Optimum design method for piezoelectric type sprayer for printing cells

An optimized design and cell printing technology, which is applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of low maximum pressure of inkjet channel and clogging of nozzle holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

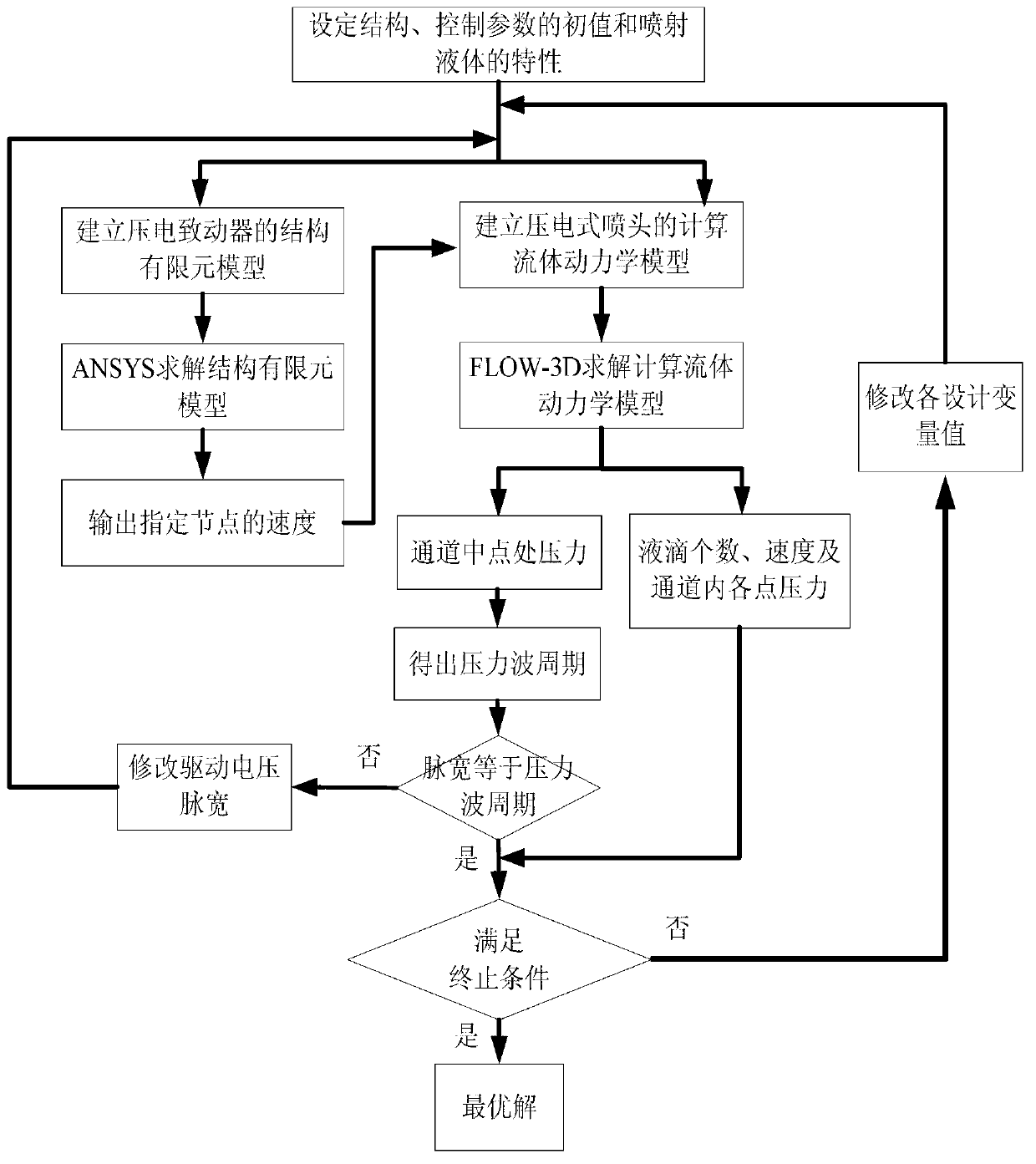

[0046] refer to figure 1 , the present invention is used for the optimization design method of the piezoelectric nozzle of cell printing, comprises the following steps:

[0047] Step 1, for a piezoelectric nozzle whose structural shape is preset, the initial structural parameter d of the nozzle, the initial control parameter p of the nozzle and the characteristics of the injected liquid are set.

