Preparation method of all-bio-based epoxy resin of double cross-linking system

A technology based on epoxy resin and double cross-linking, applied in the direction of coating, etc., can solve the problems of lack of toughness, low mechanical strength and complicated preparation method of resin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

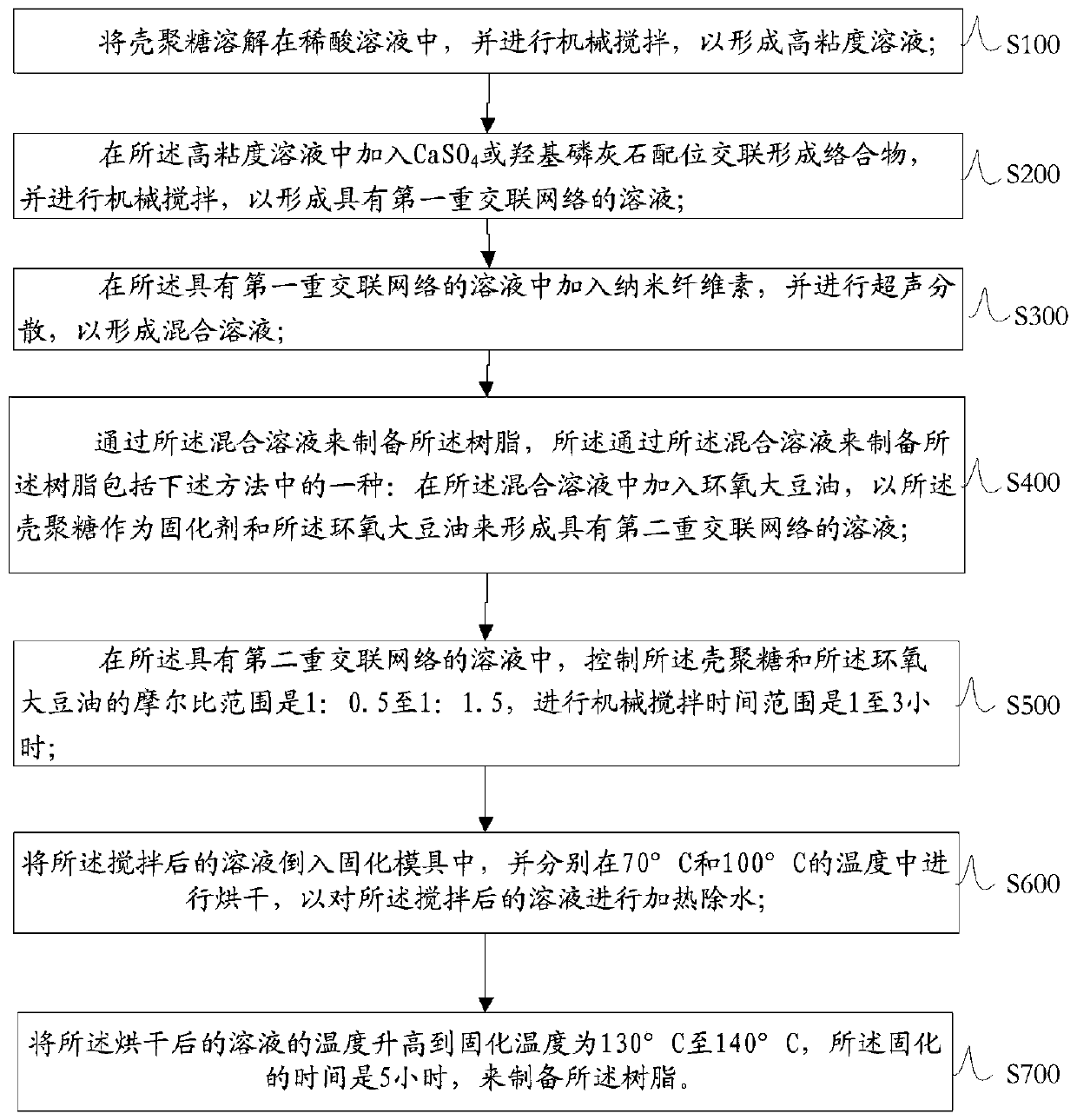

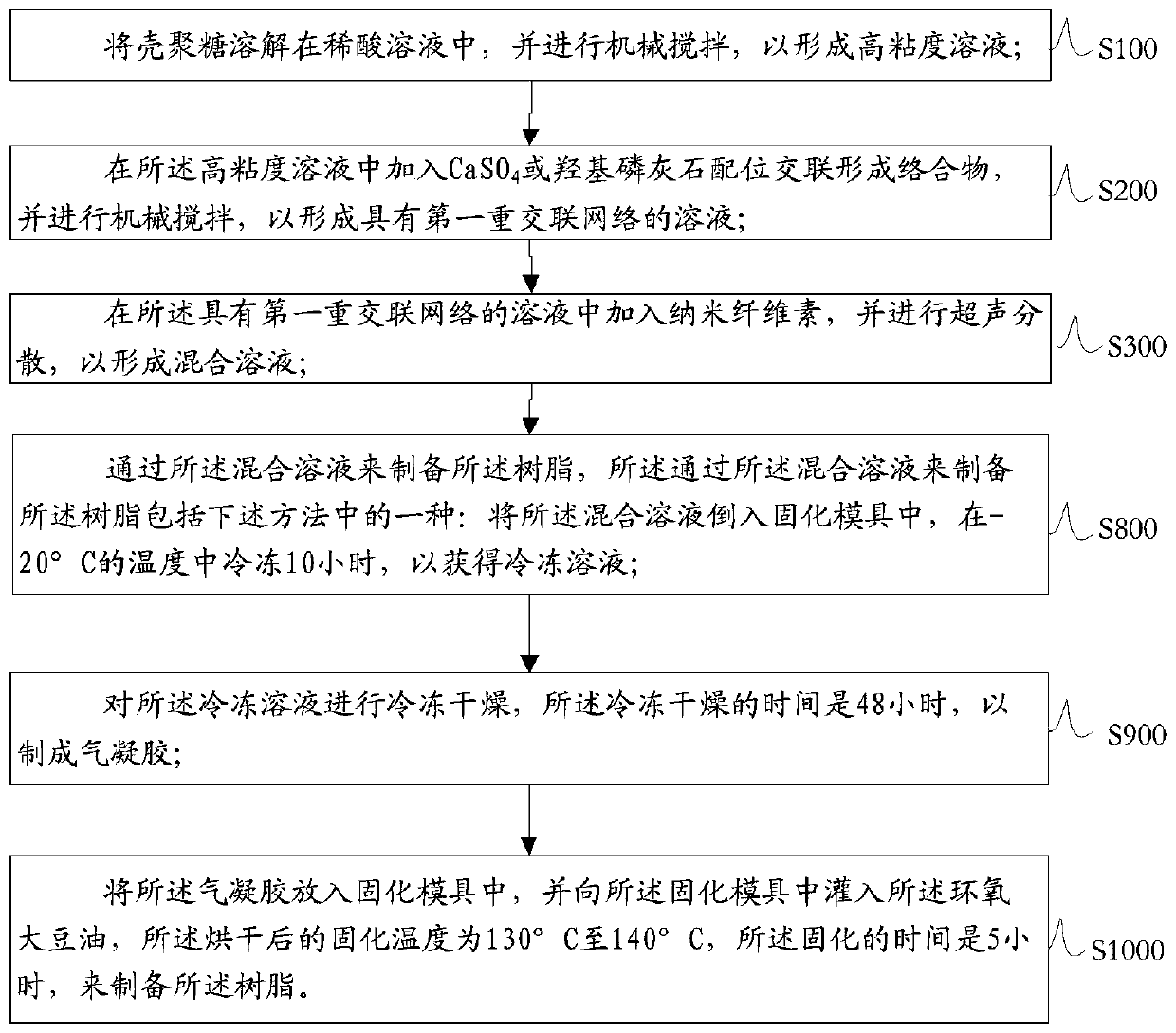

[0022] The invention discloses a preparation method of a double cross-linking system full bio-based epoxy resin. After dissolving chitosan in a dilute acid solution and performing mechanical stirring to form a high-viscosity solution, the high-viscosity CaSO was added to the solution 4Or hydroxyapatite coordination cross-linking to form a complex, and mechanical stirring to form a solution with the first heavy cross-linking network. Then, nanocellulose is added to the solution having the first heavily cross-linked network, and ultrasonically dispersed to form a mixed solution. By adding epoxidized soybean oil in the mixed solution, using the chitosan as a curing agent and the epoxidized soybean oil to form a solution with a second heavy crosslinking network; In the solution of the network, the molar ratio range of controlling the chitosan and the epoxidized soybean oil is 1:0.5 to 1:1.5, and the mechanical stirring time range is 1 to 3 hours; the stirred solution is poured i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com