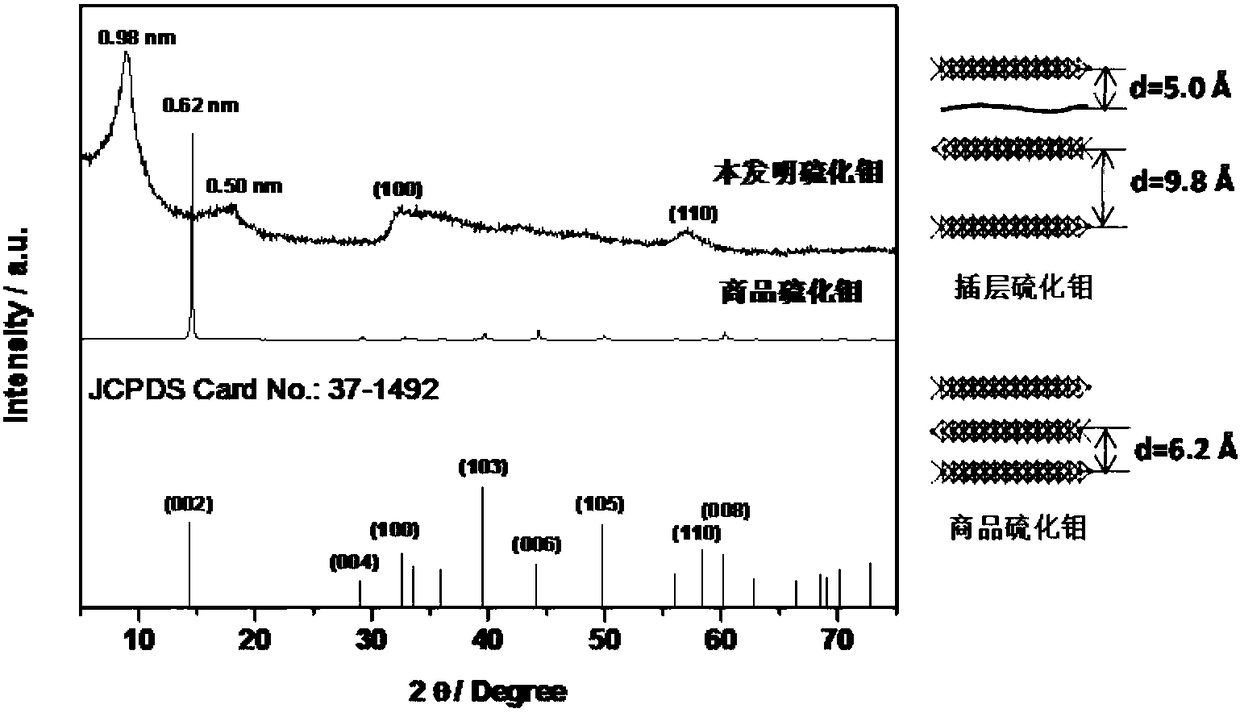

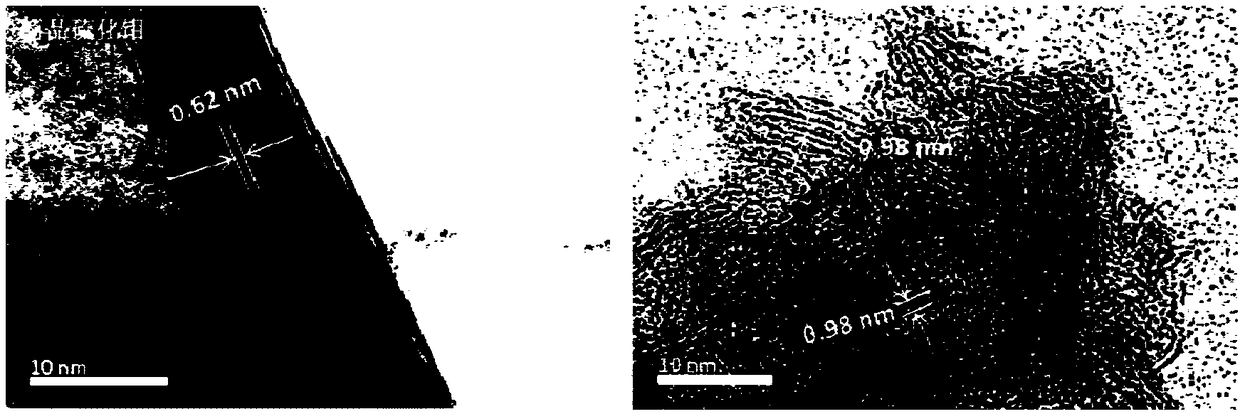

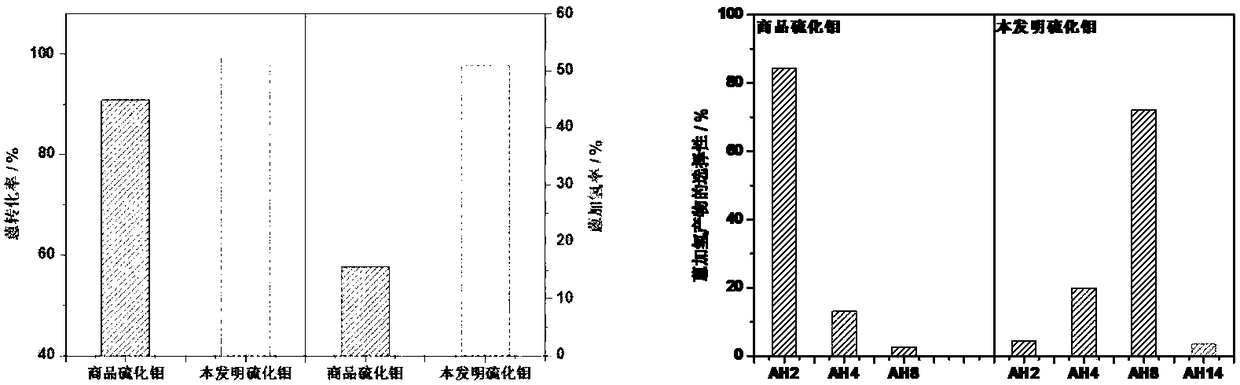

Preparation method of nano molybdenum disulfide (MoS2) hydrogenation catalyst exposed at high active site

ActiveCN108067257ARelieve pressureSynthetic conditions are safeMaterial nanotechnologyPhysical/chemical process catalystsFiltrationReactive site

The invention discloses a preparation method of a nano molybdenum disulfide (MoS2) hydrogenation catalyst exposed at a high active site. The preparation method comprises the following steps: dissolving or dispersing a certain amount of molybdenum source and sulfur source in a high-viscosity solution, and adding a reducing agent to obtain a solution or suspension liquid; adjusting and controlling the types of the molybdenum source, the sulfur source, the solvent and the reducing agent; putting the prepared solution or suspension liquid into a closed stainless steel reactor, controlling the reaction temperature to be 120-240 DEG C, and controlling the reaction time to be 3-72 hours; and after the reaction is finished, performing cooling, suction filtration, washing and drying to obtain the nano MoS2 hydrogenation catalyst exposed at the high active site. The synthetic method disclosed by the invention has the advantages of mild conditions, simple operation, high yield and the like, and the prepared nano MoS2 catalyst with expanded interlayer spacing and few layers has a high hydrogenation active site exposure rate. The nano MoS2 hydrogenation catalyst exposed at the high active site,synthesized by the method disclosed by the invention, has very high catalytic hydrogenation activity when being applied to the field of catalytic hydrogenation of oil products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

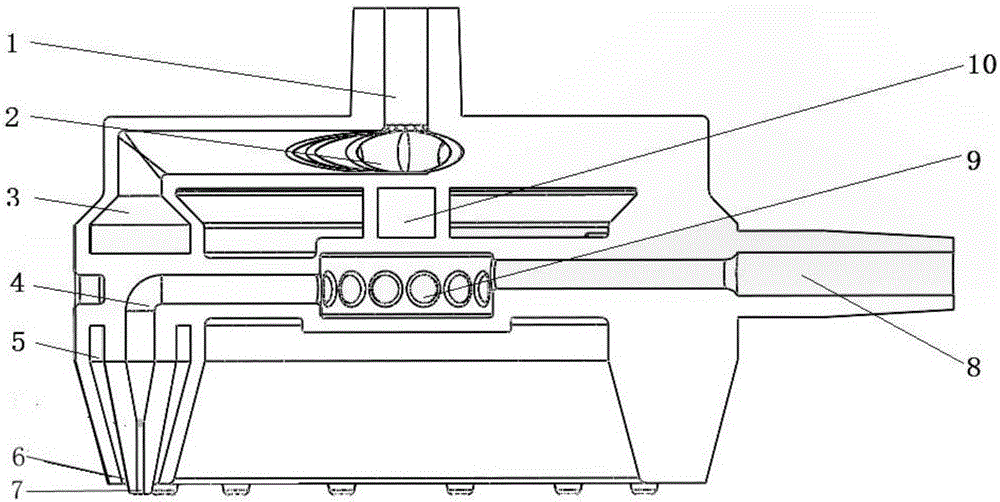

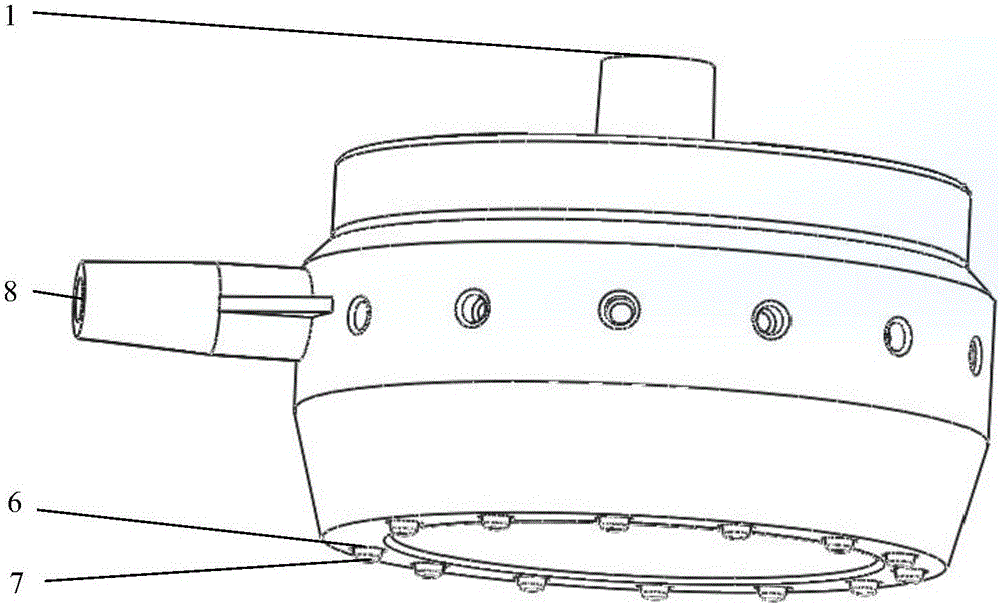

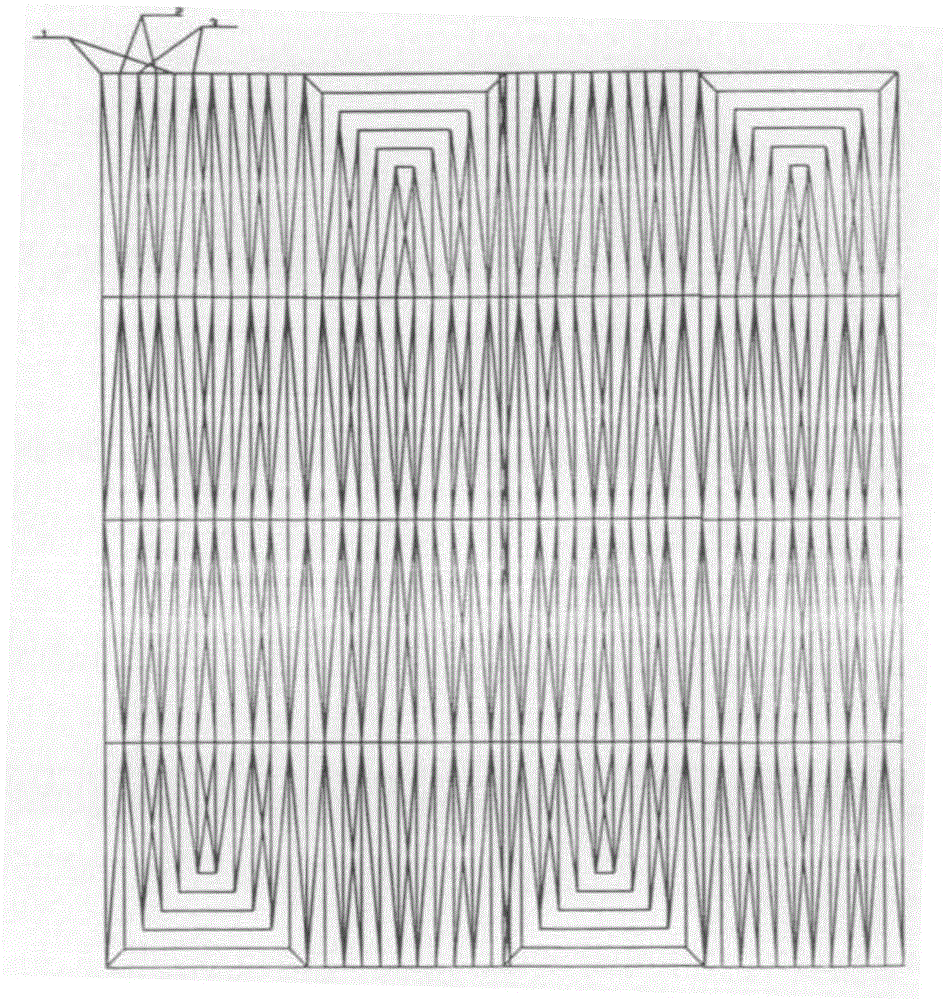

An Arrayed Electrohydrodynamic Jet Printing Head

The invention discloses an array electric fluid power printing head, which comprises an ink box, and a nozzle plate positioned at the middle part of the ink box and used for partitioning the cavity of the ink box into an upper cavity and a lower cavity; nozzle holes are distributed in the nozzle plate in an array mode, and the nozzle holes are communicated with the upper cavity and the lower cavity; the bottom of the lower part of the ink box is provided with ink outlets correspondingly arranged in an array; an upper electrode is arranged at the bottom of the nozzle plate, and a lower electrode is arranged at the bottom of the ink box, so that an electric field is formed in the lower cavity; and the ink in the upper cavity passes through the nozzle holes and enters the lower cavity, the ink forms jet under the action of the electric field of the lower cavity, and the ink is ejected for printing through the ink outlets. Because the electric fluid power printing principle is adopted in the array electric fluid power printing head, the jet diameter can reach 1 to 10 microns, and the jet is not affected by the diameter of a nozzle; and the array electric fluid power printing head has large jet dragging force, is suitable for high-viscosity solution, and does not destroy the material. The array electric fluid power printing head has the characteristics of simple structure, high printing precision and low cost, and has good industrial practicability.

Owner:HUAZHONG UNIV OF SCI & TECH

Multi-nozzle module based on 3D (three-dimensional) printing and device and technique for large-scale production of particles

InactiveCN106622413AEvenly distributedReduce the difficulty of printingAdditive manufacturing apparatusLaboratory glasswaresEnvironmental resistanceEngineering

The invention discloses a technical method for large-scale production of particles by a multi-nozzle module based on a 3D (three-dimensional) printing technique and application of the technical method. The technical method is characterized in that a single nozzle is of a coaxial annular gap air blowing structure, the middle part is provided with a fluid channel, and the coaxial annular gap is an air channel; on the basis of a two-phase flow cutting principle, liquid-phase liquid is cut by air, and liquid droplet particles are produced; by controlling air and liquid outlet pressures and flow rates, the liquid droplets with different particle sizes can be obtained; the number of nozzles can be designed according to the requirement of droplet output, and liquid and air are uniformly distributed by a distributor, so as to obtain higher droplet production efficiency. The technical method has the advantages that the preparation of 3D printing nozzle modules is simple, the material cost is low, and other complicated mechanical processing methods are not required; the prepared particles are free from the pollution by poisonous matters, such as a continuous phase and surfactants; the technical method is especially suitable for preparing high-viscosity solution and suspension droplets containing insoluble particles, is widely applied to the fields of medical care, petroleum, biology, environment protection and the like, and is suitable for large-scale industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

