Quick micro-mixing device for high-viscosity solution

A micro-mixing, high-viscosity technology, used in mixers, mixing methods, dissolution, etc., can solve the problems of long mixing time and complex structure, and achieve the effect of reducing pollution and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with accompanying drawings and examples.

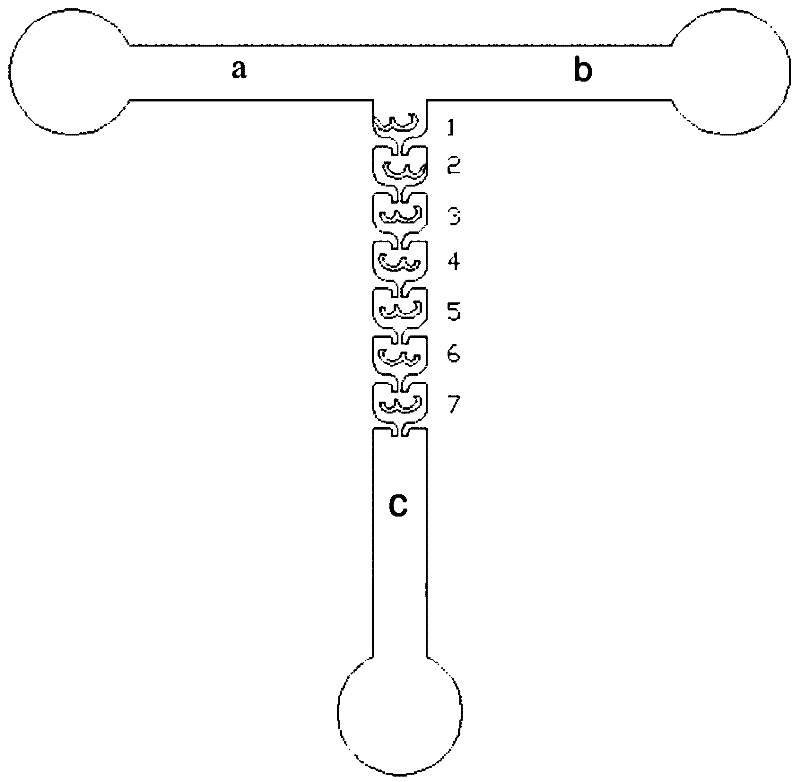

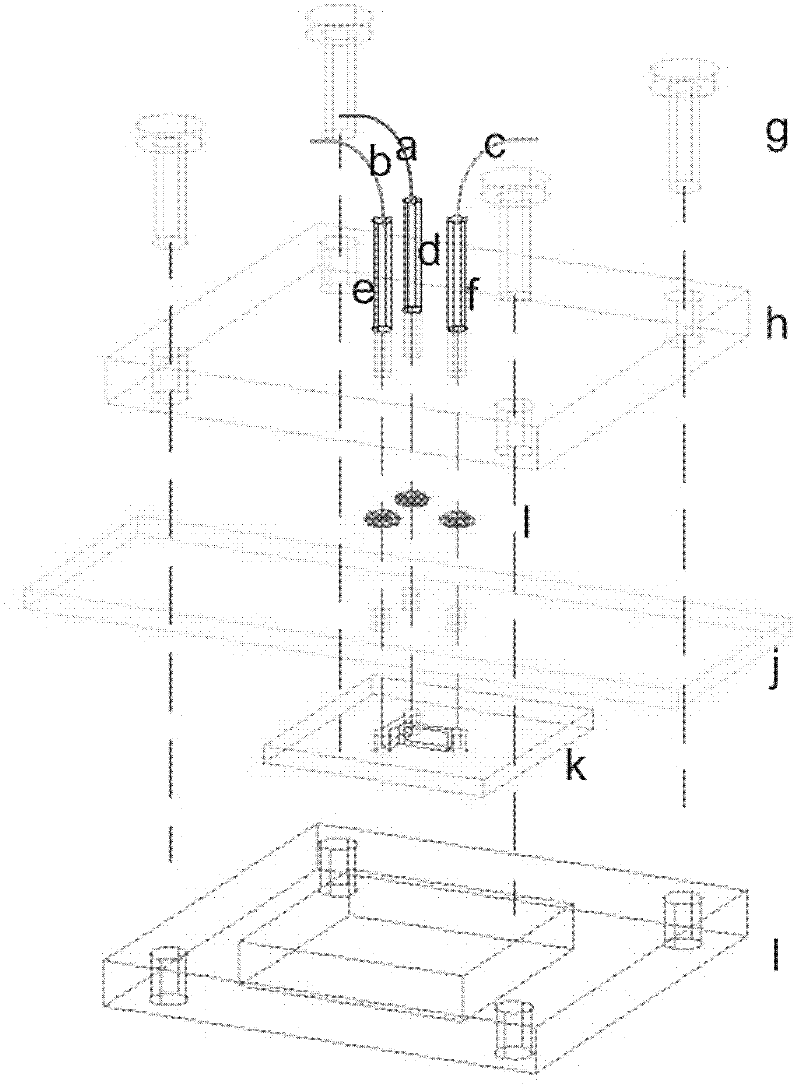

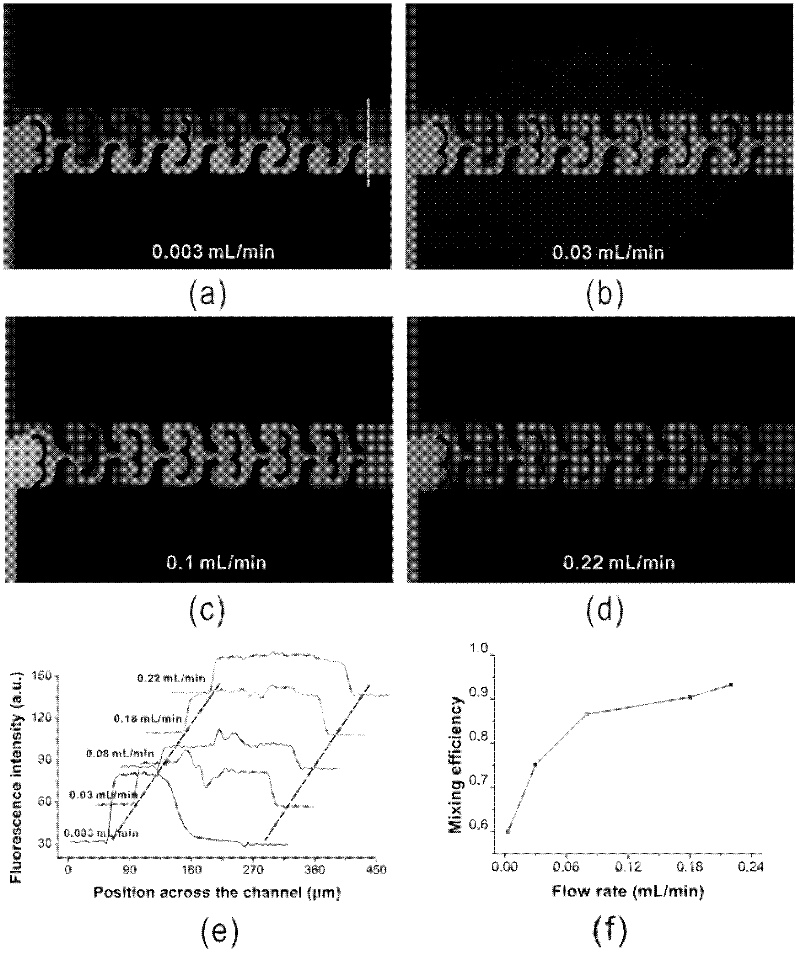

[0019] The rapid micro-mixing device includes a PDMS thin layer, and three connected channels are processed on the PDMS thin layer, wherein two solution inlet channels a and b are symmetrical about the third solution outlet channel c, and the sequential processing in the solution outlet channel has multiple an ω-shaped microstructure. The three-channel connection can be Y-shaped, T-shaped or arrow-shaped, and the two openings of the ω-shaped microstructure face the intersection of the three channels. As an optimization, the ω-shaped microstructures are arranged in the channel in such a way that the size difference between the left and right openings is alternately positive and negative. Compared with the method of simply repeatedly arranging the ω-shaped microstructures in the channel, this method can more effectively cause the disturbance of the solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com