Supercapacitor battery

A technology for supercapacitors and batteries, which is applied in the directions of hybrid capacitor electrodes, hybrid capacitor terminals, hybrid capacitor separators, etc., and can solve problems such as limitations in the field of supercapacitor batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

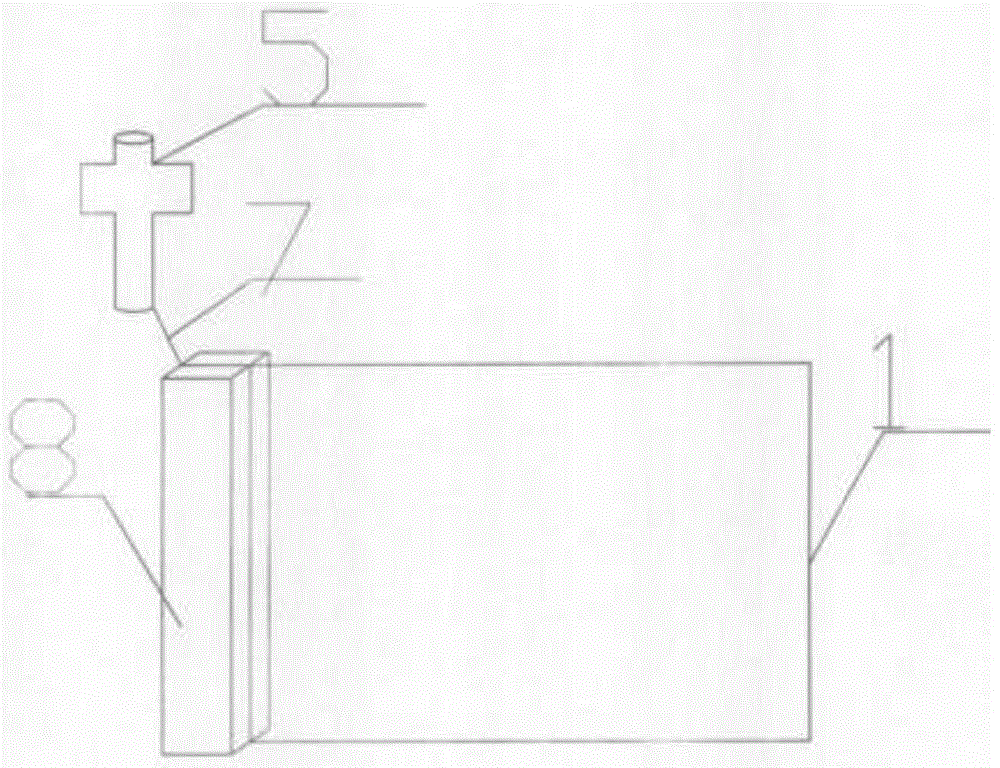

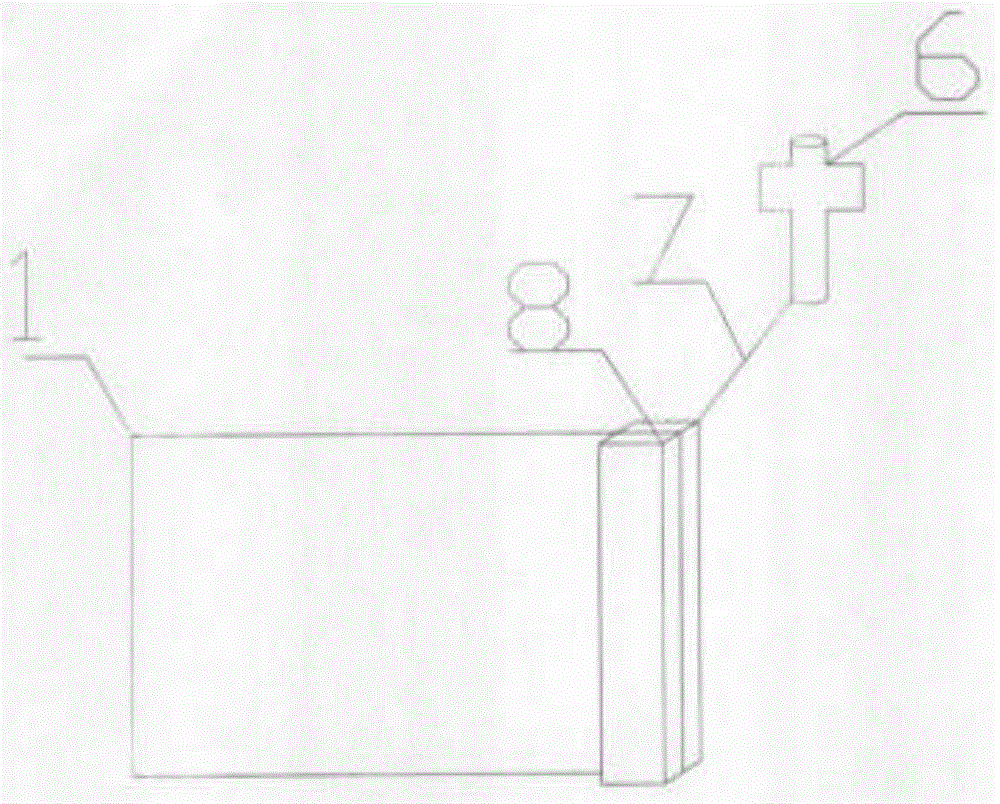

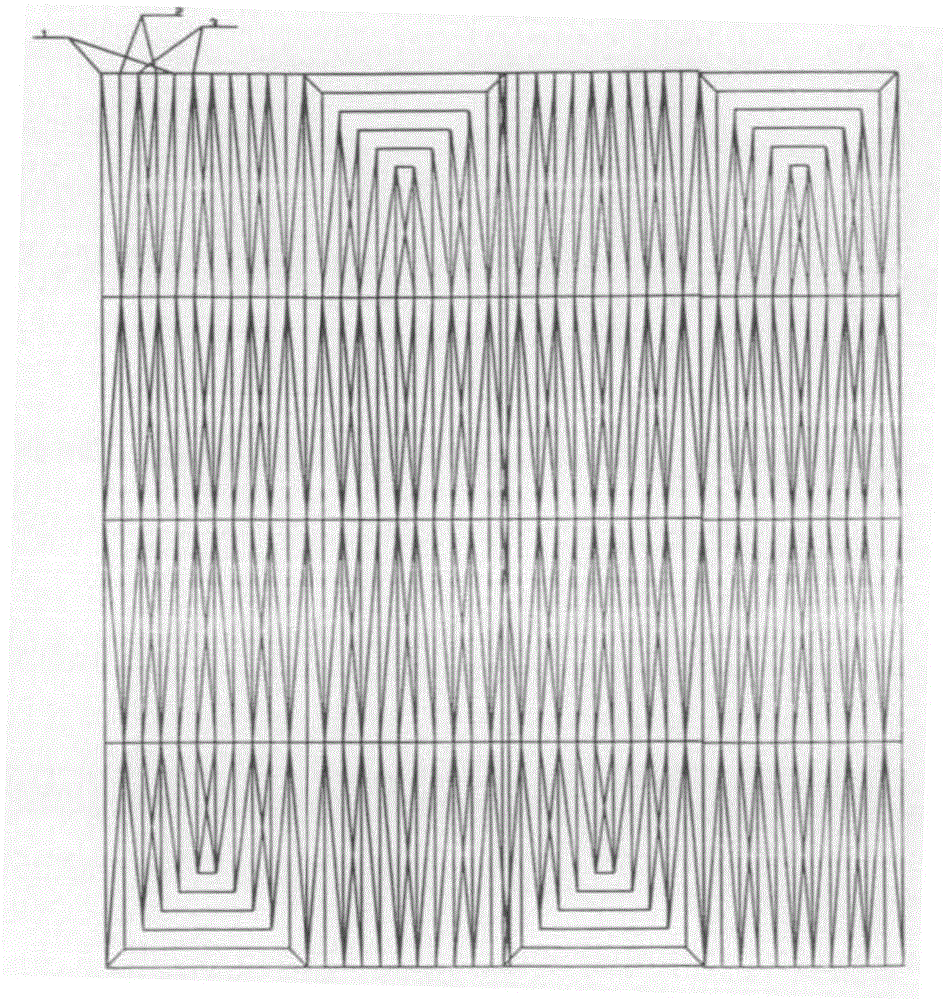

[0032] Organosilicon powder is carbonized at high temperature into silicon carbide powder. The mass ratio of silicon carbide powder to polyphenylene sulfide resin is 84:16. At the same time, metal titanium or α-titanium alloy is embedded in the electrode mold. The phenylene sulfide resin is hot-pressed at a temperature of 260°C and a pressure of 1.2Mpa to form a supercapacitor battery electrode. The electrode is pre-embedded with multiple strands of metal titanium or titanium alloy strands, and is connected by titanium or titanium alloy strands at a thickness of The 8um metal titanium or titanium alloy thin end plate is in contact with the ultra-high viscosity NMP electrolyte of lithium methylaminobutyrate, lithium polysulfide, lithium perchlorate, and lithium phosphate, and then the 18um polyphenylene sulfide film is used as the The diaphragm becomes half of the supercapacitor battery; then the polyphenylene sulfide film is in contact with the diaphragm and is an ultra-high vi...

Embodiment 2

[0034] Organosilicon powder is carbonized at high temperature into silicon carbide powder. The mass ratio of silicon carbide powder to polyphenylene sulfide resin is 84:16. At the same time, metal titanium or α-titanium alloy is embedded in the electrode mold. The phenylene sulfide resin is