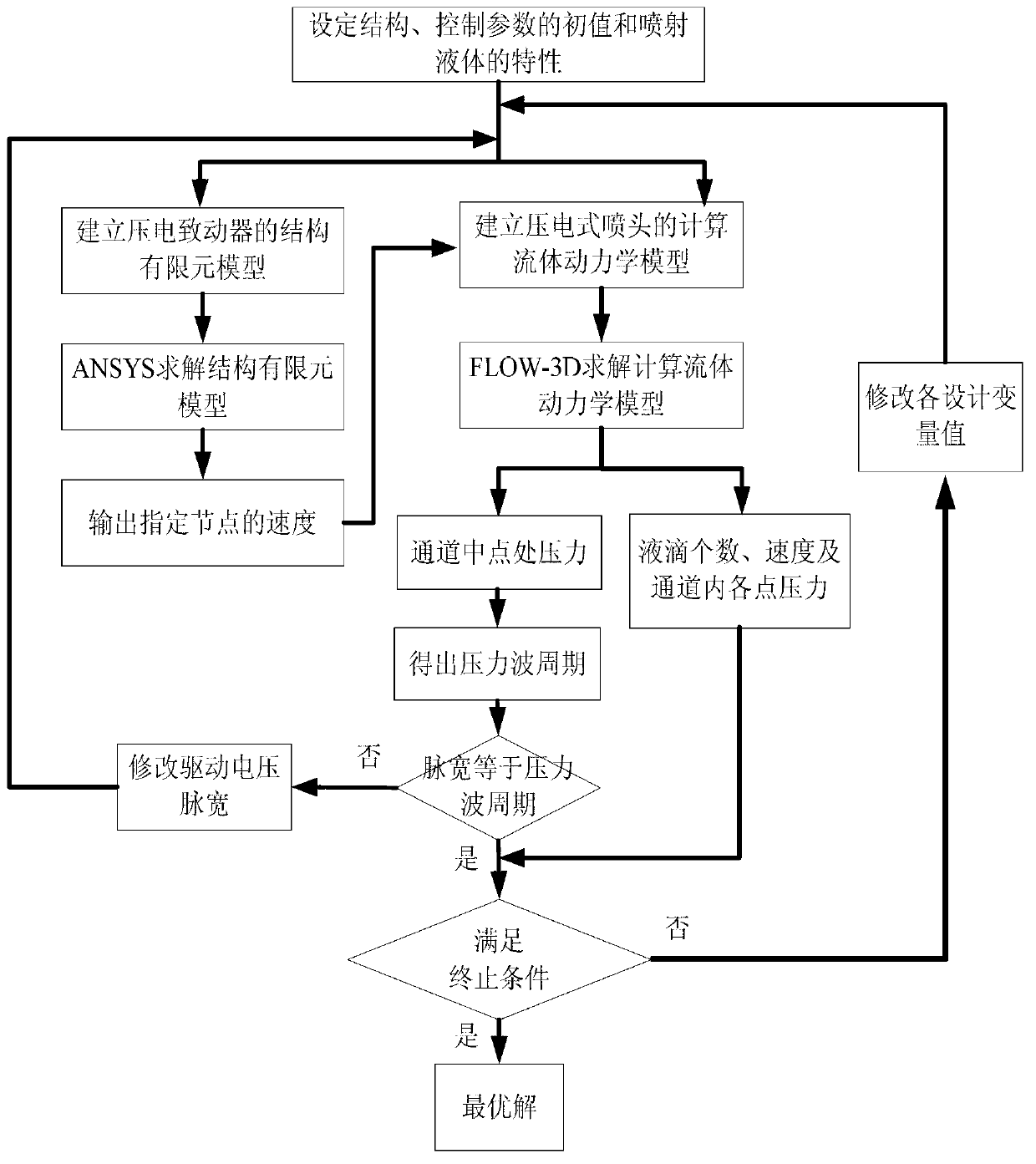

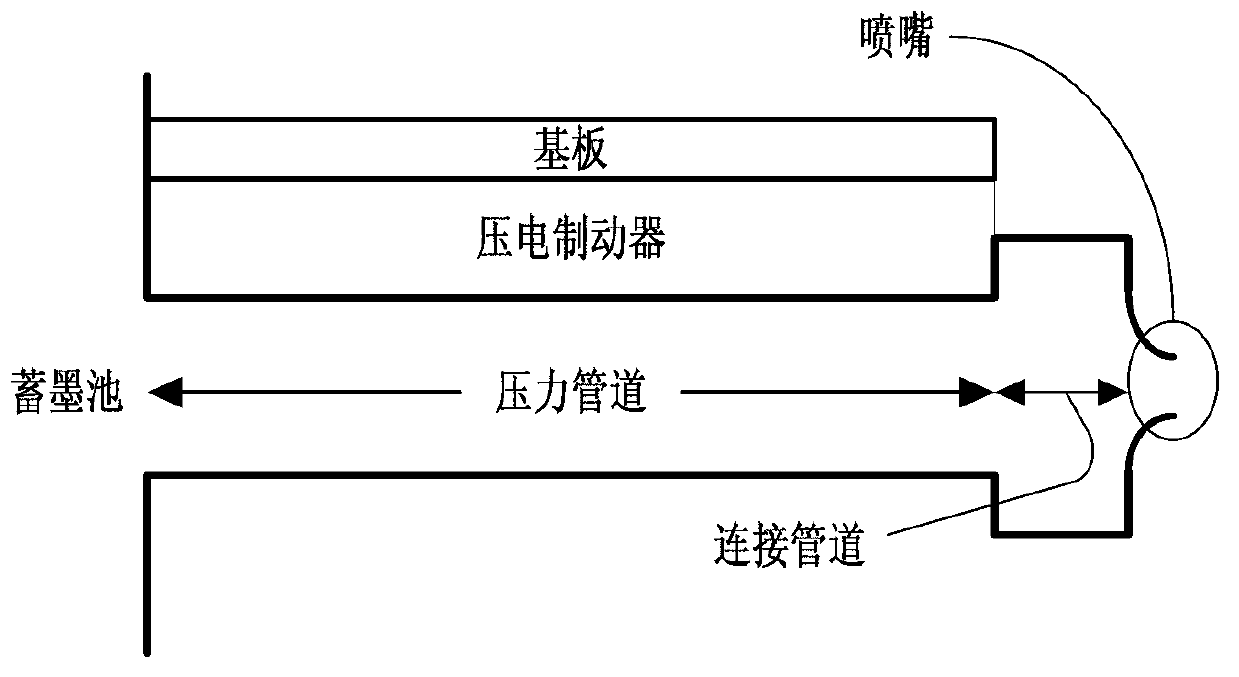

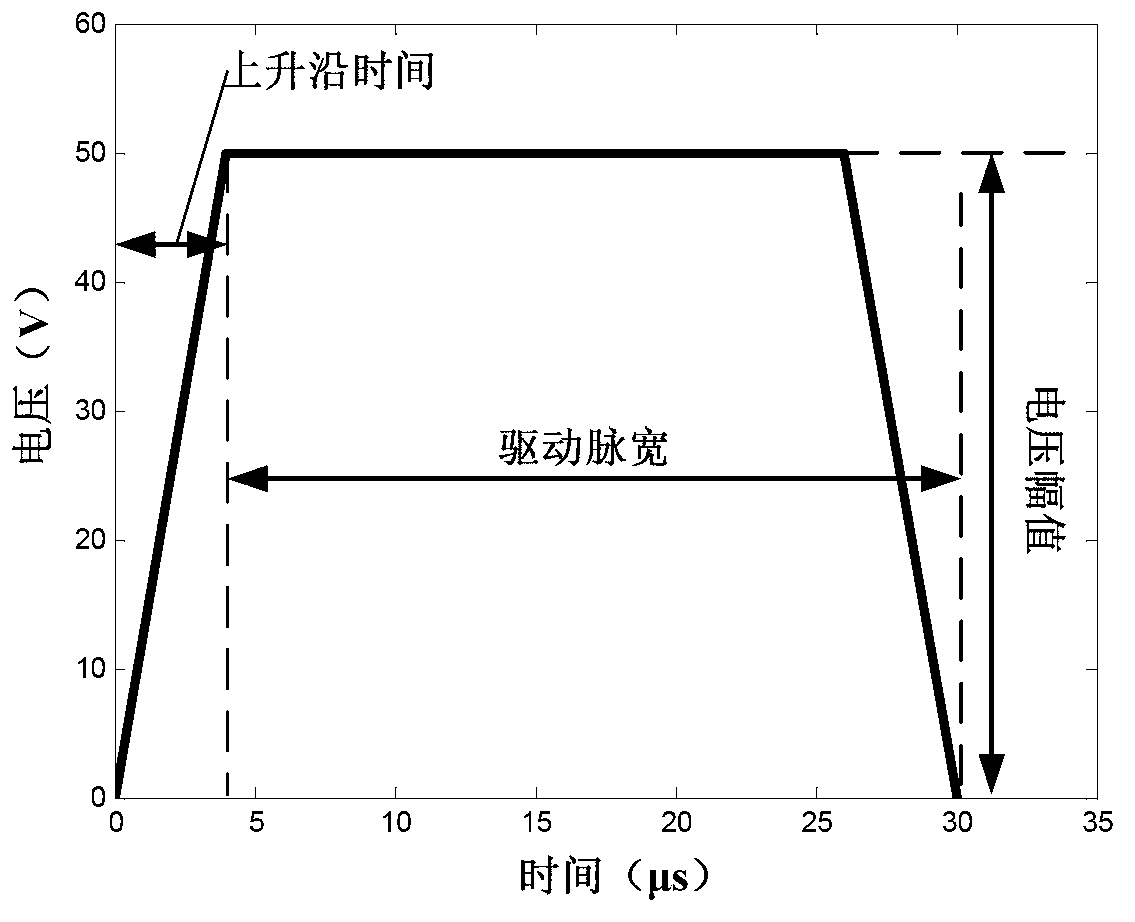

Optimum design method for piezoelectric type sprayer for printing cells

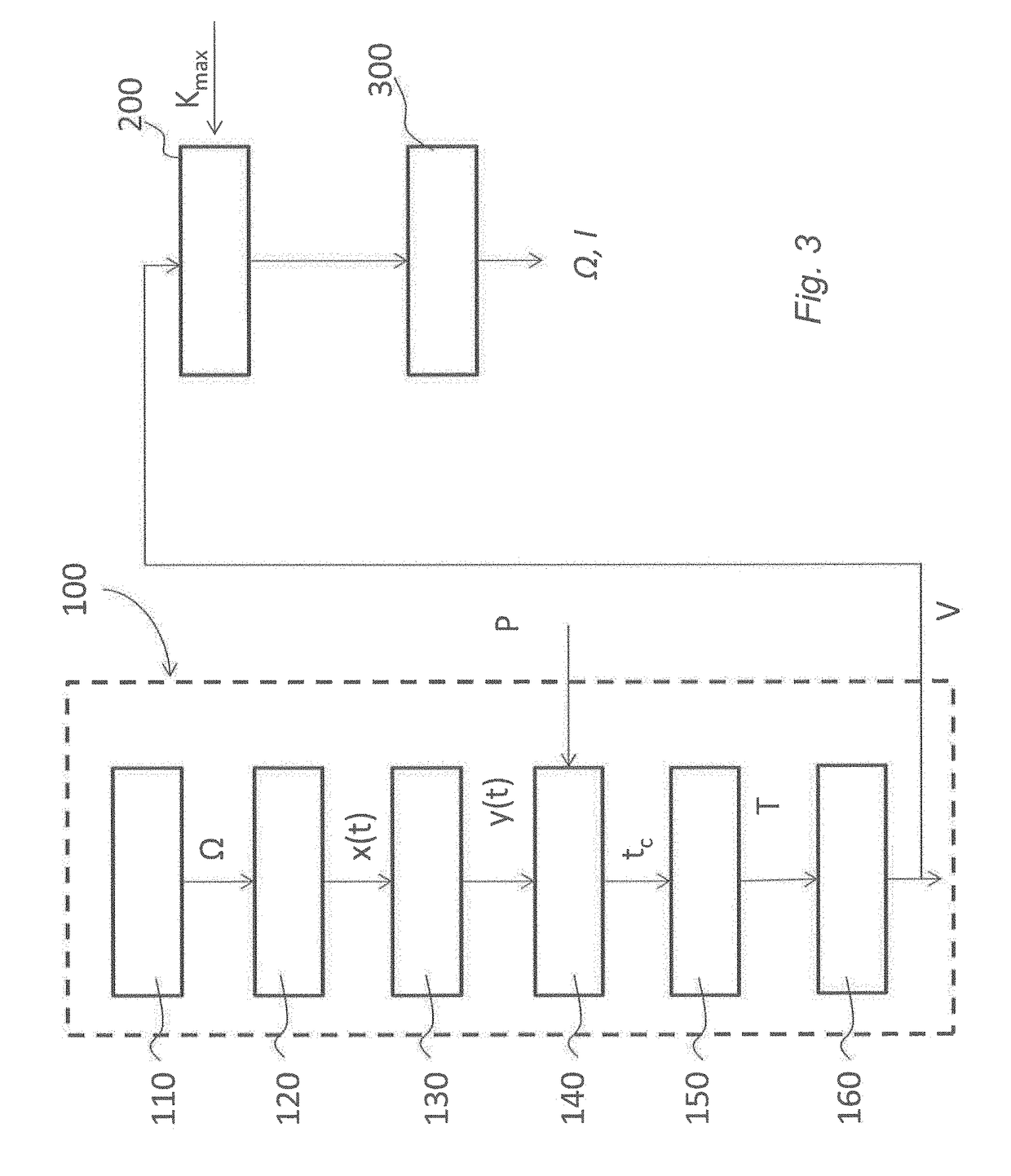

InactiveCN103218479AImprove efficiencyRealize comprehensive electromechanical designSpecial data processing applicationsVoltage pulseElement model

The invention discloses an optimum design method for a piezoelectric type sprayer for printing cells. The optimum design method is mainly utilized to solve the problems that a spraying hole is easily plugged and the survival rate of cells is low when a present piezoelectric type sprayer is used for printing the cells. The method comprises the following steps: solving a speed of an appointed node on the basis of a structural limited element model of a piezoelectric actuator; establishing a computational fluid dynamic model of the sprayer and solving according to an initial parameter and the obtained speed to obtain a condition for drop forming and the pressure of each part in the sprayer; solving a pressure wave period according to the obtained pressure, correspondingly adjusting a voltage pulse width and solving a corresponding result again; and by aiming at the demand of a user on the drop forming, establishing an optimized mathematical model and utilizing a value optimizing algorithm to solve to obtain a design parameter which meets the demand of the user and has the minimal passage maximum pressure and design the piezoelectric type sprayer. According to the optimum design method, the problems that the spraying hole is plugged and the survival rate of cells is low when the piezoelectric type sprayer is used for printing a high-viscosity cell solution are solved, and the electromechanical integrated design of the sprayer is realized.

Owner:XIDIAN UNIV

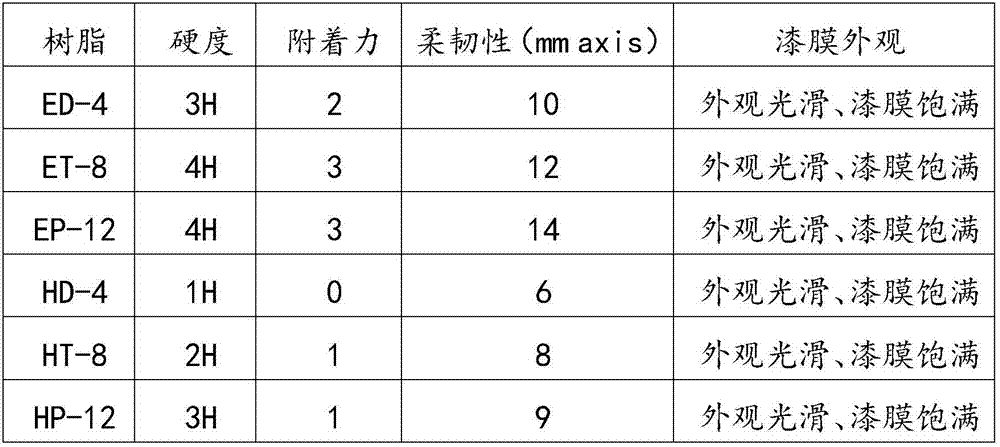

Synthesis method and application of ultraviolet-curing acrylate resin

The invention belongs to the field of chemical material synthesis and particularly relates to a synthesis method of ultraviolet-curing acrylate resin with a hyperbranched structure and application of the ultraviolet-curing acrylate resin in the field of paint. The method includes the step that amine monomers and acrylate monomers are subjected to a Michael addition reaction to obtain the AxBy type hyperbranched resin. The resin obtained through the method can achieve curing and cross-linking under the action of ultraviolet, and is large in molecular weight, low in volatility and small in smell. Each molecule contains multiple acrylate functional groups, the photo-curing speed of the resin is high, and the hardness of solid products is high. Besides, the resin molecules have a highly-branched three-dimensional spherical structure, the molecules are not likely to entangle, the solution viscosity is much lower than that of linear molecules with the same molecular weight, and a high-solid low-viscosity solution can be formed. The ultraviolet-curing acrylate resin with the hyperbranched structure can be applied to the fields of paint, adhesives, printing ink, 3D printing and the like, and has extremely good market prospects.

