Antibacterial and hemostasia compound sponge and preparation method thereof

A composite sponge and nanocomposite material technology, applied in pharmaceutical formulations, surgical adhesives, applications, etc., can solve the problems of poor toughness and insignificant hemostatic effect, and achieve the prevention of wound infection, excellent antibacterial properties and thermal stability, inhibiting The effect of bacterial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

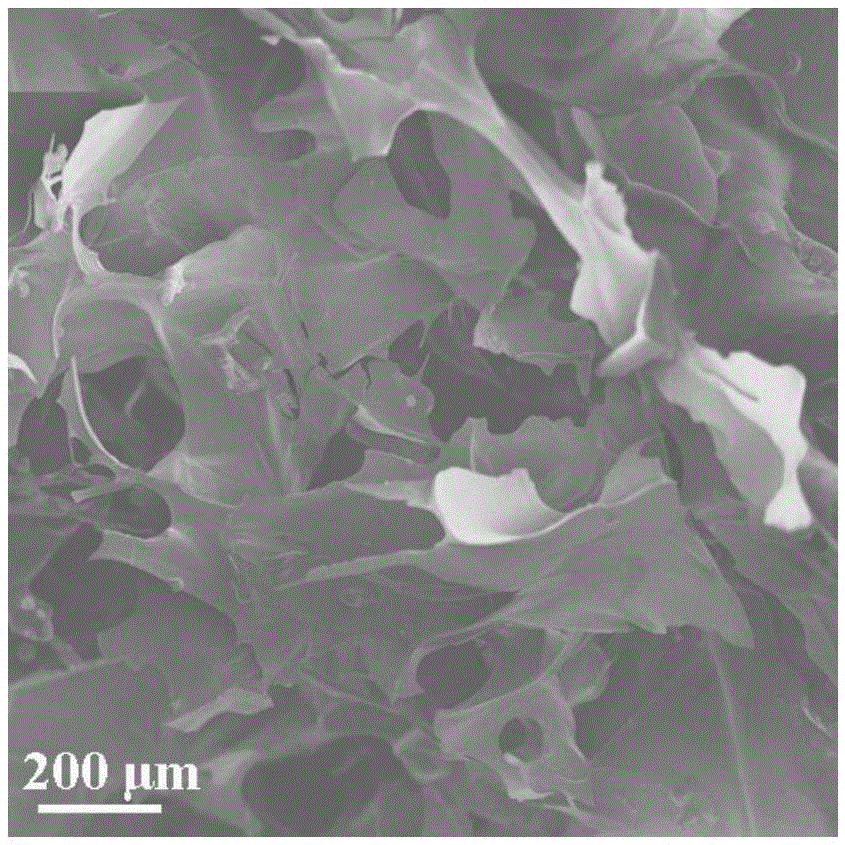

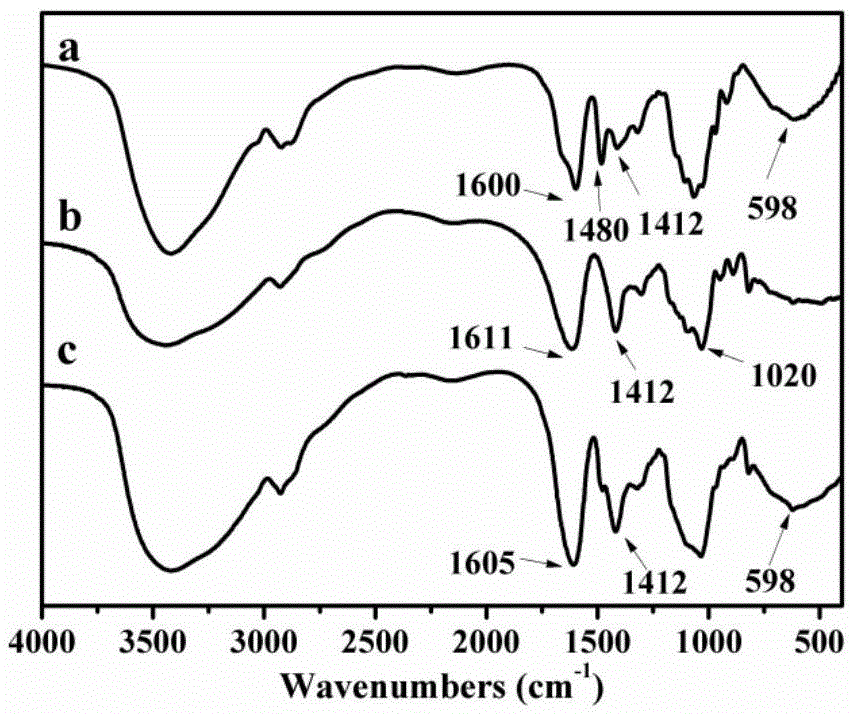

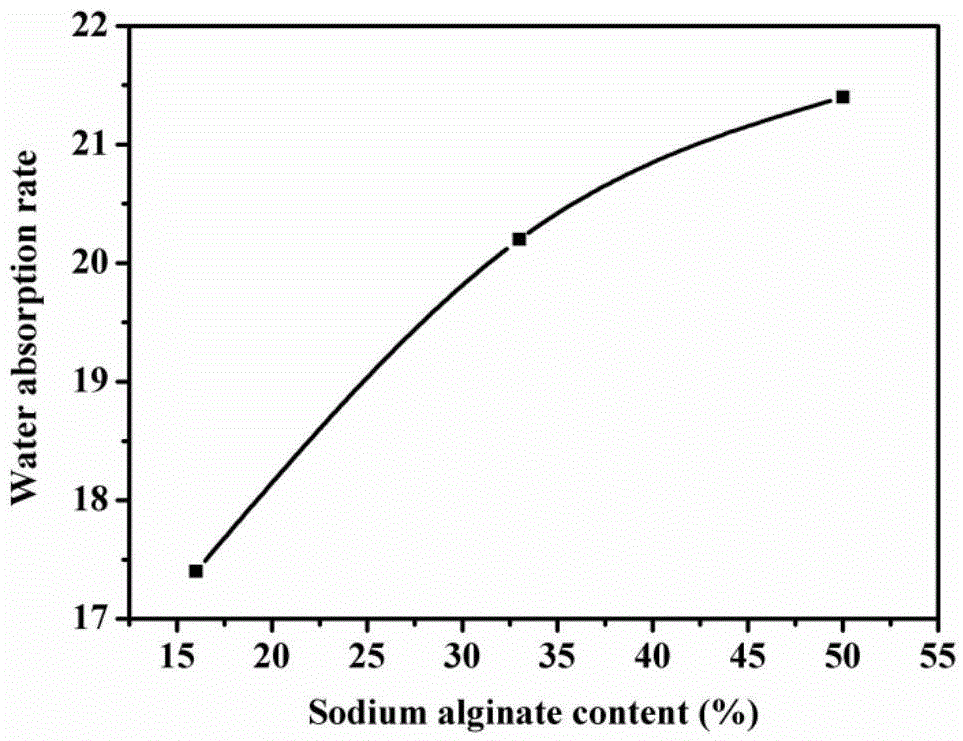

[0029] 0.5g carboxymethyl chitosan quaternary ammonium salt / organic montmorillonite nanocomposite material is dissolved in deionized water and is made into the solution of 50mg / mL, wherein the weight average molecular weight of used carboxymethyl chitosan quaternary ammonium salt is 2.5×10 5 , the degree of substitution of carboxymethyl is 40%, and the degree of substitution of quaternary ammonium salt is 60%. Dissolve 0.1g of sodium alginate in deionized water to make a 10mg / mL solution. Polysaccharide quaternary ammonium salt / organic montmorillonite nanocomposite solution and sodium alginate solution are evenly mixed and then transferred to the mold. The weight ratio is about 5:1, soaked in 1wt% calcium chloride solution, reacted for 0.5h and freeze-dried to obtain the composite sponge.

Embodiment 2

