Method for improving heat resistance of sisal fibers

A technology of sisal fiber and heat resistance, which is applied in the field of plant fiber processing, can solve the problems of poor high temperature resistance of natural sisal fiber, and achieves the effects of good dispersibility, improved heat resistance, and improved bundle fiber strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] During the implementation of the present invention, carry out according to the following steps:

[0022] Step 1: Cut ordinary sisal fibers into 1-3cm fiber segments, soak in saturated Ca(OH) 2 In the solution for 6 hours, remove the impurities on the sisal fiber, remove and drain the excess Ca(OH) 2 solution, only the Ca(OH) adsorbed by the sisal fiber 2 Solution, air-dried or oven-dried to obtain modified sisal fiber.

[0023] The second step: soak the modified sisal fiber obtained in the first step in the silica sol, soak for 20min, take it out, drain off the excess silica sol, and only keep the silica sol adsorbed by the modified sisal fiber, at a temperature of 60- Drying at 100°C to cross-link and solidify the silica sol, and the heat-resistant sisal fiber can withstand a high temperature of 350°C.

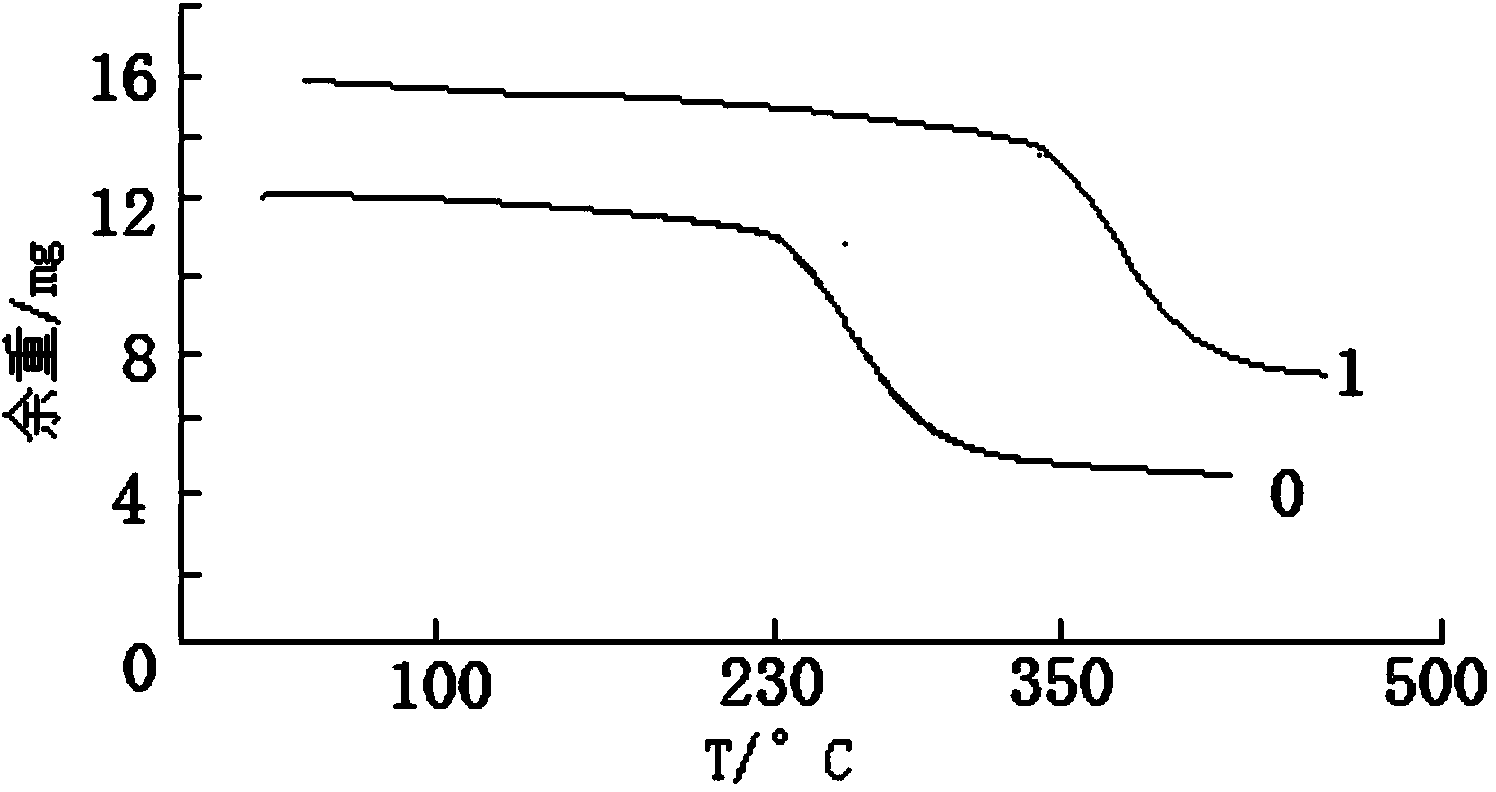

[0024] The obtained heat-resistant sisal fiber and the common sisal fiber soaked in 1%NaOH solution were used to carry out the thermal weight loss test under the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com