Owner:ZHUHAI FEIYANG NOVEL MATERIALS

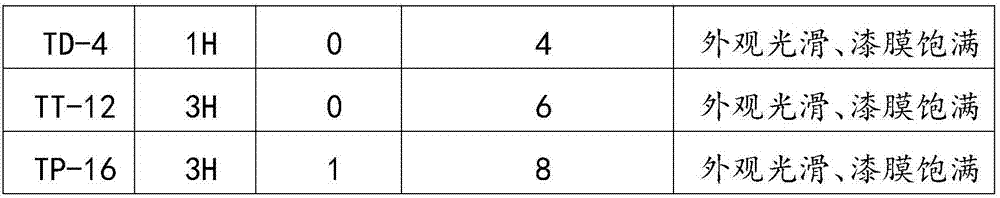

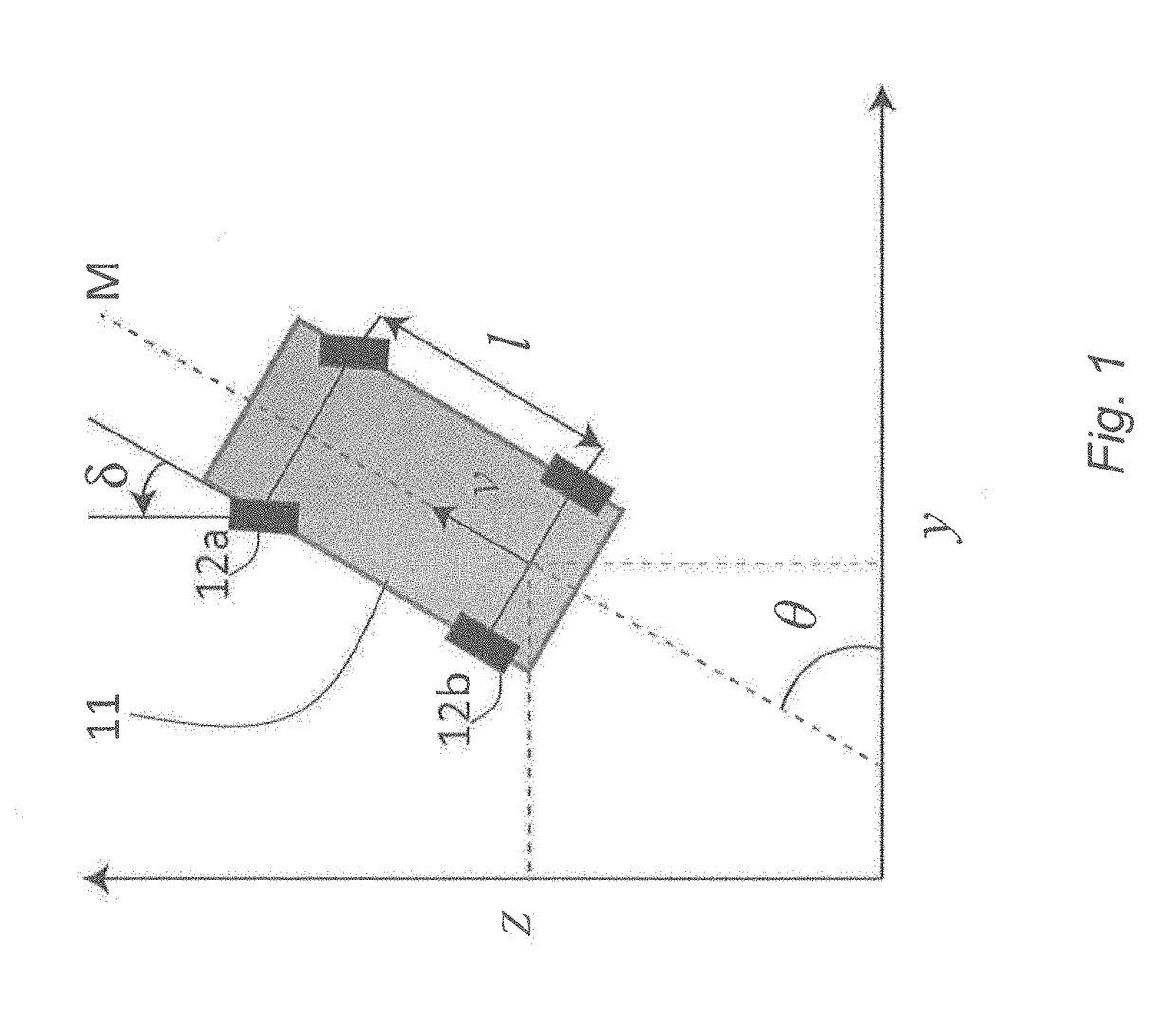

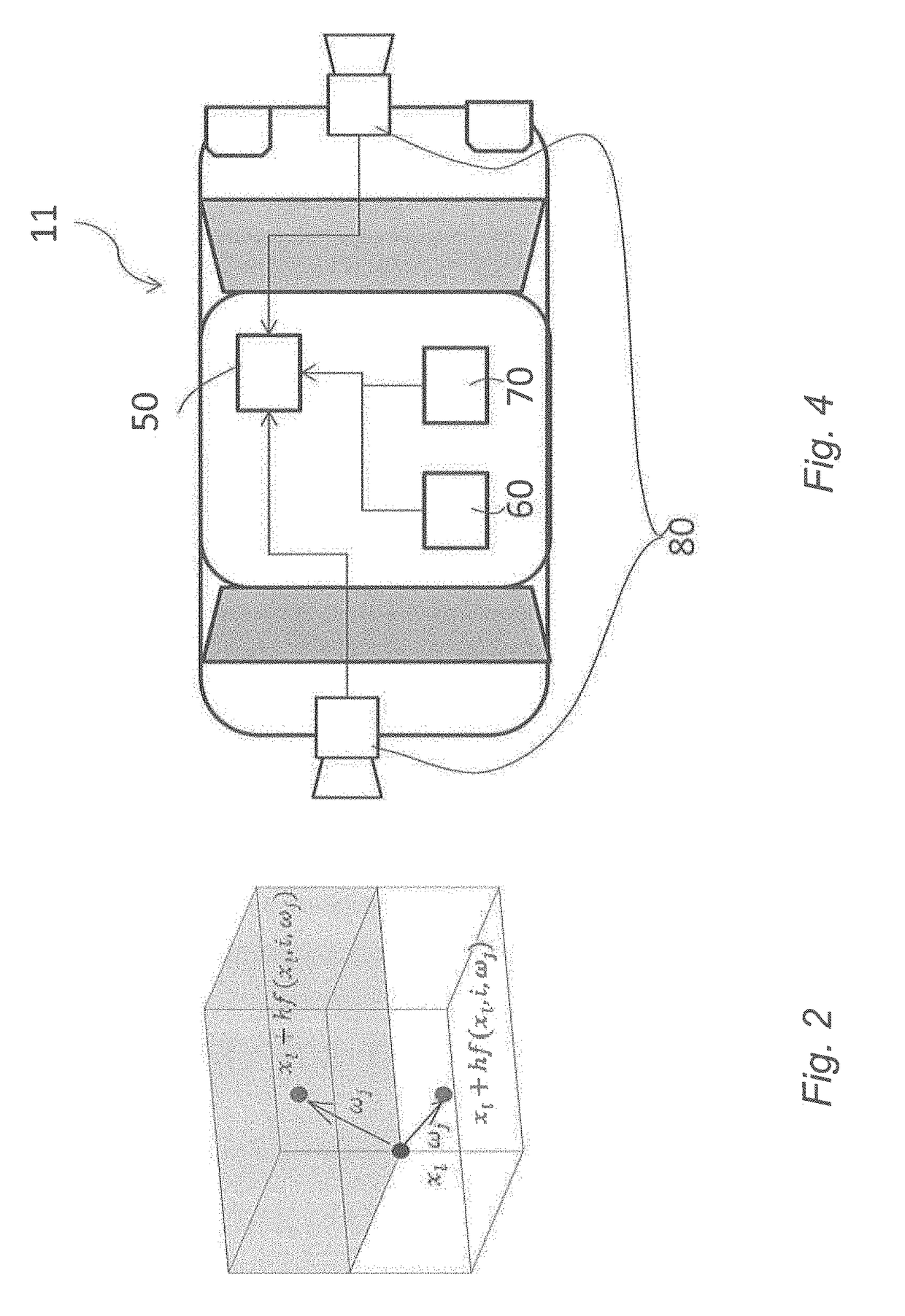

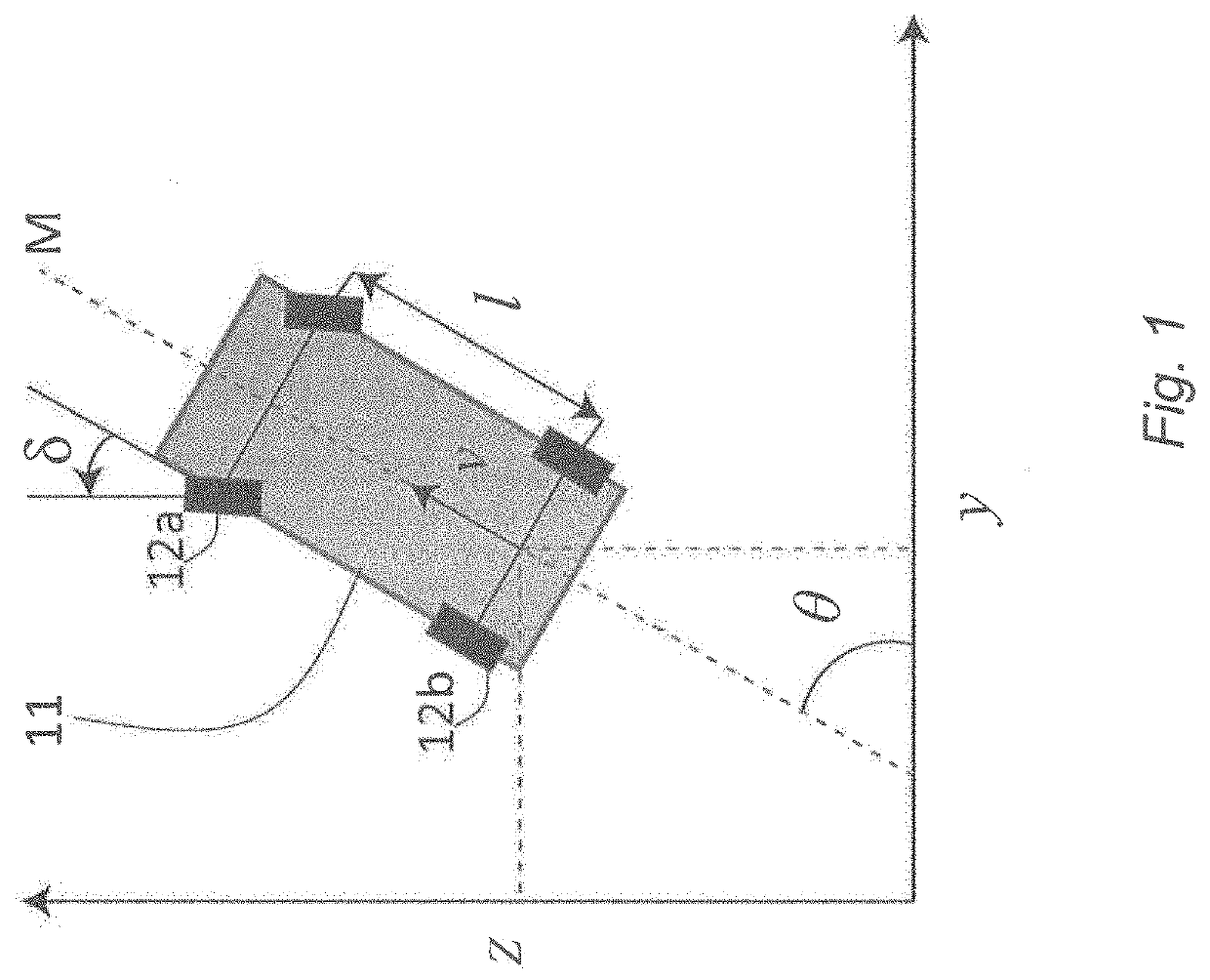

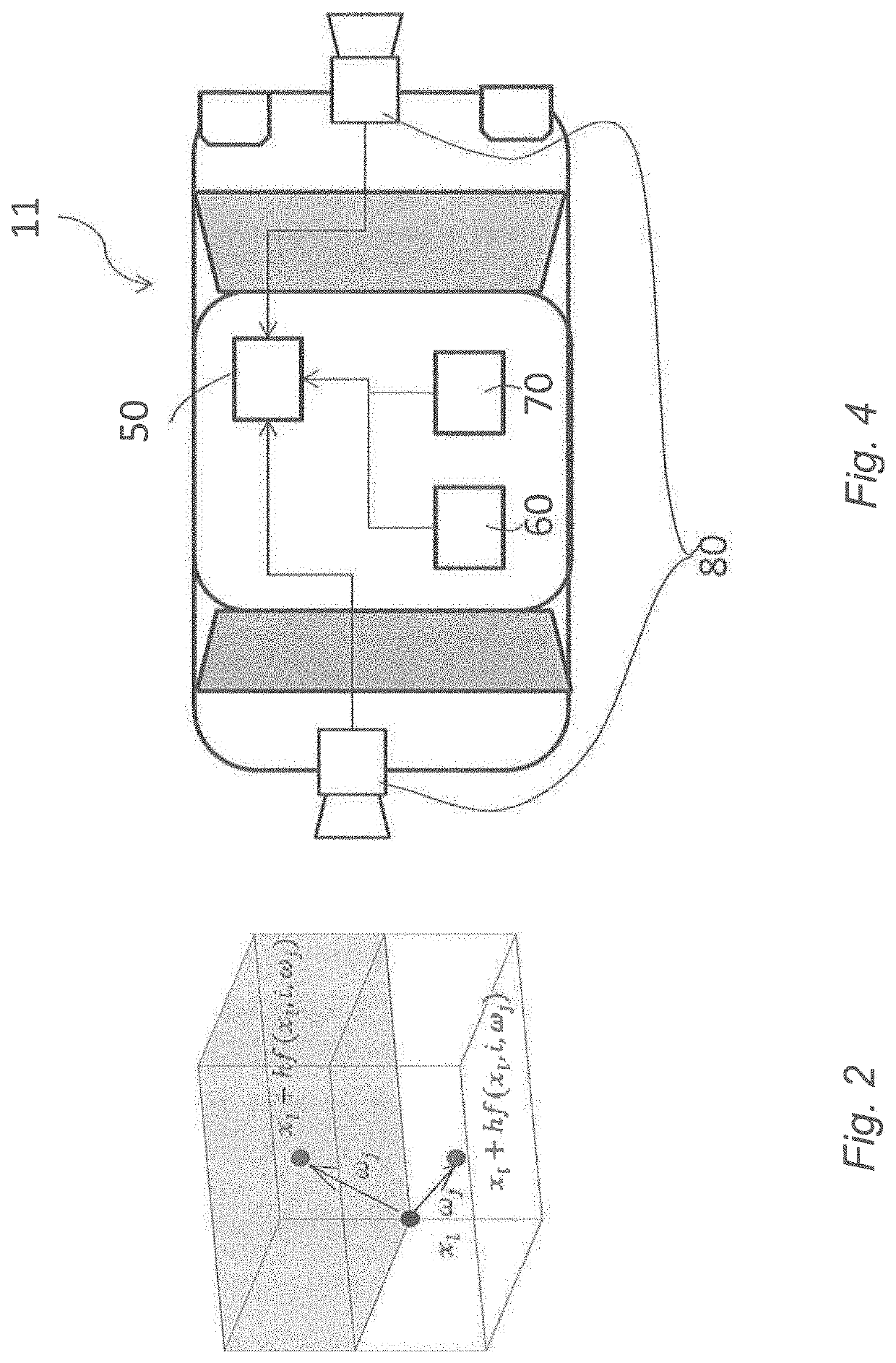

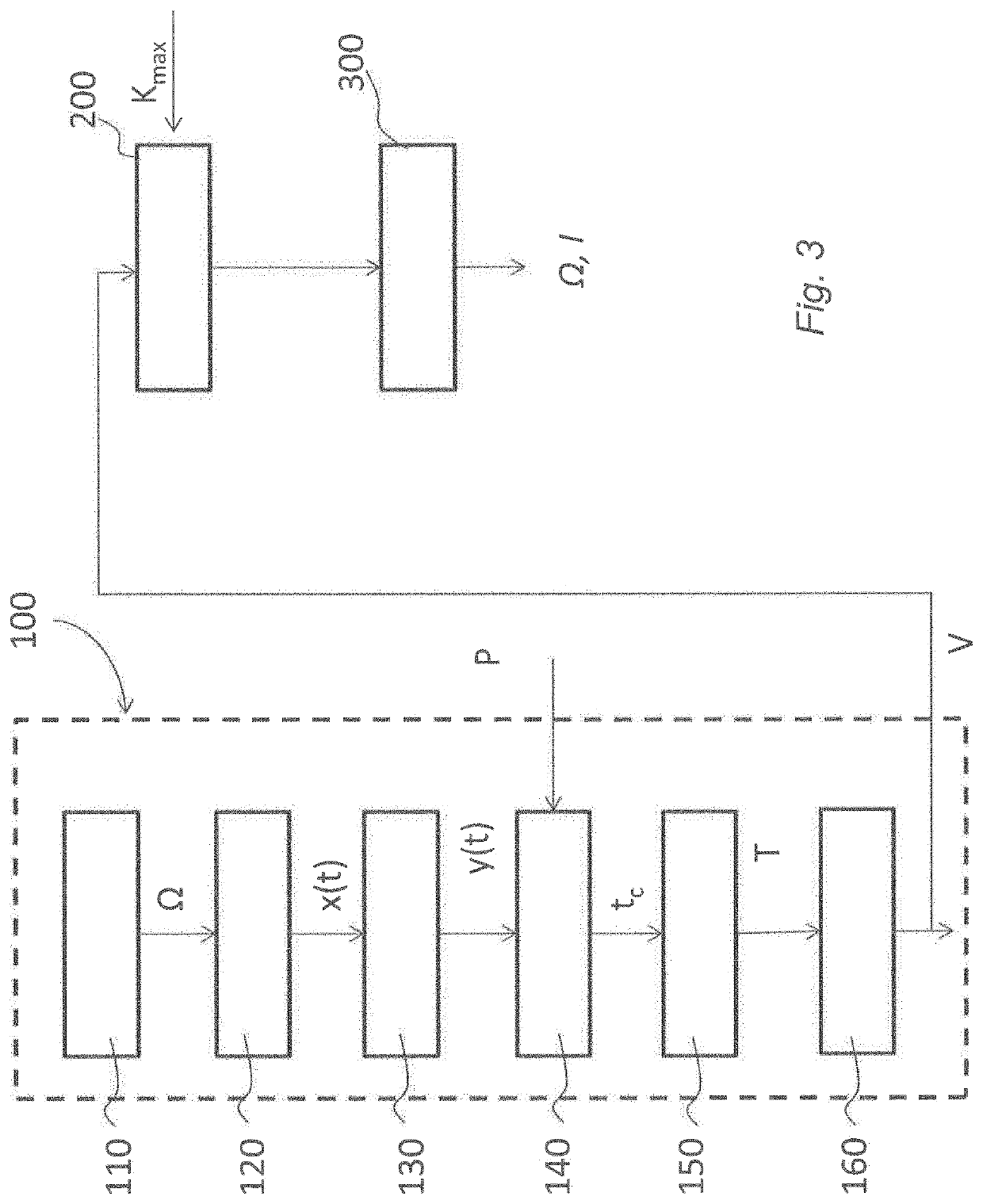

Path planning method for computing optimal parking maneuvers for road vehicles and corresponding system

ActiveUS20190001967A1Improve mobilityInstruments for road network navigationAutonomous decision making processHamilton–Jacobi–Bellman equationArrival time

Path planning method for computing optimal parking maneuvers for road vehicles including the steps of computing a set of value functions of a cost function of parking maneuvers reaching the target set of states as unique viscosity solution of a Hamilton Jacobi Bellman equation, supplying the set of value functions, together with a starting state of the vehicle, as input to the dynamic programming calculation procedure calculating at least the set of vehicle controls. The set of equations modeling the evolution of the state of said road vehicle is a switched system of equations between a first sub-system if the vehicle is in forward motion and a second sub-system if the vehicle is in reverse motion. The cost function takes into account the arrival time a number of direction changes of the road vehicle between forward motion and reverse motion.

Owner:FAB ITAL MAGNETI MARELLI SPA +1

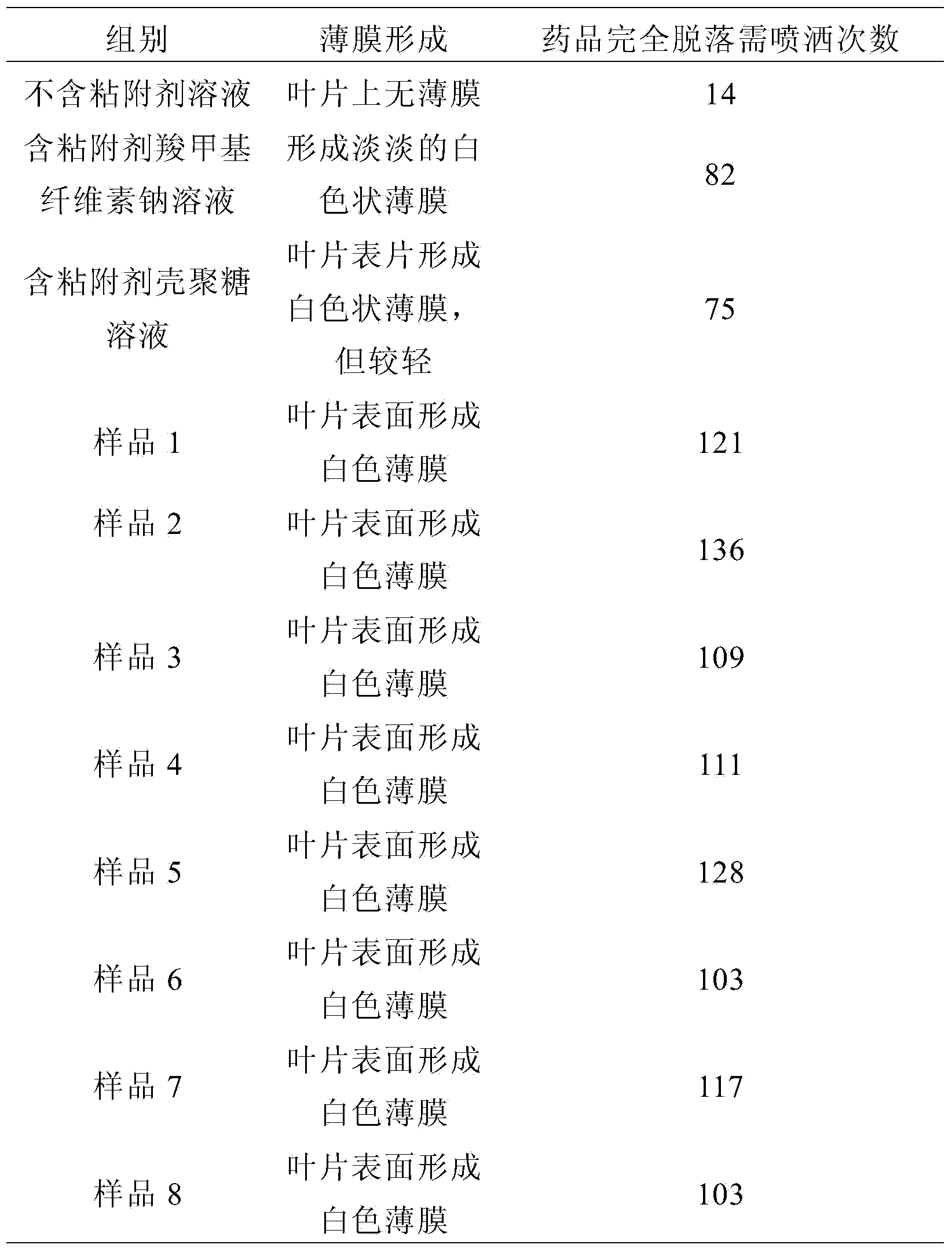

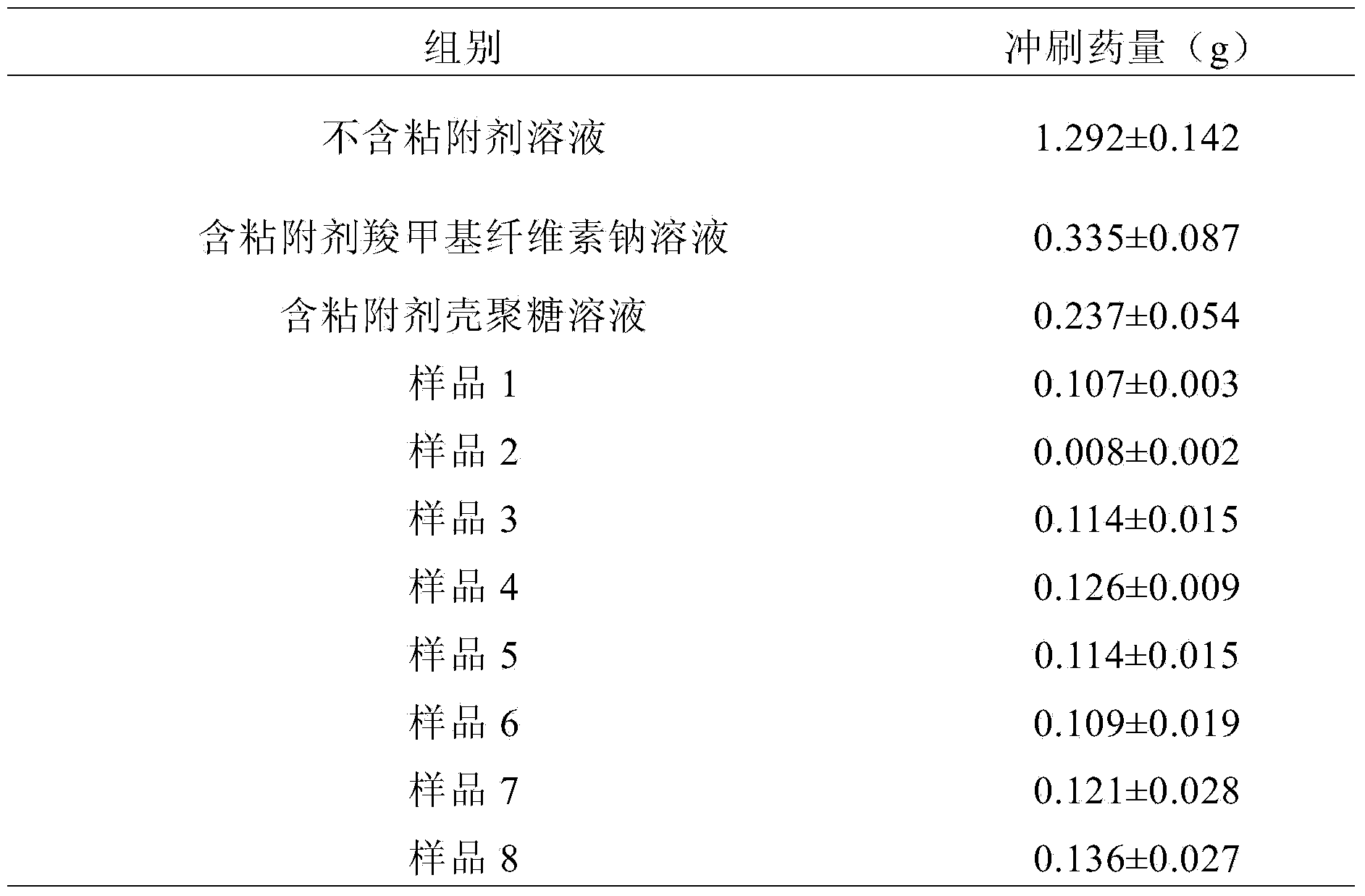

High-adhesion jujube fruit shrink disease resisting emulsion and preparation method thereof

The invention relates to a high-adhesion jujube fruit shrink disease resisting emulsion and a preparation method of the emulsion. The high-adhesion jujube fruit shrink disease resisting emulsion comprises effective constituents (streptomycin, instant boron, berberine), adhesives (chitosan, sodium carboxymethyl cellulose (CMC-NA)-glycerin) and an emulsifier (tween 80). The preparation method comprises the following steps: mixing 1-4% of a chitosan solution (acetic acid solution) with 1% of a sodium carboxymethyl cellulose-glycerin solution according to the ratio of 1:(3-5) to prepare a high-viscosity solution, adding the effective constituents (according to that the ratio of streptomycin to instant boron to berberine is (2-4):(2-4):1) in the high-viscosity solution, then mixing the mixed solution with the emulsifier, dissolving at an ultrasonic condition, heating in water bath and stirring, at last obtaining the emulsion. The emulsion can strongly inhibit the jujube fruit shrink disease, aims to achieve high adhesion, rain-wash resistance, as well as toxic-free and environment-friendly effects, and has the advantages of stability, high efficiency and low cost.