[0031] 0.4g carboxymethyl chitosan quaternary ammonium salt / organic montmorillonite nanocomposite material is dissolved in deionized water and is made into the solution of 40mg / mL, wherein the weight average molecular weight of used carboxymethyl chitosan quaternary ammonium salt is 4.0×10 5 , the degree of substitution of carboxymethyl is 50%, the degree of substitution of quaternary ammonium salt is 65%, 0.2g of sodium alginate is dissolved in deionized water to make a solution of 20mg / mL, under the condition of stirring, the carboxymethyl shell Polysaccharide quaternary ammonium salt / organic montmorillonite nanocomposite solution and sodium alginate solution are evenly mixed and then transferred to the mold. The weight ratio is about 2:1, soaked in 2wt% calcium chloride solution, reacted for 1.0h and freeze-dried to obtain the composite sponge.

Embodiment 3

[0033] 0.3g carboxymethyl chitosan quaternary ammonium salt / organic montmorillonite nanocomposite material is dissolved in deionized water and is made into the solution of 30mg / mL, wherein the weight average molecular weight of used carboxymethyl chitosan quaternary ammonium salt is 8.0×10 5 , the degree of substitution of carboxymethyl is 60%, the degree of substitution of quaternary ammonium salt is 75%, 0.3g of sodium alginate is dissolved in deionized water to make a solution of 30mg / mL, under the condition of stirring, the carboxymethyl shell Polysaccharide quaternary ammonium salt / organic montmorillonite nanocomposite solution and sodium alginate solution are evenly mixed and then transferred to the mold. The weight ratio is about 1:1, soaked in 3wt% calcium chloride solution, reacted for 2 hours and freeze-dried to obtain the composite sponge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com