Polymer fluororubber as well as preparation method and application thereof

A fluororubber and reaction kettle technology, applied in the direction of coating, can solve the problems of difficult to meet the requirements of coating viscosity, low viscosity, etc., and achieve the effects of increasing molecular weight, good sag resistance, and high fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 30L deionized water to a 50L horizontal reactor, evacuate until the oxygen content is less than 50ppm, add a mixed monomer of chlorotrifluoroethylene and vinylidene fluoride with a molar ratio of 1:1 until the pressure of the reactor is 2.5Mpa, and raise the temperature at the same time To 40°C, add 3g of potassium permanganate, 1g of potassium bromide, 15g of sodium hydroxide, and 50g of sodium perfluoropolyether carboxylate to start the reaction. During this period, add the mixed monomer in the above ratio to maintain the pressure of the reactor at 3.5Mpa. When the mixed monomer is fed to 10kg, add 1kg of perfluoromethyl vinyl ether, and continue to react until the mixed monomer is fed to 13kg, then stop. Recover the unreacted monomer to the monomer storage tank, evacuate, release the emulsion, add a small amount of MgCl 2 The target product was condensed, washed with deionized water, dried and sent for inspection. The results are shown in Table 1.

Embodiment 2

[0028] 50L horizontal reactor, add 30L deionized water, evacuate until the oxygen content is less than 50ppm, add the mixed monomer of perfluoropropylene and vinylidene fluoride with a molar ratio of 2:8 until the pressure of the reactor is 3.5Mpa, and at the same time Raise the temperature to 40°C, add 3g of potassium permanganate, 1g of potassium bromide, 15g of sodium hydroxide, and 50g of sodium perfluoropolyether carboxylate to start the reaction. During this period, add the mixed monomer in the above ratio to maintain the pressure of the reactor at 5.0Mpa. When the feed reaches 10kg, add 1kg of perfluoromethyl vinyl ether, and continue the reaction until the mixed monomer feeds to 13kg, then stop. Recover the unreacted monomer to the monomer storage tank, evacuate, release the emulsion, add a small amount of MgCl 2 The target product was condensed, washed with deionized water, dried and sent for inspection. The results are shown in Table 1.

Embodiment 3

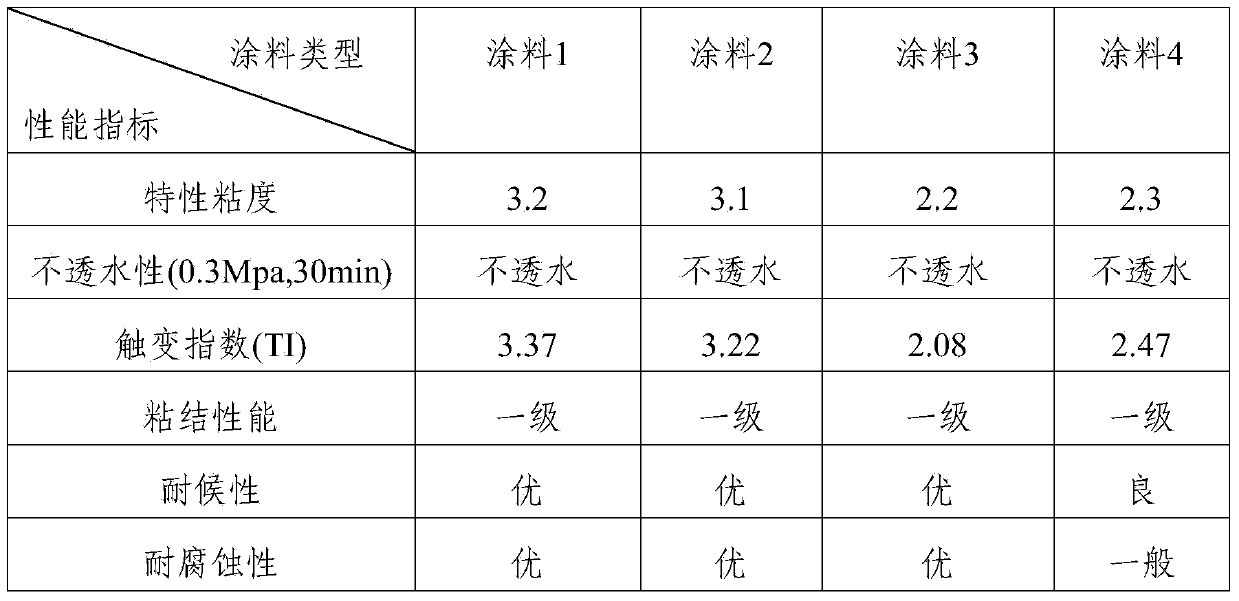

[0034] This example is intended to illustrate the effect of the fluororubber of the present invention on improving the performance of coatings, but is not limited to the coatings described in Example 3.

[0035] This embodiment provides a coating containing fluorine rubber.

[0036] The fluororubber that embodiment 1 and 2, comparative example 1 obtains is dissolved in ethyl acetate, obtains the solution A, B, C that is swelling critical state of 30wt%, in 200g certain solvent type epoxy resin paint, Add 30g of the above-mentioned solutions A, B, and C, and disperse evenly to obtain coatings 1, 2, and 3; add 2.5g of fumed silica to 200g of the above-mentioned similar epoxy resin to obtain coating 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com