Owner:BIOCHEM ENG COLLEGE OF BEIJING UNION UNIV

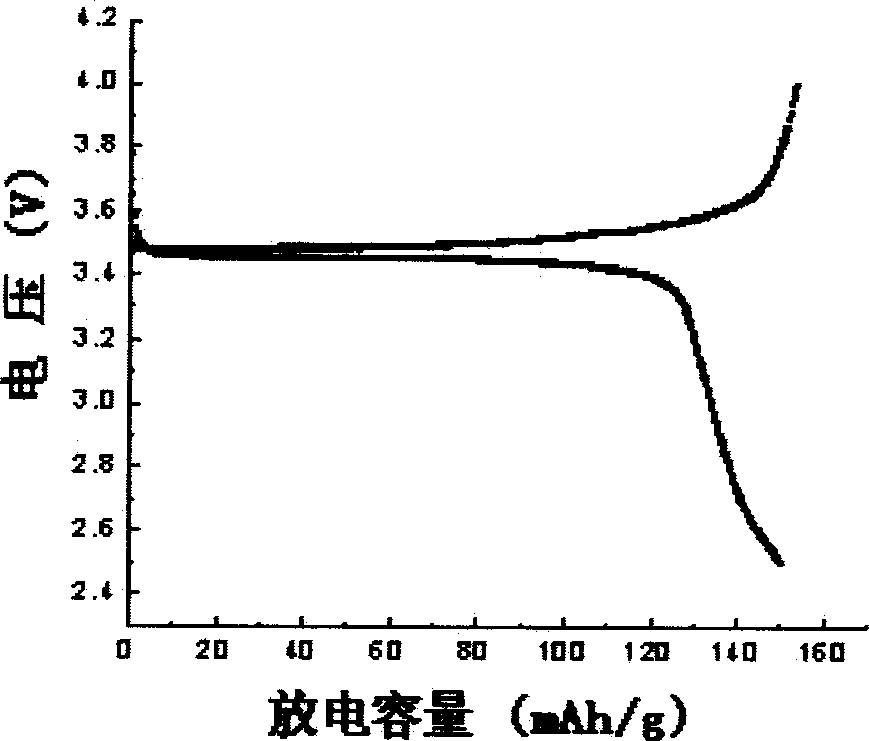

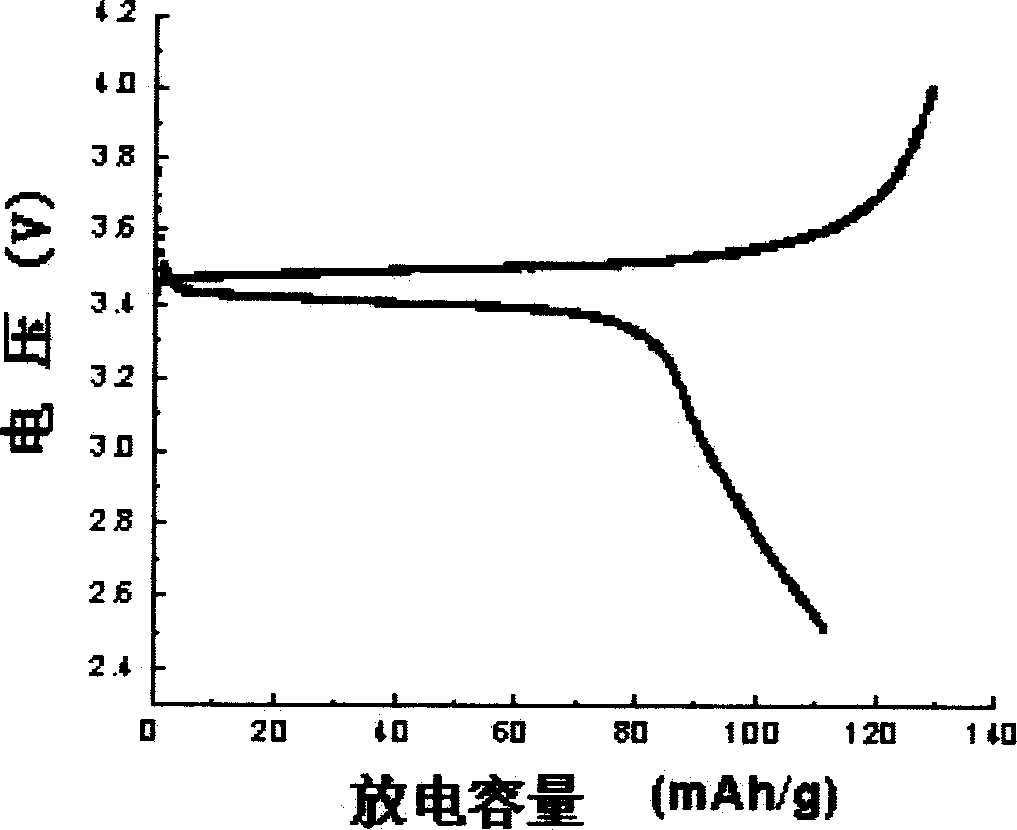

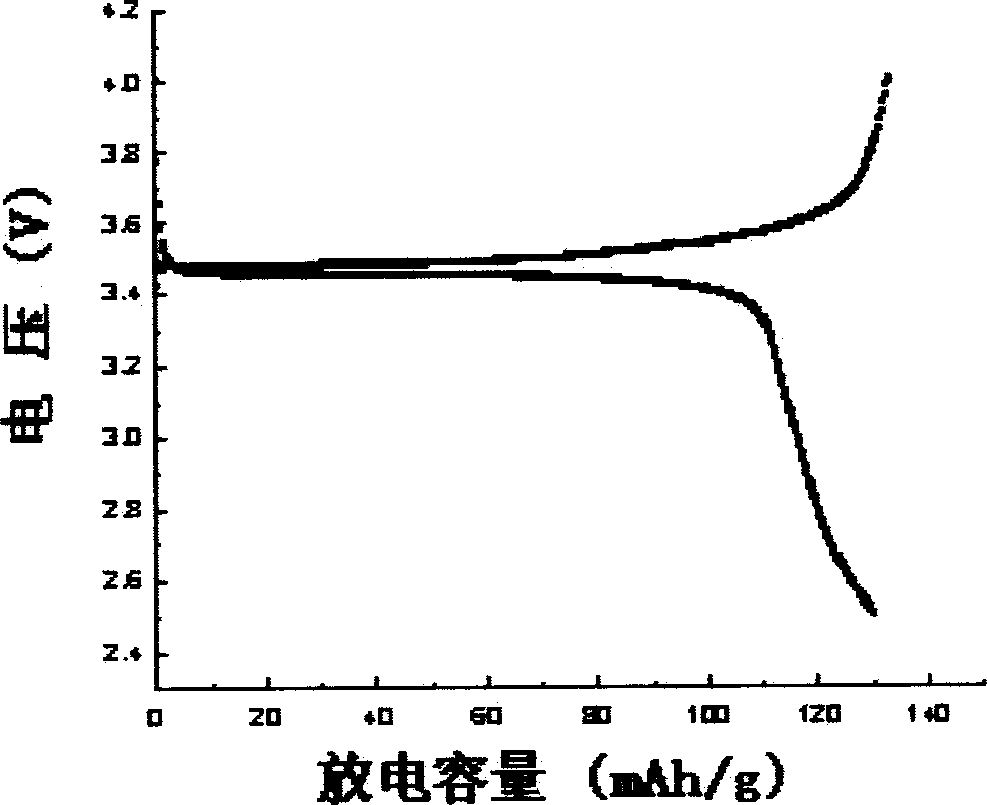

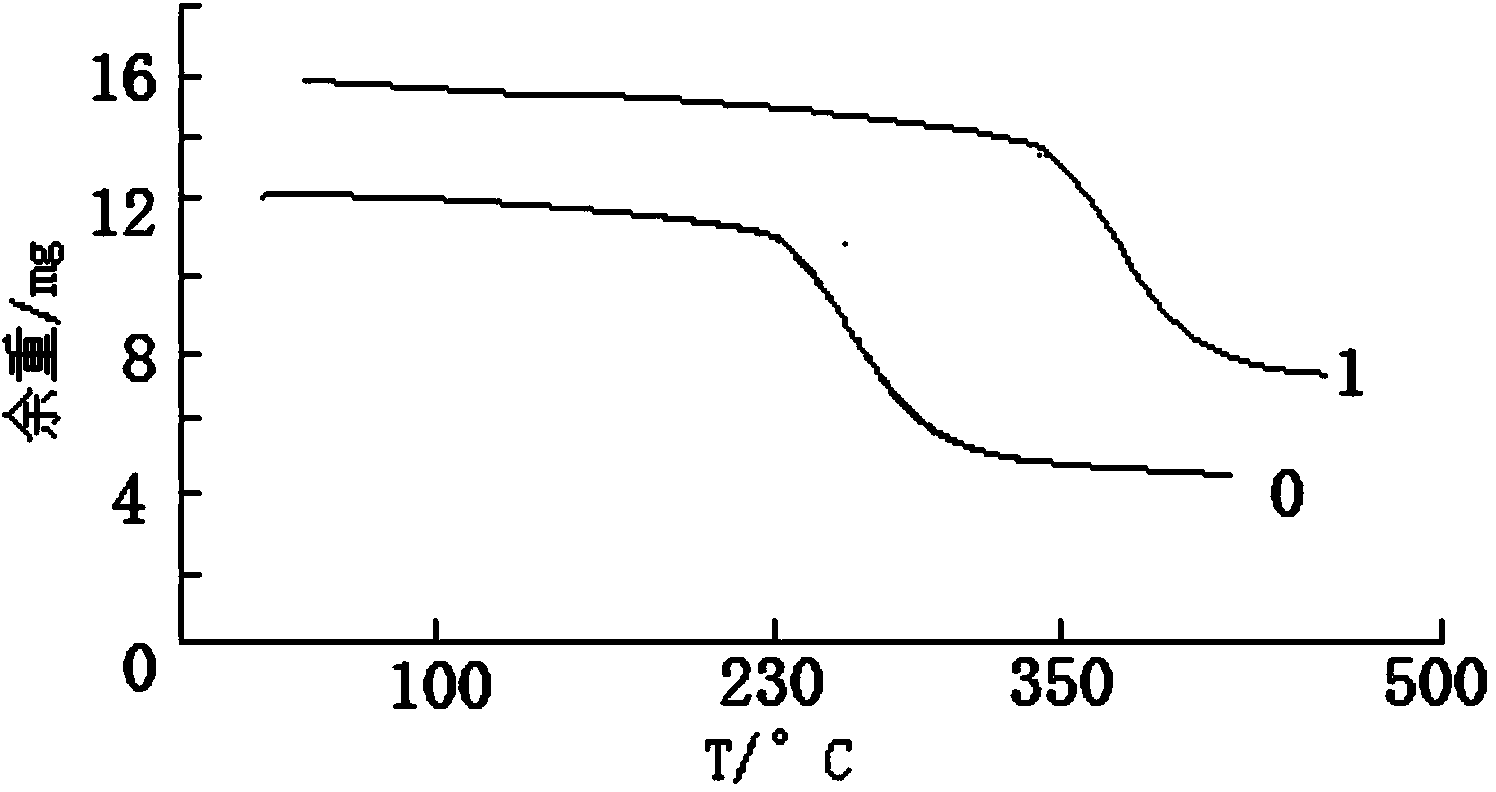

Method for preparing LimMn(XO4)y Lithium ion cell electrode material

InactiveCN1850609ASimple processProcess conditions are easy to controlElectrode manufacturing processesPhosphorus compoundsCross-linkElectrical battery

The invention is a method for preparing electrode material for LimMn(XO4)y type lithium ion battery, using acrylate and its derivative as monomers, mixing monomers with metallic ion water solution or monomer and metallic ion water solution to prepare an uniform, stable, moderate-viscosity solution, then adding in initiator to make chemical cross-linking reaction of acrylate to form polymer network structure, bonding metallic ions with carboxylate radicals, and fixing them in the microstructures of the polymer network, drying and obtaining polymer precursor; making polymer precursor pyrogenation and then burning, obtaining corresponding nano material for lithium ion battery. And its process is simple and easy to control, convenient to large-scale production.

Owner:WUHAN UNIV

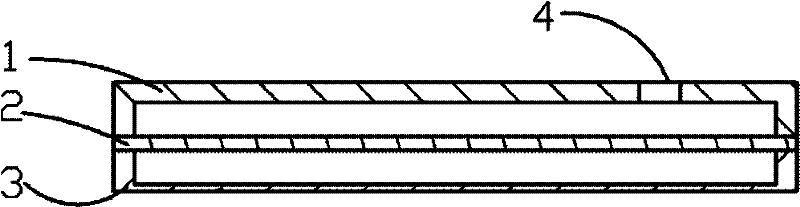

Dry analytical element capable of reducing influence of hemolysis for body fluid component measurement

ActiveUS8163472B2Reduce impactReduce the burden onMicrobiological testing/measurementMaterial analysisHemolysisBody fluid sample

It is an object of the present invention to reduce influence of hemolysis in a dry analytical element used for measurement of components in a body fluid sample such as blood. The present invention provides a method for producing a dry analytical element for body fluid component measurement comprising at least a reagent layer containing an H2O2 color developing reagent and a spreading layer provided on the reagent layer, which comprises steps of providing a spreading layer substrate on the reagent layer containing an H2O2 color developing reagent and preparing a spreading layer by coating a low-viscosity solution containing oxidase to the spreading layer substrate and then coating a high-viscosity solution containing other reagent components than oxidase thereto.

Owner:FUJIFILM CORP

Method for improving heat resistance of sisal fibers

The invention discloses a method for improving the heat resistance of sisal fibers. The method comprises the following steps: firstly, cutting general sisal fibers into sections, soaking the sections in a saturated Ca(OH)2 solution, removing impurities, fishing out, draining the excess Ca(OH)2 solution, and airing to prepare modified sisal fibers; secondly, soaking the modified sisal fibers in silica sol, taking out, draining the excess silica sol, stoving, and cross-linking and solidifying the silica sol, wherein the silica sol is alkaline silica sol and the mass percent concentration of SiO2 is 25%-40%. According to the method, a lot of cavities are formed in the rough surfaces of the sisal fibers treated with the saturated Ca(OH)2 solution; the silica sol is a low-viscosity solution with good dispersity, can fully permeate into the cavities of the sisal fibers and forms glassy-state substances on the surfaces of the sisal fibers, so that the sisal fibers are isolated from the outside through part of the glassy-state substances, and the heat resistance and the fiber bundle strength of the sisal fibers are improved.