hot-pressed at a temperature of 280°C and a pressure of 1.0Mpa to form a supercapacitor battery electrode. The electrode is pre-embedded with multiple strands of metal titanium or titanium alloy strands, and is connected by titanium or titanium alloy strands at a thickness The 18um metal titanium or titanium alloy thin end plate is in contact with the ultra-high viscosity NMP electrolyte of lithium methylaminobutyrate, lithium polysulfide, lithium perchlorate, and lithium phosphate, and then the 33um polyphenylene sulfide film is used as the The diaphragm becomes half of the supercapacitor battery; then the polyphenylene sulfide film is in contact with the diaphragm and is an ultra-high visc...

Embodiment 3

[0036] Organosilicon powder is carbonized at high temperature into silicon carbide powder. The mass ratio of silicon carbide powder to polyphenylene sulfide resin is 84:16. At the same time, metal titanium or α-titanium alloy is embedded in the electrode mold. The phenylene sulfide resin is hot-pressed at a temperature of 268°C and a pressure of 1.1Mpa to form a supercapacitor battery electrode. The electrode is pre-embedded with multiple strands of metal titanium or titanium alloy strands, and is connected by titanium or titanium alloy strands at a thickness of The 16um metal titanium or titanium alloy thin end plate is in contact with the ultra-high viscosity NMP electrolyte of lithium methylaminobutyrate, lithium polysulfide, lithium perchlorate, and lithium phosphate, and then the 28um polyphenylene sulfide film is used as the The diaphragm becomes half of the supercapacitor battery; then the polyphenylene sulfide film is in contact with the diaphragm and is an ultra-high v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com