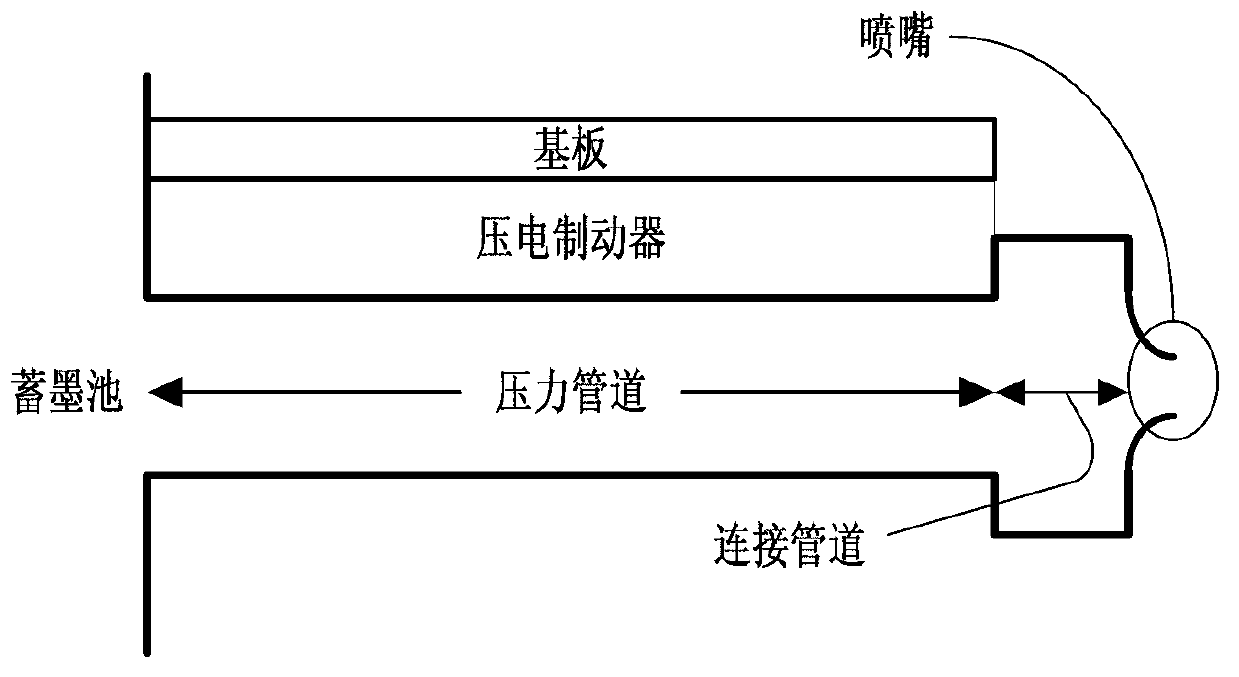

[0048] The structure of the piezoelectric nozzle is referred to figure 2 , which is mainly composed of piezoelectric actuator, ink storage tank, ink jet channel and nozzle. connected; piezoelectric actuators of equal length are distributed on one side of the pressure pipe;

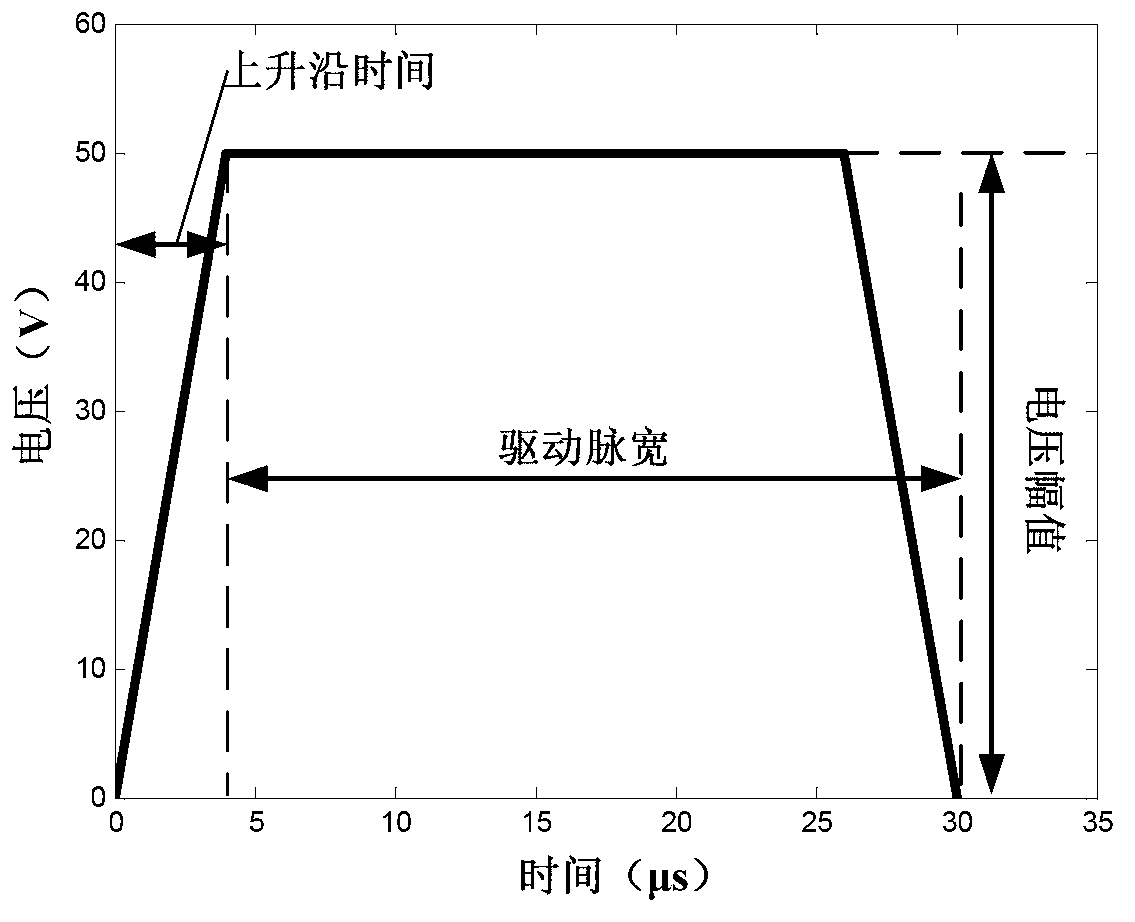

[0049] The initial structural parameters d of the nozzle, including the length l of the piezoelectric actuator 1 , width w 1 , height h 1 , the length of the pressure pipe l 2 , width w 2 , height h 2 , the length of the connecting pipe l 3 , width w 3 , height h 3 , nozzle length l n , the nozzle in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com