Owner:SHANDONG UNIV OF SCI & TECH

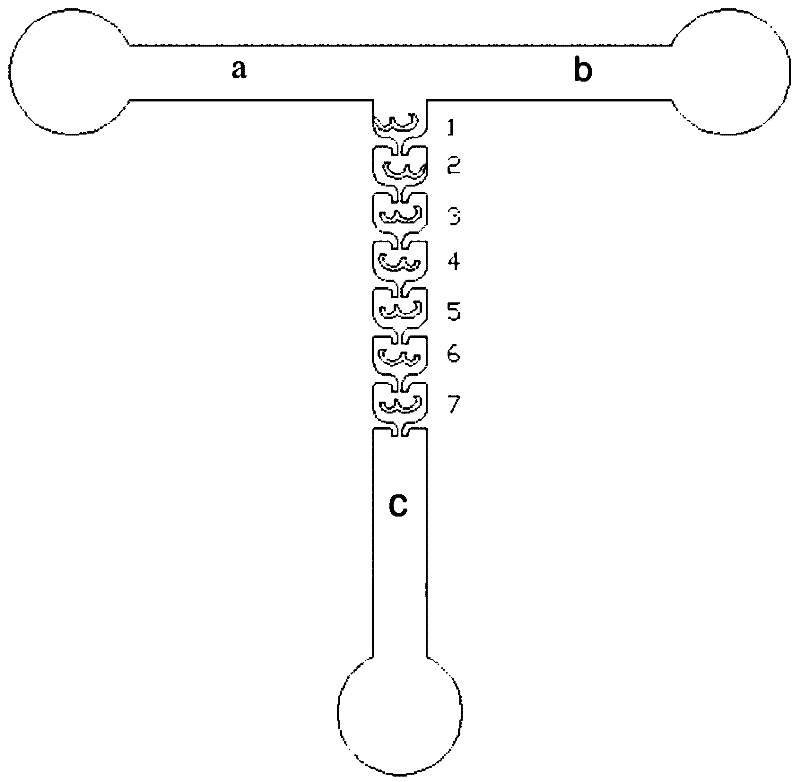

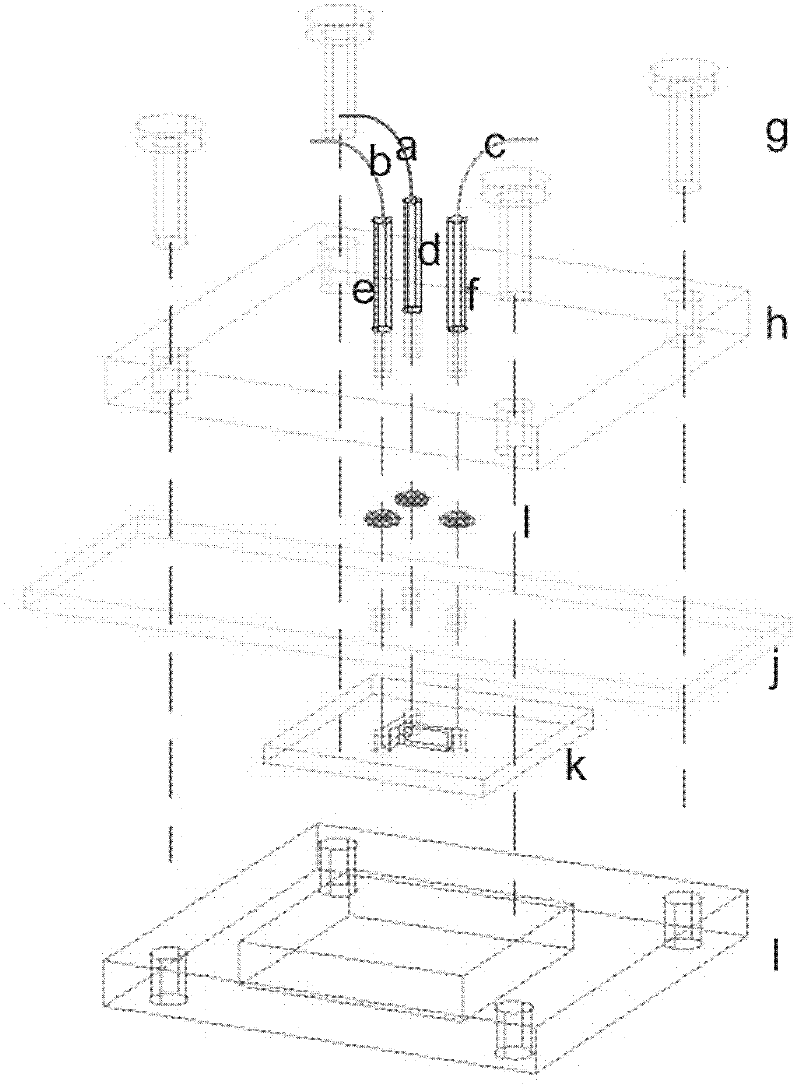

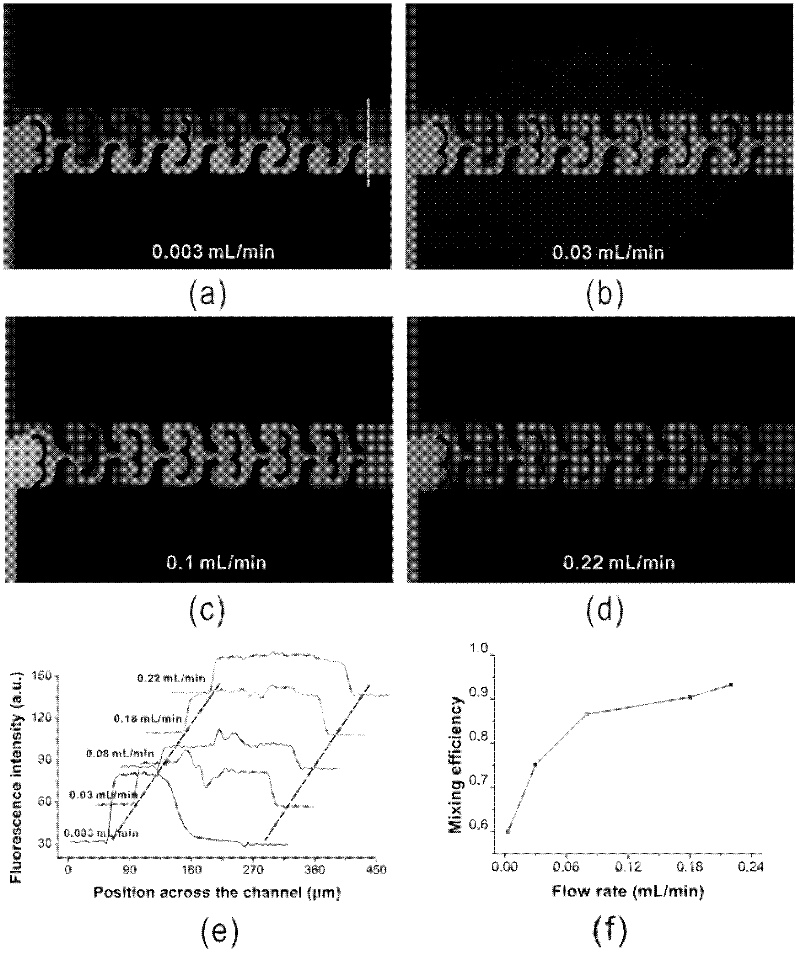

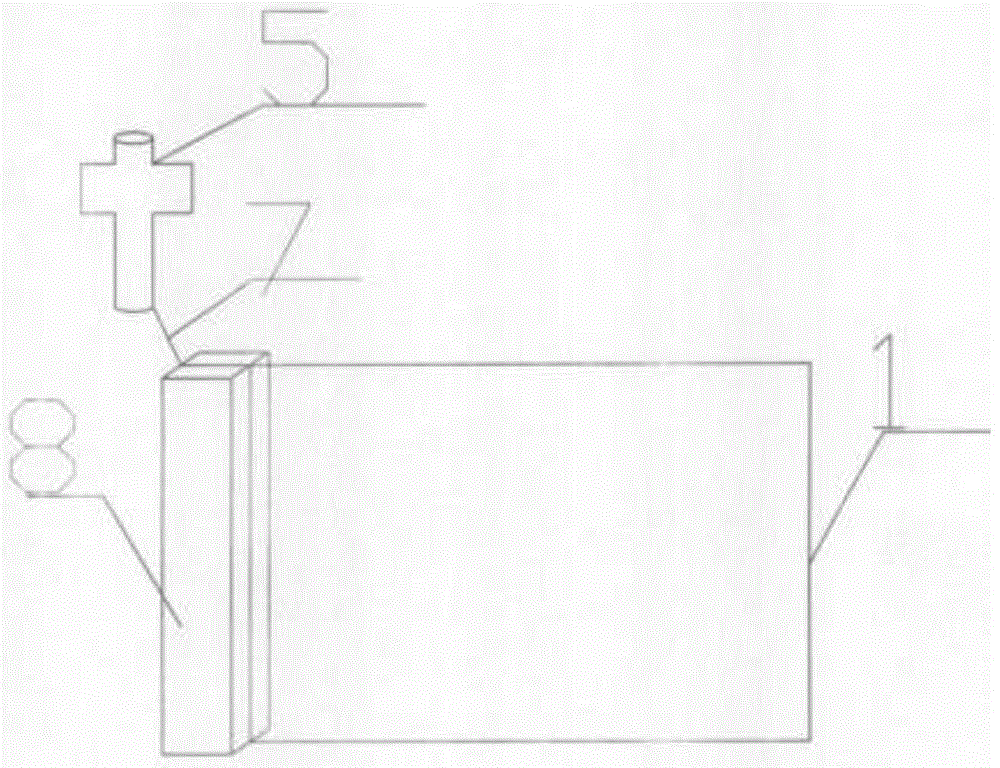

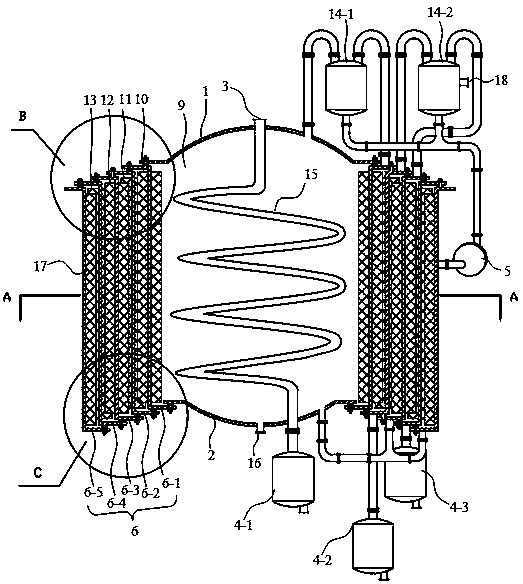

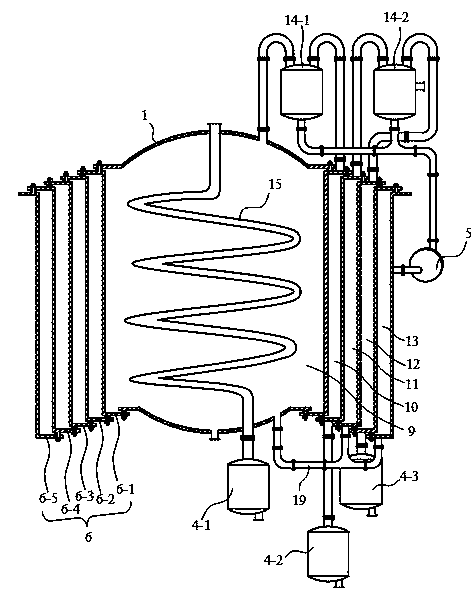

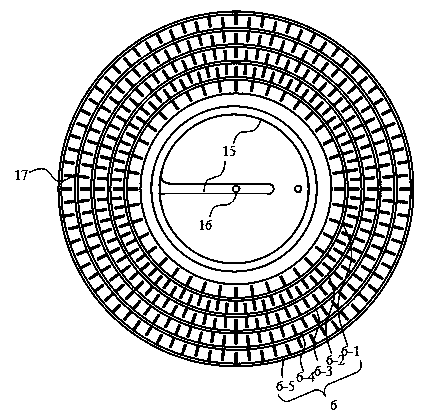

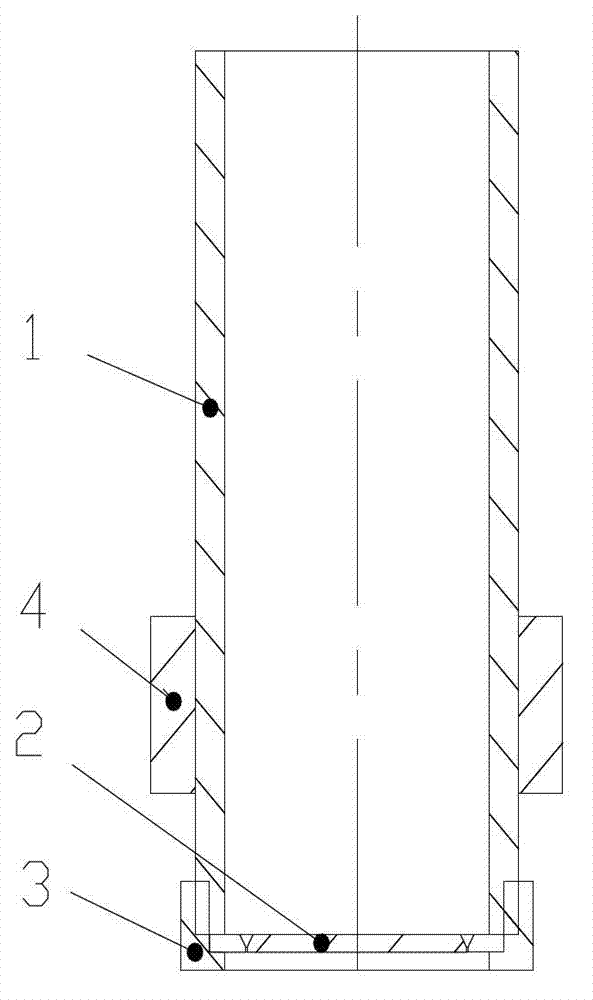

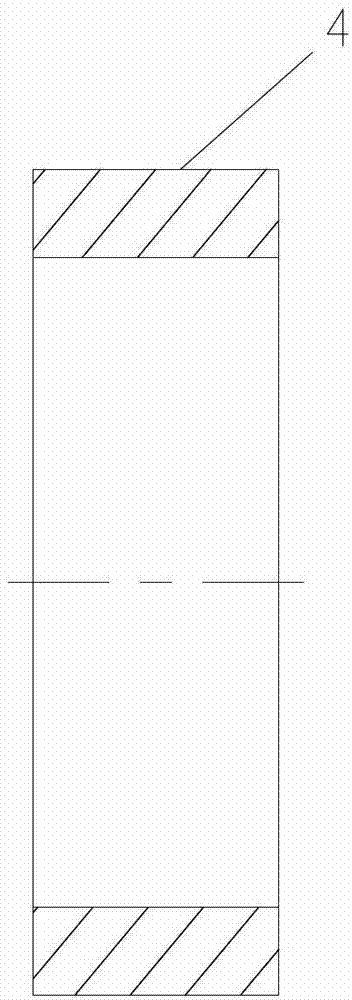

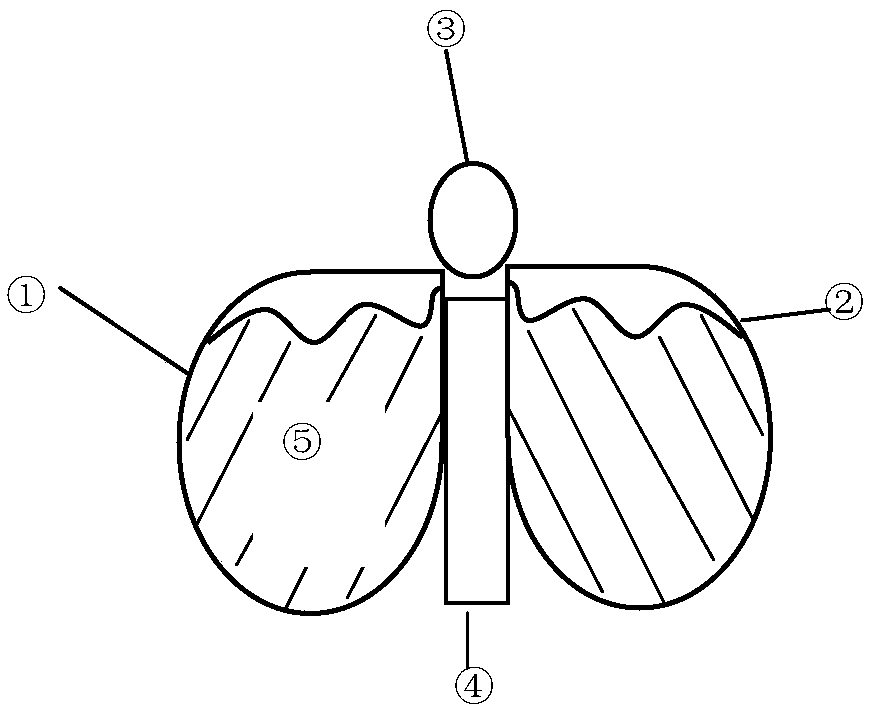

Quick micro-mixing device for high-viscosity solution

The invention discloses a quick micro-mixing device for high-viscosity solution. The device comprises a PDMS (Polydimethylsiloxane) thin layer, and is characterized in that: three communicated passages are processed on the PDMS thin layer, wherein two solution inlet passages are symmetric about a third solution outlet passage; a plurality of w-shaped microstructures are sequentially processed in the solution outlet passage; and two openings of the w-shaped microstructures face an intersection of the three passages. The device has a simple structure and a simple processing process and can finish full mixing of the high-viscosity solution in 500 microseconds.

Owner:HUAZHONG UNIV OF SCI & TECH

Supercapacitor battery

ActiveCN103985567AStrongly corrosiveReduced service lifeHybrid capacitor separatorsHybrid capacitor electrodesConductive materialsSulfide

The invention discloses a supercapacitor battery. The supercapacitor battery is mainly composed of electrodes, an electrolyte, a membrane, end plates, a lead and a packaging material. The main conductive material of the electrodes is silicon carbide. The electrode lead is directly connected with the battery end plates in a welding mode through a multi-strand sterepsinema with the diameter ranging from 1 mm to 4 mm, and the multi-strand sterepsinema is made of metallic titanium fibers or titanium alloy fibers. The NMP ultrahigh viscosity solution of methylamino butyric acid lithium, polysulfide lithium, lithium perchlorate and lithium phosphate serves as the electrolyte. A polyphenylene sulfide thin film serves as the membrane. The end plates are made of metallic titanium or titanium alloy. The packaging material is formed by welding an ultra-thick polyphenylene sulfide injection molding part and a thin film in a laser mode. One electrode, one end plate, the electrolyte, the membrane, the electrolyte, the other end plate and the other electrode are overlapped in sequence or wound into the 88-188 layers of the supercapacitor battery. The supercapacitor battery has the advantages of being high in temperature resistance, low in temperature resistance, corrosion resistant, short in charging time, large in number of circulation times and long in service life, and can be widely applied to places with the very hostile environmental conditions.

