Multi-line micro jet atomizer

A micro-jet and atomizer technology, applied in the field of atomizers, can solve problems such as increased energy, uneven product particle size distribution, and easy wall-hanging of particles, so as to reduce interaction, reduce wall-hanging phenomenon, and save energy material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

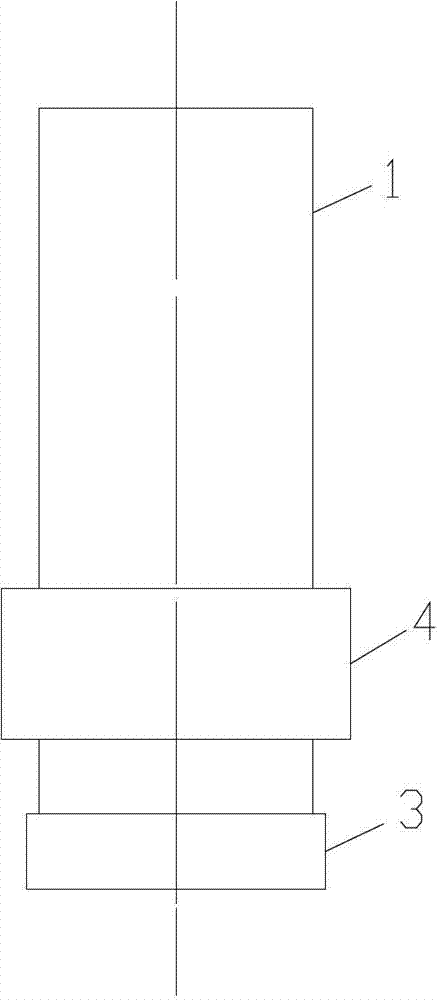

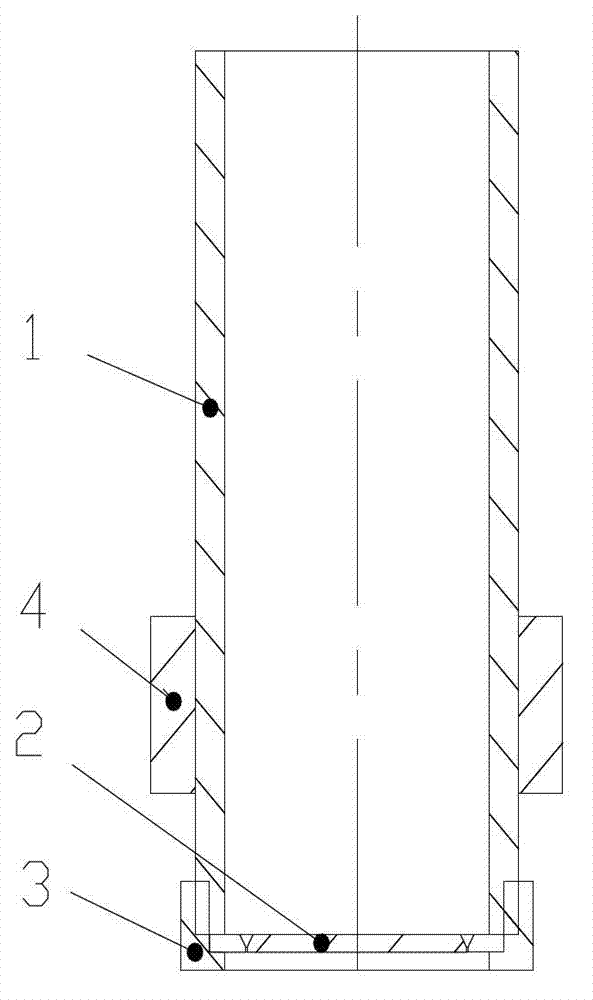

[0020] see Figure 1-7 , The embodiment of the present invention is provided with a nozzle tube 1, a porous nozzle 2, a lock nut 3 and a piezoelectric ceramic ring 4. The porous nozzle 2 is arranged at the inlet end of the nozzle tube 1, and the porous nozzle 2 is screwed to the inlet end of the nozzle tube 1 through the lock nut 3 and pressed tightly on the inlet end of the nozzle tube 1, and the piezoelectric ceramic ring 4 is set on the outer wall of the nozzle tube 1.

[0021] The nozzle pipe 1 is a metal pipe. The porous nozzle 2 is a circular perforated plate of precious metal that is stamped and formed and cannot be cut by strong acid, strong alkali, high temperature and high pressure. The thickness of the porous nozzle 2 is 1mm. The eight holes 21 set in the multi-hole nozzle 2 are evenly distributed in concentric circles. The front portion of the hole 21 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com