Owner:扬州荣可然科技有限公司

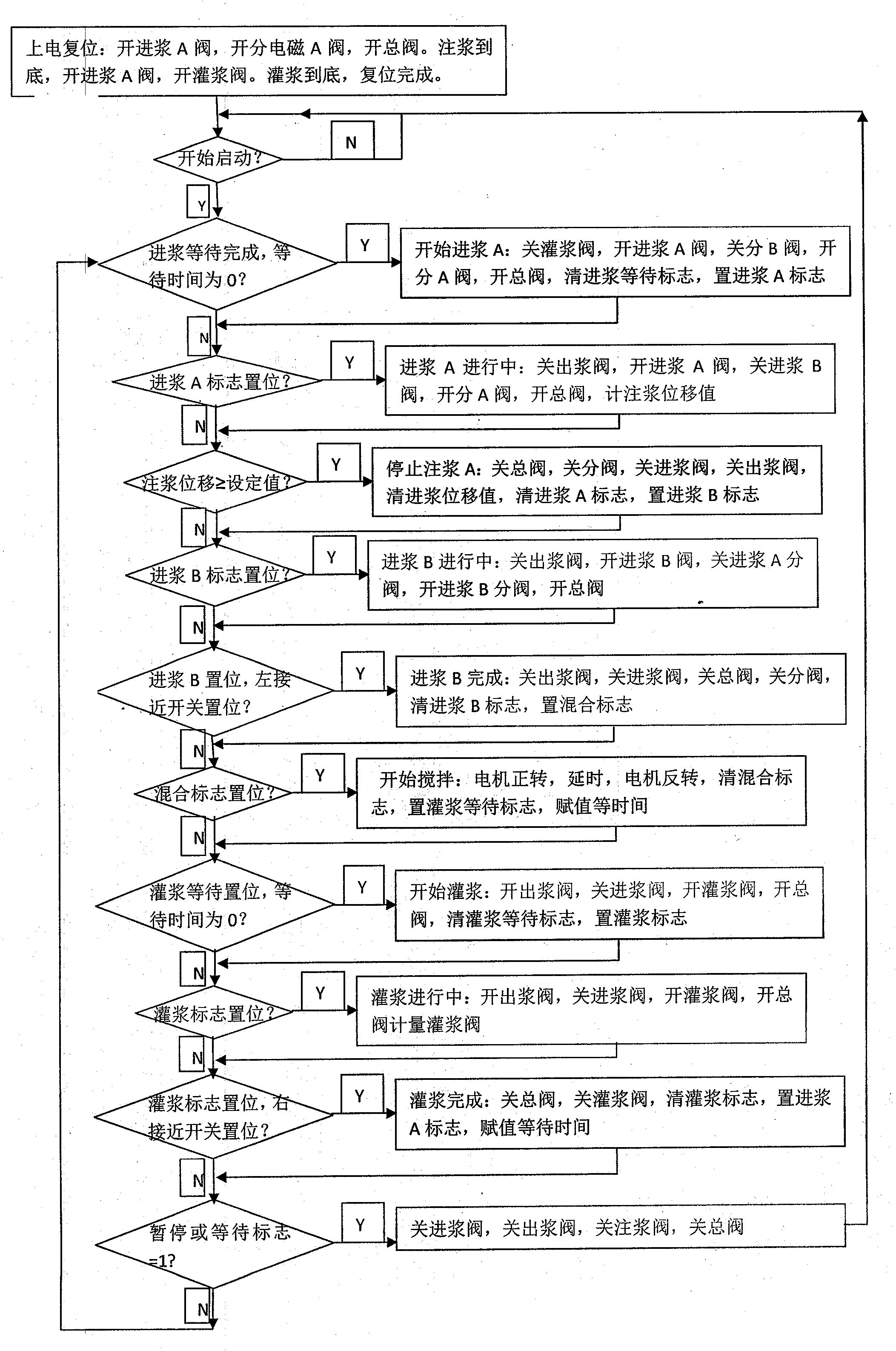

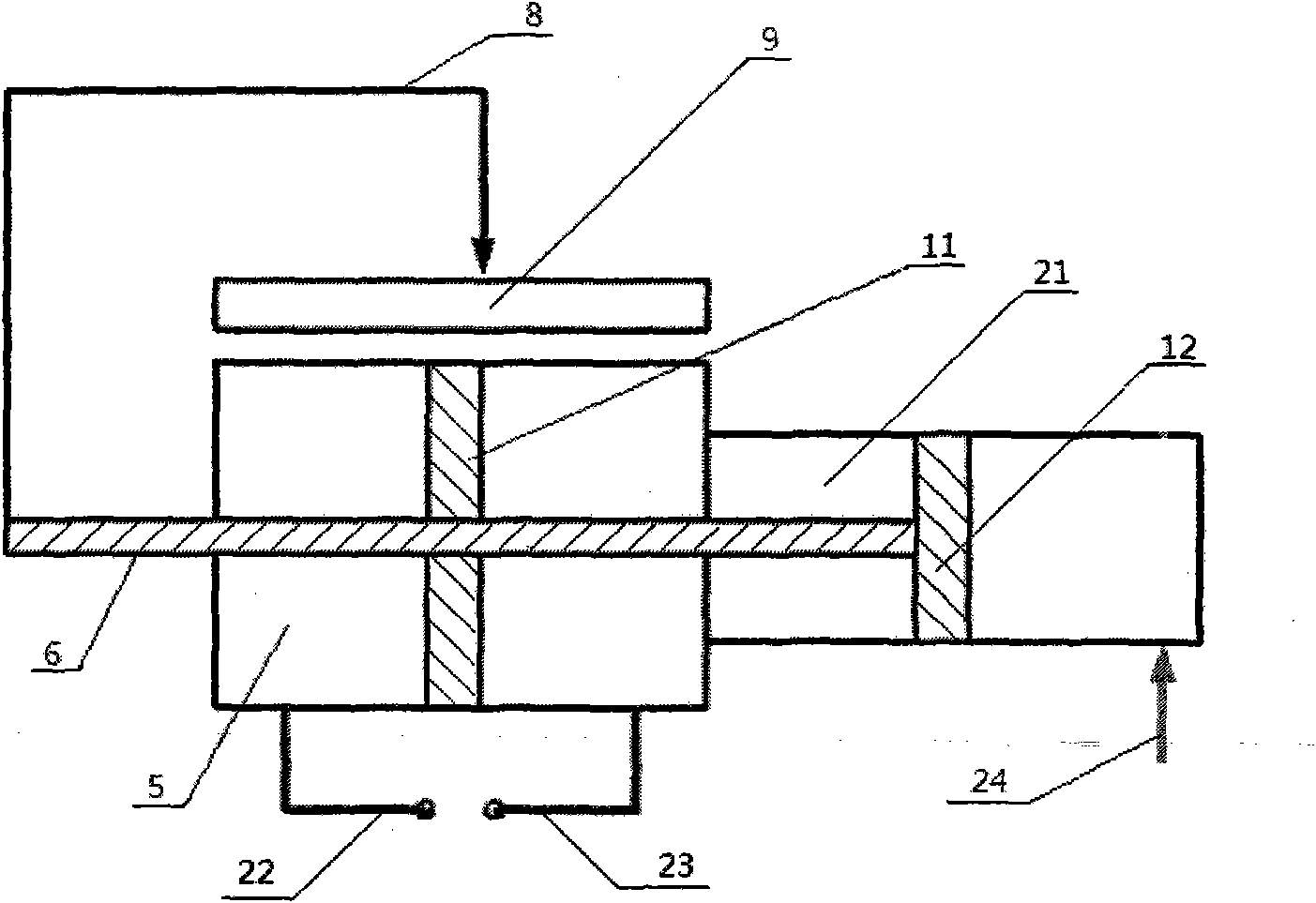

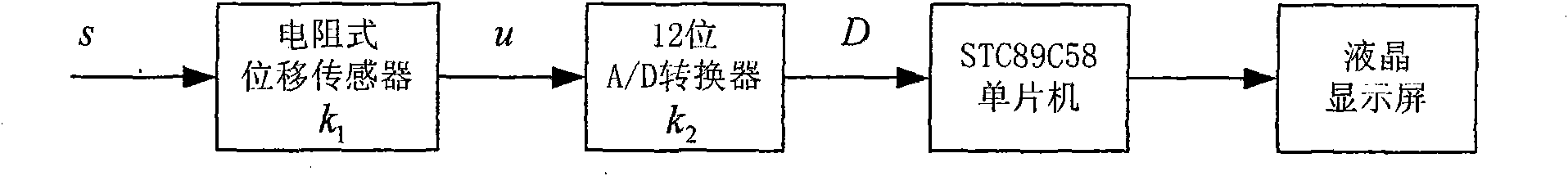

Chemical grouting flowmeter, measuring method and pneumatic single cylinder double-liquid type chemical grouting pump

ActiveCN102147276AGuaranteed accuracyGuarantee the quality of chemical groutingVolume/mass flow measurementPump controlHydraulic cylinderChemical grouting

The invention relates to a chemical grouting flowmeter for measuring high-viscosity solution, a method for measuring flow by using the flowmeter and a pneumatic single cylinder double-liquid type chemical grouting pump applying the chemical grouting flowmeter. The pneumatic single cylinder double-liquid type chemical grouting pump comprises an adjustable air valve, the chemical grouting flowmeterand a control circuit; an air cylinder is provided with a main electromagnetic air valve and a sub-electromagnetic air valve; a displacement sensor is provided with a left approach switch and a rightapproach switch; the tip of a hydraulic cylinder is provided with an A component grout-feeding electromagnetic liquid valve, a B component grout-feeding electromagnetic liquid valve and a grouting electromagnetic liquid valve; and the hydraulic cylinder is provided with a mixer for mixing grouting liquid. With the adoption of the chemical grouting flowmeter, the method and the pneumatic single cylinder double-liquid type chemical grouting pump, the flow of chemical grouting can be accurately measured, so that the proportion of chemical grouting components can be continuously adjusted, and theuse is convenient.

Owner:HUNAN QUANCHEN TECH

Novel multiple-effect evaporation device

ActiveCN103977583AImprove heat transfer performanceReduce lossesMultiple-effect evaporationStrong acidsEngineering

The invention discloses a novel multiple-effect evaporation device which comprises an upper cover, a lower cover, a steam inlet, a condenser and a feed pump, wherein the upper cover and the lower cover are arranged at the upper end and the lower end of the center of a sleeve structure respectively so as to form a flange structure; multiple sleeves are concentrically and sequentially arranged from interior to exterior so as to form the sleeve structure; a single-effect feed liquid chamber, a double-effect heating chamber, a double-effect feed liquid chamber, a triple-effect heating chamber and a triple-effect feed liquid chamber are respectively formed; two adjacent feed liquid chambers are communicated with each other through a U-shaped pipe. A triple-effect evaporation mode is formed by adopting the multilayer sleeves, and the device is simple in structure and convenient to operate. Compared with a traditional process, the process of the novel multiple-effect evaporation device has the advantages that the occupied area is reduced, the heat transfer and evaporation efficiency is improved, the heat loss is reduced, various corrosive solutions such as strong acid and strong base, and high-viscosity solutions are concentrated by adopting a corrosion-resistant coating, the application range of the device is widened, and the service life is prolonged.

Owner:TIANJIN RUNJIE INNOVATION ENVIRONMENTAL PROTECTION TECH

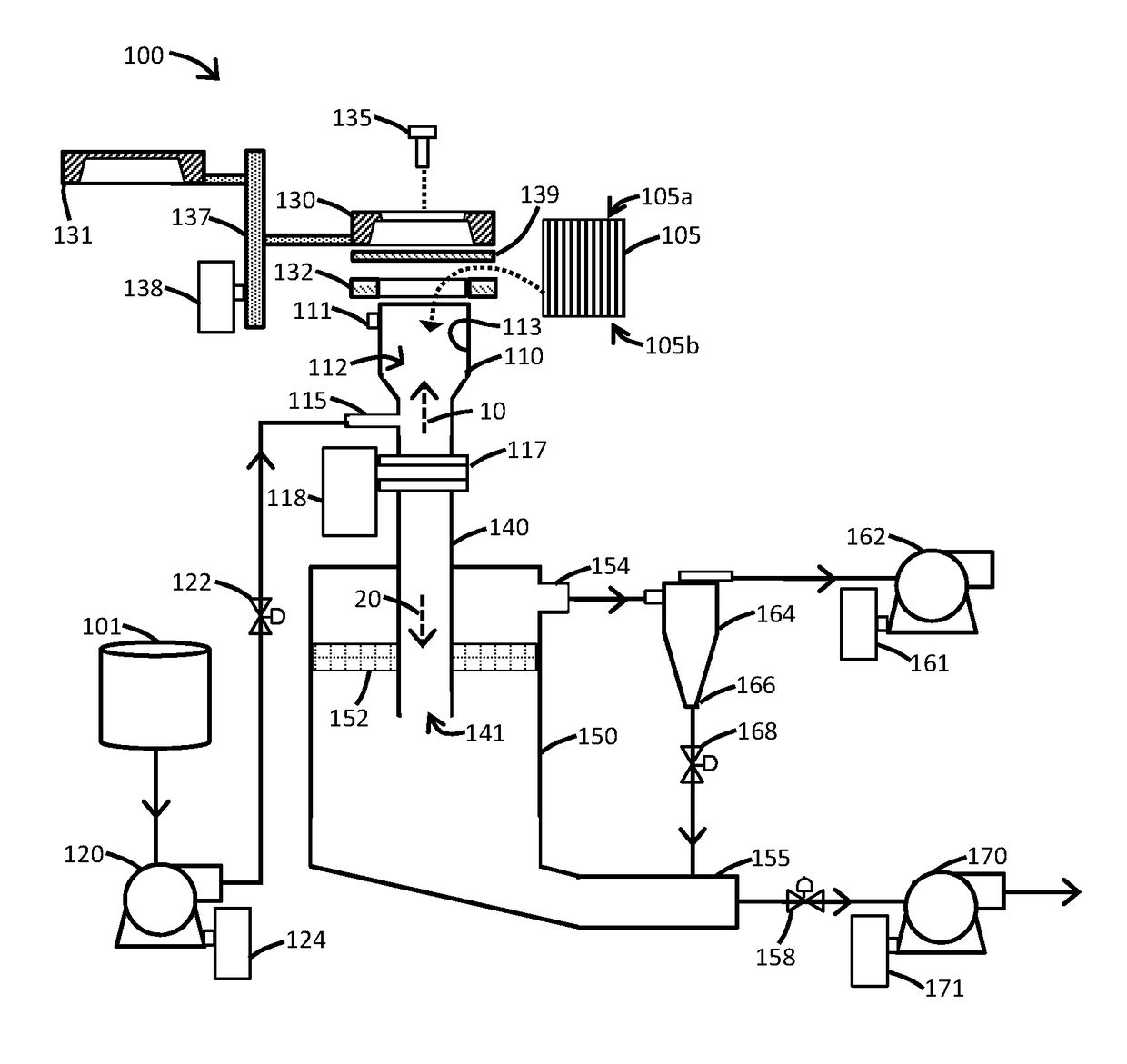

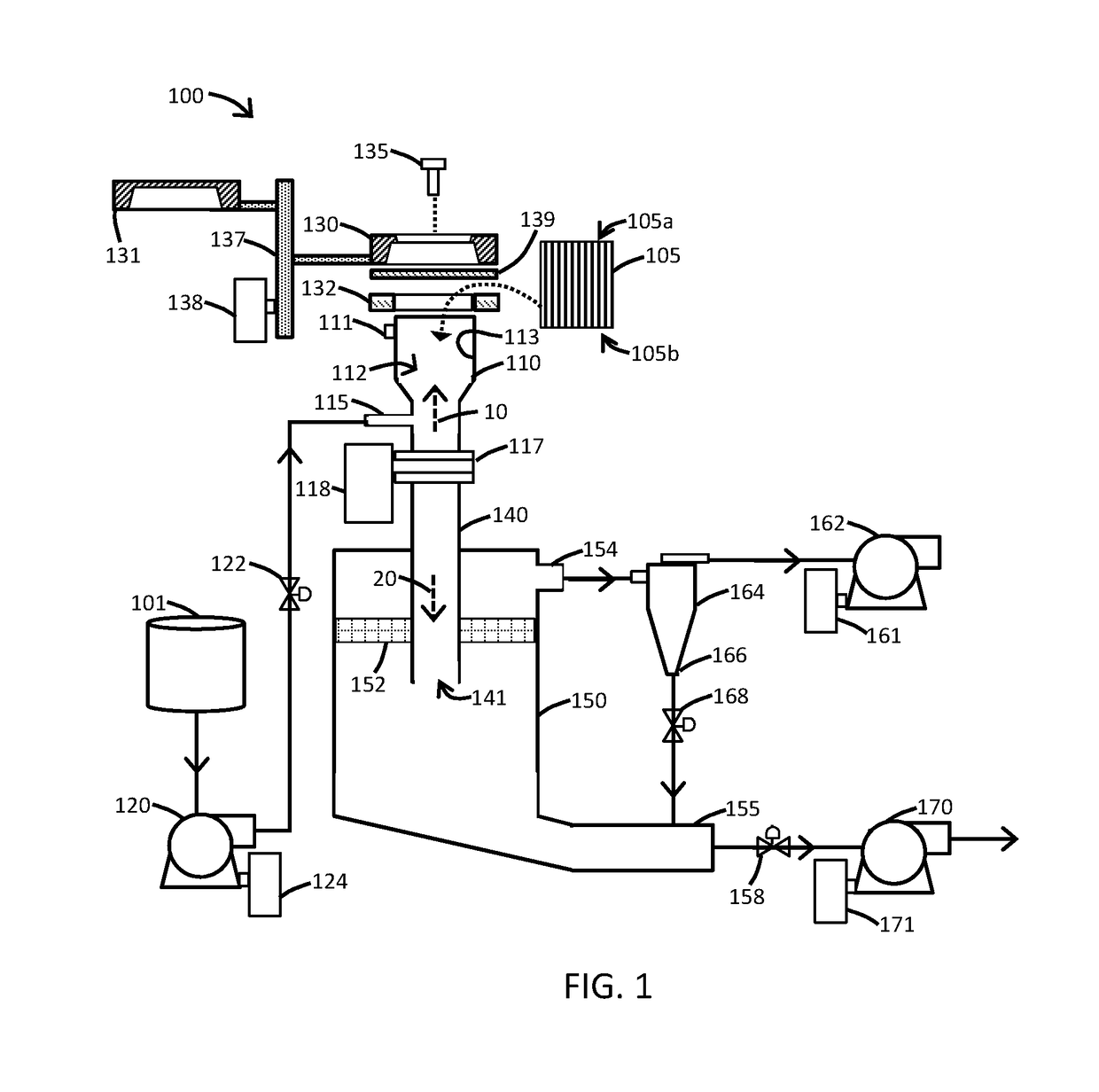

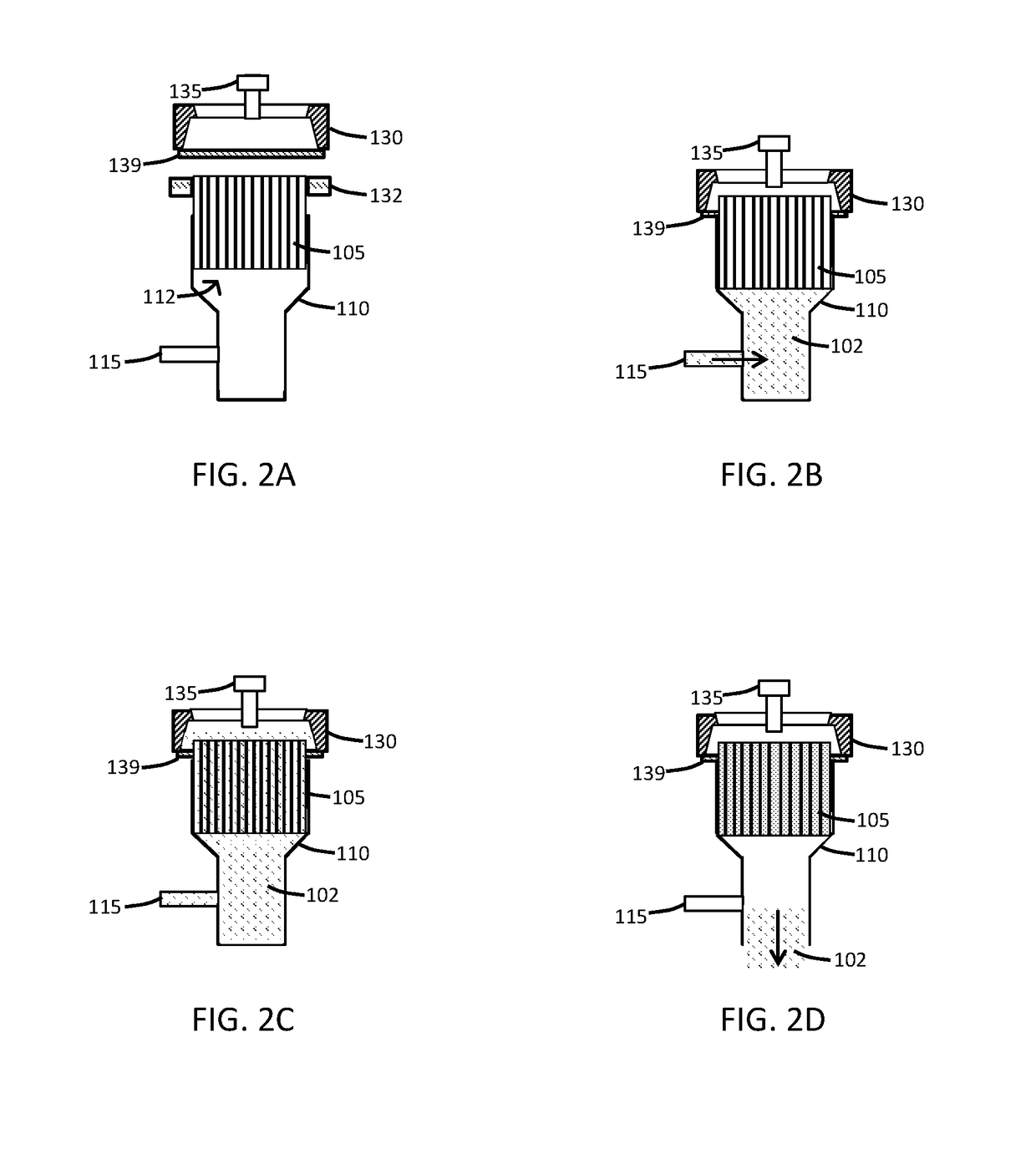

Systems and methods for solution coating a substrate

Described herein is a coating system configured for providing a washcoat onto a substrate. The coating system can be configured to pump a coating solution, particularly a low viscosity solution, into a coating vessel have the substrate positioned therein. The coating system further includes elements configured for removal of a non-coating portion of the coating solution from the substrate and recycling of the non-coating portion. Also described herein are methods for applying a washcoat to a substrate as well as multi-station coater systems.

Owner:BASF CORP

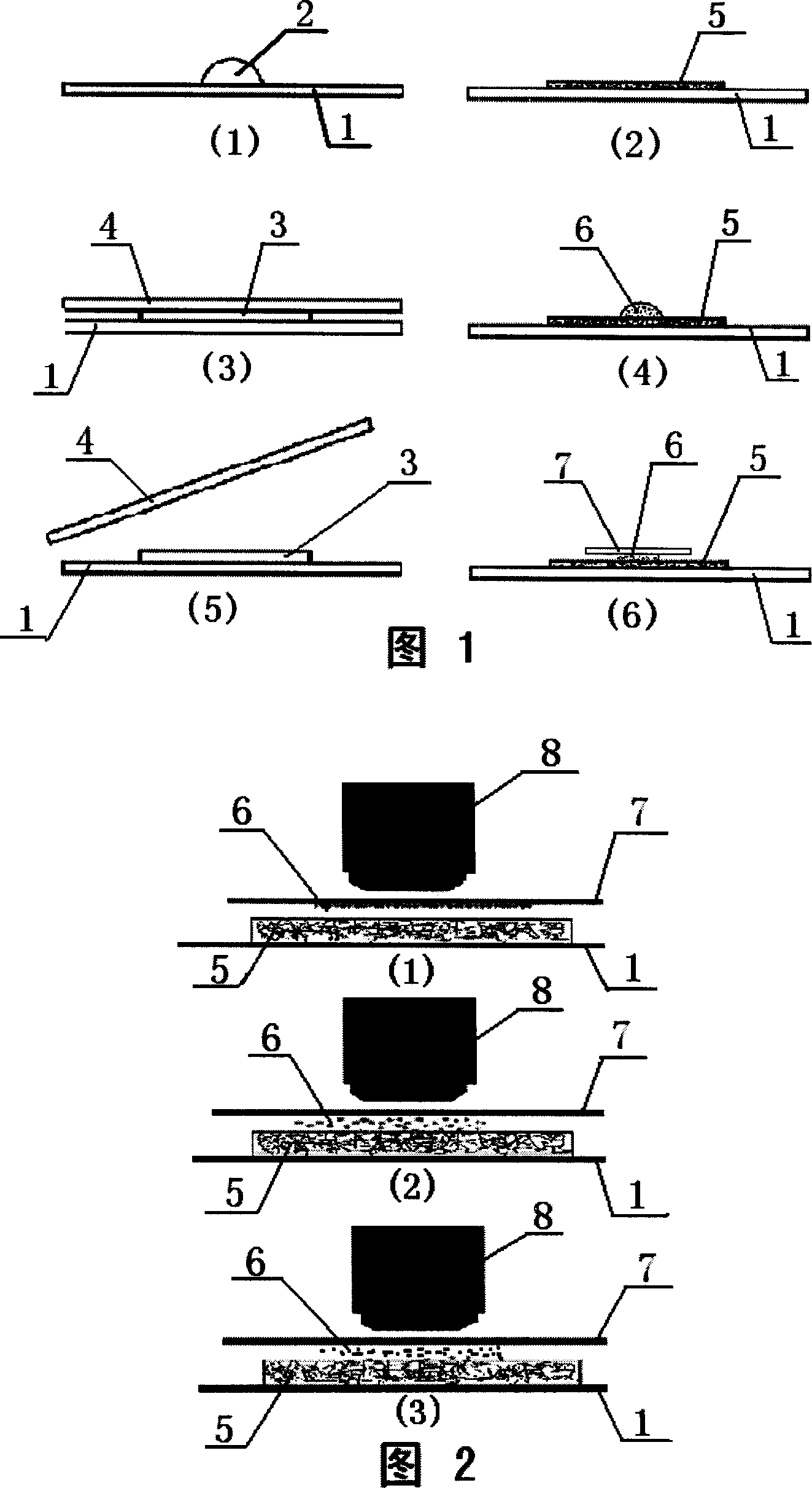

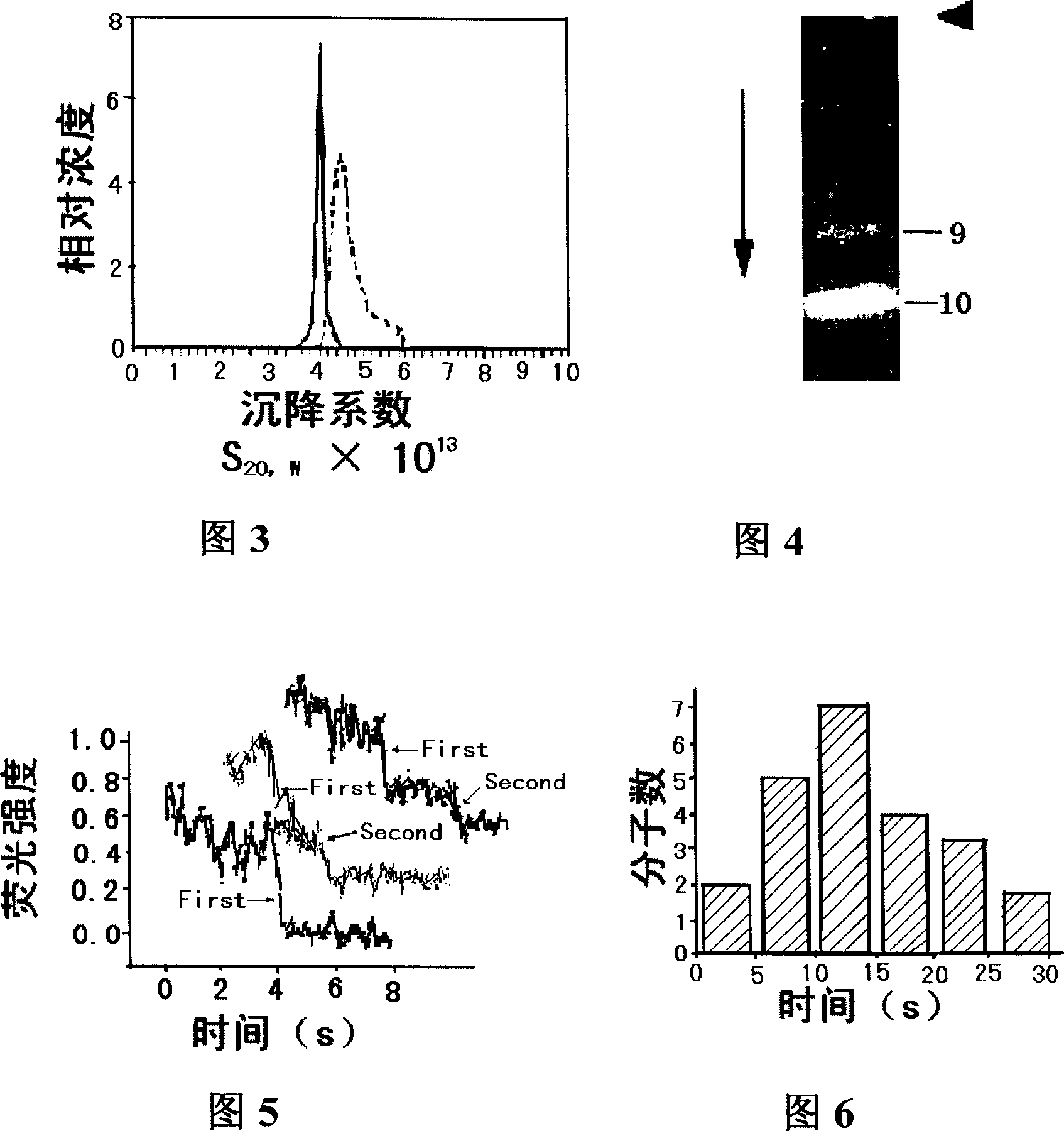

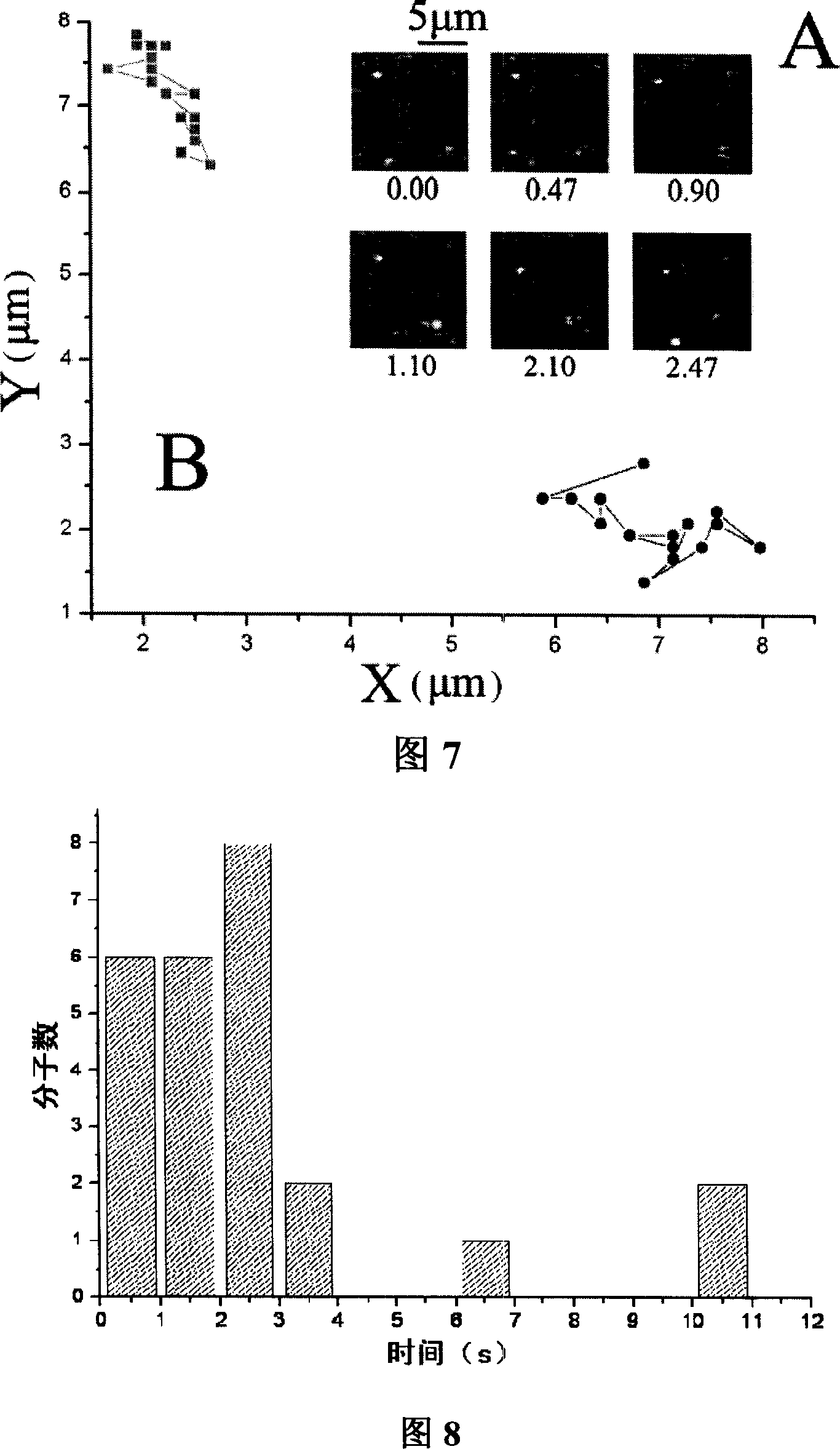

Unimolecular tracing method in low viscosity solution

InactiveCN101000297ARealize dynamic real-time monitoringLow costIndividual particle analysisFluorescence/phosphorescenceMicroscopic observationFluorescent imaging

The invention relates to single molecule tracing method in low viscosity solution. It uses dye marked molecule as tracing object, dehydrated agarose gel to decorate slide, processes fluorescence imaging for the single molecule in the solution between the cover glass and agarose gel. It includes the following steps: forming agarose gel film on the slide; covering the cover glass; sending to obverse by the microscope to do single molecule fluorescence imaging. The method of invention can realize dynamical real time monitoring, has low cost, simple and fast operation.

Owner:HUNAN UNIV

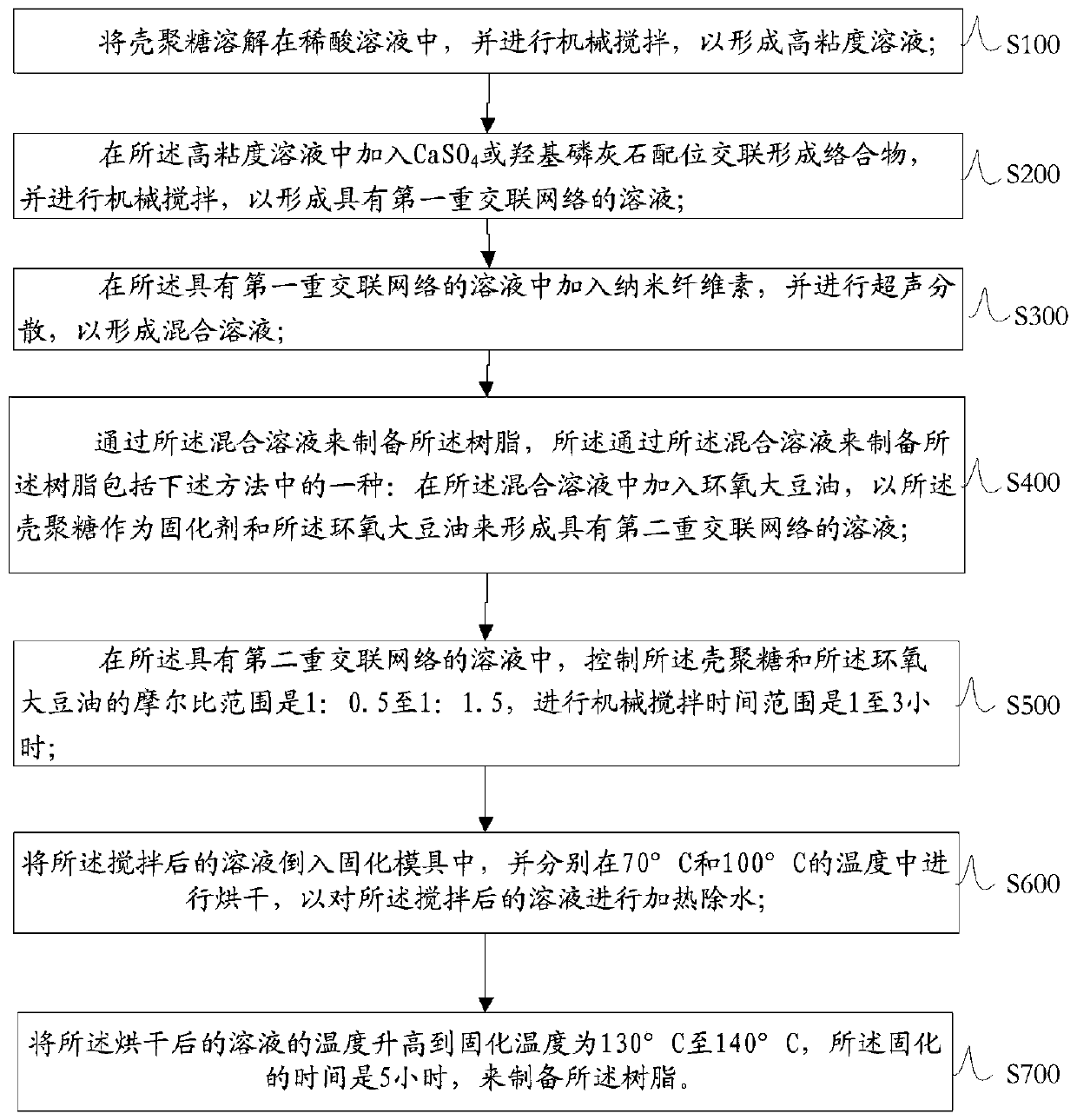

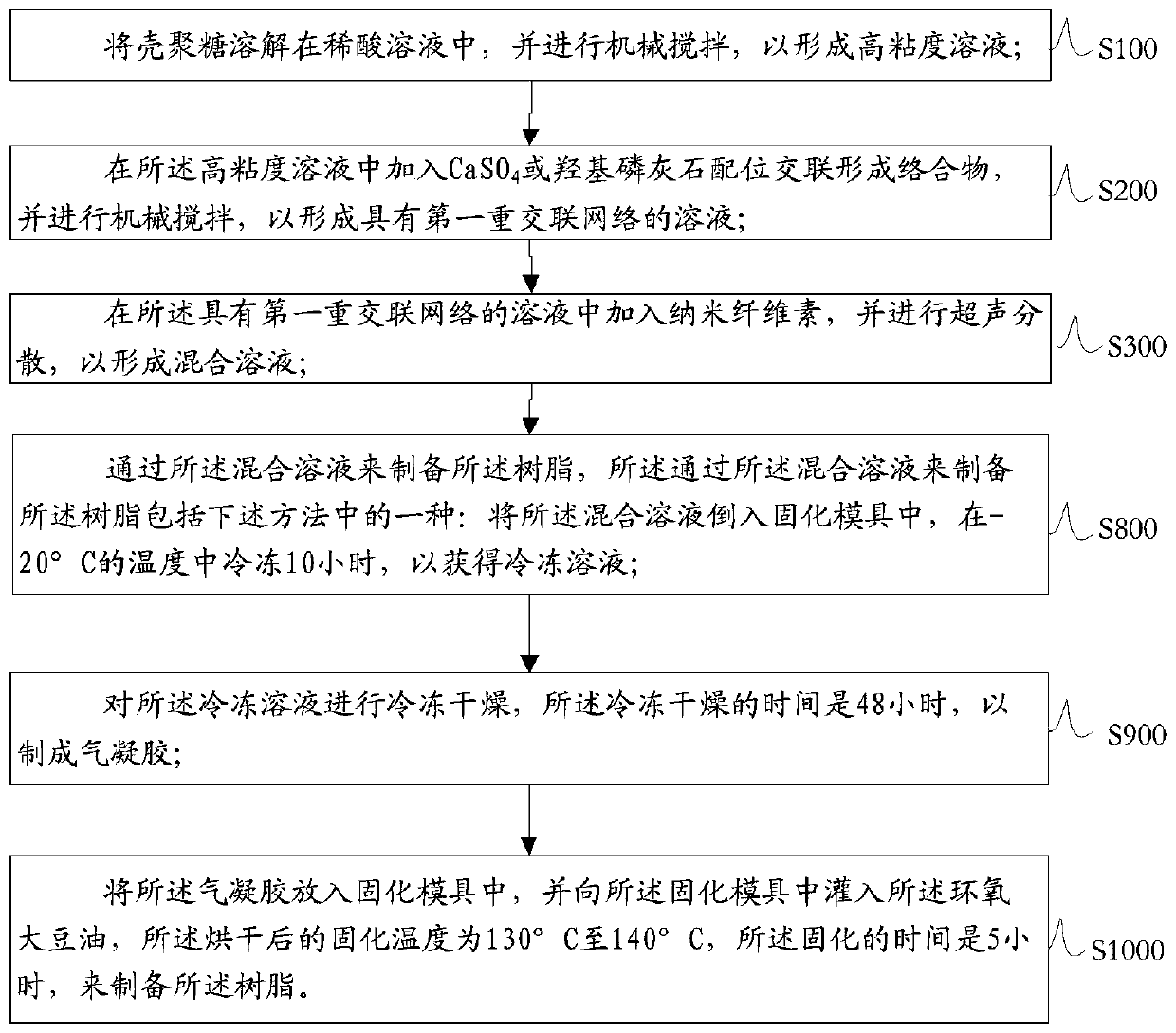

Preparation method of all-bio-based epoxy resin of double cross-linking system

ActiveCN109867967AOvercome resilienceImprove toughness and strengthCoatingsEpoxyUltrasonic dispersion

The invention discloses a preparation method of all-bio-based epoxy resin of a double cross-linking system, and belongs to the technical field of high polymer materials with sustainable development. The preparation method comprises the following steps: dissolving chitosan in a dilute acid solution, and carrying out mechanical stirring to prepare a high-viscosity solution; adding CaSO4 or hydroxyapatite into the high-viscosity solution for coordination crosslinking to form a complex, and carrying out mechanical stirring to prepare a solution with a first cross-linking network; adding nano-cellulose into the solution with the first cross-linking network, and carrying out ultrasonic dispersion to prepare a mixed solution; and preparing the resin through the mixed solution. Through the preparation method provided by the invention, toughness and mechanical strength of the resin are enhanced, the adopted materials in the preparation process are beneficial to environmental protection, and thetechnical effects of the preparation method are simplified.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

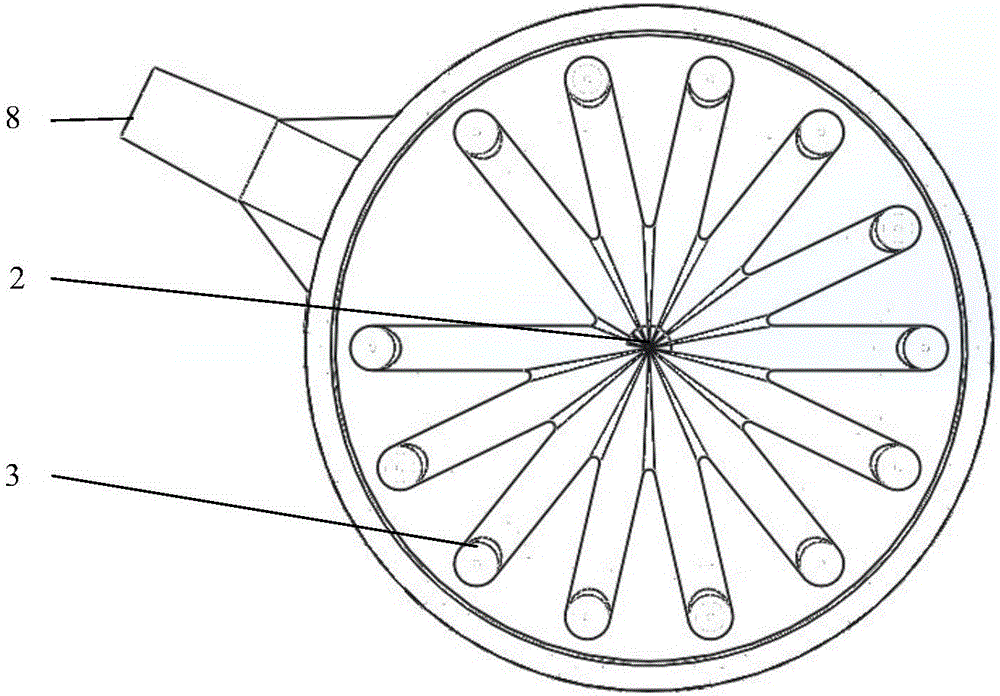

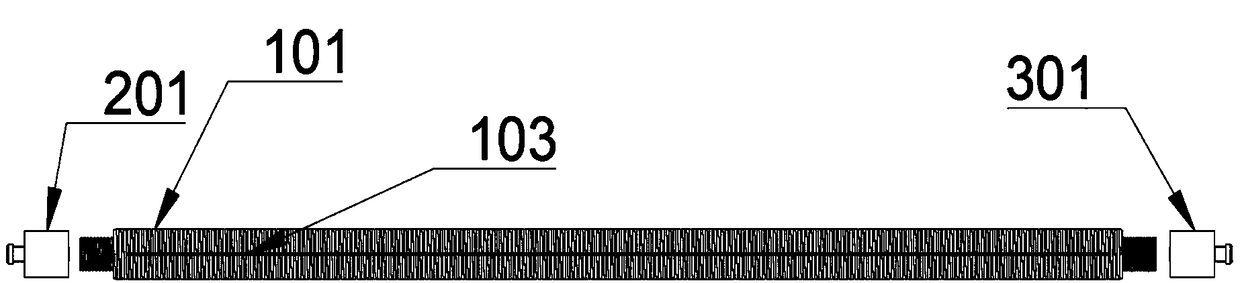

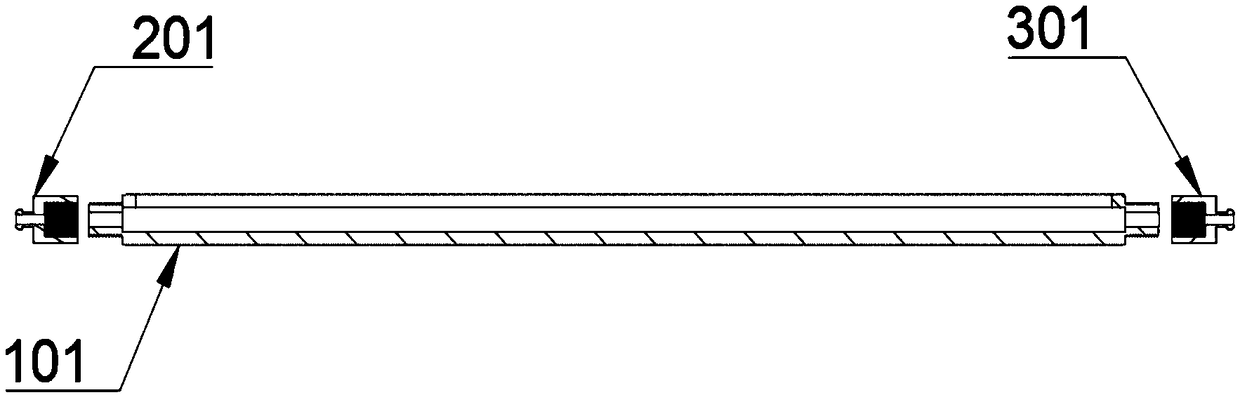

Multi-line micro jet atomizer

InactiveCN103111083AImprove atomization effectUniform sizeEvaporation by sprayingMaterials scienceEnergy source

The invention discloses a multi-line micro jet atomizer, relates to atomizers, and provides a multi-line micro jet atomizer which can disperse high-viscosity solution uniformly, guarantees size uniformity of particle products, and achieves a great a mount of atomized high-viscosity fluid. The multi-line micro jet atomizer is provided with a sprayer pipe, a porous sprayer, locking nuts and piezoelectric ceramic rings; the porous sprayer is arranged at the inlet end of the sprayer pipe, and is screwed and compressed on the sprayer pipe inlet end through the locking nuts and the sprayer pipe inlet ends; the piezoelectric ceramic rings are sleeved on the outer wall of the sprayer pipe. High-viscosity liquid materials can be atomized well; liquid drops are uniform in size; the yield can be improved obviously. The uniform size of products is ensured, besides, multi-line production is realized; the yield of atomizers is increased greatly, and the continuous efficient production during atomization and drying process can be improved further; and additionally the interaction among the liquid drops can be lowered effectively, the particle wall adhesion phenomenon is reduced; and energy source materials are saved obviously.

Owner:XIAMEN UNIV

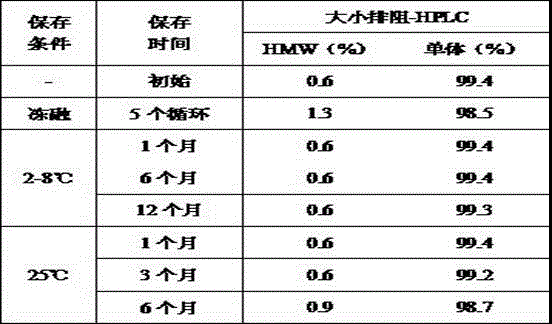

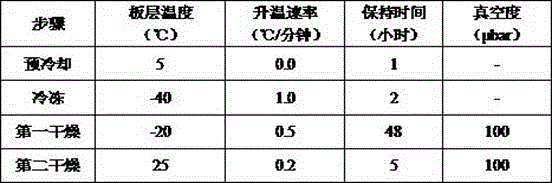

Protein medicinal preparation containing beta-glucan as auxiliary material

InactiveCN105749290AHas the ability to absorb water and swellAvoid gatheringPowder deliveryPeptide/protein ingredientsCell AggregationsProtein aggregation

The invention discloses a protein medicinal preparation containing beta-glucan as an auxiliary material. The preparation is prepared from at least one protein medicinal material having a concentration of 10-300mg / ml, a buffer agent having a salt concentration of 1-120mM and pH value of 6.5+ / -1.5, a stabilizing agent which is beta-glucan and has a concentration of 0.1-10 percent, and a nonionic surfactant having a concentration of 0.01-0.1 percent. The beta-glucan is a high-molecular polymer formed by connecting monomer beta-D-glucopyranose through beta-(1-3) and beta-(1-6). Soluble beta-glucan has a water-absorbing swelling capability, has an excellent water binding capacity in water, can form a high-viscosity solution after being dissolved in water, can be used for effectively preventing protein aggregation and enhancing the protein stability, and can be used as a protecting agent of protein medicines.

Owner:SUZHOU KANGJU BIOTECHNOLOGY CO LTD

Polymer fluororubber as well as preparation method and application thereof

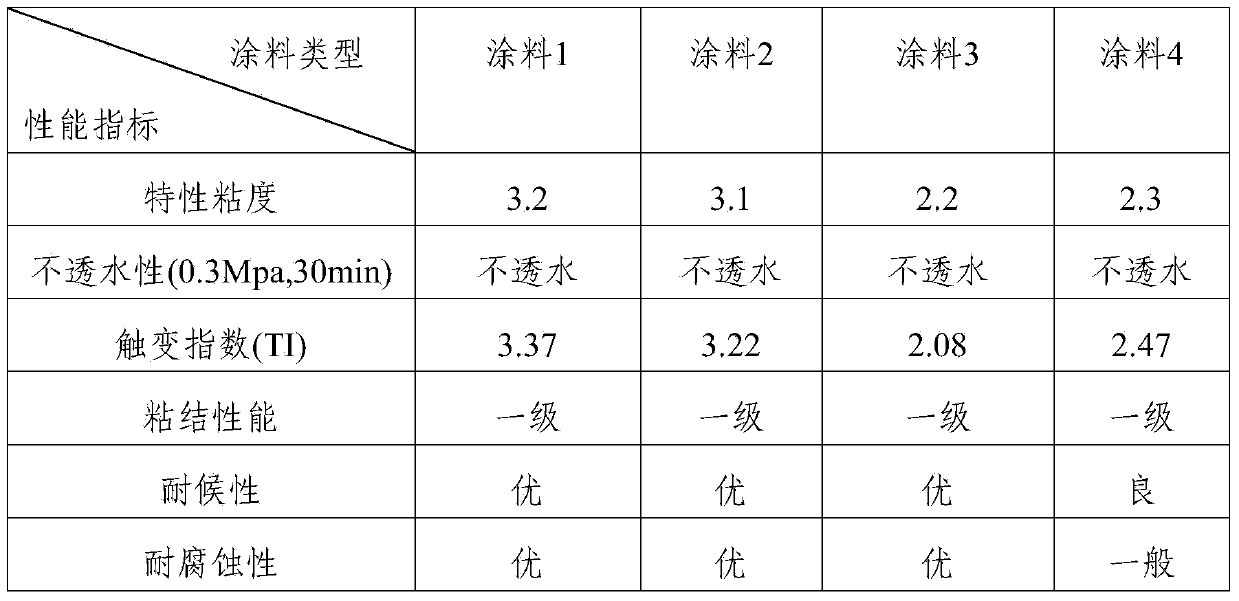

The invention relates to a preparation method of fluororubber. The preparation method comprises the following steps: copolymerizing two or more main polymer monomers under high-pressure and low-temperature conditions by the combined effects of a redox initiation system and an emulsifier, introducing modified monomers, and polymerizing to obtain the fluororubber. According to the preparation method, polymerization reaction conditions are controlled and aids such as the redox initiation system and the emulsifier are optimized, so that the molecular weight of the fluororubber is effectively increased and the weight-average molecular weight reaches more than 800,000; the obtained fluororubber has the fluorine content more than 40% and the intrinsic viscosity more than 5.0; a dissolved high-viscosity solution has the characteristics of high fluorine content, ageing resistance, weather resistance and corrosion resistance, and can be used as a thickening agent with good settling resistance and sag resistance in paint.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Scrape coating device applied to preparation of perovskite batteries and thin film preparation method

PendingCN109395980ASimple structureEasy to operateLiquid surface applicatorsCoatingsEngineeringLarge size

The invention discloses a scrape coating device applied to preparation of provskite batteries and a thin film preparation method. The scrape coating device applied to preparation of the perovskite batteries comprises a bar which comprises a bar body; a liquid storage cavity extending axially is arranged in the bar body and used for storing feed liquid; the bar body is provided with a slit extending axially in the surface and communicated with the liquid storage cavity. According to the embodiment, the scrape coating device is adaptable to preparation of large-area thin film or laminated structures; the bar of the scrape coating device can keep continuous and enough liquid feed quantity in long-distance scrape coating process and keep coated products uniform; the scrape coating device is good for coating of low-viscosity solution on large-size substrates.

Owner:KUNSHAN GCL OPTOELECTRONIC MATERIAL CO LTD

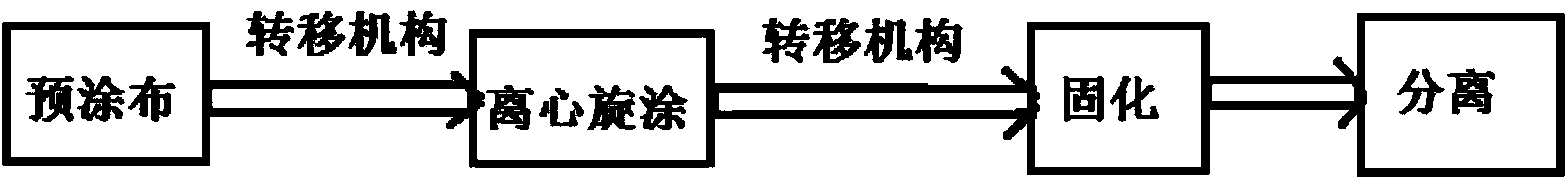

Thin polymer film preparation process

ActiveCN104241448AUniform thicknessEliminate thick edge problemsSemiconductor devicesPolymer scienceCentrifugation

A thin polymer film preparation process includes the steps of firstly, conducting pre-coating, wherein a carrier substrate is coated with a polymer precursor solution to form a primary body film; secondly, adjusting the thick centrifugal edge, wherein the carrier substrate is made to do high-speed centrifugal movement through a spin coating device, the solution on the thick edge portion of the primary body film is thrown out in the centrifugation process, and the edge of the primary body film on the carrier substrate is thinned; thirdly, solidifying the primary body film with the centrifugal thick edge adjusted in the second step and the carrier substrate together, and separating the thin film and the carrier substrate which are solidified to obtain a self-supported finished thin polymer film. The polymer precursor solution in the first step is a high-viscosity solution, wherein the viscosity of the solution ranges from 800 cp to 20000 cp. The centrifugal rotating speed of a centrifugation device in the second step ranges from 100 r / min to 10000 r / min, and the levelness of a centrifugation platform is smaller than 5 mm / m. The thin polymer film preparation process can effectively solve the thick edge problem generated in the film formation process of the high-viscosity polymer solution, and film forming uniformity is improved.

Owner:王磊 +1

Path planning method for computing optimal parking maneuvers for road vehicles and corresponding system

ActiveUS10960876B2Improve mobilityInstruments for road network navigationAutonomous decision making processSimulationHamilton–Jacobi–Bellman equation

Path planning method for computing optimal parking maneuvers for road vehicles including the steps of computing a set of value functions of a cost function of parking maneuvers reaching the target set of states as unique viscosity solution of a Hamilton Jacobi Bellman equation, supplying the set of value functions, together with a starting state of the vehicle, as input to the dynamic programming calculation procedure calculating at least the set of vehicle controls. The set of equations modeling the evolution of the state of said road vehicle is a switched system of equations between a first sub-system if the vehicle is in forward motion and a second sub-system if the vehicle is in reverse motion. The cost function takes into account the arrival time a number of direction changes of the road vehicle between forward motion and reverse motion.

Owner:FAB ITAL MAGNETI MARELLI SPA +1

Mouthwash and low-viscosity solution

ActiveCN110538134ALow viscosityAvoid formingCosmetic preparationsToilet preparationsGellan gumSphingomonas elodea

The invention relates to the field of oral care, in particular to mouthwash and a low-viscosity solution. The mouthwash is prepared from hyaluronic acid, gellan gum, probiotics and water, wherein themass ratio of the hyaluronic acid to the gellan gum is 1.2:1 to 4:1, and the total mass of the hyaluronic acid and the gellan gum accounts for 0.07-0.2% of the total mass of the mouthwash. The certainamount of hyaluronic acid and the certain amount of gellan gum are added in the mouthwash, and thus the probiotics can be suspended while the low viscosity is met; and the mass ratio of the hyaluronic acid to the gellan gum is 1.2:1 to 4:1, the total mass of the hyaluronic acid and the gellan gum accounts for 0.07-0.09% of the total mass of the mouthwash, thus the mouthwash has the characteristicof small viscosity, and meanwhile the probiotics can be suspended. Through the gellan gum, a system is prone to forming plastic gel, the gumming condition can be improved by adding the hyaluronic acid, thus the system returns to the fluid state, the plastic gel is prevented from being formed, and meanwhile the fluid mouthwash can suspend the probiotics.

Owner:YUNNAN BAIYAO GRP HEALTH PROD CO LTD

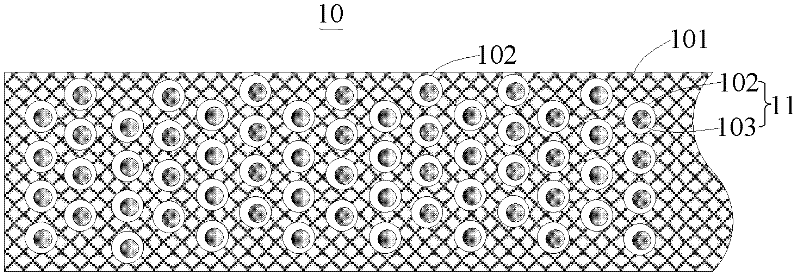

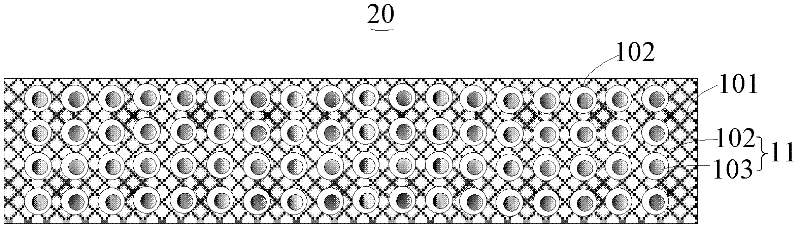

Medium substrate based on composite material and manufacturing method thereof

The invention discloses a medium substrate based on a composite material. The medium substrate comprises a first conductive foil and the composite material attached to the first conductive foil, wherein the composite material comprises a parent material, powder particles with high dielectric constant, and an organic polymer material for wrapping the powder particles with high dielectric constant, a core-shell structure is formed by the powder particles with high dielectric constant and the organic polymer material, the parent material and the organic polymer material are mutually immiscible, the core-shell structure is randomly and discretely distributed and embedded in the parent material, and the particle size of the powder particles with high dielectric constant is 0.1um-2um. The core-shell structure which takes high dielectric ceramic as a core and an organic polymer film as a shell, and a parent material solution are mixed in certain proportion to prepare a viscosity solution, and then the viscosity solution is baked and cured to enable the core-shell structure to be randomly and discretely distributed and embedded in the parent material, so that the loss of the formed composite material and the medium substrate based on the composite material can be reduced by 50% or more.

Owner:KUANG CHI INST OF ADVANCED TECH

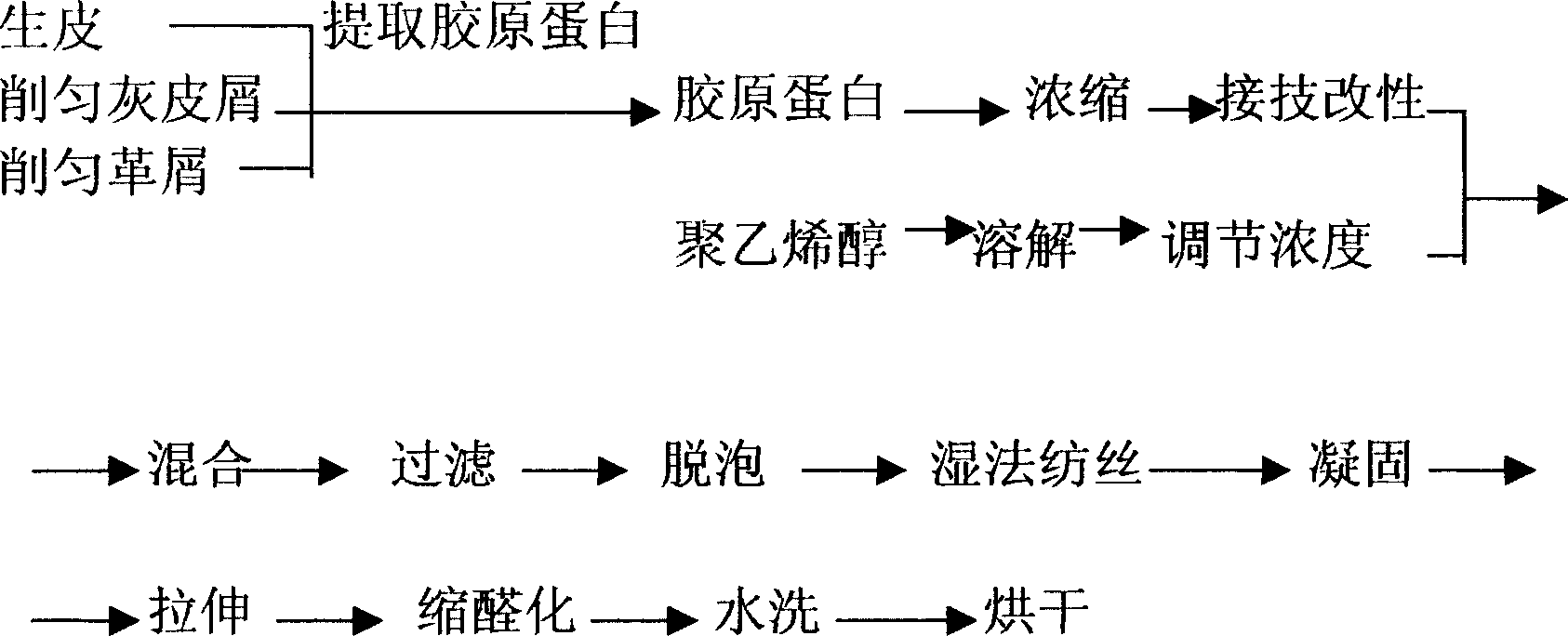

Collagen protein composite fiber and its producing method

InactiveCN1181232CComfortable to wearGood hygroscopicityConjugated artificial filamentsLeather industryFiber

A collagen composite fiber and a production method thereof belong to new materials and a production method thereof in the technical field of textile industry. Collagen is a protein separated and extracted from animal hides or leather industrial waste. After being grafted and modified by adding vinyl monomer modifiers, it is mixed with polyvinyl alcohol and stirred evenly to prepare spinning fibers with a certain concentration and viscosity. liquid, and after wet spinning, coagulation, stretching and acetalization treatment, the collagen composite fiber for the textile industry can be obtained, wherein the raw materials of each component are calculated by weight percentage: collagen content 10~ 45%, vinyl monomer modifying agent content of 5-20%, polyvinyl alcohol content of 50-85%, the sum of the composition weight of the above-mentioned percentages is 100%. The fiber has good affinity with human skin, good hygroscopicity, comfortable wearing and easy coloring.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com